Preparation method of thiamethazide

A technology of thiamethoxam and oxadiazine, which is applied in the field of preparation of thiamethoxam, can solve the problems of increased work, low yield of waste water, etc., and achieve the effects of reducing waste water, less three wastes, and saving unit consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

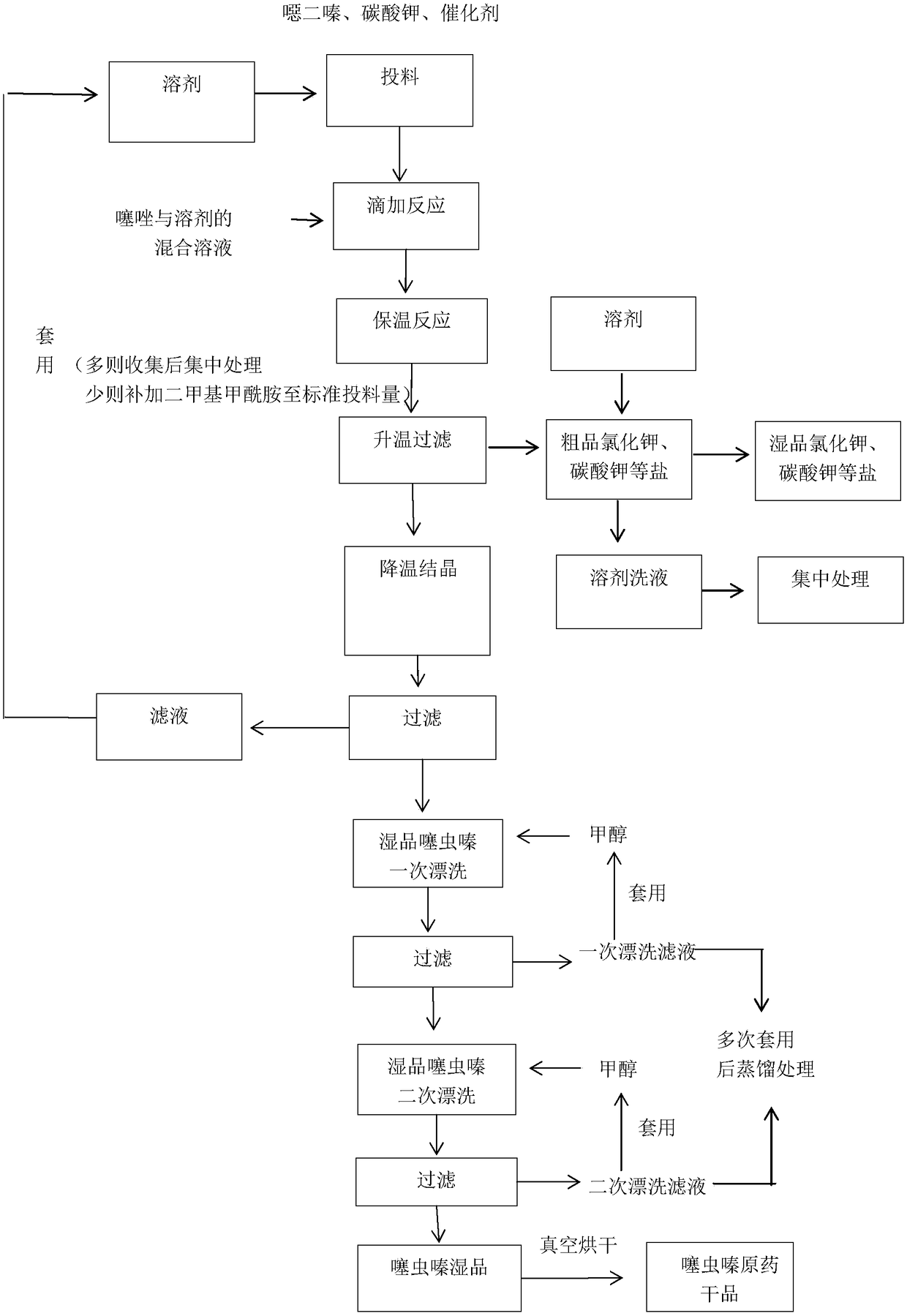

[0020] Please refer to figure 1 , the embodiment of the present invention provides a kind of preparation method of thiamethoxam, comprises the following steps:

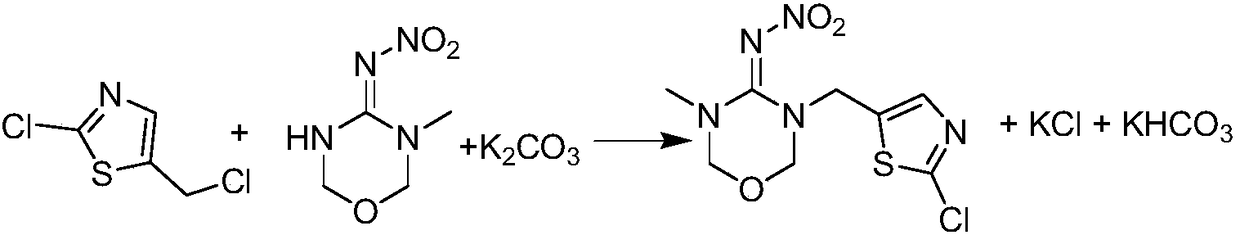

[0021] S1. Add metered solvent, 3-methyl-4-nitroimino-1,3,5-oxadiazine, potassium carbonate and catalyst in sequence in the reactor, solvent, potassium carbonate and 3-methyl-4 - The mass ratio of nitroimino-1,3,5-oxadiazine is preferably 20-40:10:8, stirring to make the materials evenly mixed, and raising the temperature to 25-35°C;

[0022] S2. Add dropwise the mixture of 2-chloro-5-chloromethylthiazole and solvent in the above reaction system at a rate of 40-60ml / h, control the temperature not higher than 35°C, 2-chloro-5-chloromethylthiazole After the mixture with the solvent is added dropwise, stir and react for 8-16 hours, and check whether the reaction is complete by thin-layer chromatography. If the reaction is not complete, continue the reaction. After the reaction is completed, proceed to step S3;

[0023]...

Embodiment 1

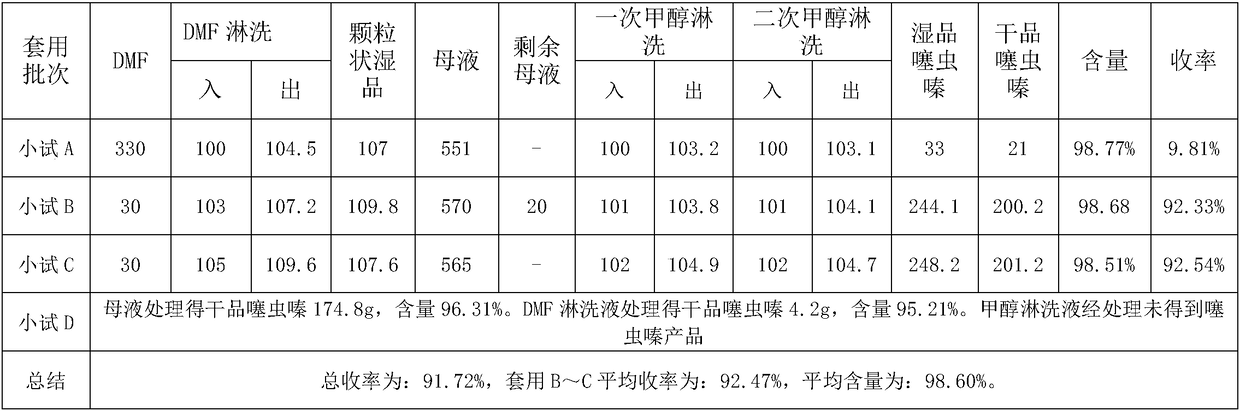

[0028] Complete the continuous application of the mother liquor for 2 times

[0029] Small test A: Add metered 300g N,N-dimethylformamide (DMF), 117.5g 3-methyl-4-nitroimino-1,3,5-oxadiazine, 116g carbonic acid in a three-necked flask Potassium, 3g catalyst, then dropwise add the mixed solution of 148g 2-chloro-5-chloromethylthiazole and 30g DMF, control the temperature at 30-35°C, stir and react for 8h, thin layer chromatography (TLC) detects that the reaction is complete, the reaction Incomplete, continue the reaction, the reaction is complete, the reaction system remains in a yellow suspension state, heat to 65-70°C, filter the coarse salt while it is hot, rinse the coarse salt with 100g DMF to obtain DMF eluent A and granular wet product A107g (collected and processed), cooled to 0-5°C for crystallization and filtration, 551g of the filtrate (mother liquor A) was used as a solvent, and the filter cake was rinsed twice with 100g*2 methanol, and the obtained methanol lotion ...

Embodiment 2

[0036] Complete the continuous application of the mother liquor for 2 times, verify Example 1:

[0037] Small test E: Add metered 300g N,N-dimethylformamide, 117.5g 3-methyl-4-nitroimino-1,3,5-oxadiazine, 116g potassium carbonate, 3g of catalyst, then dropwise add a mixed solution of 148g 2-chloro-5-chloromethylthiazole and 30gDMF, control the temperature at 30-35°C, stir for 8h, TLC detects that the reaction is complete, and the reaction system remains in a yellow suspension state. to 65-70°C, filter while hot, and rinse the filter cake with 100g DMF to obtain DMF eluent E and granular wet product Eg (collected and processed), the filtrate is cooled to 0-5°C and filtered, and the filtrate is 552g (mother liquor E) Used as solvent, the filter cake was rinsed with 100g*2 methanol, the resulting methanol lotion was E1, E2, the obtained wet product thiamethoxam was 36g, dried to obtain 22.5g of light yellow powdered thiamethoxam, and the detected content was 98.69%. The yield wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com