A kind of waste high temperature incineration treatment equipment

A treatment equipment and high-temperature technology, which is applied in the field of high-temperature waste incineration treatment equipment, can solve the problems of affecting waste treatment efficiency, insufficient waste combustion, and heavy processing workload, so as to reduce the amount of dust in the exhaust gas, improve the combustion effect, and reduce follow-up work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

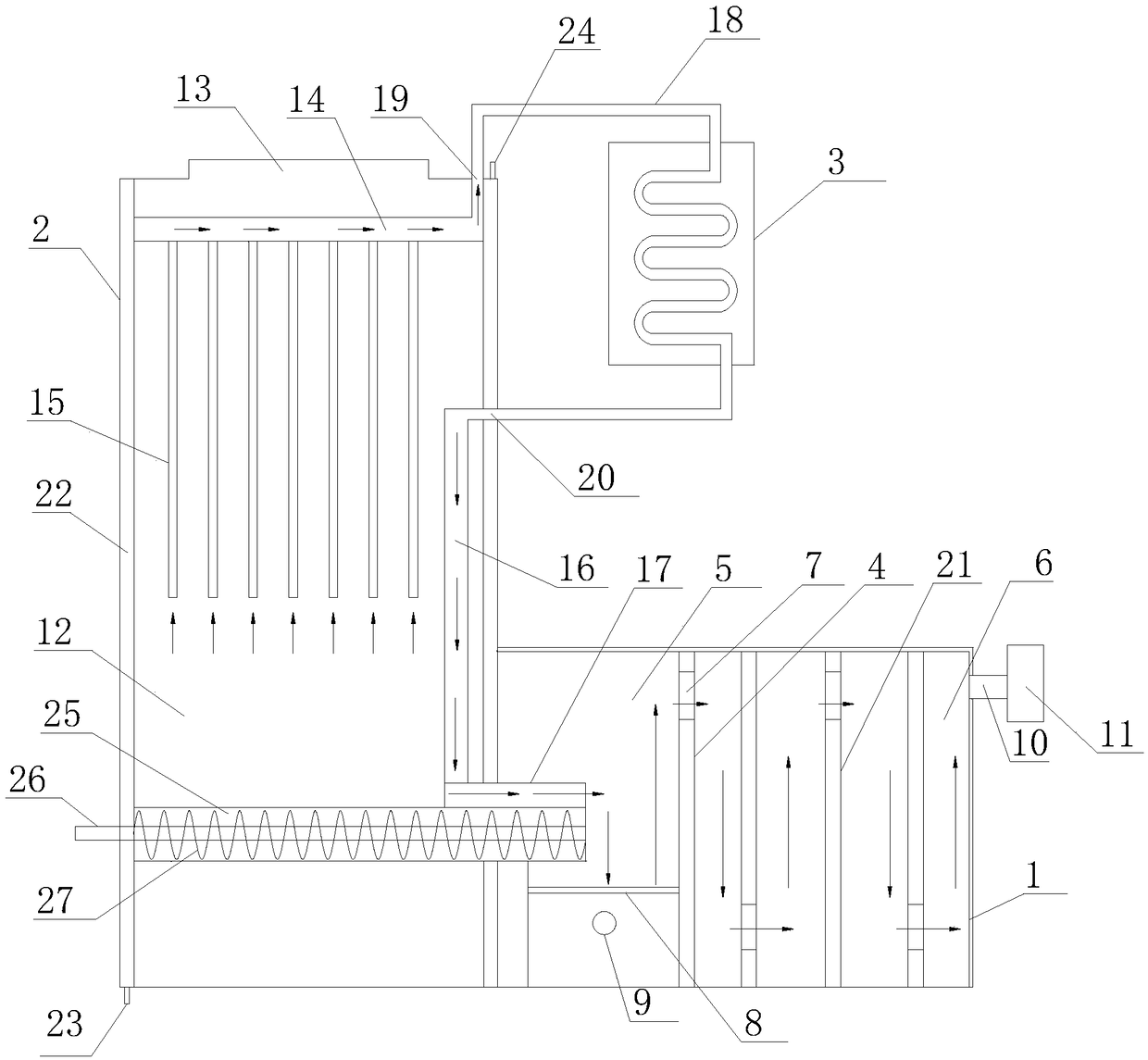

[0018] refer to figure 1 , the present invention proposes a high-temperature waste incineration treatment equipment, including a first furnace body 1, a second furnace body 2, a screw feeding mechanism, an internal circulation mechanism, and a water cooling box 3, wherein:

[0019] The first furnace body 1 has a chamber, the first vertical partition 4 is arranged in the chamber, the first vertical partition 4 separates the chamber into a combustion chamber 5 and an exhaust gas buffer chamber 6, and the top of the first vertical partition 4 is provided with a The combustion chamber 5 communicates with the exhaust gas buffer chamber 6 through a vent hole 7 , and the combustion chamber 5 is provided with a furnace bridge 8 and an oxygen supply device 9 . The first furnace body 1 is provided with an exhaust pipe 10 communicating with the exhaust gas buffer chamber 6, and the exhaust pipe 10 is provided with a fan 11; a plurality of second vertical partitions 21 are arranged at int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com