Preparation method of calamine lotion

A technology for calamine and lubricant, which is applied in the field of preparation of calamine lotion, can solve the problems of difficult agglomeration, difficulty in obtaining powder, and a gritty feeling after long-term storage, saves follow-up work, and improves the stability of suspension. The effect of improving the property and powder solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

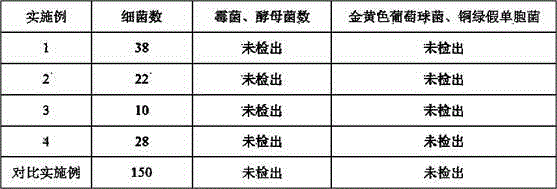

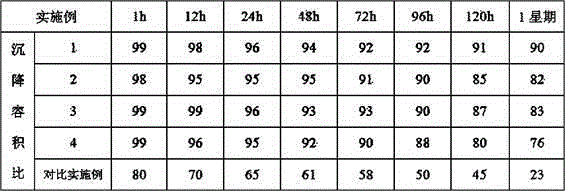

Embodiment 1

[0028] 150kg of calamine and 500kg of zinc oxide are prepared into superfine powder with a diameter of 3μm by a jet mill. The two are ground and mixed by dry method, and they are mixed with isopropanol 10L and glycerol 30L to wash repeatedly, then Add the mixture of colloidal microcrystalline cellulose, potassium citrate and sodium tartrate (mass ratio 1:1), glycerin, magnesium stearate=1:0.2:0.9:0.01 to mix the suspension stabilizer, and the concentration is 30%- The 50% suspension is finally filled into a finished product.

Embodiment 2

[0030] 150kg of calamine and 500kg of zinc oxide are prepared into ultrafine powder with a diameter of 5μm by a jet mill. The two are ground and mixed by dry method, and they are mixed with isopropanol 10L and glycerol 50L to wash repeatedly, then Add colloidal microcrystalline cellulose, potassium dihydrogen phosphate, glycerin, magnesium stearate=1:0.3:1.0:0.03 to mix the suspension stabilizer, prepare a suspension with a concentration of 30%-50%, and finally fill the finished product.

Embodiment 3

[0032] 150kg of calamine and 500kg of zinc oxide are prepared into ultrafine powder with a diameter of 8μm by a jet mill. The two are ground and mixed by dry method. They are mixed with isopropanol 10L and glycerol 80L to wash repeatedly, then Add colloidal microcrystalline cellulose, sodium tartrate, glycerin, magnesium stearate=1:0.3:1.0:0.05 to mix the suspension stabilizer, prepare a suspension with a concentration of 30%-50%, and finally fill the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com