A domestic waste disposal device

A treatment device and technology for domestic waste, applied in the direction of combustion type, combustion method, lighting and heating equipment, etc., can solve the problems of insufficient combustion of waste, waste of heat energy, high cost, reduce dust, reduce follow-up work, and reduce temperature concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

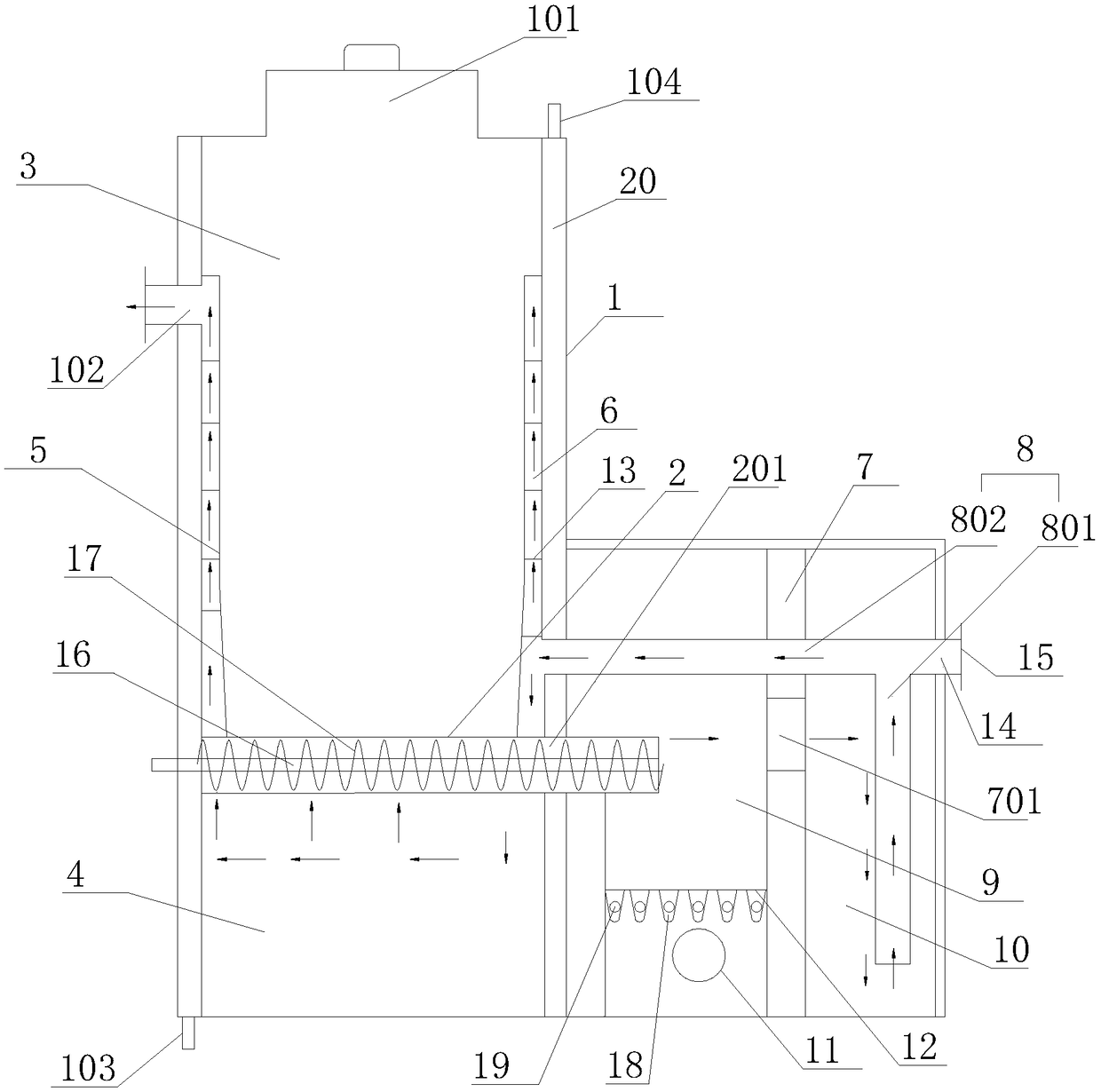

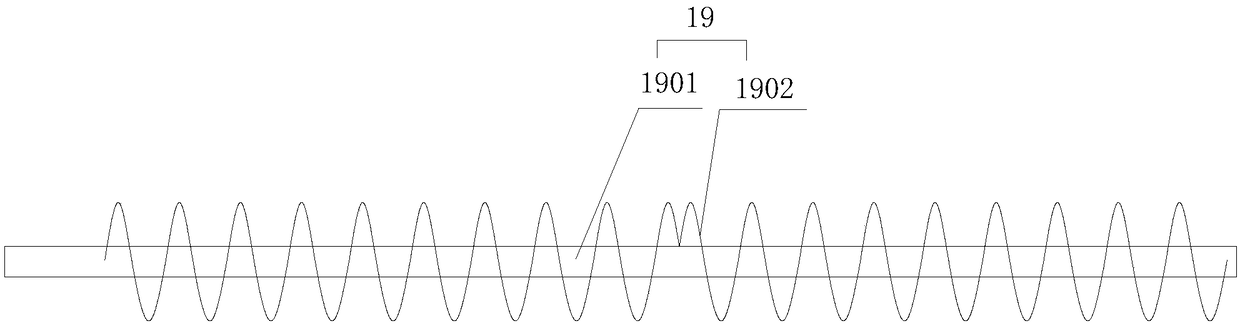

[0018] refer to figure 1 , figure 2 , the present invention proposes a domestic waste treatment device, comprising a furnace body 1 and a screw conveying mechanism, the furnace body 1 has a first chamber and a second chamber, wherein:

[0019] The first chamber is provided with a transverse partition 2 made of heat-conducting material. The transverse partition 2 separates the first chamber into a storage chamber 3 and a tail smoke preheating chamber 4. The top of the furnace body 1 is provided with a storage chamber 3 A connected feed port 101, an annular baffle 5 is provided in the material storage chamber 3, and a closed annular smoke return chamber 6 is formed between the annular baffle 5 and the inner wall of the material storage chamber 3, and the smoke outlet of the tail smoke preheating chamber 4 The mouth is connected with the smoke inlet of the annular smoke return chamber 6, and the furnace body 1 is provided with a smoke exhaust port 102 connected with the annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com