Energy-saving and environment-friendly type garbage disposal device

A garbage disposal device, energy-saving and environmental protection technology, applied in the direction of combustion type, combustion method, lighting and heating equipment, etc., can solve the problems of low heat utilization rate of garbage combustion, insufficient garbage combustion, incomplete garbage treatment, etc., to reduce heat sources Supply, reduce dust, reduce the effect of follow-up work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

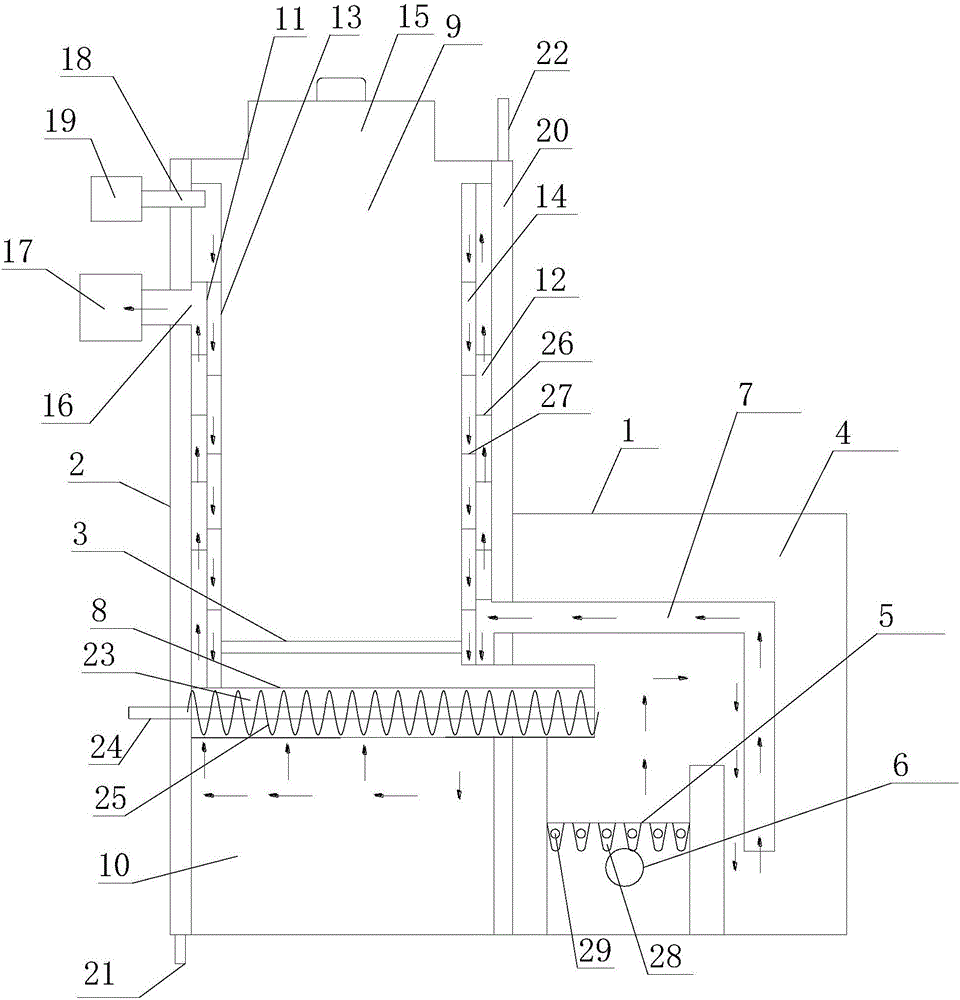

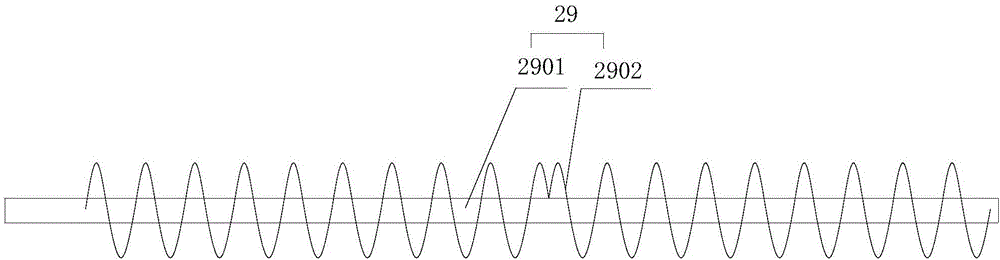

[0020] refer to figure 1 , figure 2 , the present invention proposes an energy-saving and environment-friendly garbage disposal device, comprising a first furnace body 1, a second furnace body 2, a screw feeding mechanism, and a plurality of air guide pipes 3, wherein:

[0021] The first furnace body 1 has a combustion chamber 4 , and a furnace bridge 5 , an oxygen supply device 6 and a smoke return pipe 7 are arranged in the combustion chamber 4 .

[0022] The second body of heater 2 has a chamber, and the periphery of the chamber is provided with an annular cooling chamber 20. The second body of furnace 2 is provided with a cooling medium inlet pipe 21 and a cooling medium outlet pipe 22 communicating with the annular cooling chamber 20. The temperature of the second furnace body 2 is lowered to prolong the service life, and the hot water produced can be used for other purposes, saving resources and having high energy utilization rate. A transverse partition 8 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com