Cruciate-retaining knee prosthesis

A technology of prosthesis and parts, applied in the field of cross-retained knee prosthesis, can solve problems such as delamination, loosening, and inability to support high torsional loads of active patients, and achieve the effect of large stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0113] The following description is merely exemplary in nature of some selected variants and is not intended to limit the invention, its application or uses.

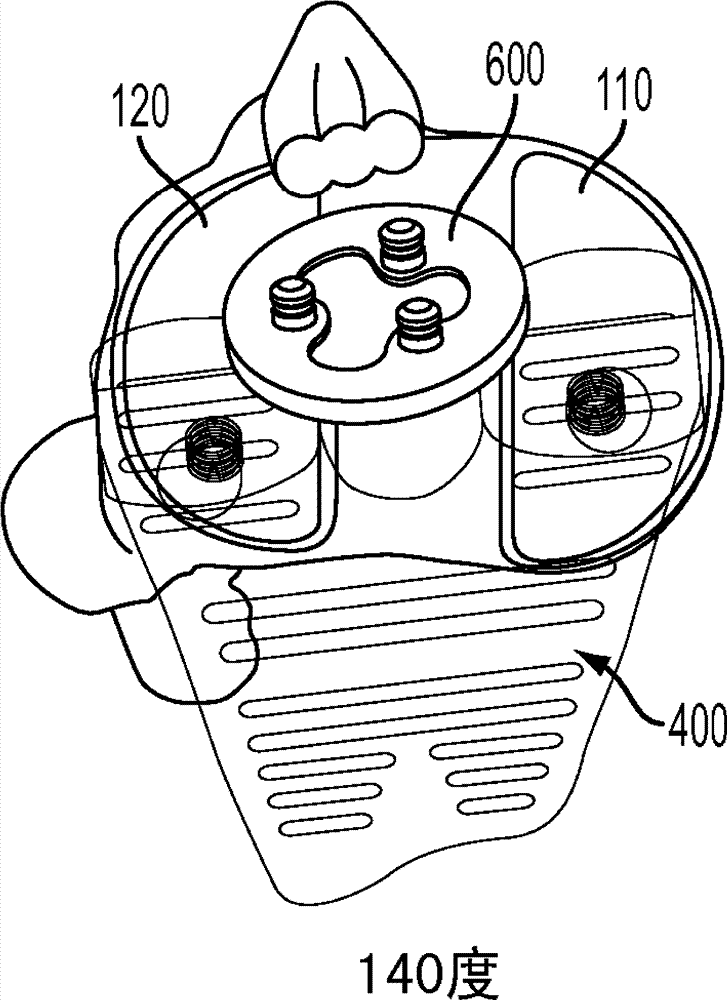

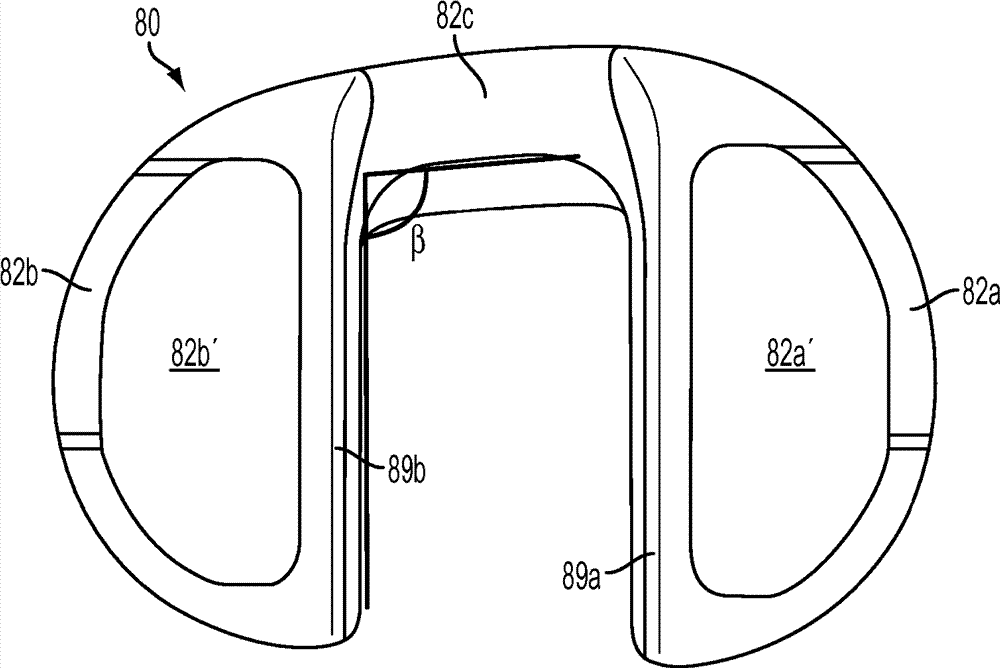

[0114] 1. Tibial base component

[0115] Figure 1-46 and 97-98 illustrate various non-limiting variations of tibial base components, some of their features are discussed below.

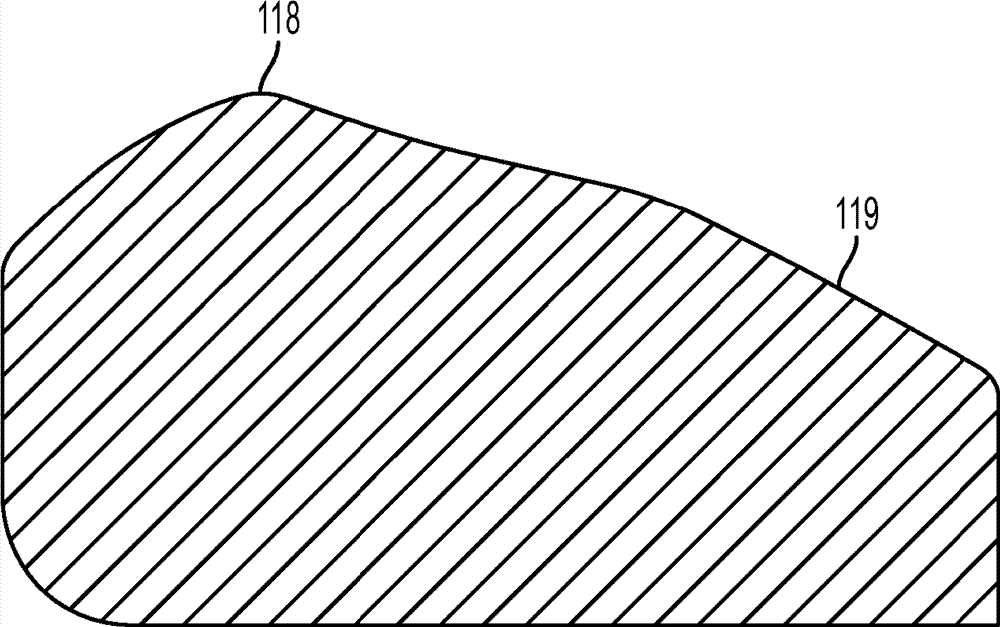

[0116] Figure 1-3 The underside of the tibial base component of the first variation is shown. Generally, the base member 10 includes an inner portion 12a, an outer portion 12b, and a connecting portion 12c. In this particular variant, the base member 10 has an asymmetrical shape in some respects. For example, if image 3 As shown in , the medial portion 12a is larger than the lateral portion 12b and aspects of the medial portion 12a extend further forward relative to the lateral portion 12b. In other variations, the base member may exhibit other asymmetry or may be symmetric.

[0117] Figure 1-3 The base member 10 includes lips 15a and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com