Tank clipping, conveying and fixing mechanism

A technology for fixing mechanisms and tanks, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of increasing production costs, increasing labor intensity of operators, and poor acceptance of tanks 200

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

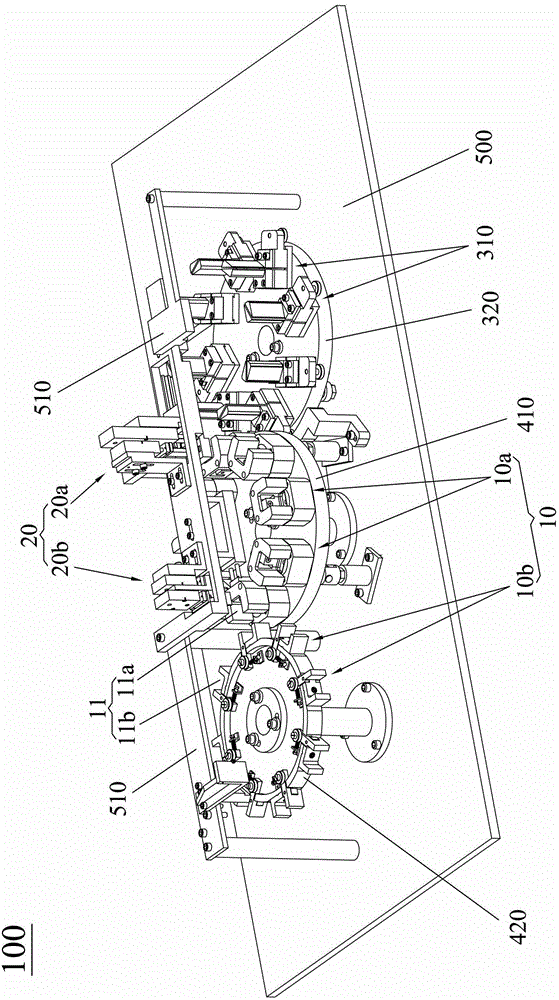

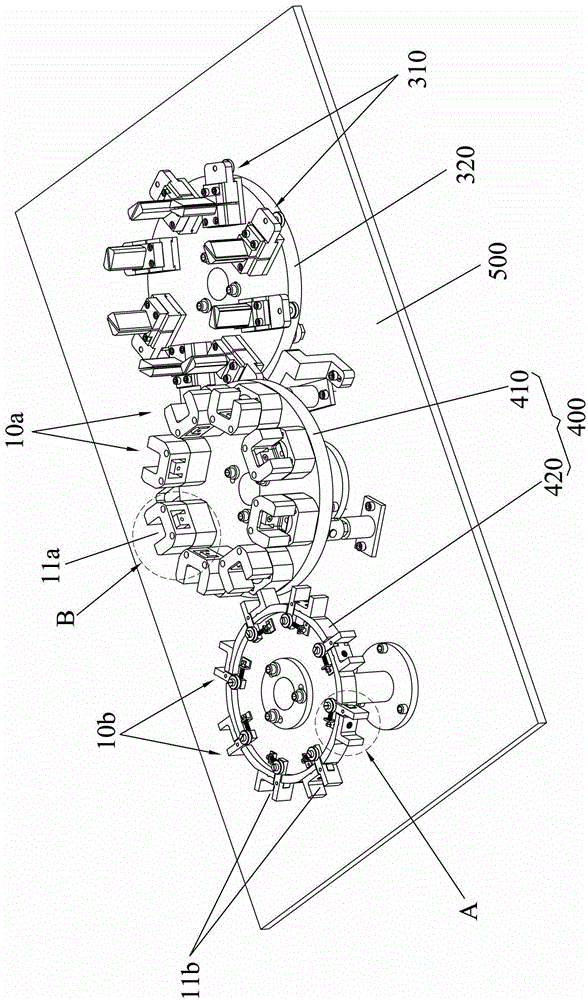

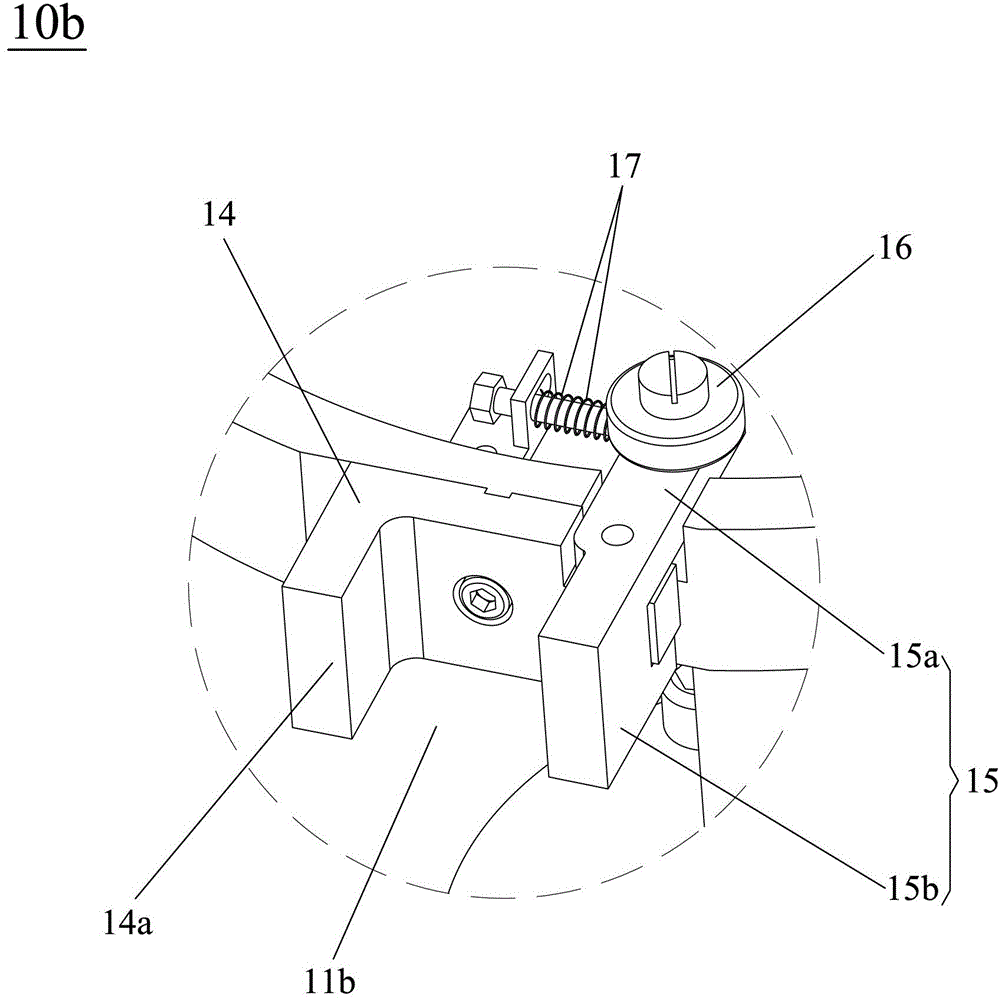

[0026] see figure 1 , figure 2 and Figure 8 , the tank body of the present invention is used to clamp and transport the fixing mechanism 100 to the previous process (for example, using Figure 8 The shown bottom cover 210 and cylinder body 220 are assembled together to form the assembly process of the tank body 200) the tank body 200 on the clamping device 310 is clamped and transported and fixed in the next process (such as the top end 222 edge sealing process of the tank body 200 , and the forming process of the pivot groove 221 of the tank body 200). Specifically, in this embodiment, there are multiple clamping devices 310, such as three, four, five, six, seven or eight, etc. well-known, so the number of clamping devices 310 is not limited here, but a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com