Cut-off machine for plastic row pins

A cutting machine and needle insertion technology, which is applied in the direction of shearing devices, shearing machine accessories, shearing machine equipment, etc., can solve the problems of high processing cost, polluting the environment, and inability to cut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

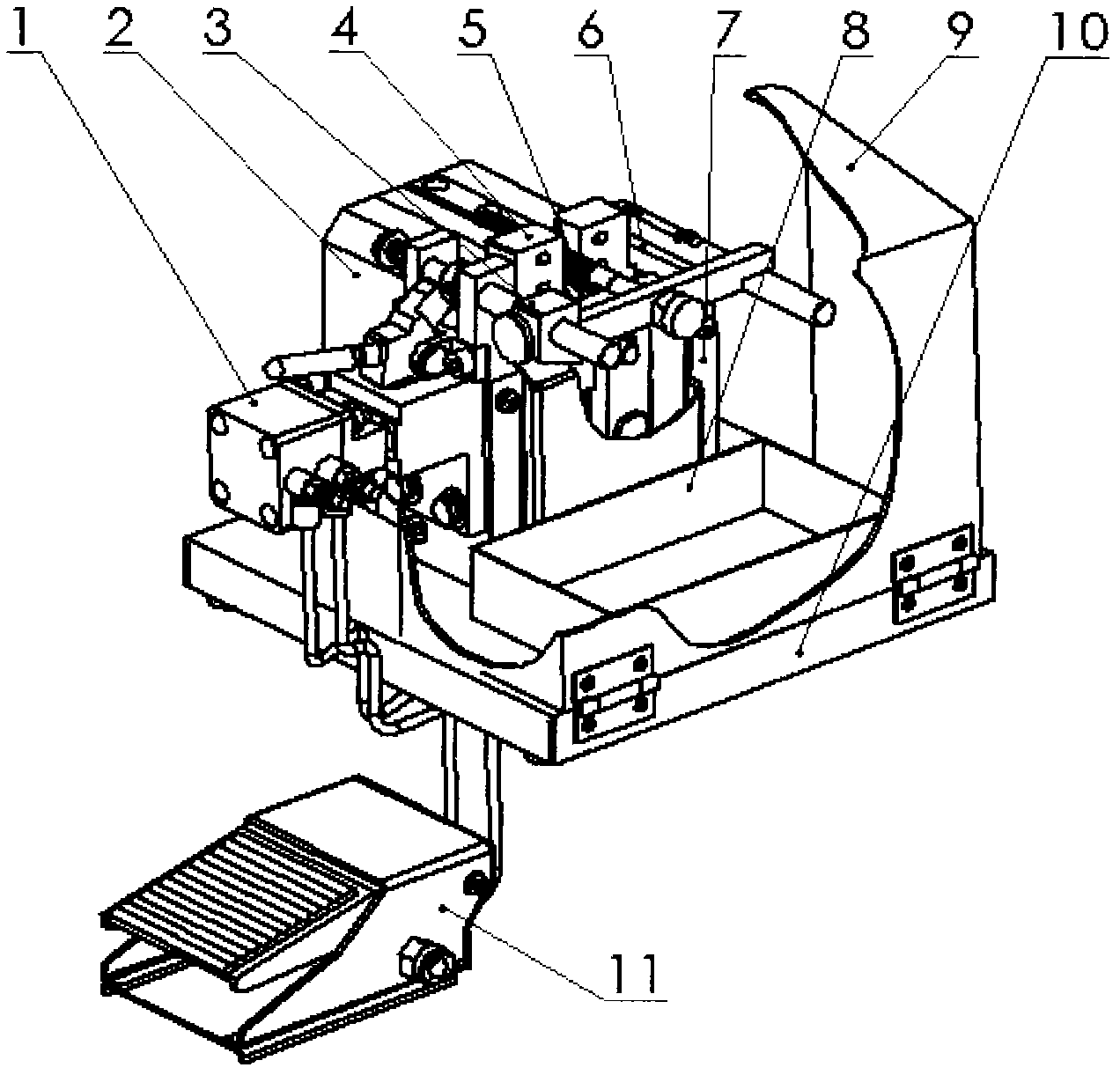

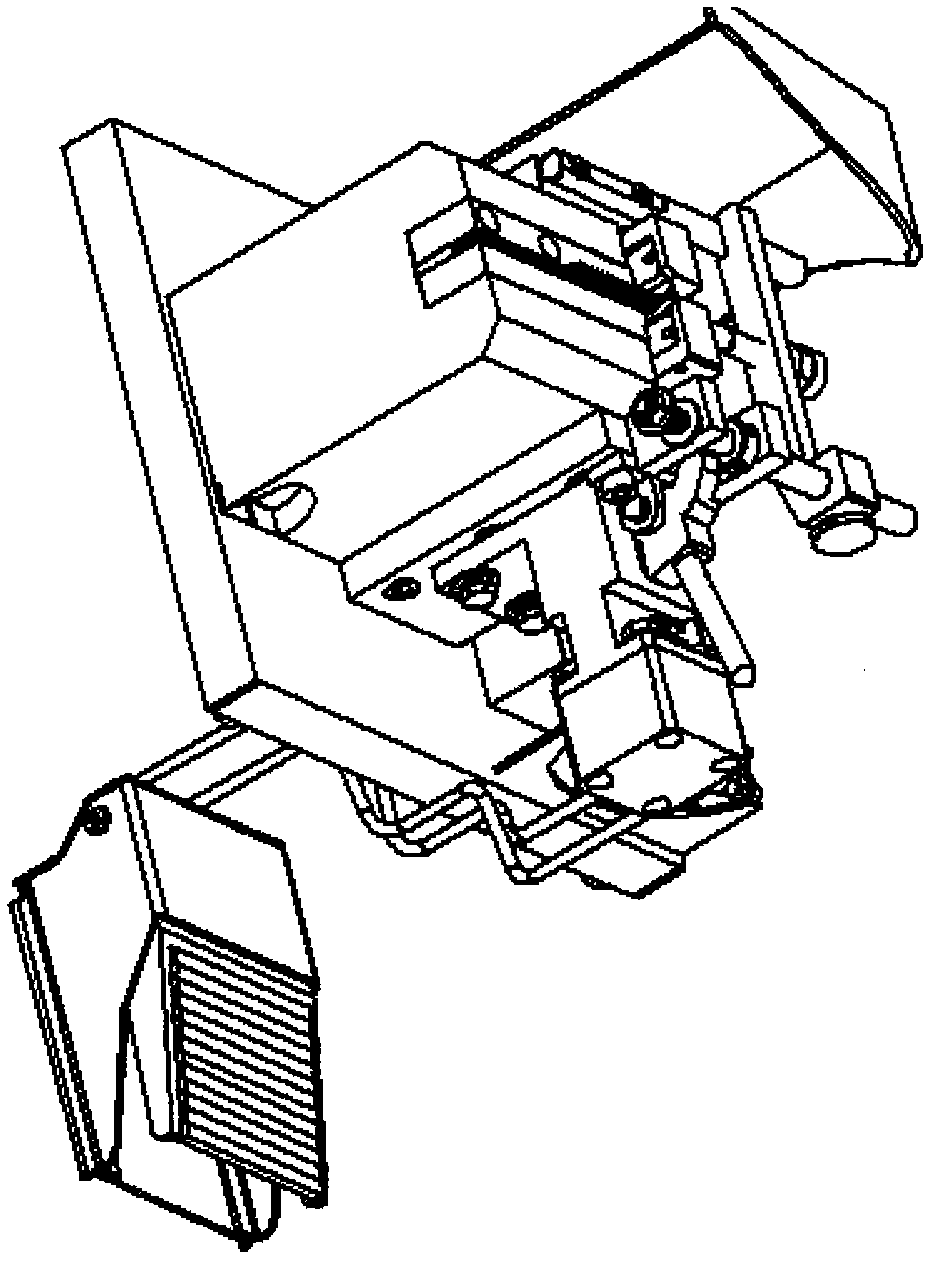

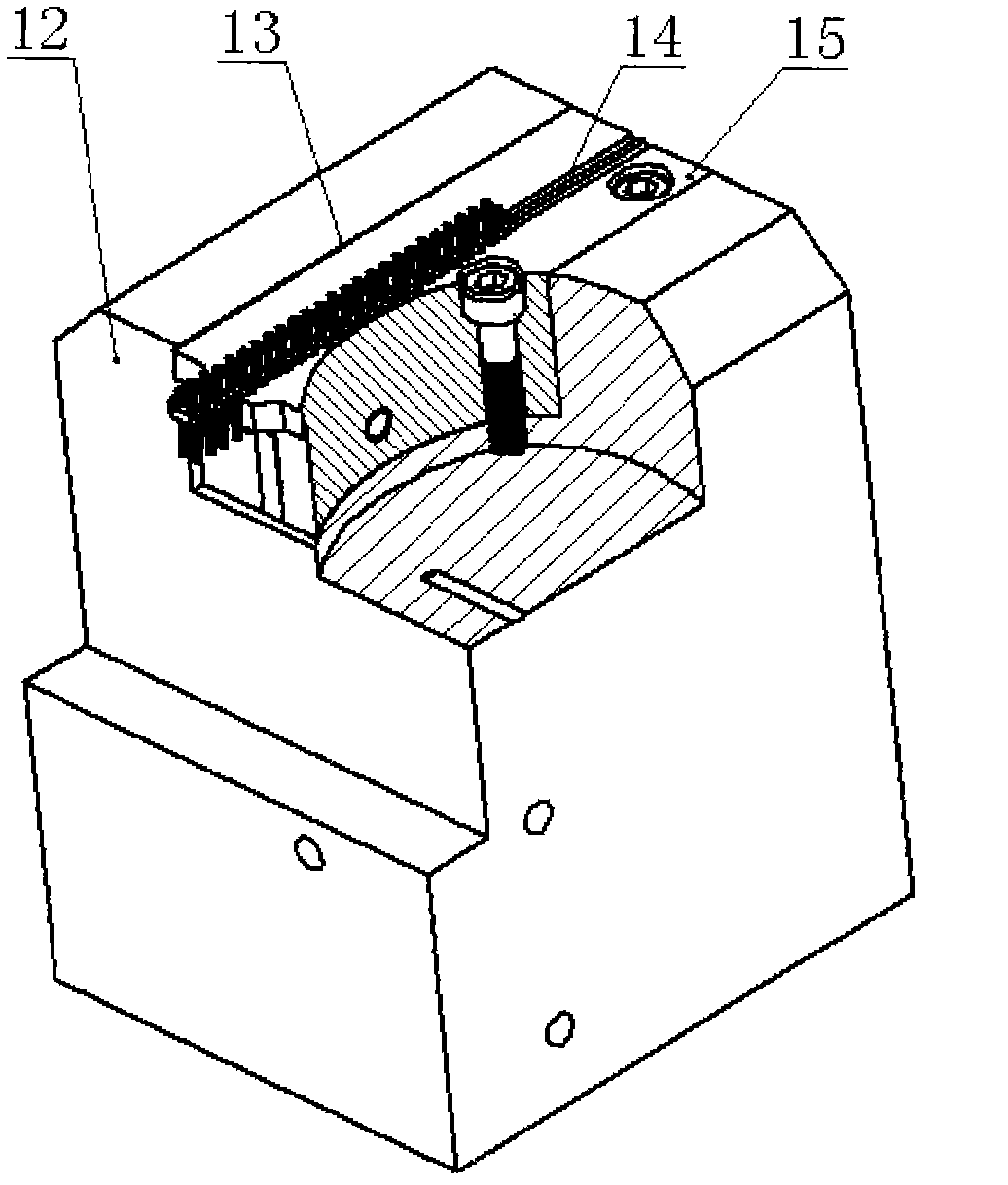

[0011] exist figure 1 , image 3 , Figure 4 , Figure 5 The middle equipment consists of a driving device (1), a pin support (2), a positioning device (3), a sliding device (4), a plastic row of pins (5), a right side plate (6), a cover plate (7), Composition such as dial (8), machine cover (9), base plate (10), pneumatic foot switch (11). Wherein the support (12), the right block (13), the pin support (14), and the left block (15) are connected by screws to assemble the pin support (2); the cylinder (16), the cylinder backing plate (17) , pressing rod (18), pressing shaft 2 (19), turning block (20), turning block support (24) pressing shaft 1 (30) form driving device (1); Stage clip (21), limit sleeve (23), Positioning shaft (25), knurled screw (26), positioning block (27), lock nut (28), positioning piece (29) etc. form positioning device (3); left slide block (31), left blade (32 ), slide shaft (33), slider compression spring (34), right blade (35), right slider (36) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com