A Limiting Method to Prevent the Displacement of Empty Pushing Segment in Shield

A technology of segment and empty pushing, which is applied in earthwork drilling, shaft equipment, wellbore lining, etc. It can solve the problems of affecting the overall construction progress, poor segment displacement effect, and high ejector cost, so as to achieve high ejector cost and improve effect, promotional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

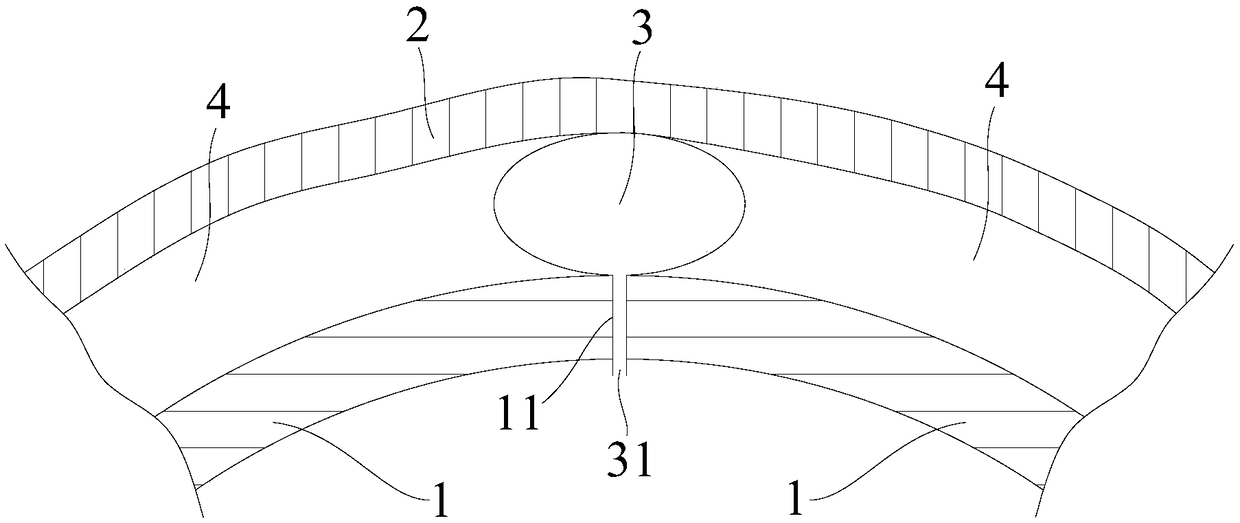

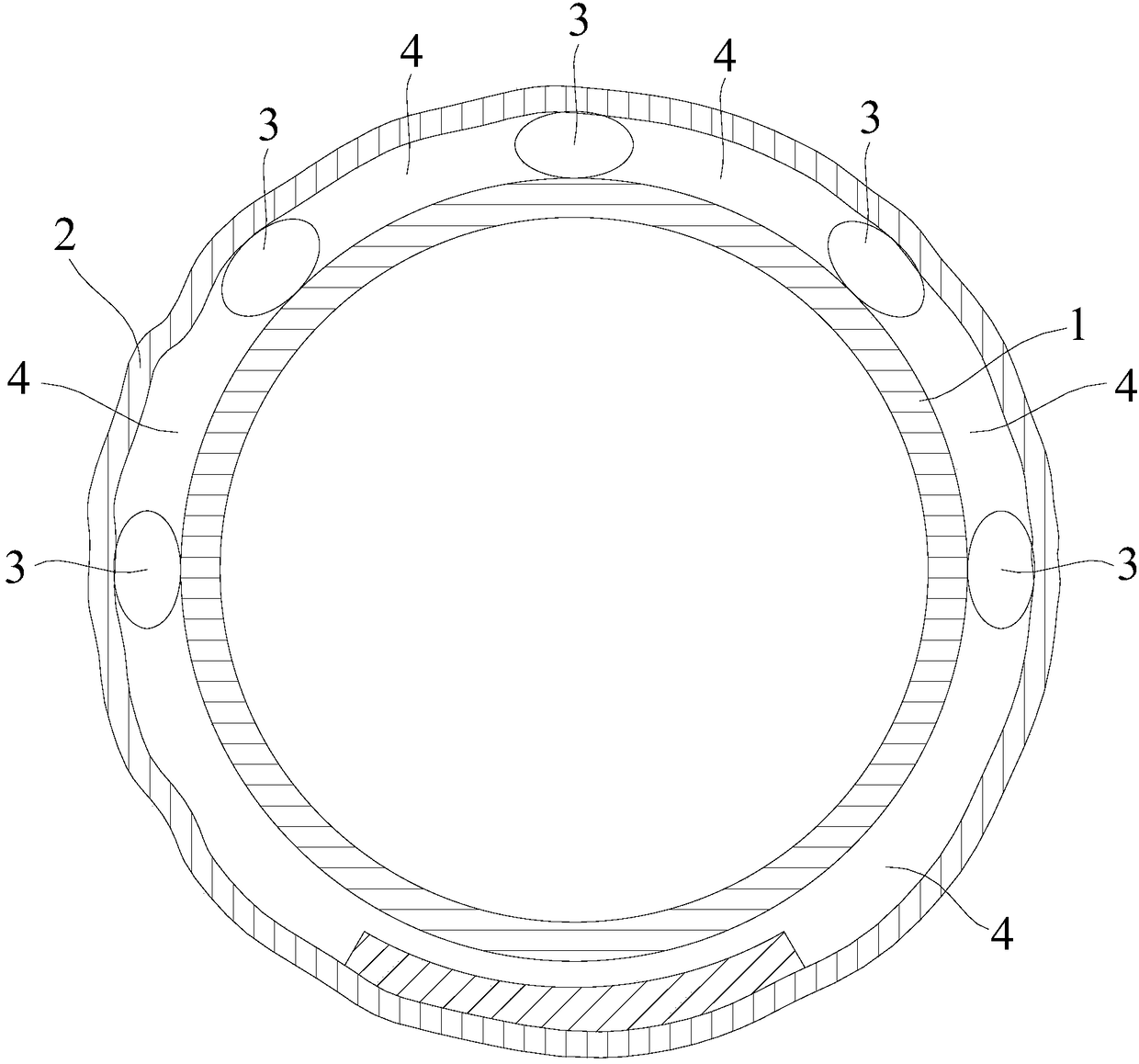

[0033] Such as Figure 1-2 As shown, a cross-sectional view of a position-limiting support segment using a method of limiting the displacement of a shield empty-push segment according to the present invention, including a segment 1, a through hole 11, an initial support system 2, and a capsule 3 , the entry channel 31 and the slot 4.

[0034] The method includes the following steps:

[0035] a. After each ring segment 1 of the shield machine comes out of the tail of the shield, several through holes 11 are opened on the segment 1;

[0036] b. Several bladders 3 are arranged in the cavity of the gap 4 between the segment 1 and the primary support system 2, each of the through holes 11 corresponds to at least one bladder 3, each of the bladders 3. There is an inlet channel 31 communicating with its inner cavity, and the inlet channel 31 cooperates with the corresponding through hole 11;

[0037] c. Connect each of the inlet passages 31 with a grouting machine, and the groutin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com