Falling-protection device

A technology for anti-falling and mounting plates, which is applied in hoisting devices, safety devices for lifting equipment, etc., can solve problems such as lack of fall protection, poor working stability, and waste of energy, and achieve low manufacturing costs, high working stability, and Simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

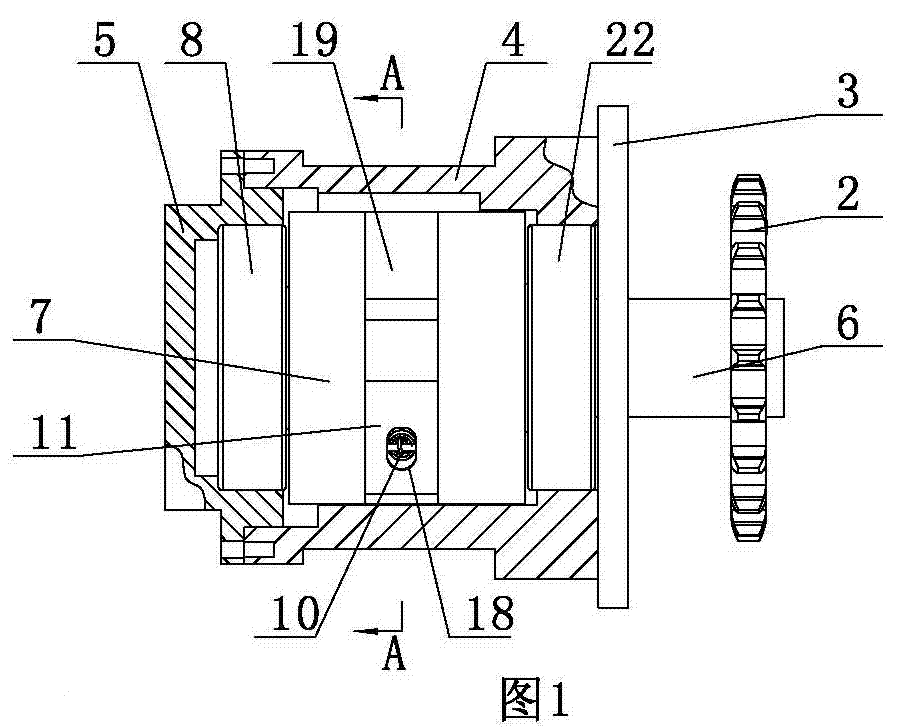

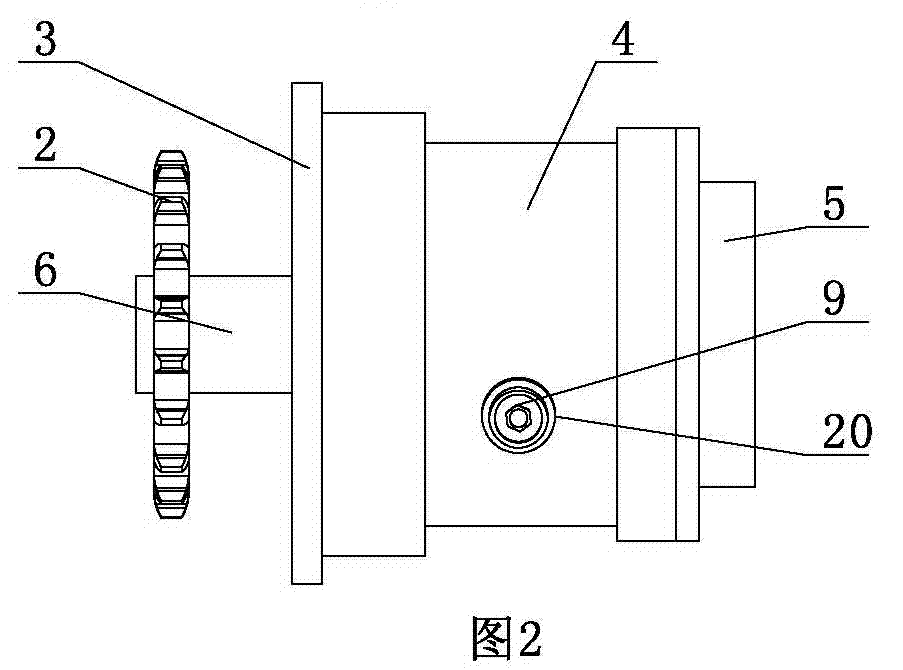

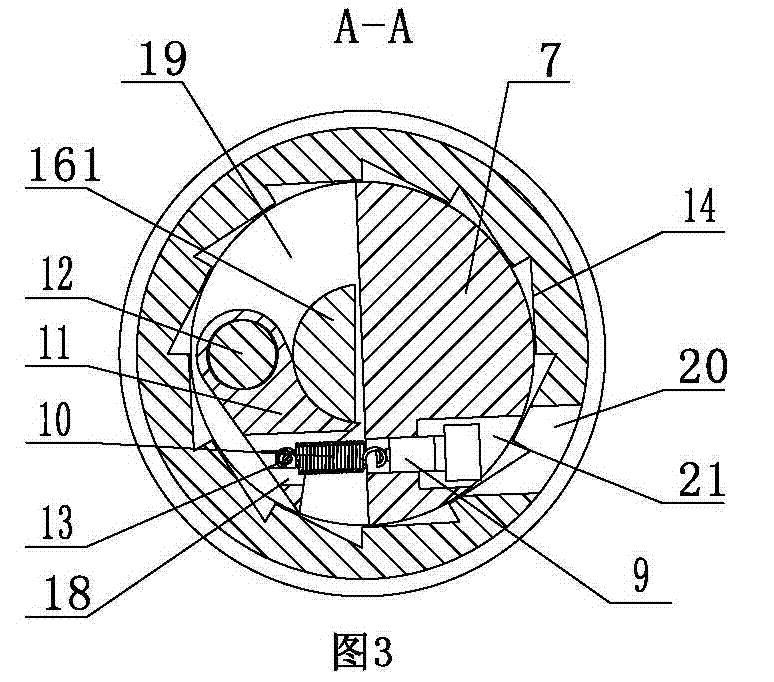

[0009] The anti-falling device of the present invention includes a housing formed by connecting a mounting plate 3 , a ratchet housing 4 and an end cover 5 . Mounting plate 3, ratchet housing 4 and end cover 5 can be made into one. But, for the convenience of maintenance, the mounting plate 3, the ratchet shell 4 and the end cover 5 can also be processed and manufactured separately, and assembled afterwards. Usually, the mounting plate 3 can also be replaced by a part of the body of the equipment, so as to connect and fix the fall arresting device with the equipment. Such as image 3 As shown, the inner wall of the ratchet housing 4 is provided with ratchet teeth 14 . A brake shaft 7 is installed in the housing, and a load shaft 6 is installed on one end of the brake shaft 7, and one end of the load shaft 6 passes out of the housing so as to be connected with the load sprocket 2 of the lifting platform. Such as Figure 4 to Figure 9 As shown, one side of the brake shaft 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com