A kind of preparation method of antibacterial micro-arc oxidation film layer

A technology of micro-arc oxidation and film layer, which is applied in the direction of anodic oxidation, coating, surface reaction electrolytic coating, etc., can solve the problem of insufficient combination of antibacterial coating and micro-arc oxidation film layer, increased process complexity, and poor antibacterial performance Film layer and other problems, to achieve the effect of being suitable for large-scale promotion and application, excellent antibacterial performance, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

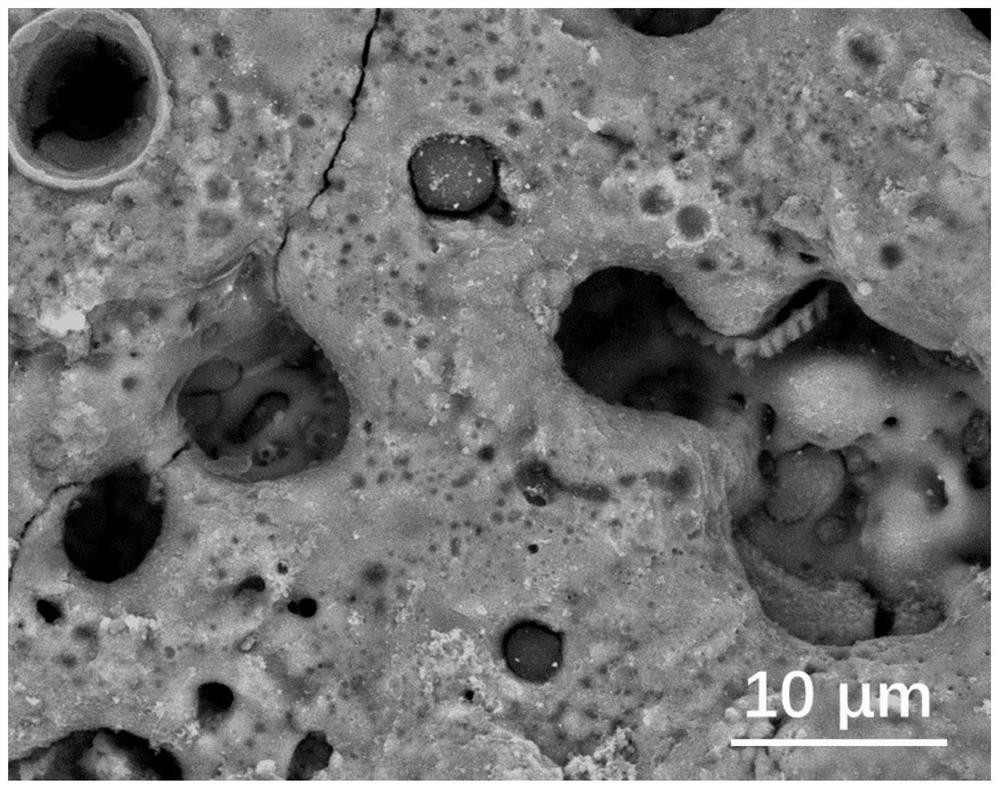

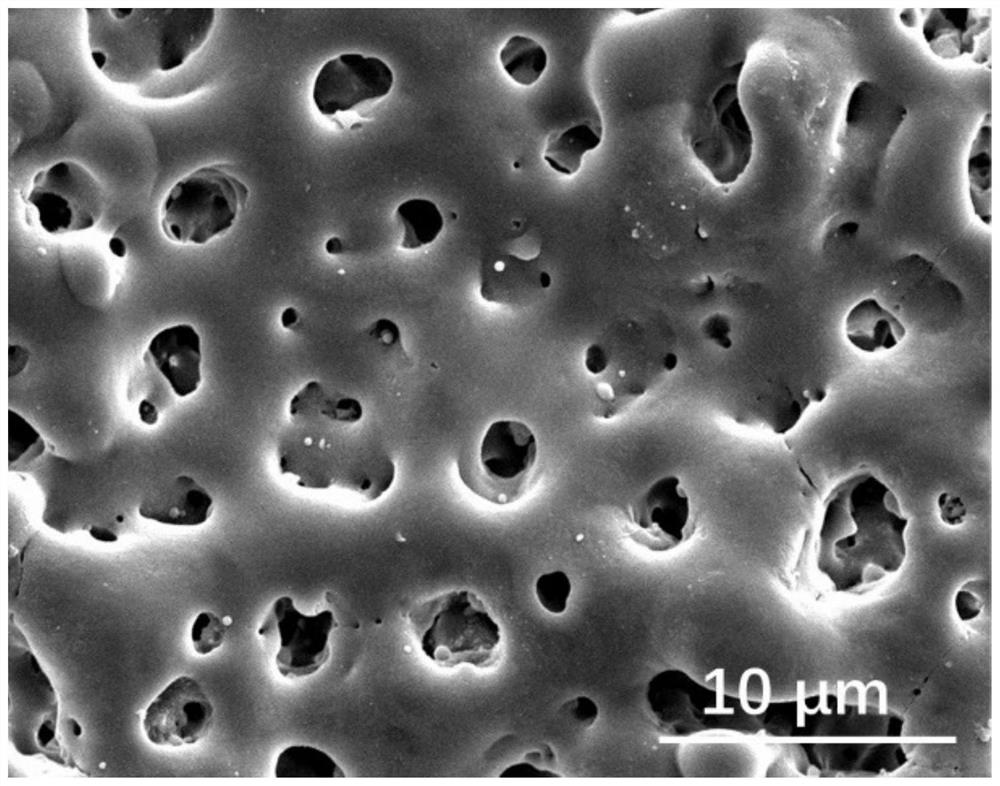

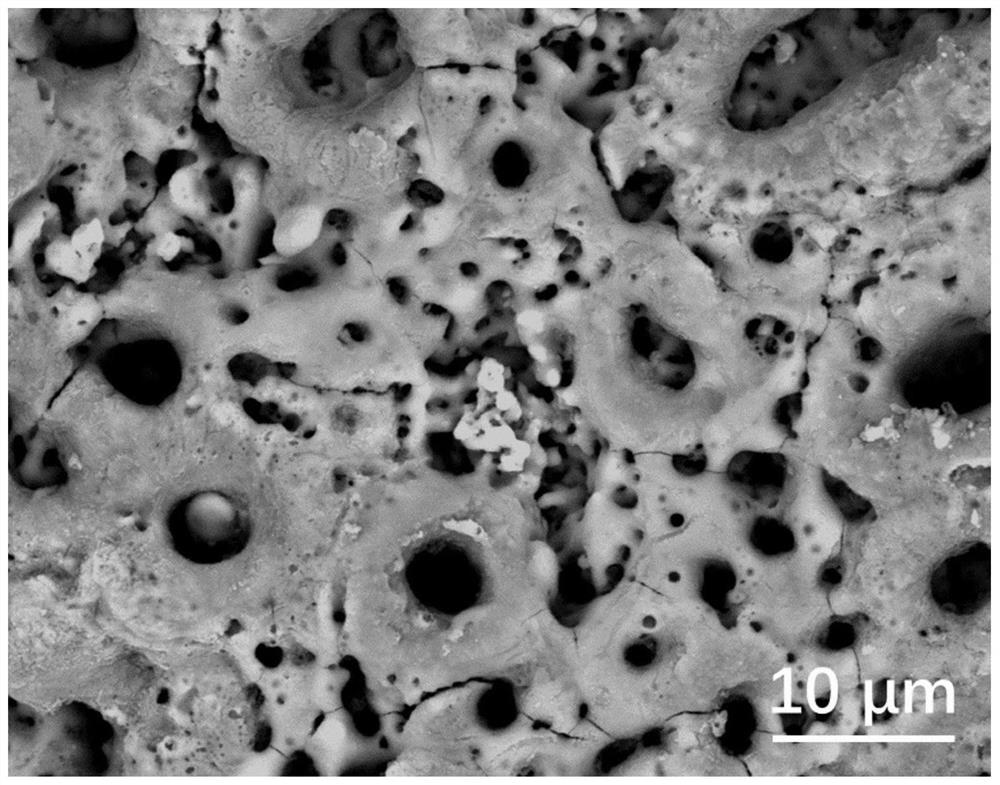

Image

Examples

Embodiment 1

[0040] A method for preparing an antibacterial micro-arc oxidation film layer, comprising the following steps:

[0041] 1) Calculate according to the silver content of 6wt%, and weigh the pure magnesium block and metallic silver particles with a purity higher than 99.5wt%, and then polish, pickle and dry the pure magnesium block;

[0042] 2) Put the pure magnesium block treated in step 1) into the smelting furnace, fill it with argon, heat it to 720°C until the pure magnesium block melts, keep it warm for 15 minutes, then raise the temperature to 750°C, add metallic silver particles, and keep it warm for 15 minutes. Lower the temperature to 680°C and let it stand for 15 minutes to remove impurities on the surface of the molten material;

[0043] 3) Inject the molten material in step 2) into a steel mold coated with a mold release agent and preheated to 280°C, and slowly immerse the steel mold in flowing water at 20°C to rapidly solidify the molten material in the mold, Demoul...

Embodiment 2

[0052]A method for preparing an antibacterial micro-arc oxidation film layer, comprising the following steps:

[0053] 1) Calculate according to the silver content of 6wt%, and weigh the pure magnesium block and metallic silver particles with a purity higher than 99.5wt%, and then polish, pickle and dry the pure magnesium block;

[0054] 2) Put the pure magnesium block treated in step 1) into the smelting furnace, fill it with argon, heat it to 720°C until the pure magnesium block melts, keep it warm for 15 minutes, then raise the temperature to 750°C, add metallic silver particles, and keep it warm for 15 minutes. Lower the temperature to 680°C and let it stand for 15 minutes to remove impurities on the surface of the molten material;

[0055] 3) Inject the molten material in step 2) into a steel mold coated with a release agent and preheated to 300°C, and slowly immerse the steel mold in flowing water at 20°C to rapidly solidify the molten material in the mold, Demoulding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com