Cress harvester

A harvester and cress technology, applied in the field of cress harvesters, can solve the problems of low labor effect and high work intensity, and achieve the effects of improving operation safety, high harvesting efficiency, and convenient water work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

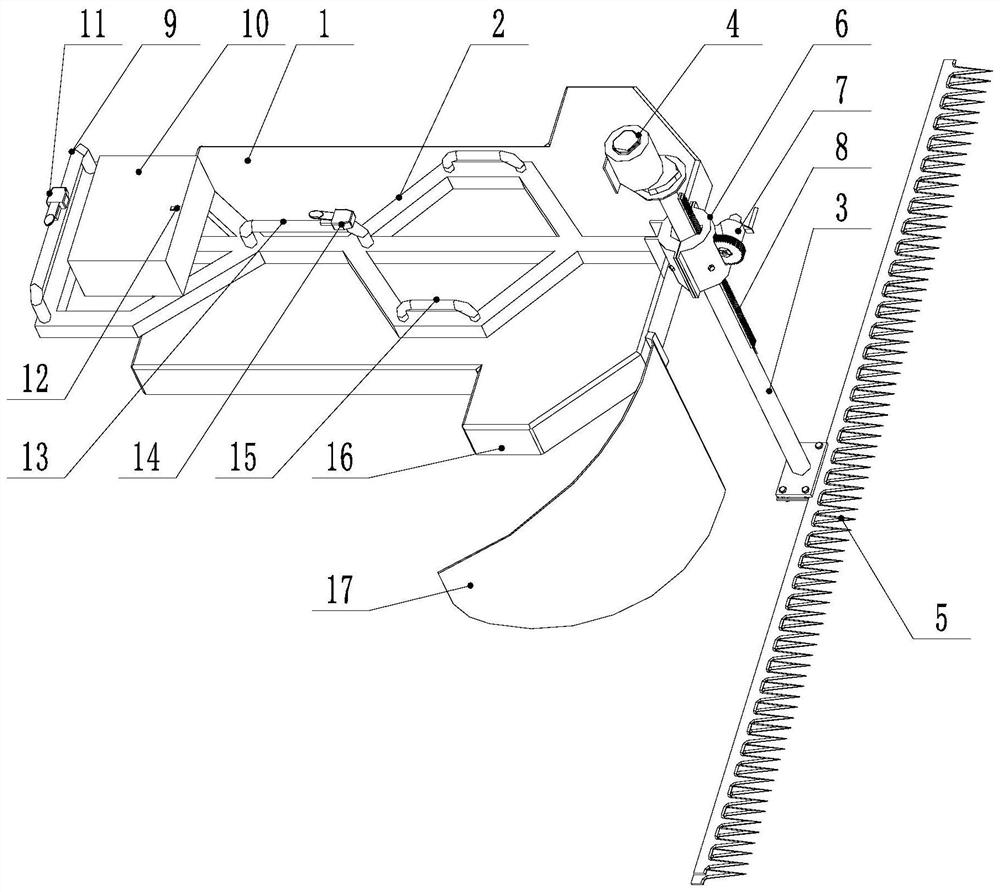

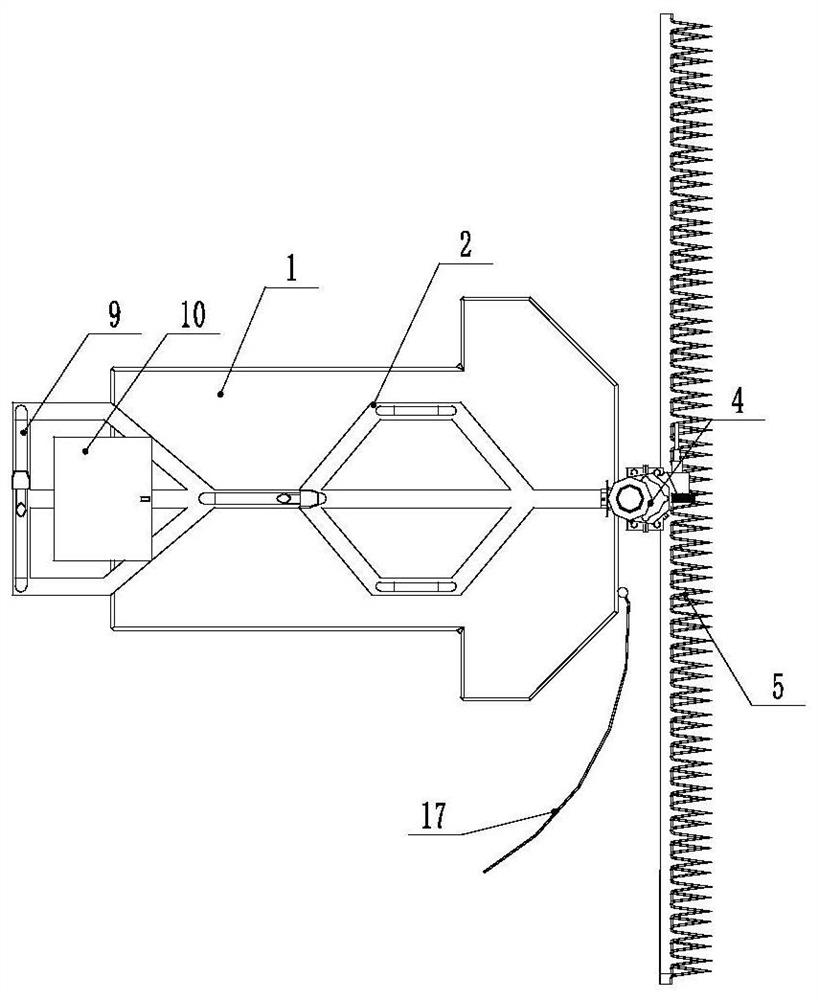

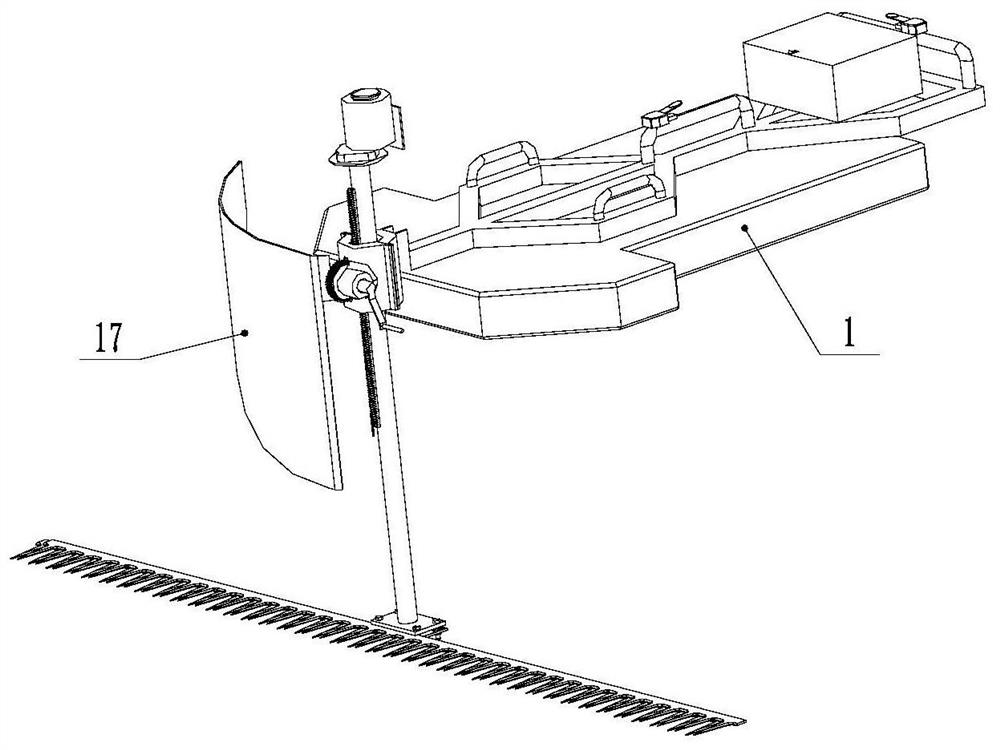

[0023] Embodiment 1: as Figure 1 to Figure 3 The shown cress harvester includes a floating plate 1 and a support 2 arranged on the floating plate 1; the support 2 includes a main beam, a trapezoidal assembly located on both sides of the middle of the main beam, and a pentagonal assembly located at the tail of the main beam . The front end of the bracket 2 is connected with a sleeve 6, the rear end of the bracket 2 is provided with a push handle 9, and a storage battery 10 is installed above the pentagonal assembly. Sleeve 6 is connected with adjustment column 3, and adjustment column 3 is provided with transmission shaft, and the motor 4 that adjusts column 3 tops is established links to each other with the cutting assembly 5 of adjustment column 3 bottoms by transmission shaft, cam assembly. The cutting assembly 5 includes two stacked elongated shearing knives, on which triangular knife heads are arranged at intervals.

[0024] Both sides of the front end of the floating p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com