Full combustion treatment equipment for household garbage

A technology for fully burning and treating equipment, applied in the direction of burning equipment, burning method, burning type, etc., can solve the problems of low utilization rate of waste combustion heat, unsatisfactory waste treatment effect, insufficient waste combustion, etc., to avoid emissions, temperature Concentrating and reducing dust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

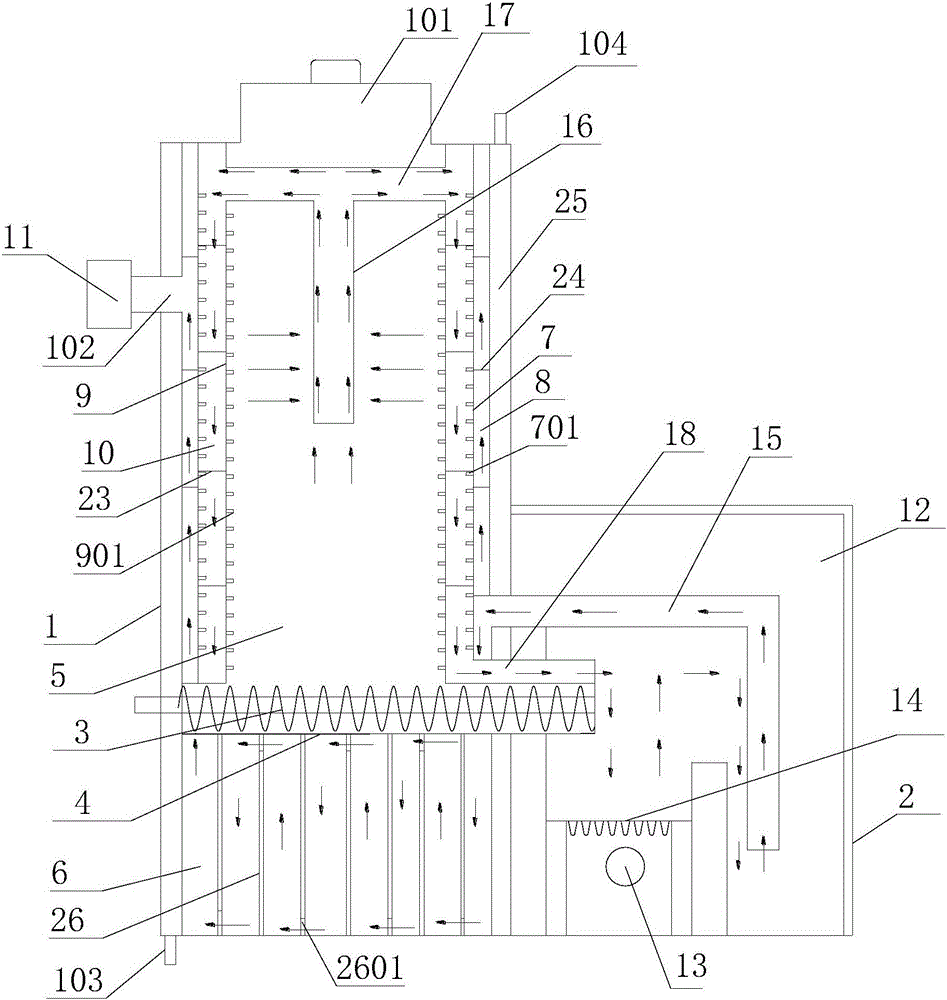

[0019] refer to figure 1 , the present invention proposes a full combustion treatment equipment for domestic waste, comprising a first furnace body 1, a second furnace body 2, a spiral material guide device 3, and an air guide device, wherein:

[0020] The first furnace body 1 has a chamber, and a cooling chamber 25 is provided on the periphery of the chamber, and a cooling medium inlet 103 and a cooling medium outlet 104 communicating with the cooling chamber 25 are provided on the first furnace body 1 . A transverse partition 4 is arranged in the chamber, and the transverse partition 4 divides the chamber into a material storage chamber 5 and a tail smoke chamber 6 sequentially from top to bottom. The first annular baffle 7 is arranged in the material storage chamber 5, and the first annular A gap is reserved between the baffle plate 7 and the inner wall of the material storage chamber 5 to form an annular heat preservation chamber 8 , and a first annular cooling rib 701 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com