Ceramic package and product encapsulation integrated machine

A ceramic shell, all-in-one technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of high frequency affecting ergonomics, product stacking, and changeover adjustment, and achieve increased productivity, quality assurance, and stable positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

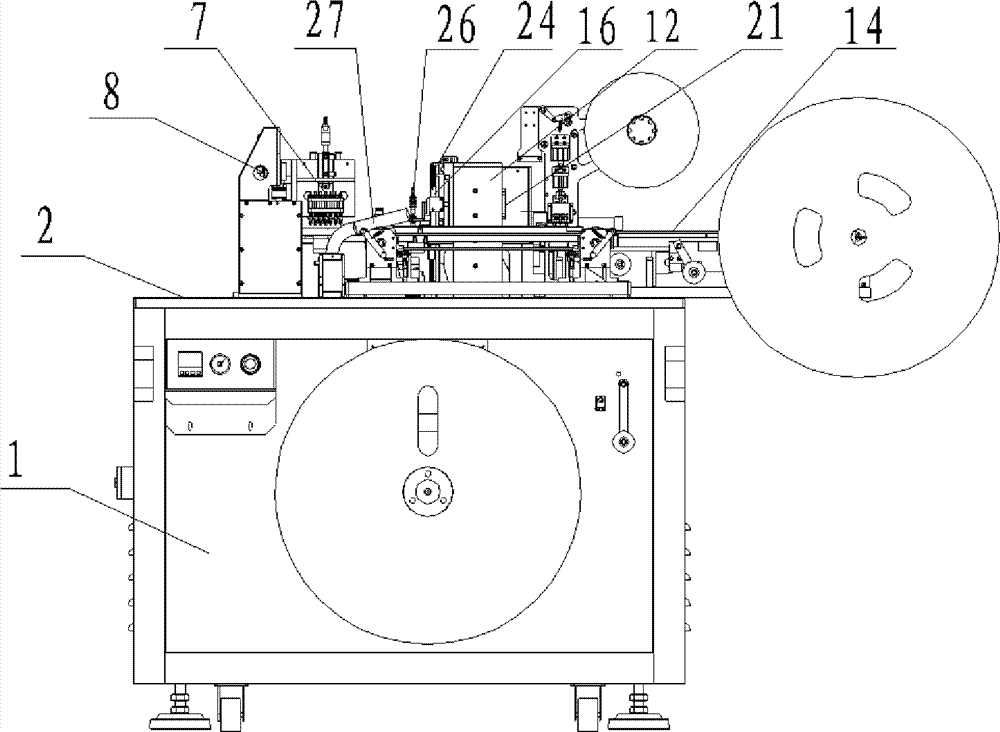

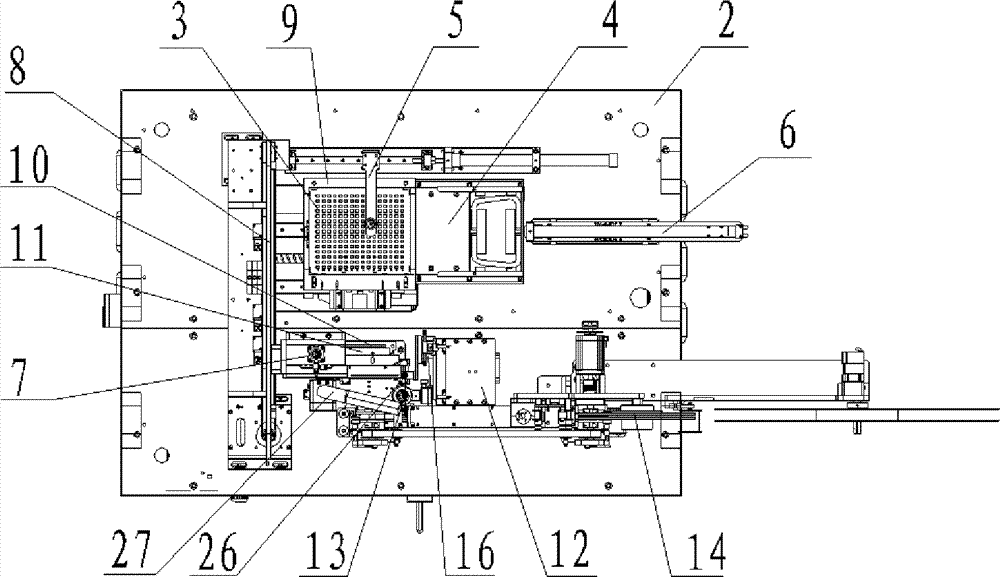

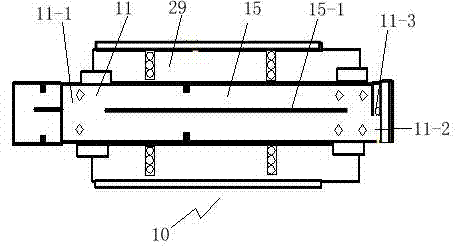

[0027] See figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8, the present invention comprises box body 1, and the upper surface of box body 1 is work table top 2, and feeding mechanism, unloading mechanism are installed on work table top 2, and feeding mechanism, unloading mechanism comprise tray carrying device, take-up platform 9, pallet The carrying device includes a material box 4, the material box 4 is a box body that runs through the front and back, the tray 3 is stacked in the material box 4, and the material box 4 is divided into a ceramic shell tray material box and a finished product tray material box, in which the materials for the ceramic shell tray are carried. The box is made by imitating the tray material box of the finished product. The purpose is to make the empty tray recovery cylinder 5 of the feeding mechanism and the unloading mechanism able to recover the empty tray on the reclaiming table 9 into the material box 4. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com