Encoder base and encoder using same

A technology of encoders and bases, applied in the field of encoders, can solve the problems of inability to inject molding, increase the thickness of encoders, and easy gaps, etc., and achieve the effect of saving material costs, saving assembly man-hours, and reducing overall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

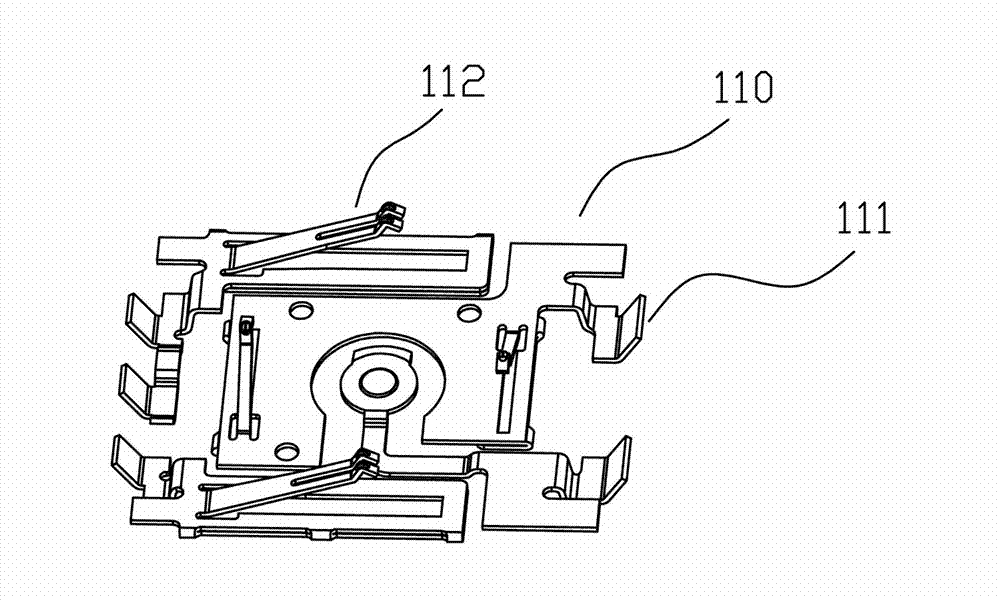

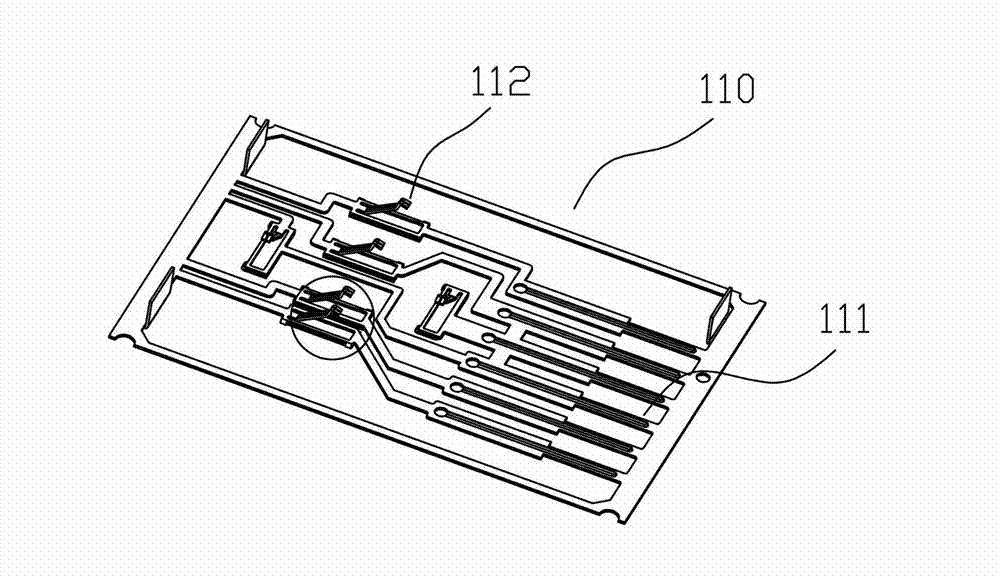

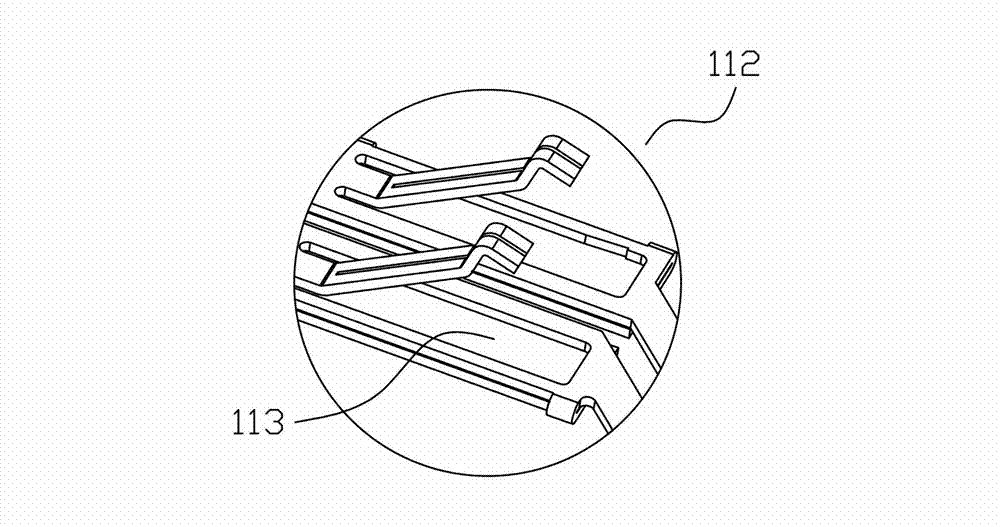

[0020] refer to Figure 1 to Figure 5 The structure of the terminal hardware sheet and the encoder base is shown. The encoder base 100 includes several sets of terminal hardware sheets 110 and a plastic body 120 overmolded outside the terminal hardware sheet 110. The terminal hardware sheet 110 includes terminals 111 and brushes. part 112, the brush of the brush part 112 is higher than the plane of the brush part due to stamping and forming, and there is a space under the brush part. There is an extension part 113 on the side of the brush part 112, and the extension part 113 is bent and attached to the The bottom surface of the brush part 112 covers the void, and the plastic body 120 encapsulates the brush part 112 and the extension part 113 as a whole.

[0021] refer to Figure 6 An encoder is shown, which includes a base 210, a code disc 220 in contact with the brush portion in the accommodating cavity of the base 210, a rotating shaft 230 inserted in the central hole of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com