Automatic photoelectric control binding machine for travel book

An automatic binding and photoelectric control technology, applied in binding and other directions, can solve the problems of uneven signatures, uncompacted signatures, skewed paper, etc., and achieve the effect of less follow-up work, convenient operation and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

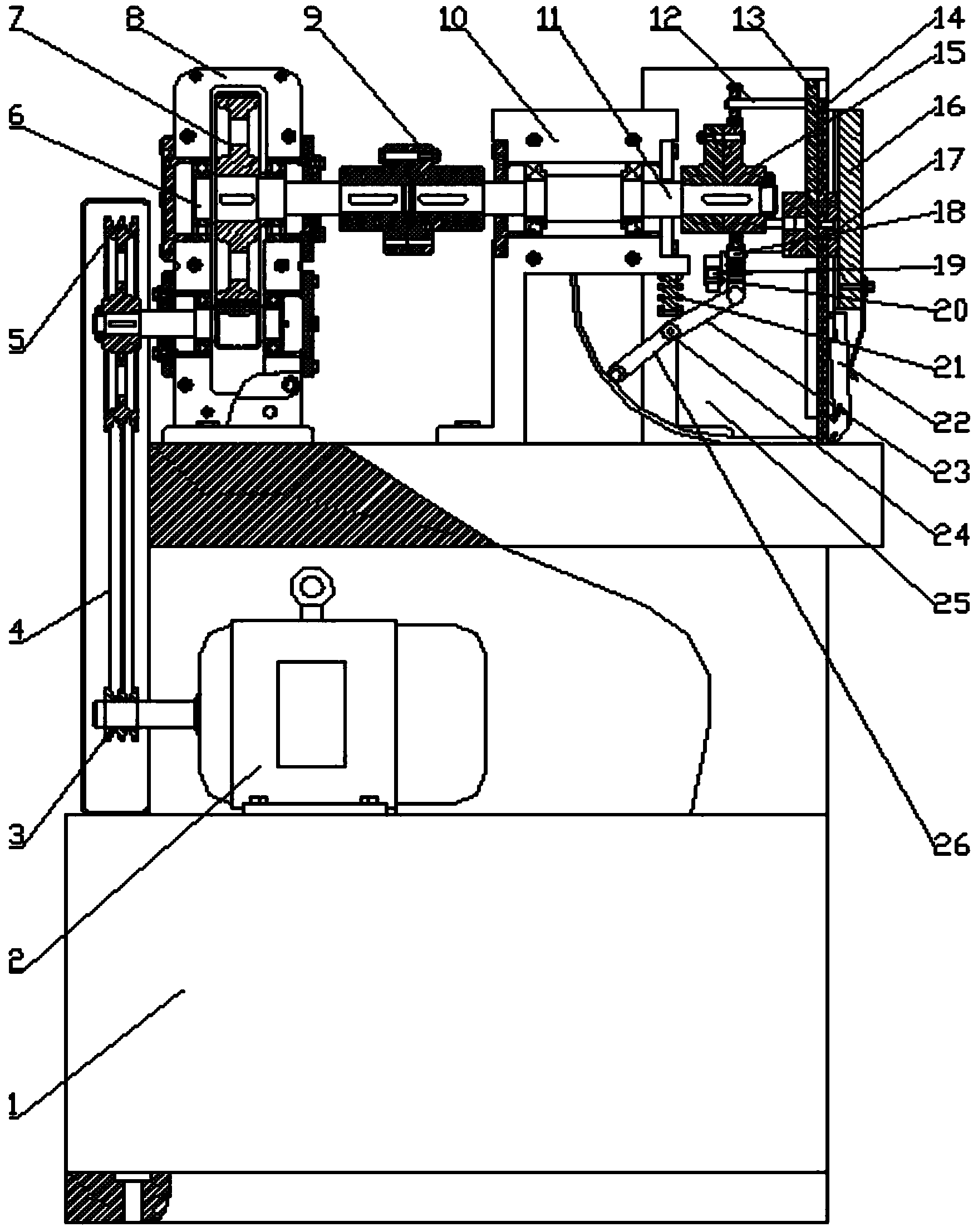

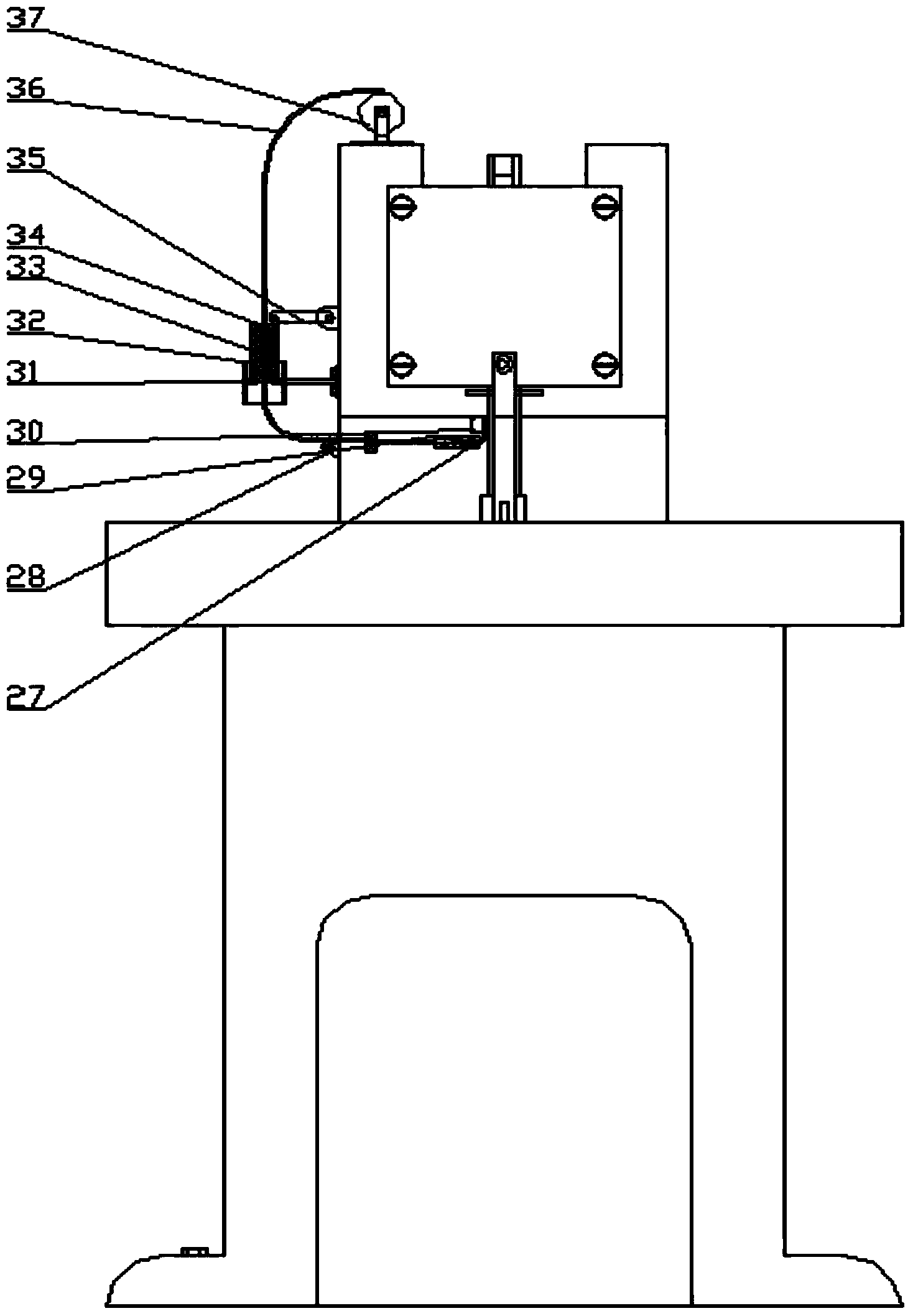

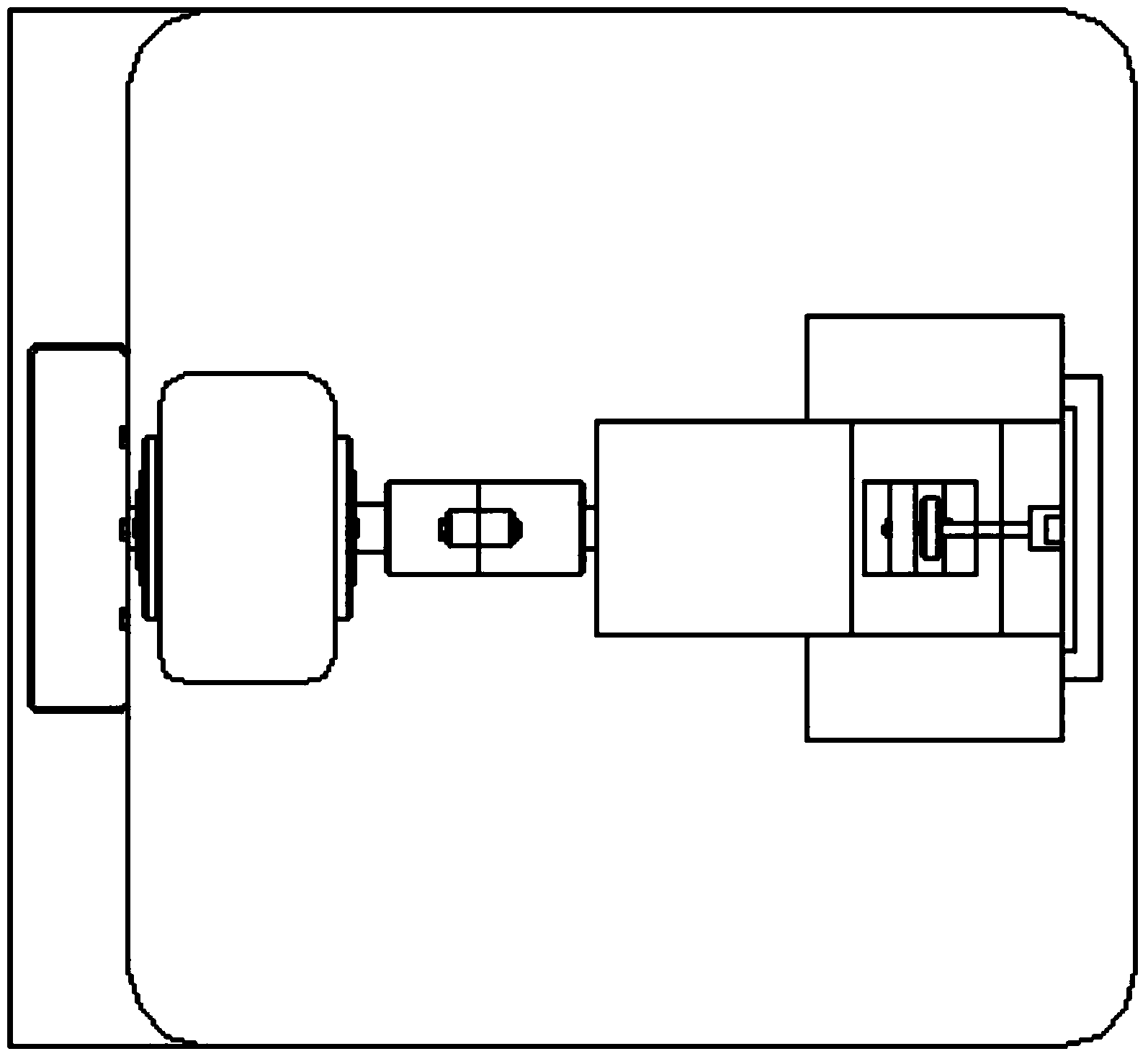

[0014] Such as figure 1 , figure 2 as well as image 3 Shown, a kind of photoelectric control stroke book automatic binding machine, comprises motor 2, small pulley 3, big pulley, big gear 5, working shaft 11, binding slider 13, forming slider, cam 15, gland 16, Slider 17, roller shaft 18, cut-off roller 19, cut-off roller shaft 20, connecting rod 23, hinge 24, box body 25, swing bar 26, photoelectric induction cutter 27, roller 28, wire guide hole 29, slide block 30, Frame 31, connecting rod 2. 32, iron wire 36, photoelectric wire feed wheel 37; Described motor 2 is arranged on support 1 top; Use V-belt 4 to connect between described big pulley 5 and described small pulley 3; The large gear 7 is arranged on the large gear shaft 6; the working shaft 11 is connected with the large gear shaft 6 using a coupling 9; the end of the working shaft 11 is provided with a cam 15;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com