Patents

Literature

39results about How to "Implement positioning operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

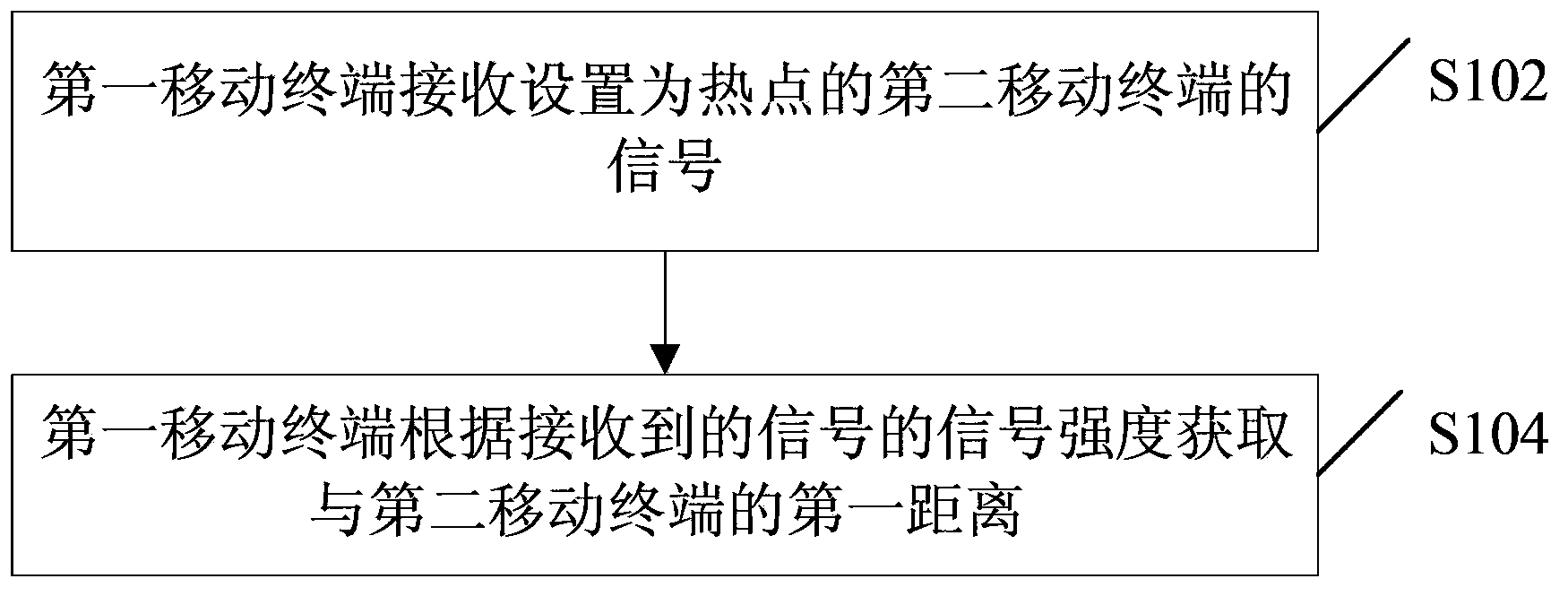

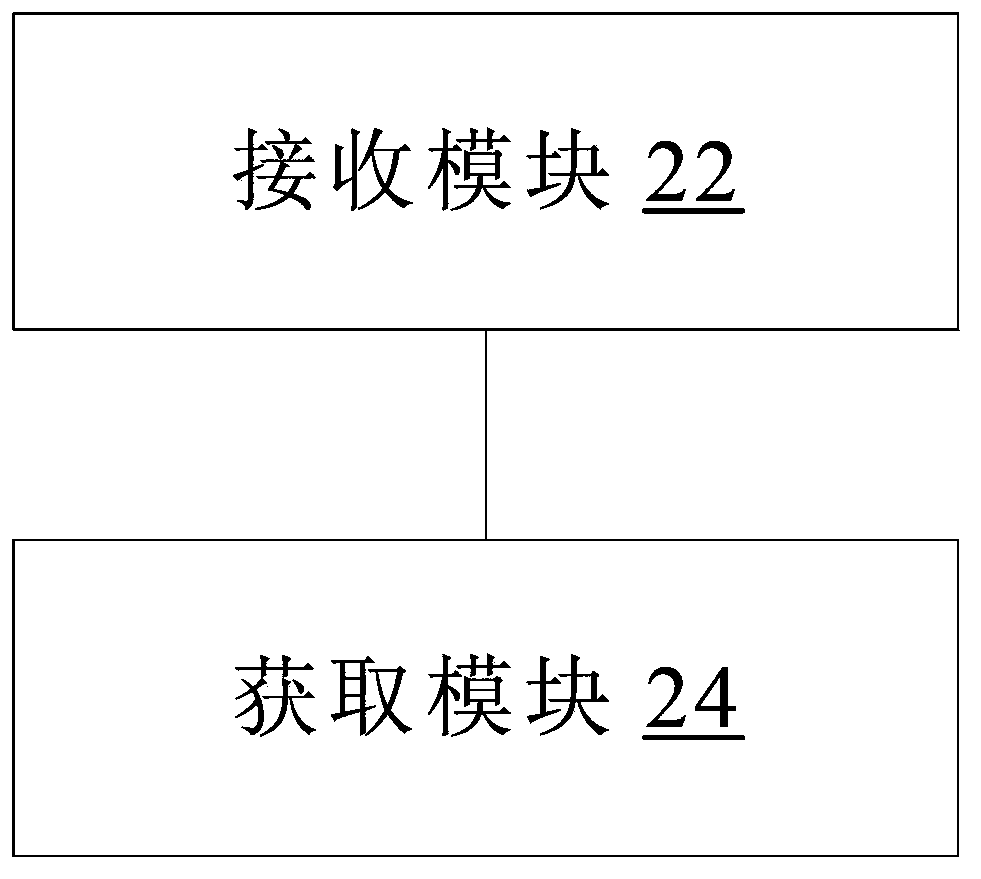

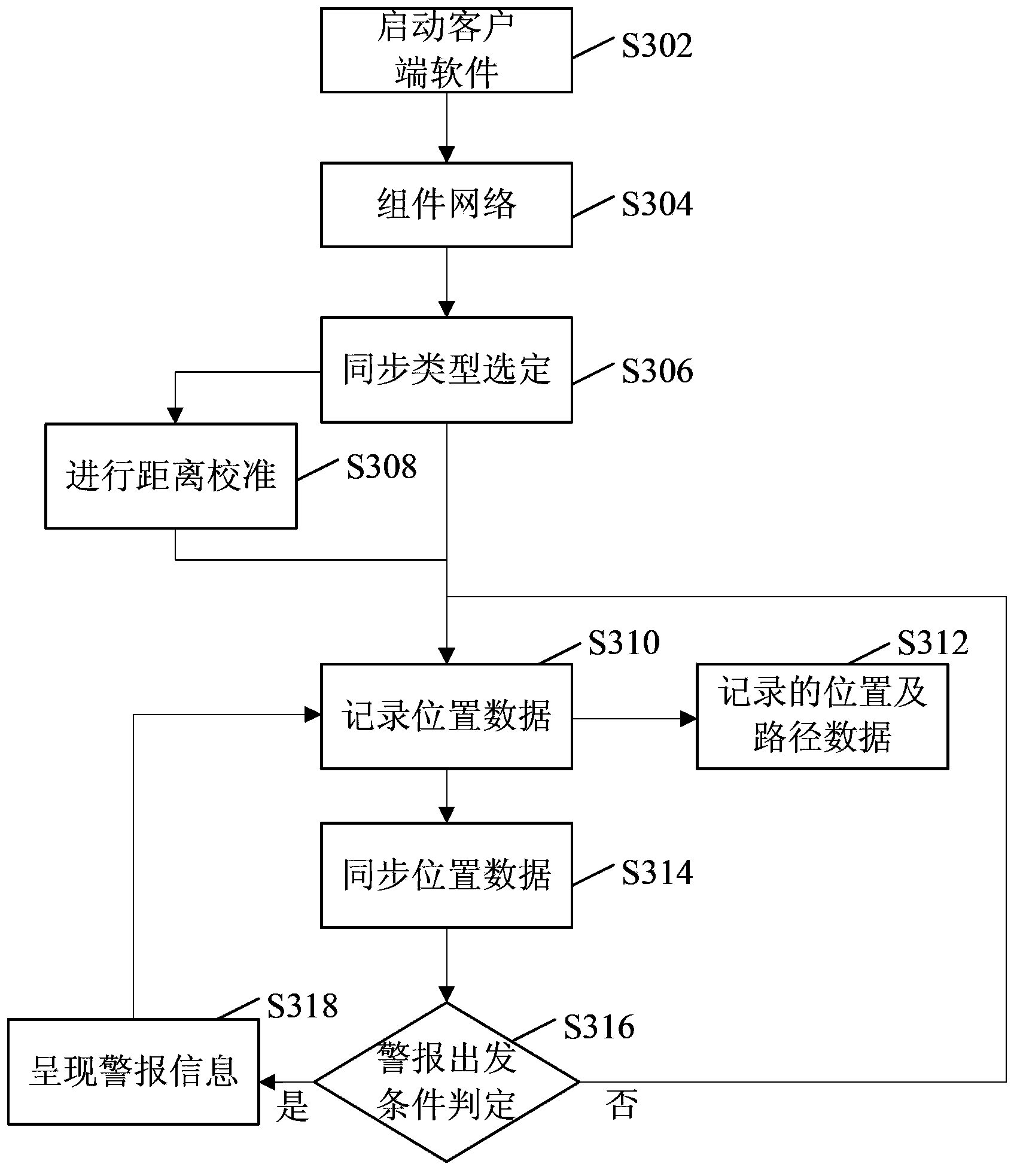

Ranging method and ranging device

InactiveCN103581821AImprove user experienceThe solution function is not perfectLocation information based serviceTelecommunicationsSignal intensity

The invention discloses a ranging method and a ranging device. The ranging method comprises the following steps: a first mobile terminal receives a signal, set as a hot point, of a second mobile terminal; and the first mobile terminal acquires a first distance between the first mobile terminal and the second mobile terminal according to the signal strength of the received signal. With the ranging method and the ranging device, the problem that mobile terminals are not fully functional in the related technology is solved, locating operation under the situation in which an external network cannot be received is realized, and the user experience is improved.

Owner:ZTE CORP

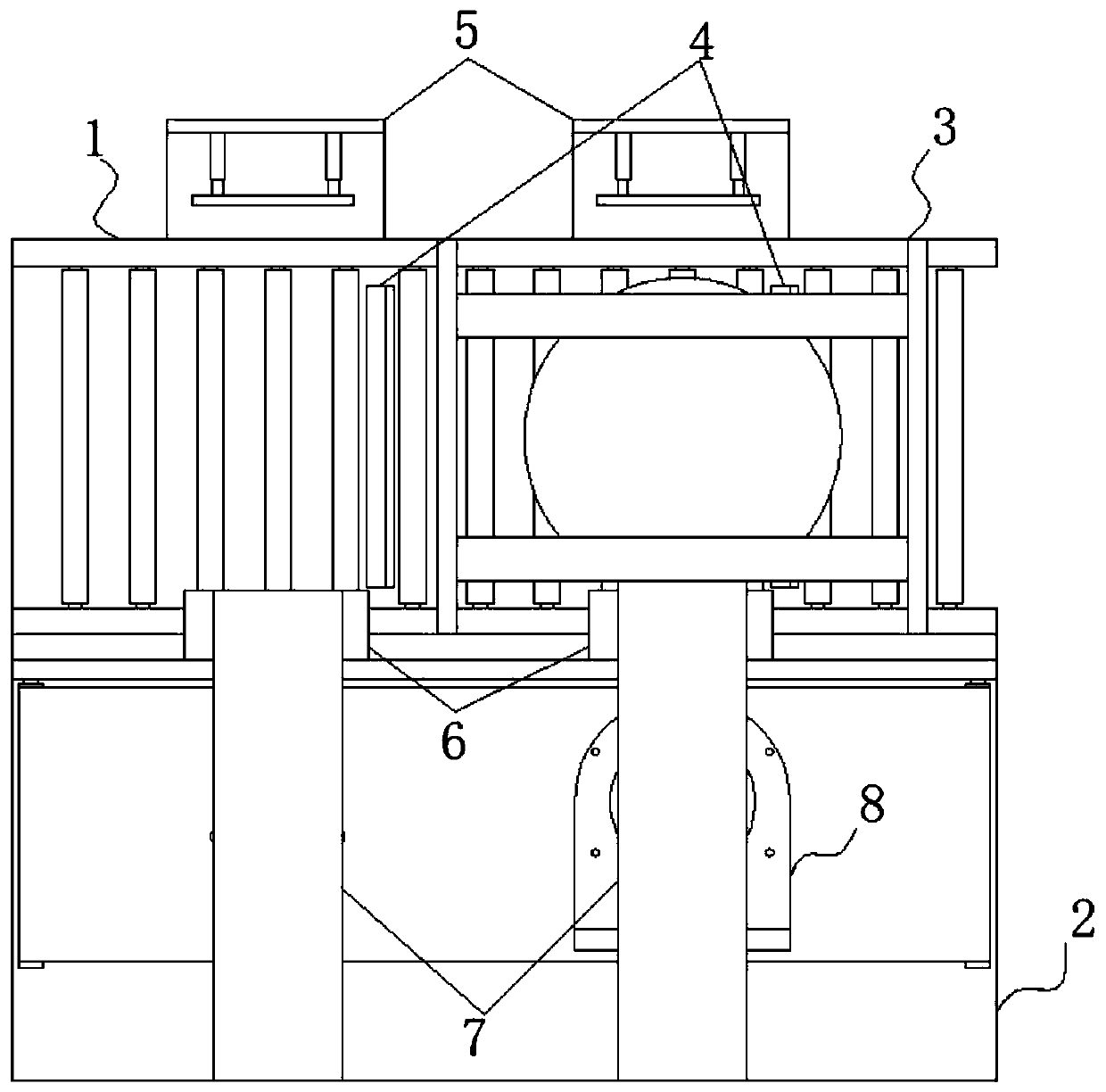

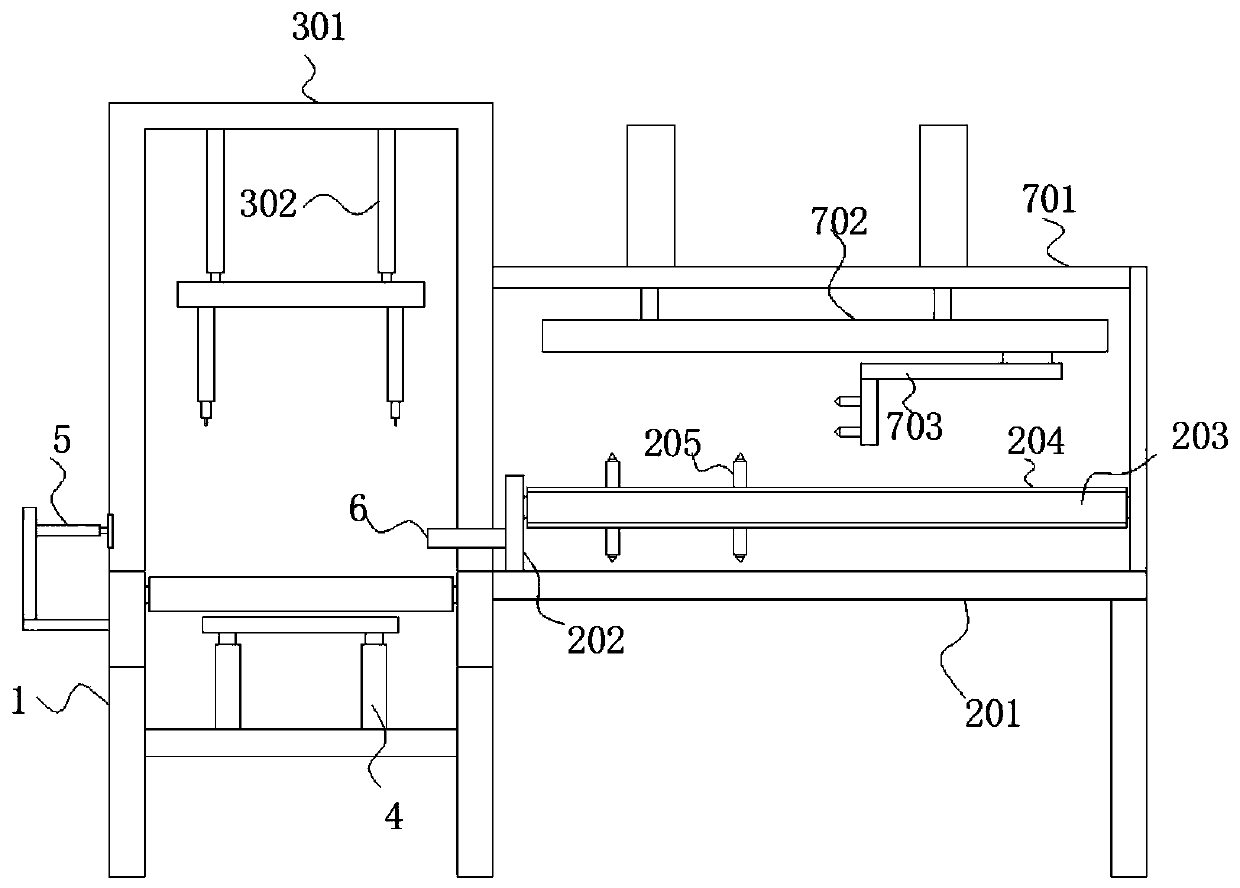

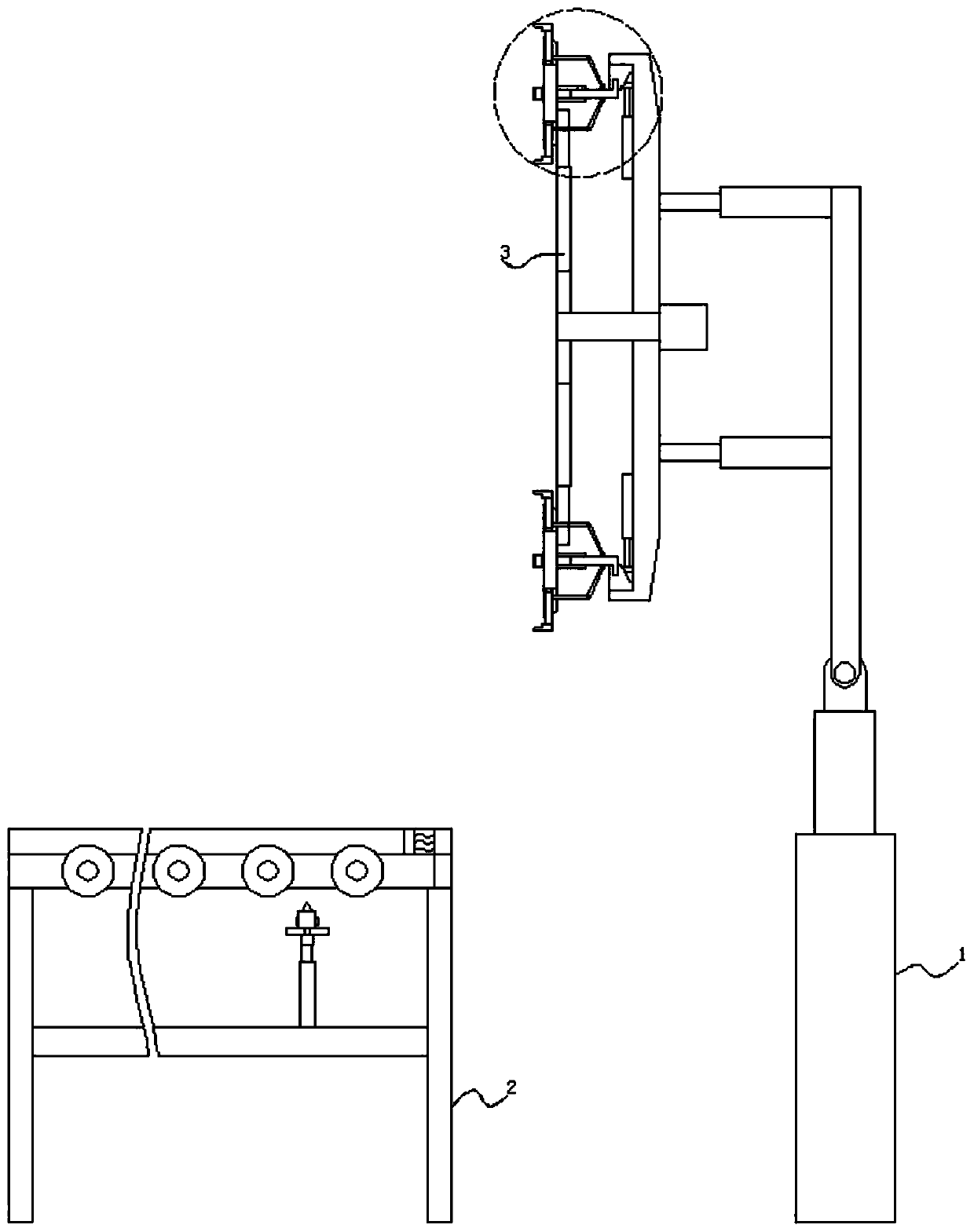

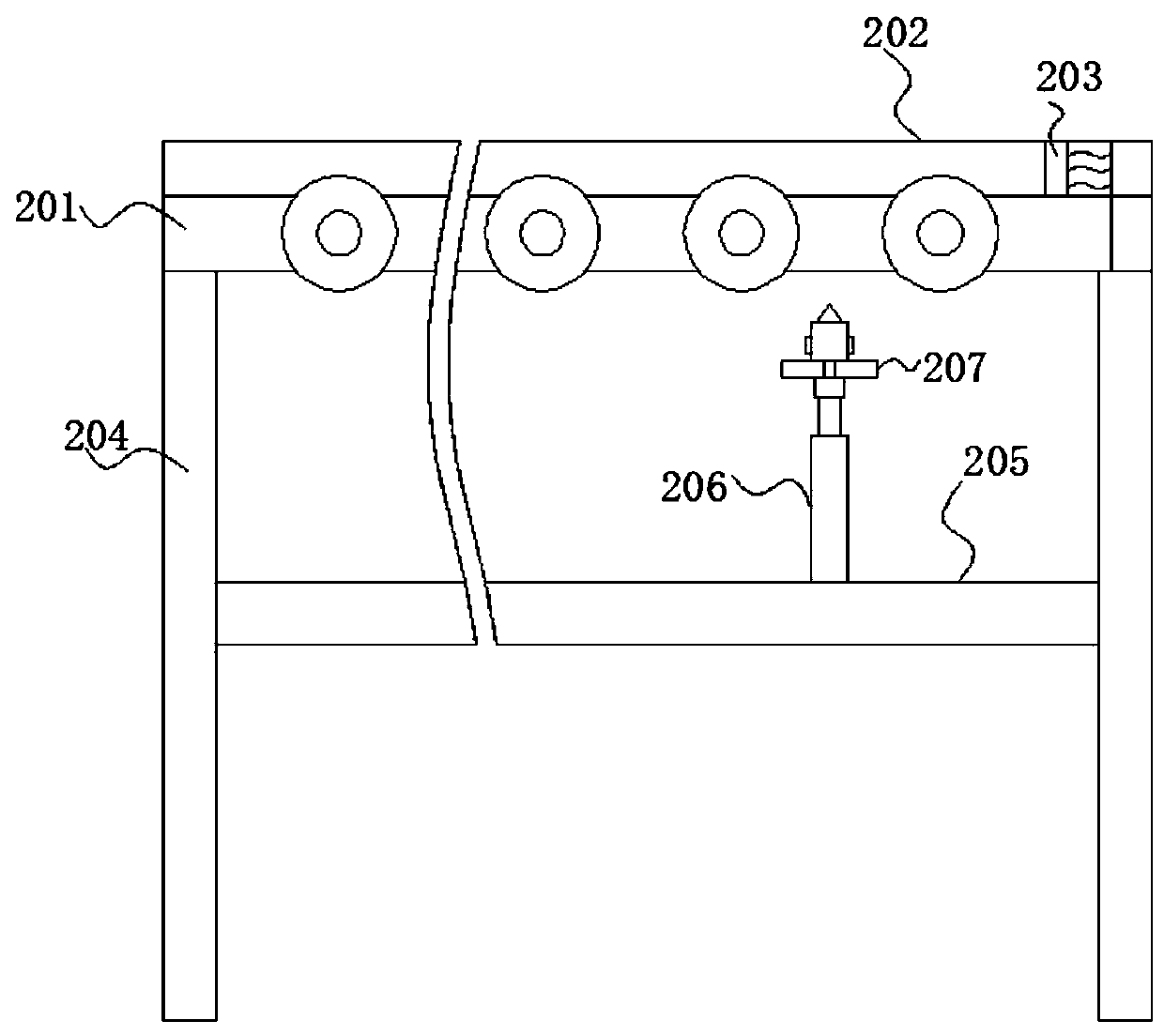

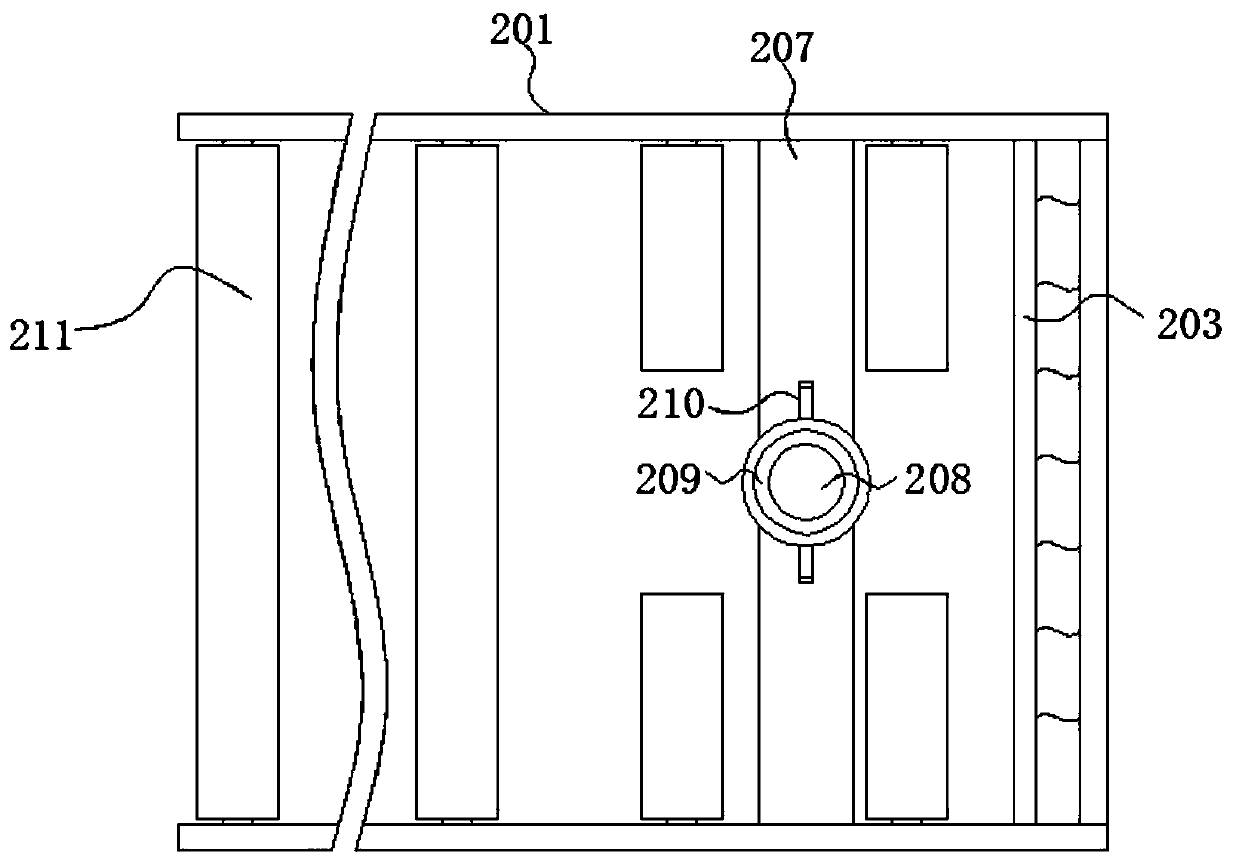

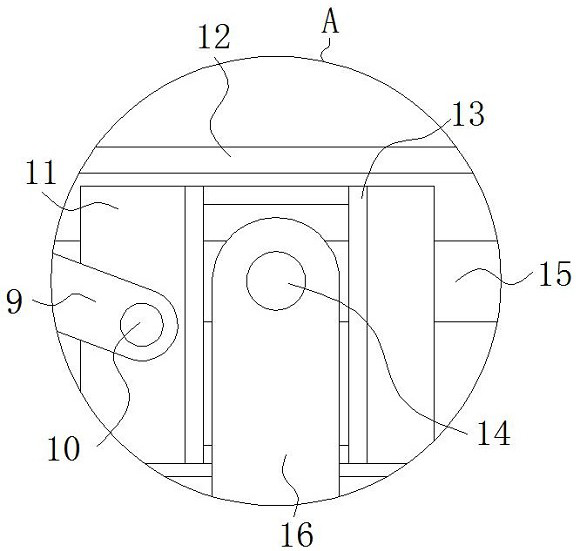

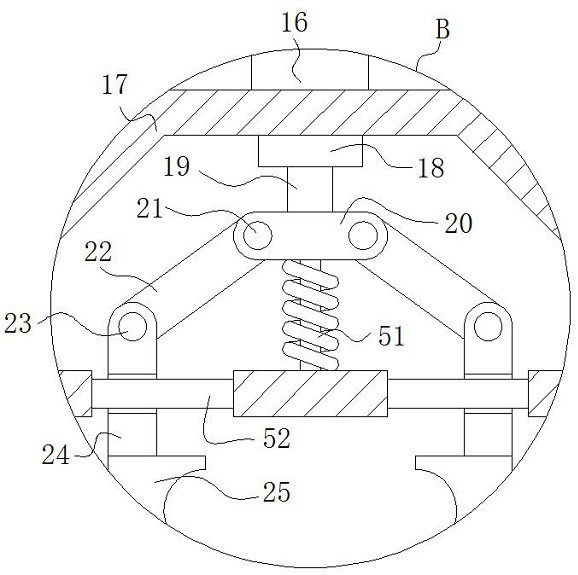

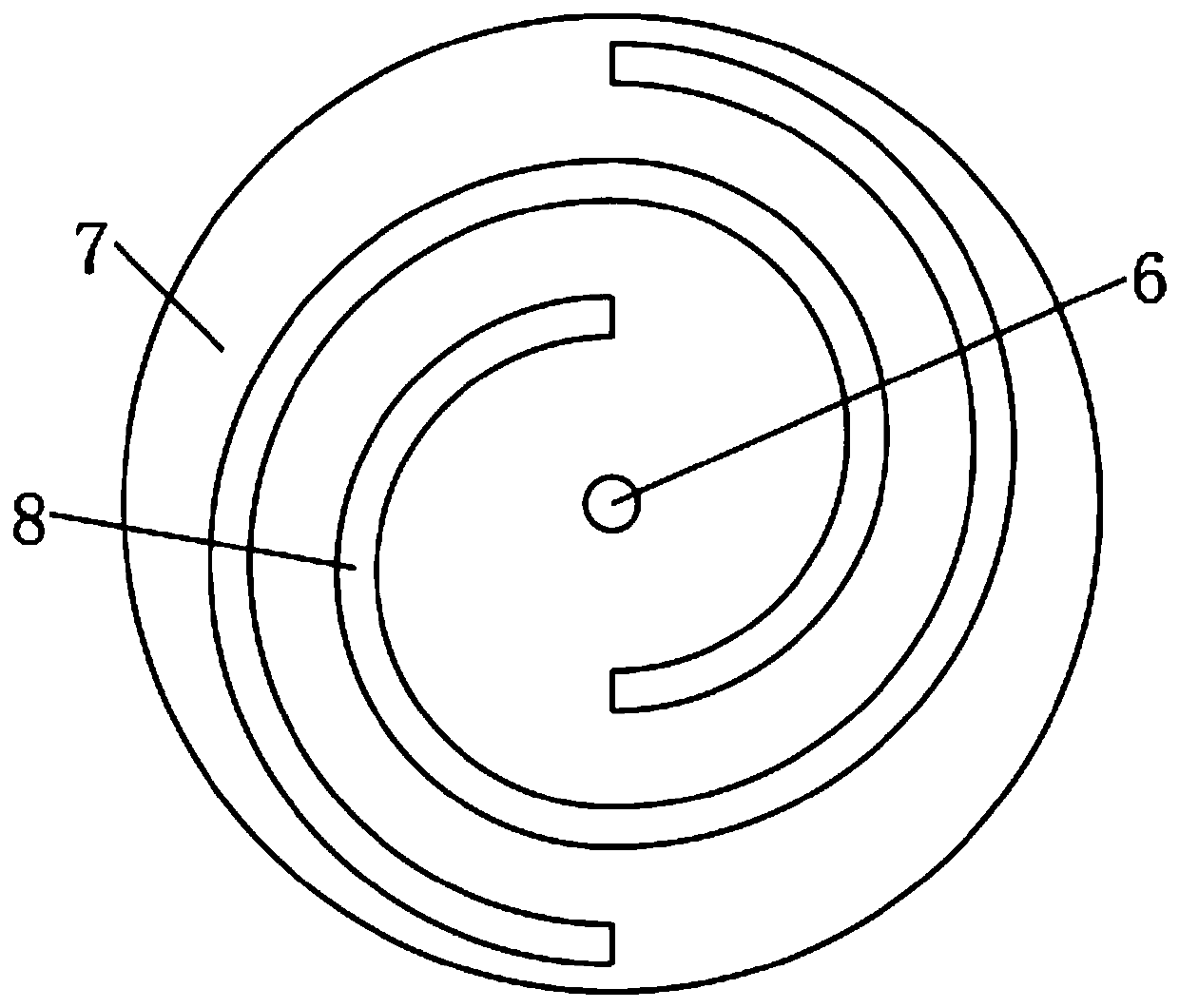

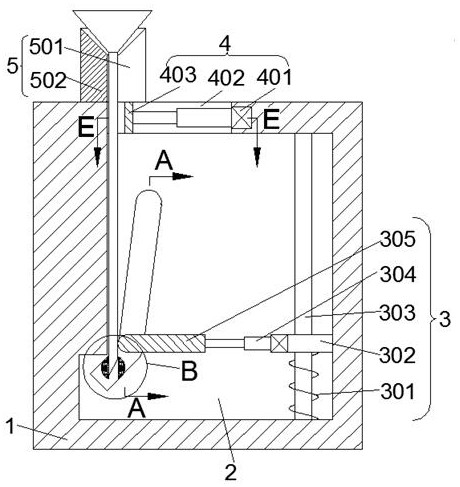

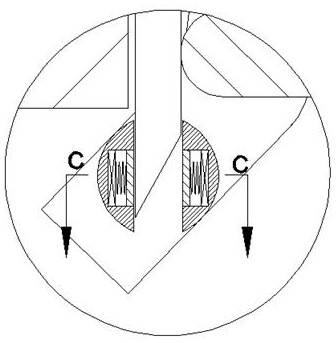

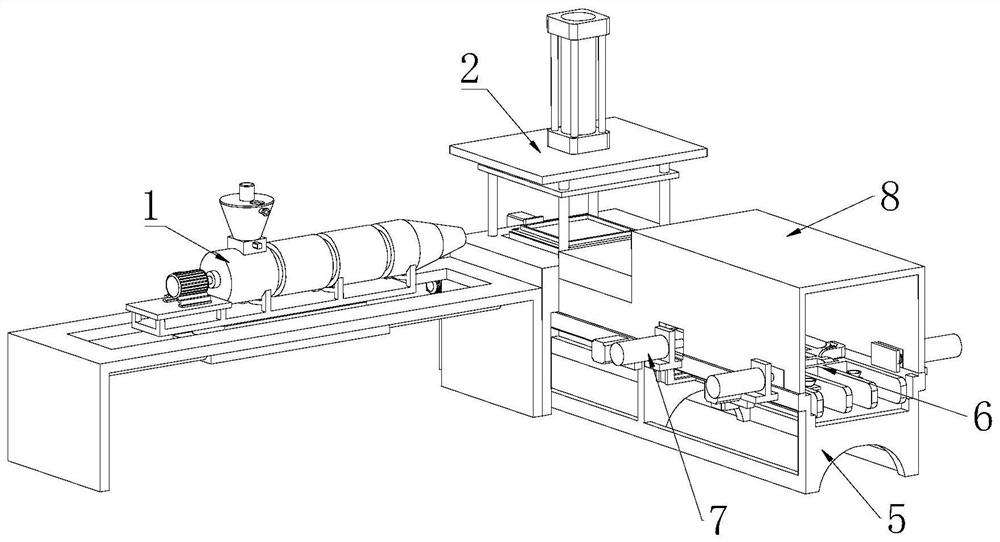

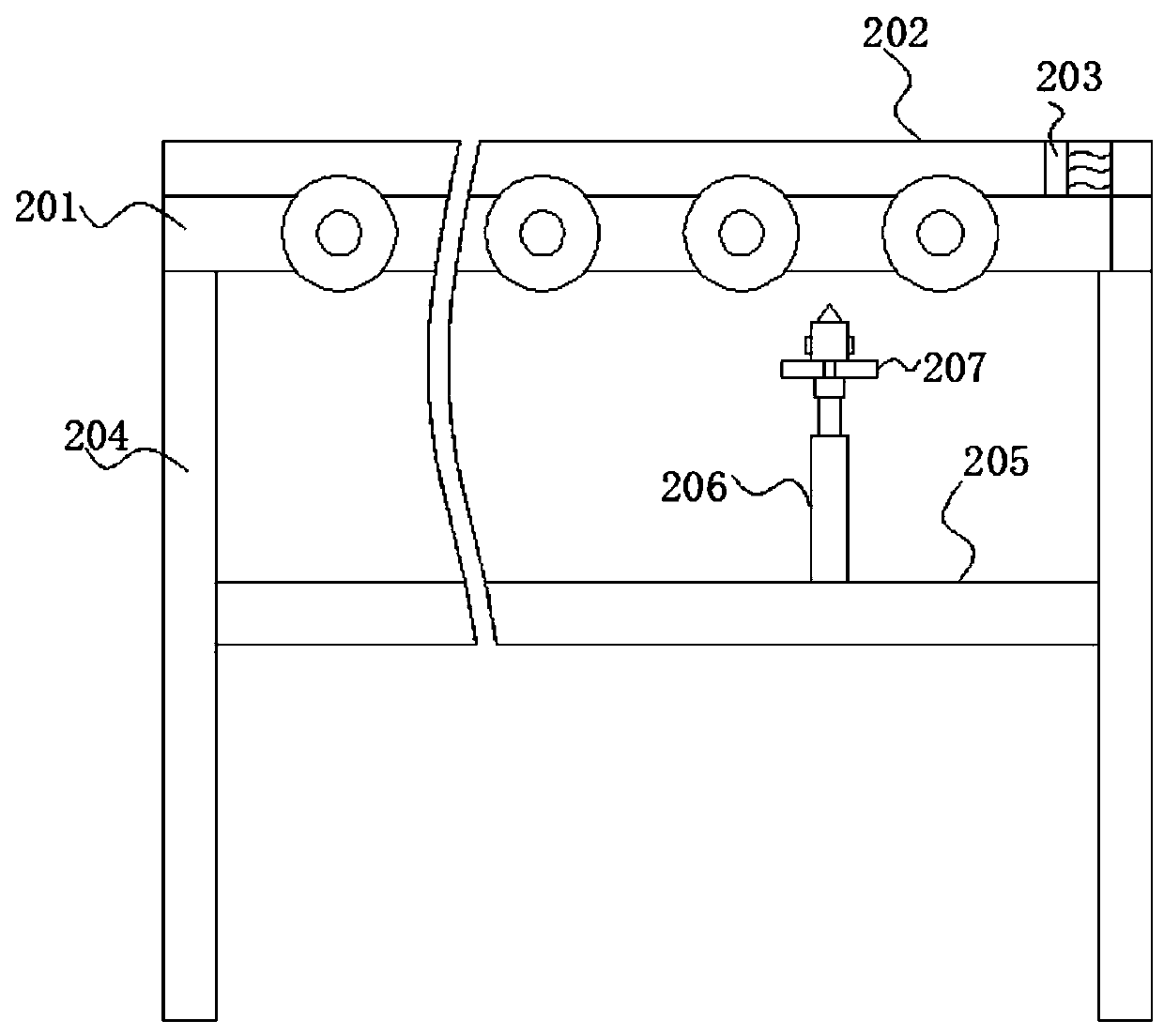

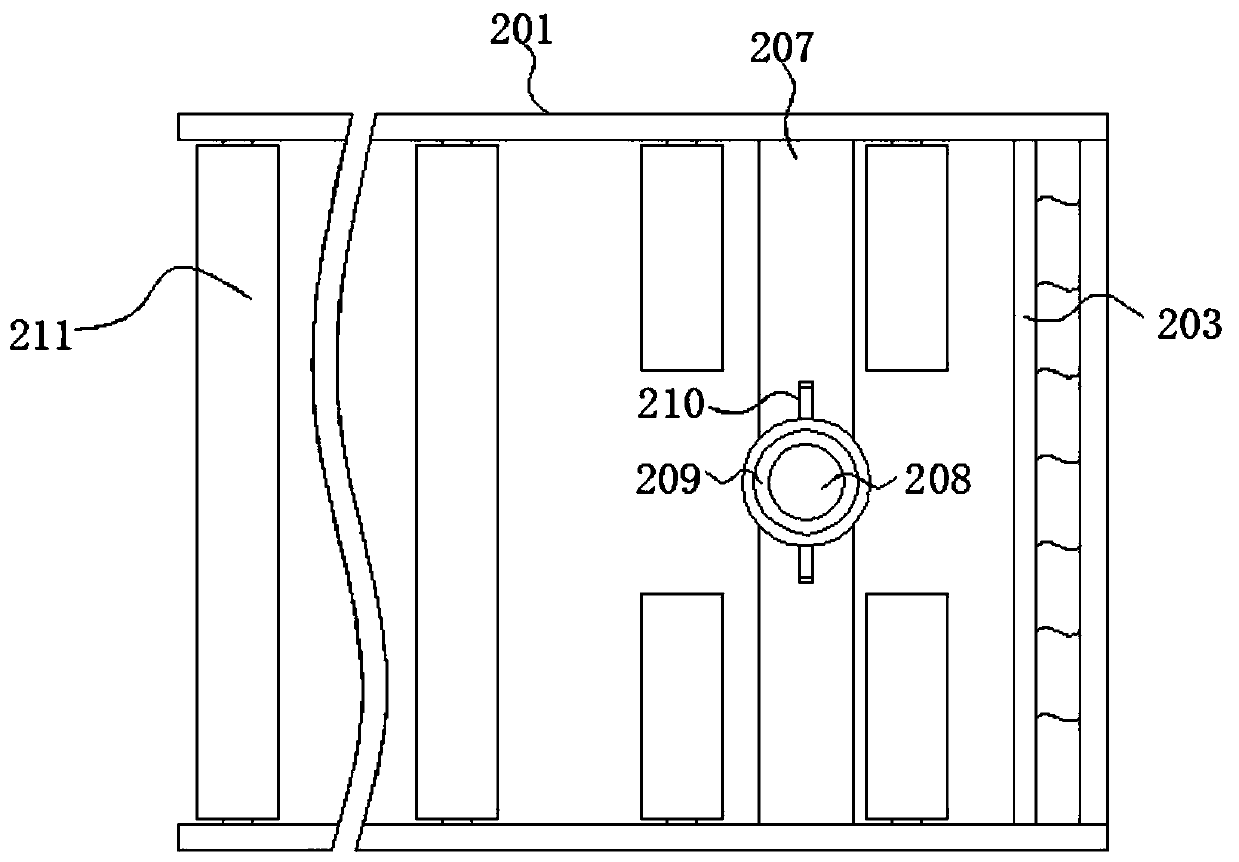

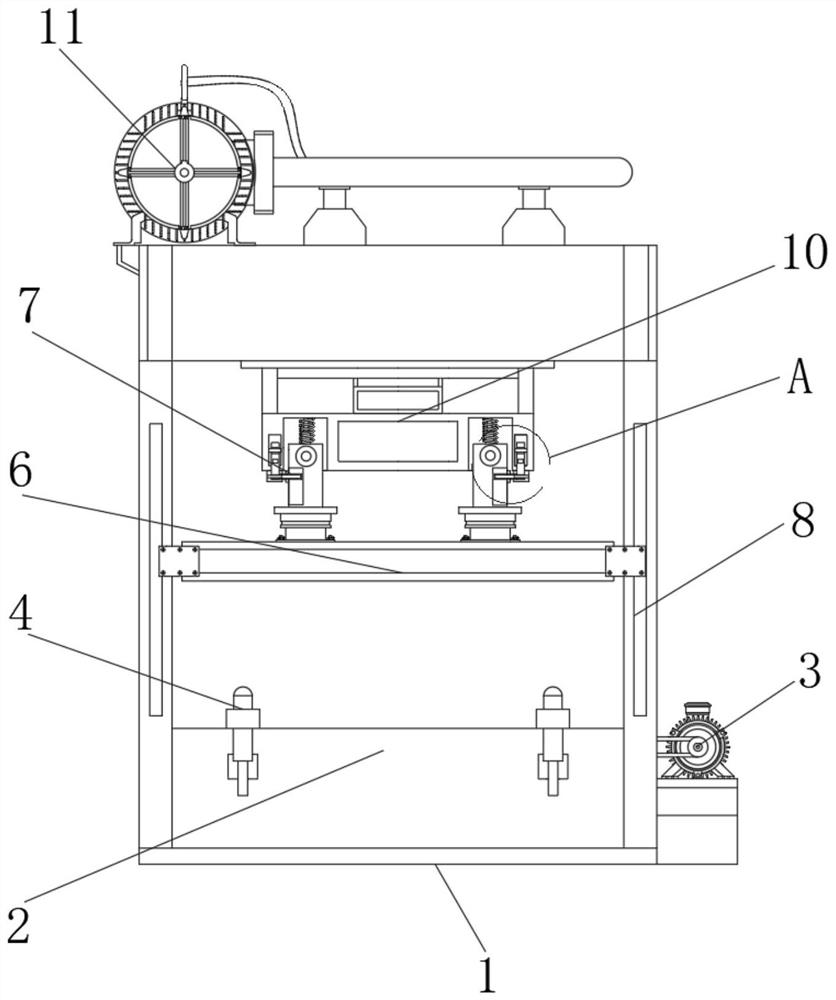

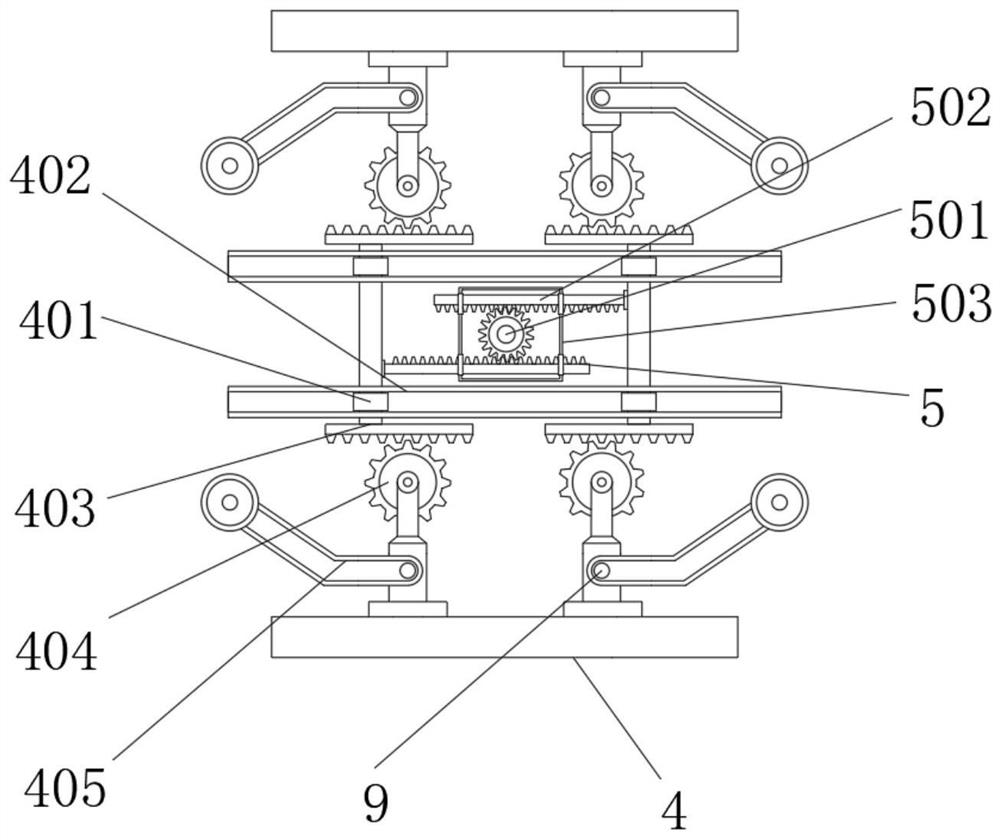

Auxiliary equipment for hole forming of motor shell

ActiveCN110496984ASimplify the difficulty of replacementImprove switching efficiencyMetal working apparatusBoring/drilling componentsEngineeringMechanical engineering

The invention belongs to the technical field of motor production, and particularly relates to auxiliary equipment for hole forming of a motor shell. According to the technical scheme, the auxiliary equipment comprises a drilling assembly used for hole forming of the motor shell. A conveying assembly is fixedly connected to the bottom of the drilling assembly. Blocking assemblies located inside theconveying assembly are mounted below the input end and the output end of the drilling assembly. A material returning assembly arranged in the length direction of the conveying assembly is mounted onone side of the conveying assembly. Pushing assemblies fixedly connected with the conveying assembly are mounted on one sides, far away from the material returning assembly, of the two blocking assemblies and are located on one side, far away from the material returning assembly, of the conveying assembly. By means of the auxiliary equipment, drilling of end portion mounting holes of different motors is realized, adjustment is carried out according to the model of the motor shell and the positions of the mounting holes, convenience in adjustment is brought to an operator, the motor machining efficiency is improved, the consistency of the drilling of the mounting holes of the motor shell is improved, and the motor production efficiency is improved.

Owner:中擎电机有限公司

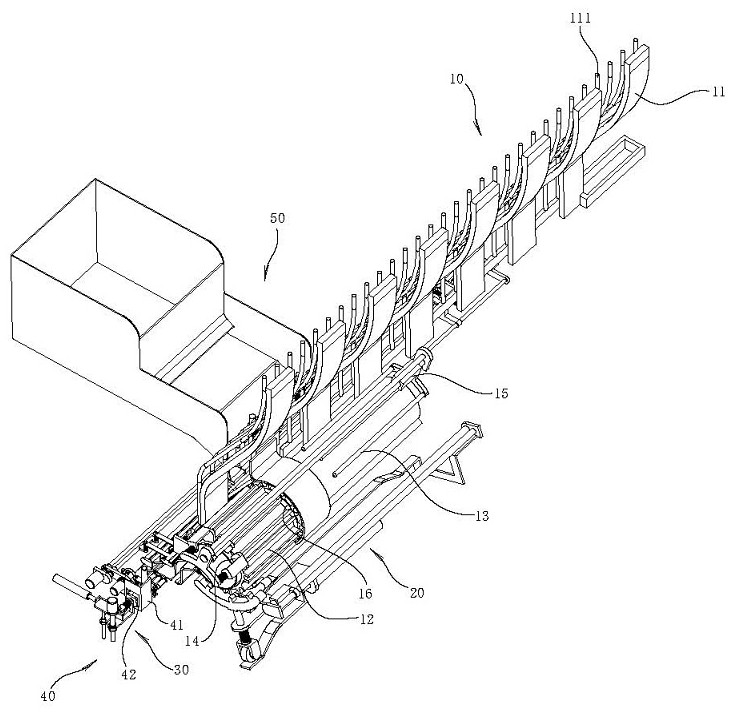

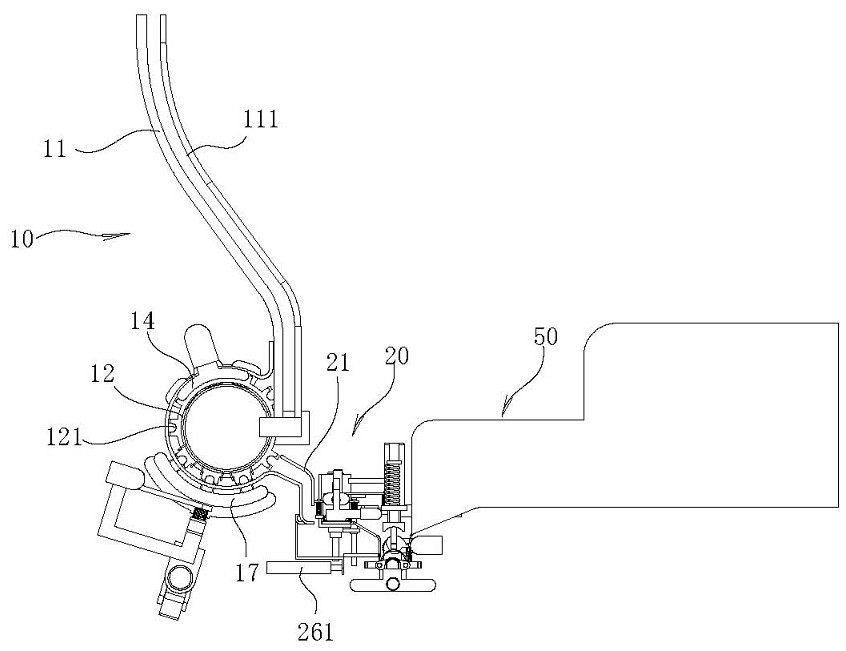

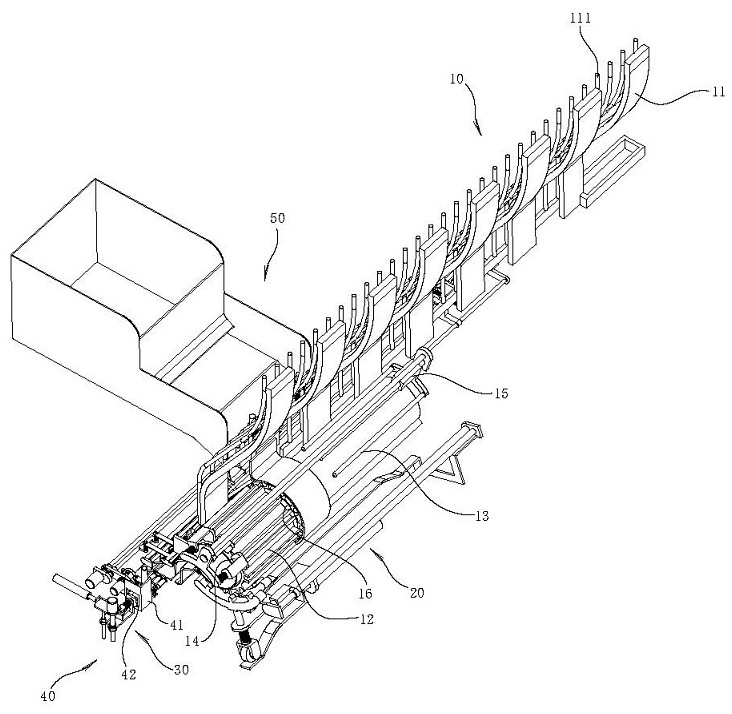

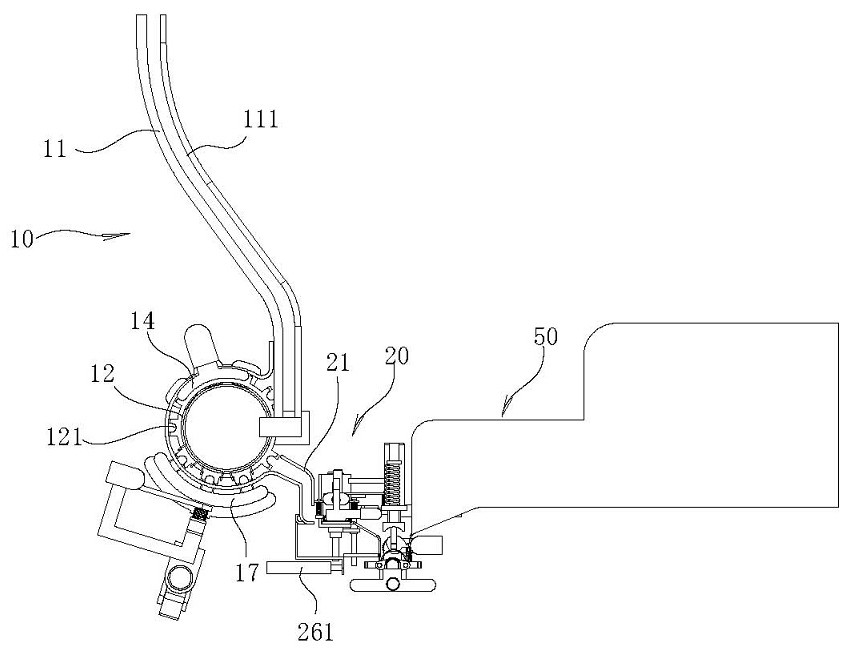

Electric appliance wire and production method thereof

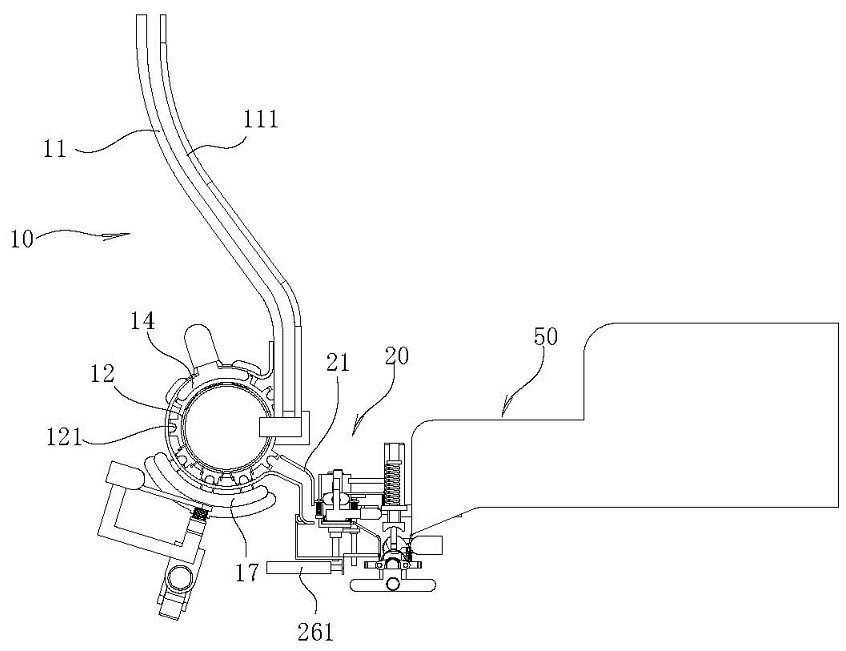

ActiveCN111884013ARealize plug-in production operationsGuarantee product qualityContact member assembly/disassemblyProduction qualityCable harness

The invention relates to an electric appliance wire and a production method thereof, so that a single wire harness is arranged in an alignment groove in an alignment roller of a wire harness leading-out device, and alignment operation on a plurality of wire harnesses is implemented by utilizing a wire harness wiring needle alignment mechanism; the single wire harness in the alignment groove of thealignment roller is made to move, and the wire harness wiring needle is inserted into a positioning hole of a plug on a plug positioning device; the plug on the plug positioning device is pushed outinto a protective sleeve penetrating device; the protective sleeve threading mechanism is started to enable a protective sleeve to be threaded on the multiple sets of tightened wire harnesses in a sleeving mode, then threading operation of the protective sleeve is completed, and the production efficiency of the wire harnesses can be effectively improved while the production quality of the wire harnesses is ensured.

Owner:YJH ELECTRICAL EQUIP

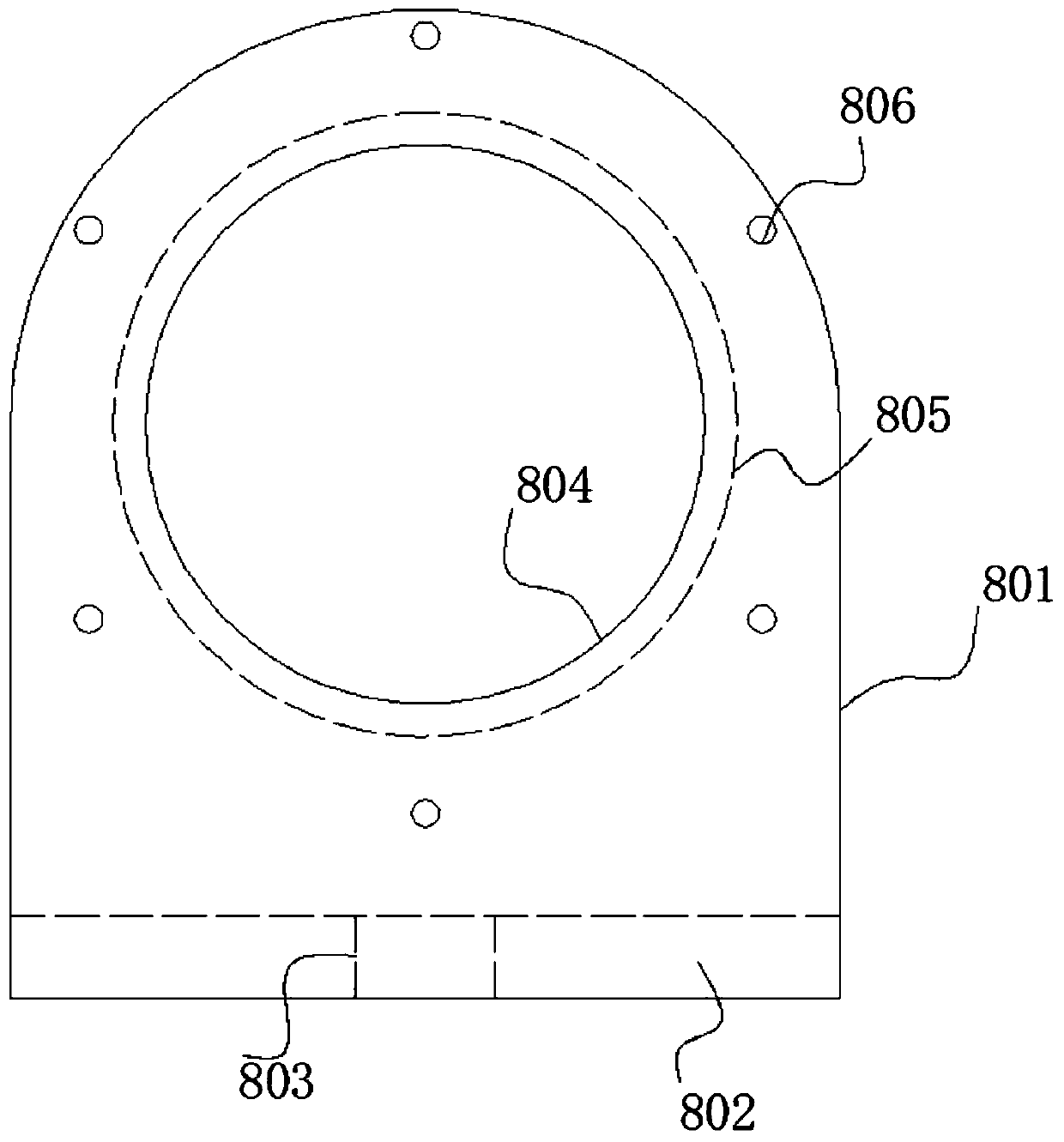

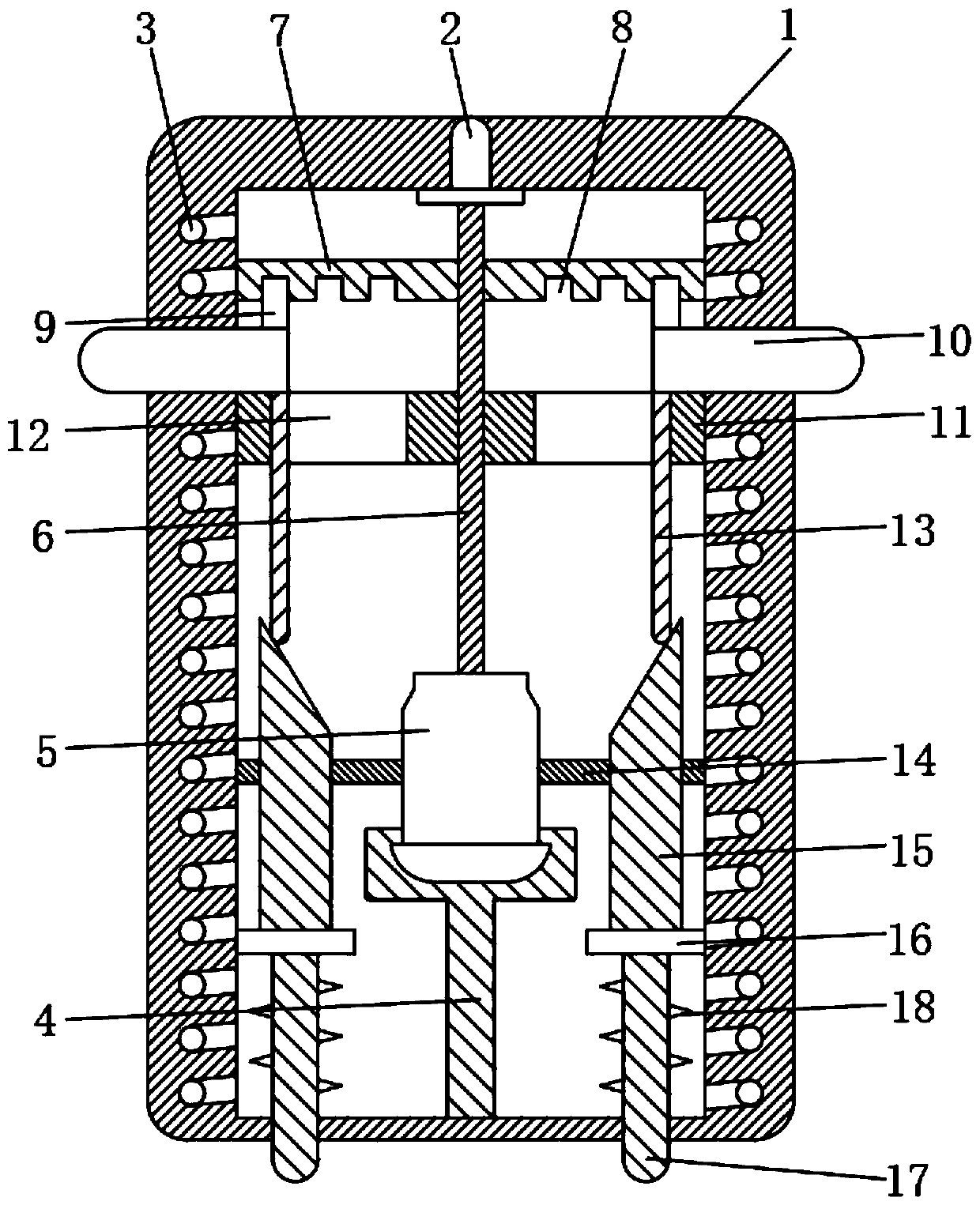

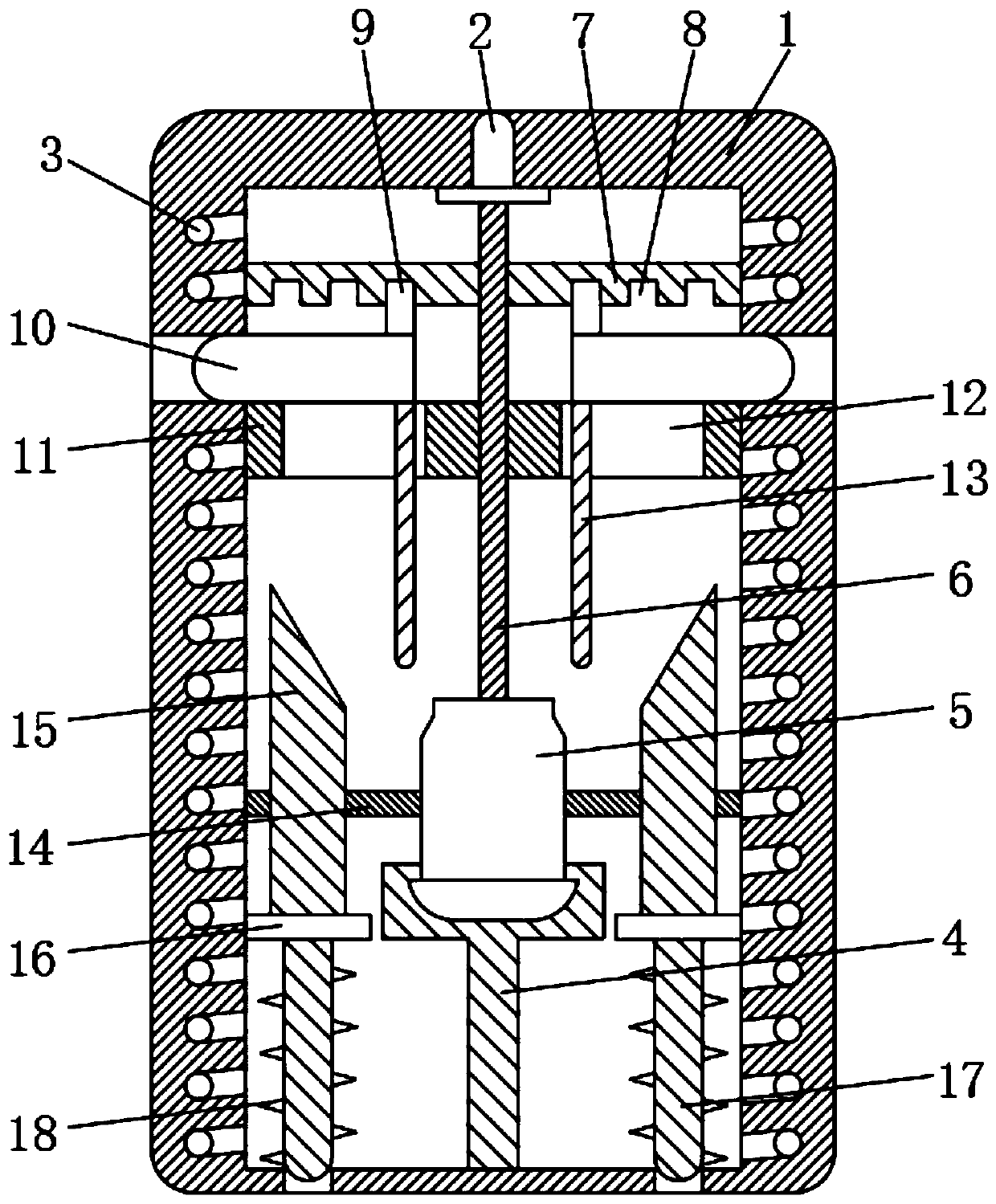

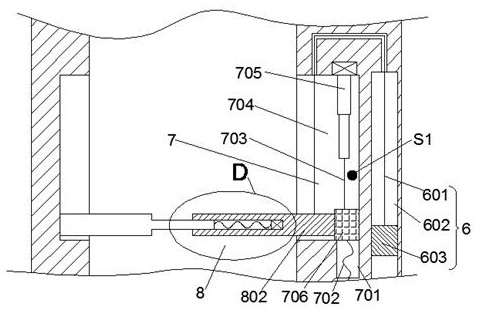

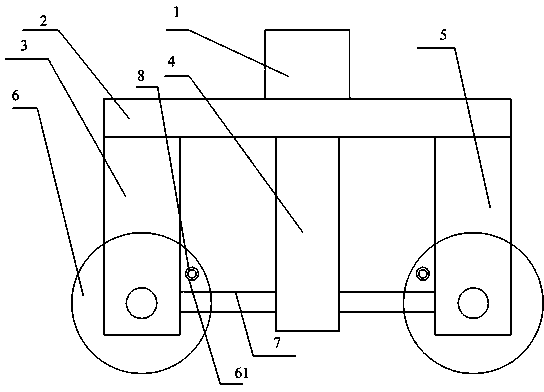

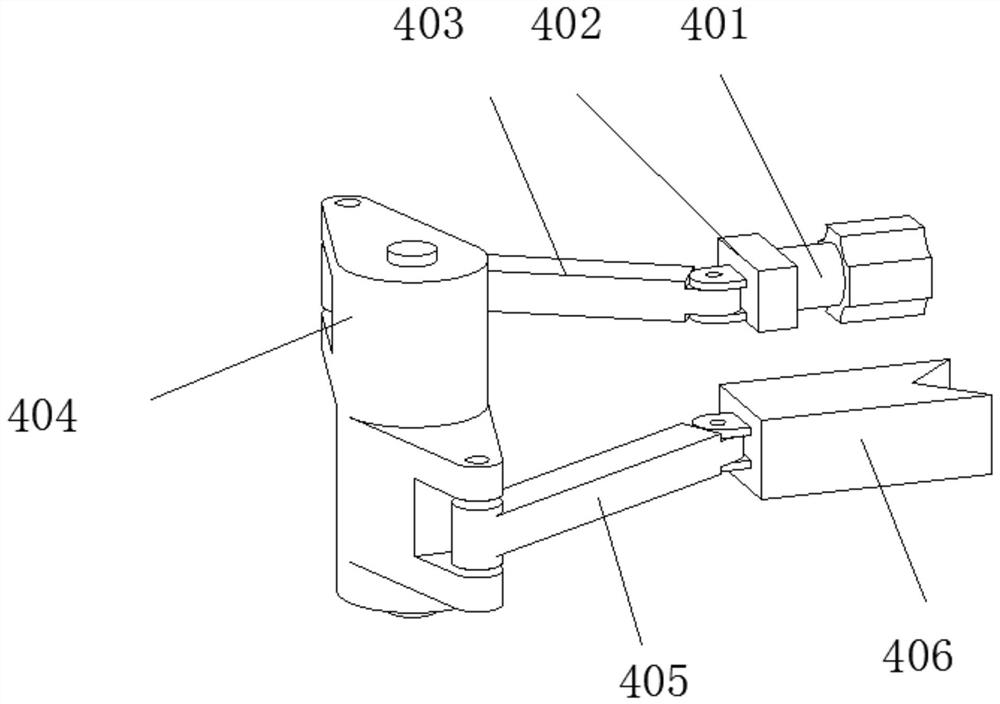

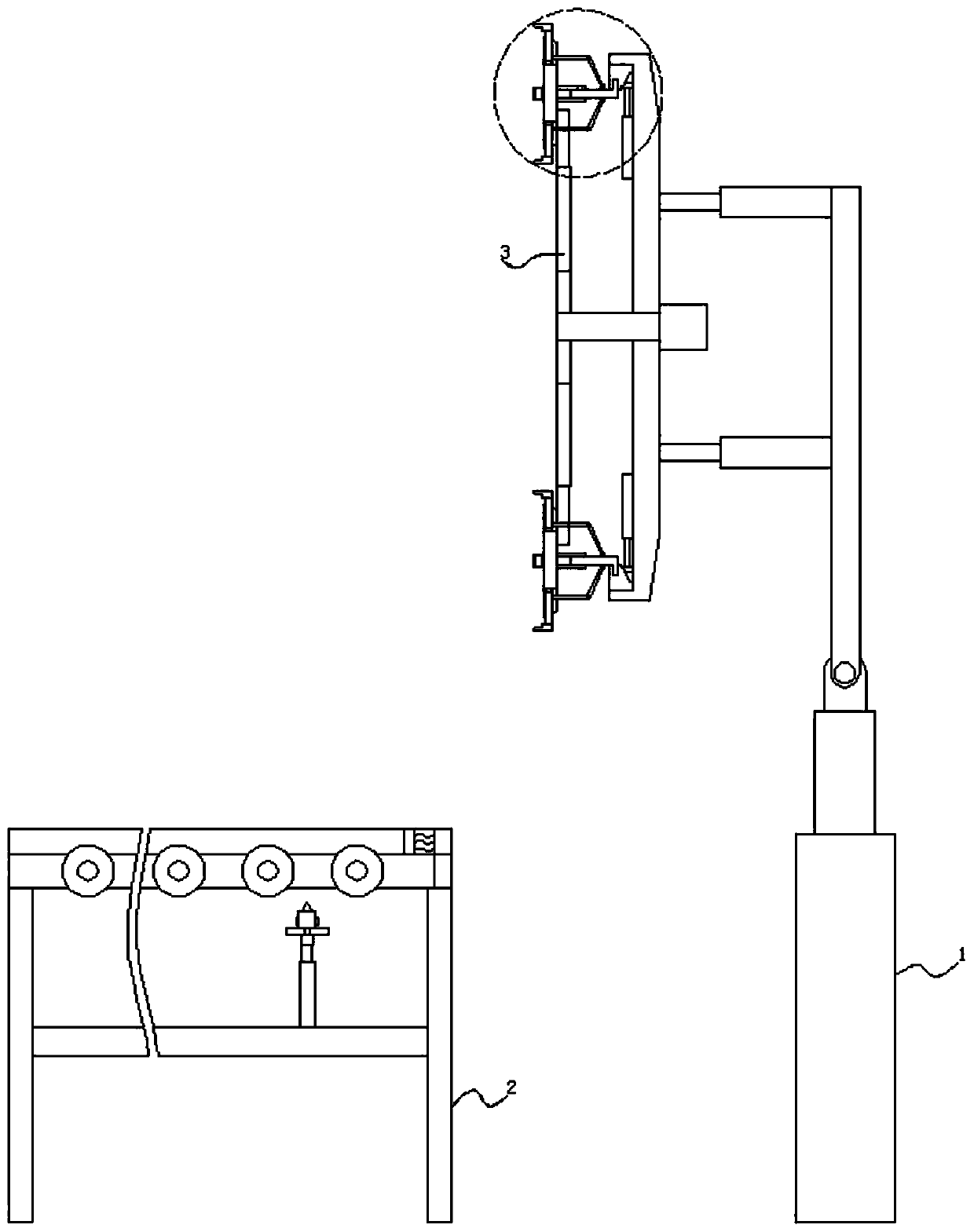

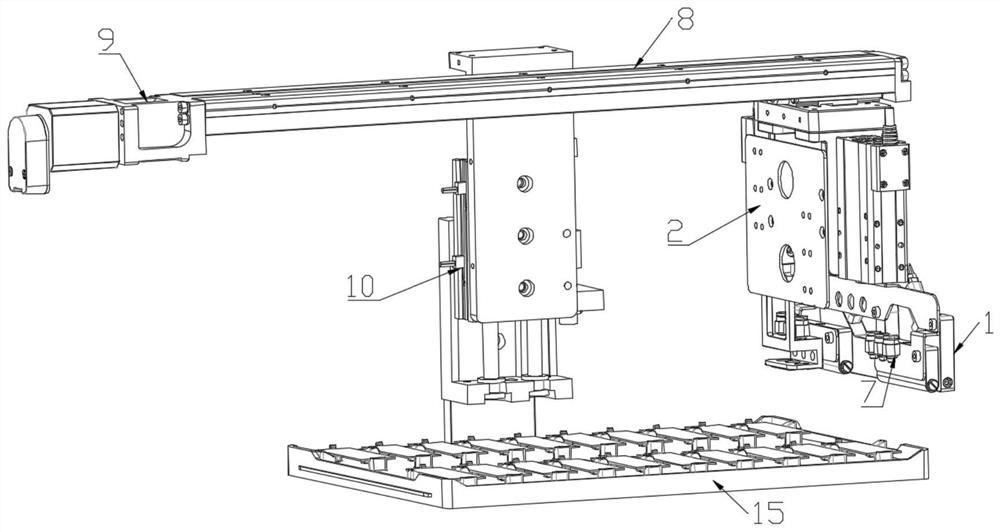

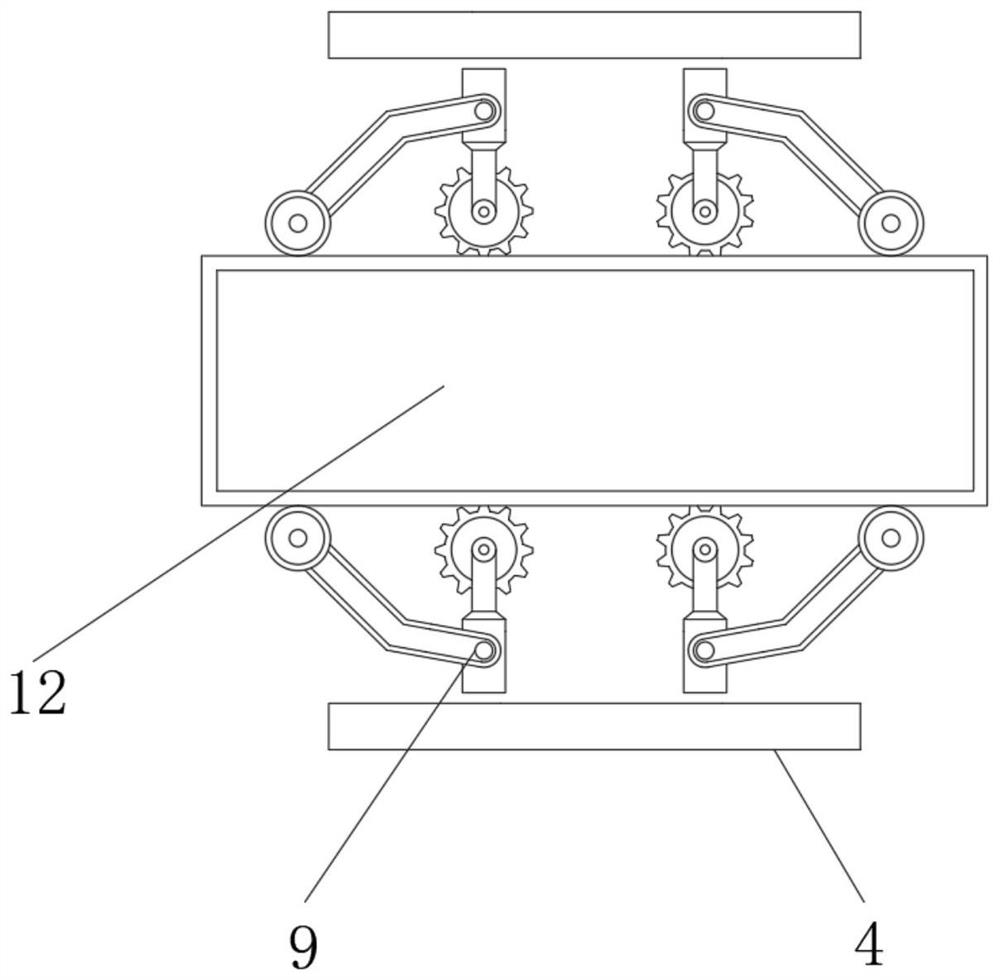

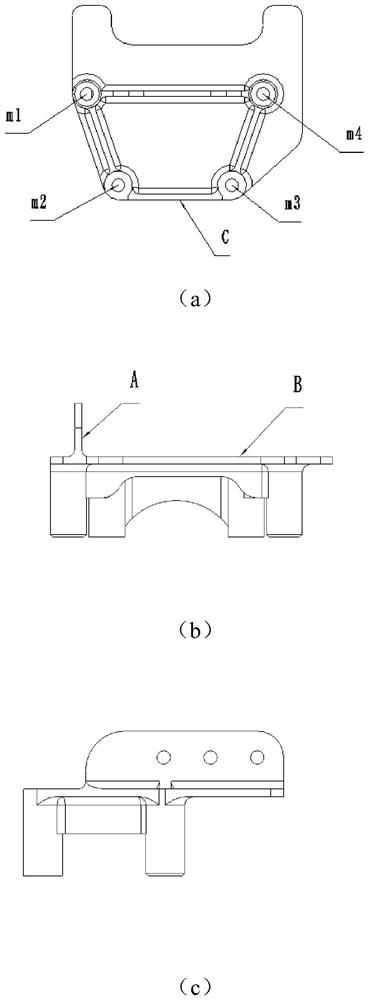

Motor end cover plate machining auxiliary equipment

ActiveCN110524300ALow change efficiencyImprove processing efficiencyMetal working apparatusEngineeringContinuous production

The invention belongs to the technical field of motor processing, specially relates to motor end cover plate machining auxiliary equipment that comprises a conversion assembly with a swing plate; oneside of the swing plate is fixedly connected with a first driving mechanism perpendicular to the swing plate; the output end of the first driving mechanism is fixedly connected with a supporting discparallel to the swing plate. A switching mechanism used for switching and clamping the motor end cover plate is fixedly connected to the outer ring of the side, away from the swing plate, of the supporting disc; the center of the supporting disc is movably sleeved with a rotating shaft; extending plates distributed along the axis of the rotating shaft in an array mode are fixedly connected to theouter ring of the end, away from the swing plate, of the rotating shaft, and U-shaped connecting plates are fixedly connected to the ends, away from the rotating shaft, of the extending plates. According to the motor end cover plate machining auxiliary equipment, positioning, feeding and discharging operation during motor end cover plate machining is achieved, continuous production can be achievedin cooperation with a machine tool, the situations that a traditional manual feeding mode is low in efficiency and high in labor intensity, and potential safety hazards exist are changed, and the motor end cover plate machining efficiency is improved.

Owner:中擎电机有限公司

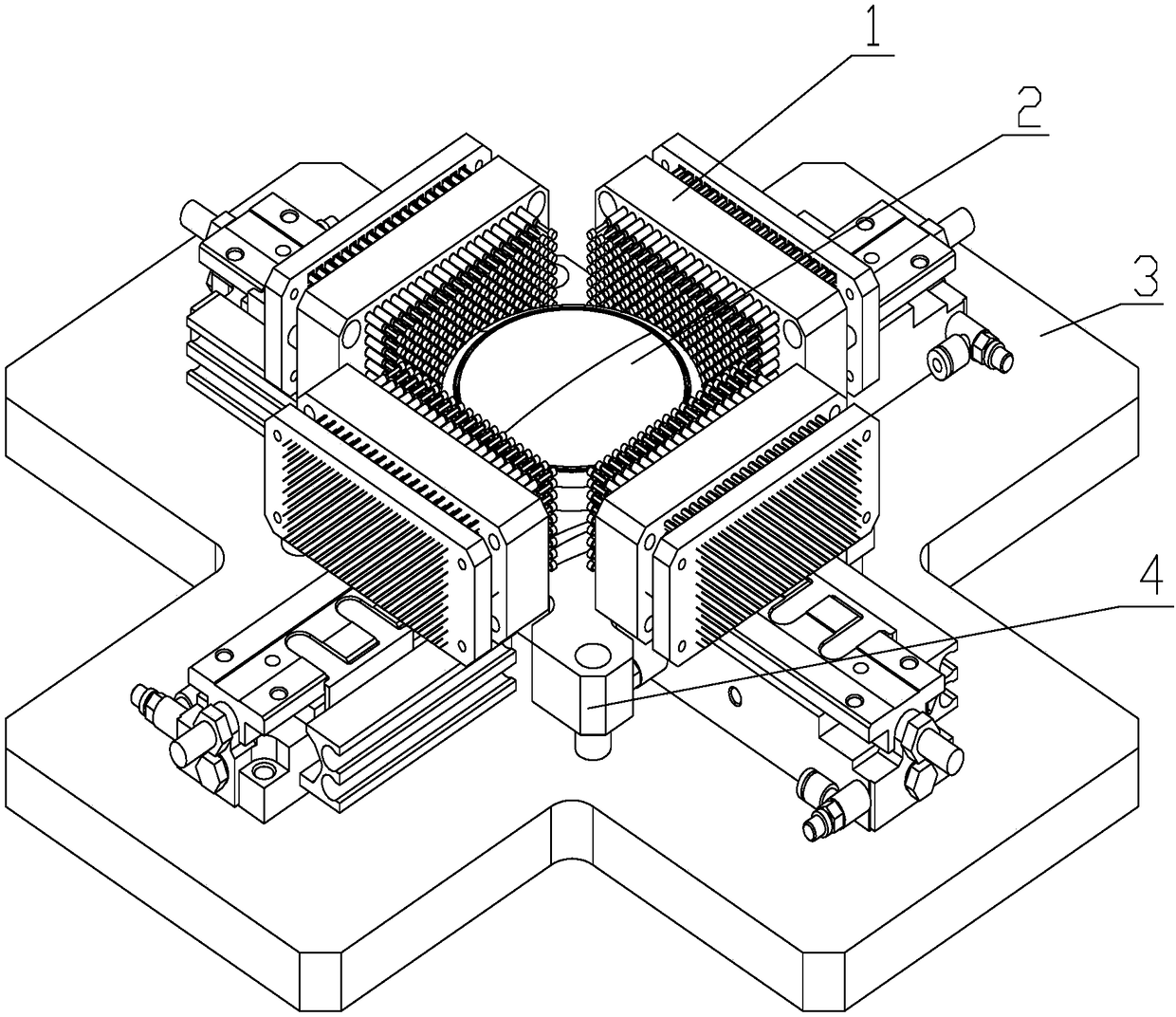

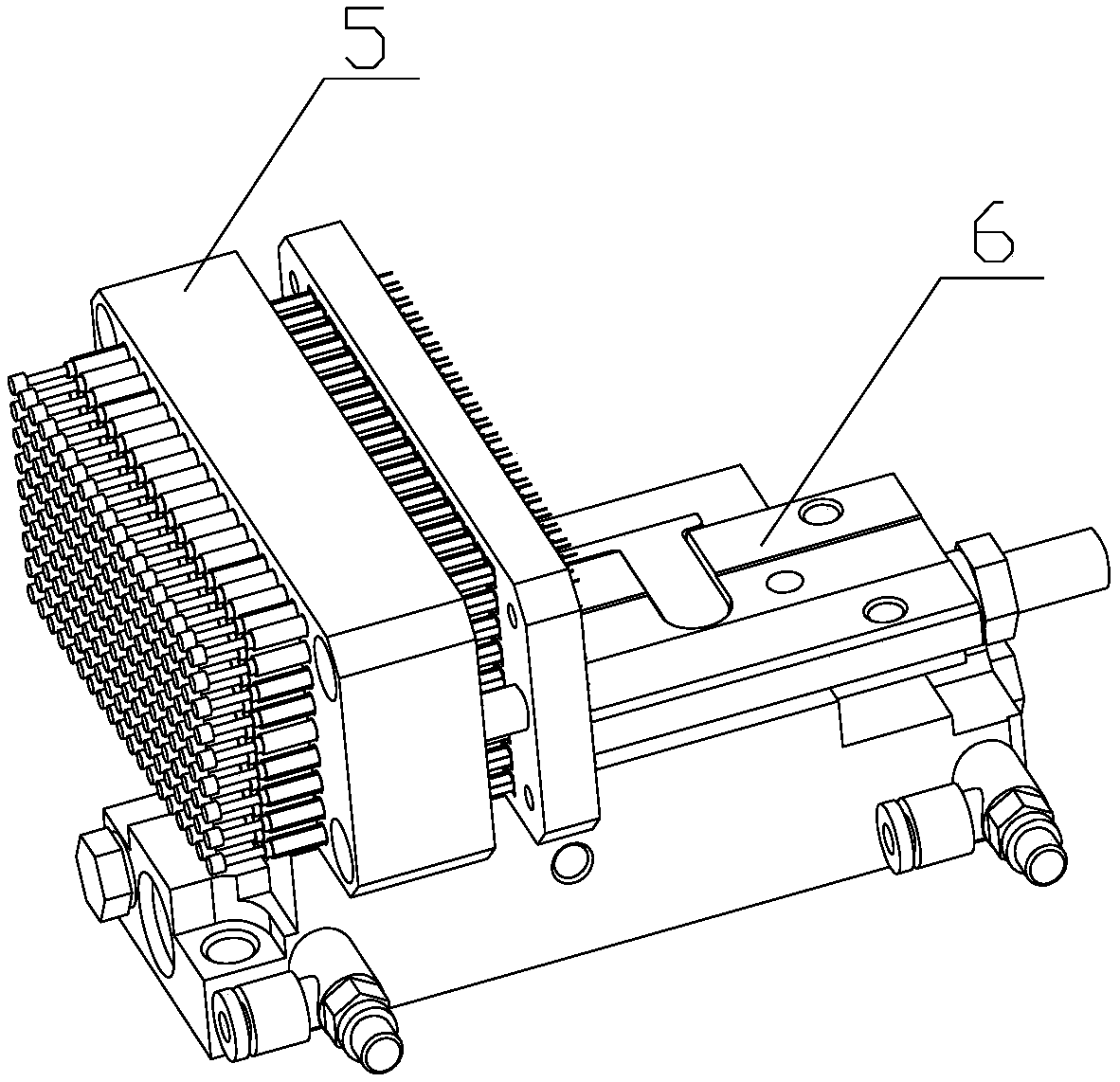

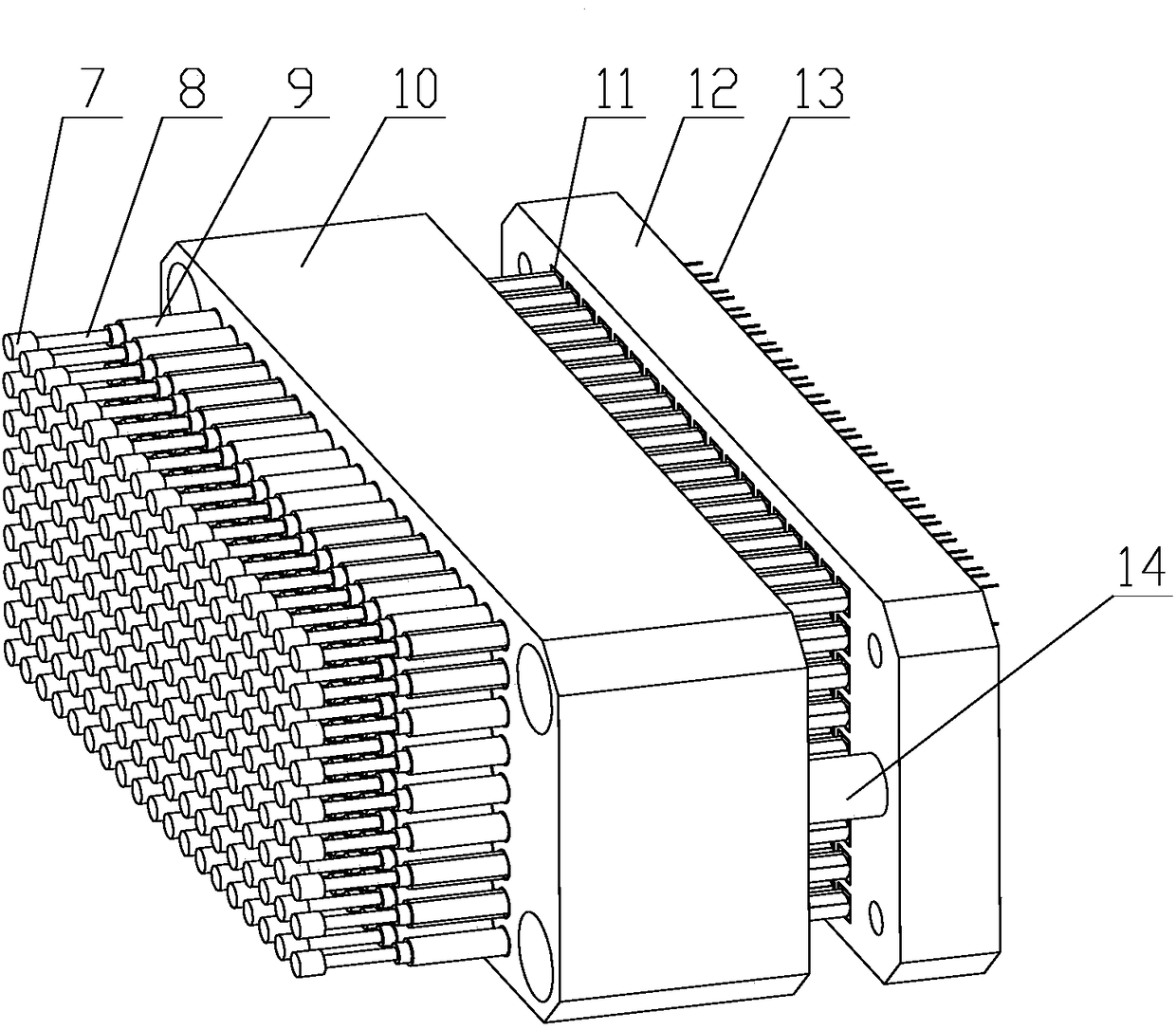

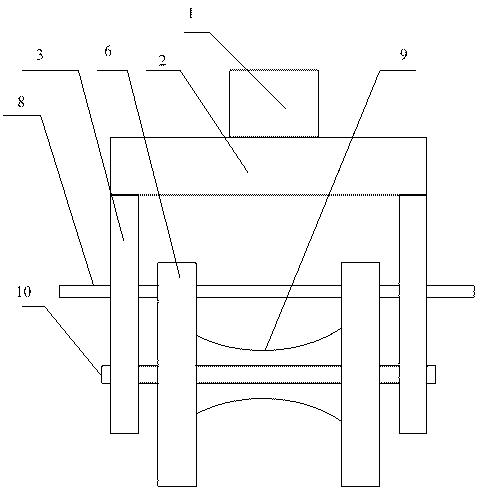

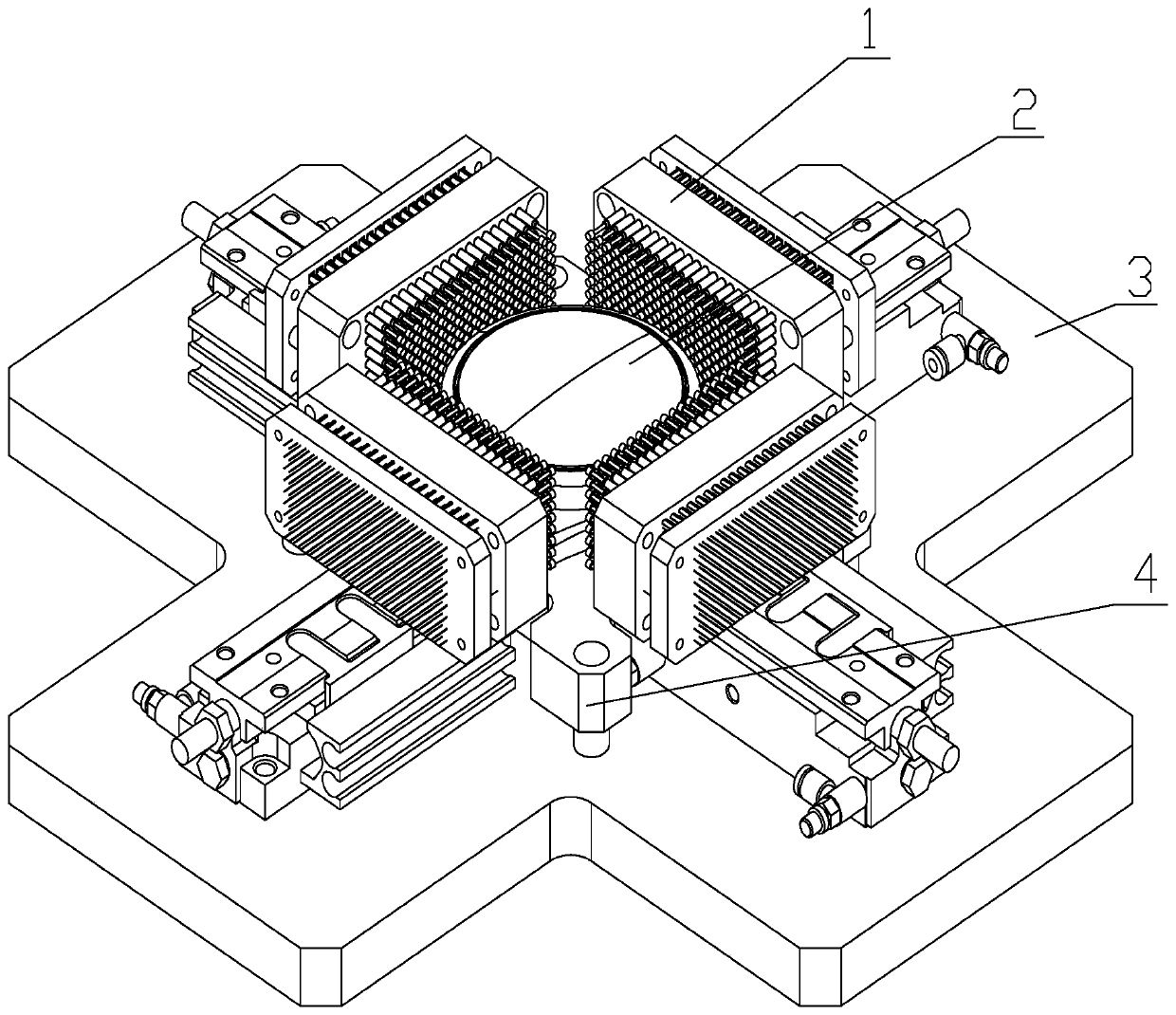

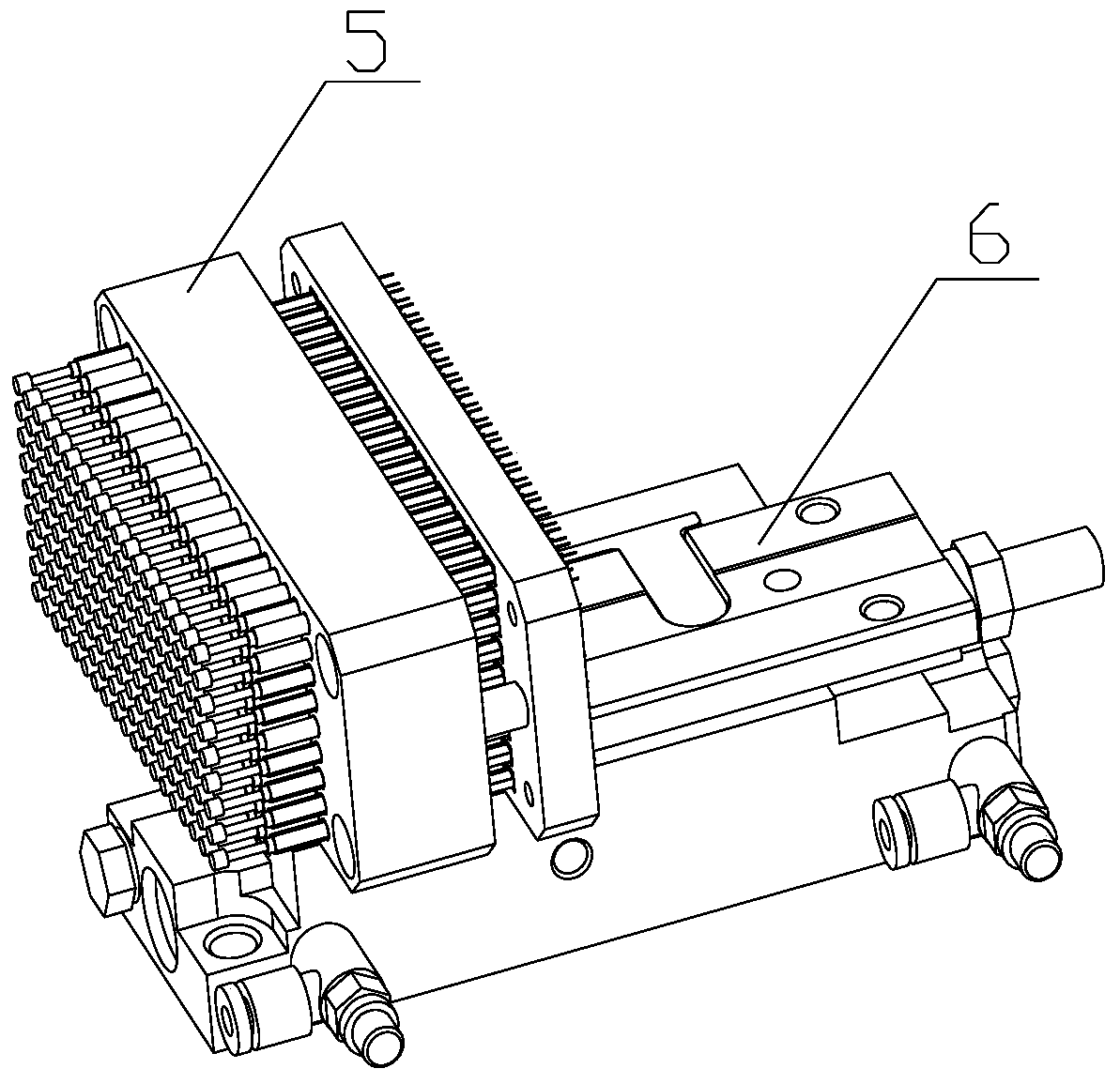

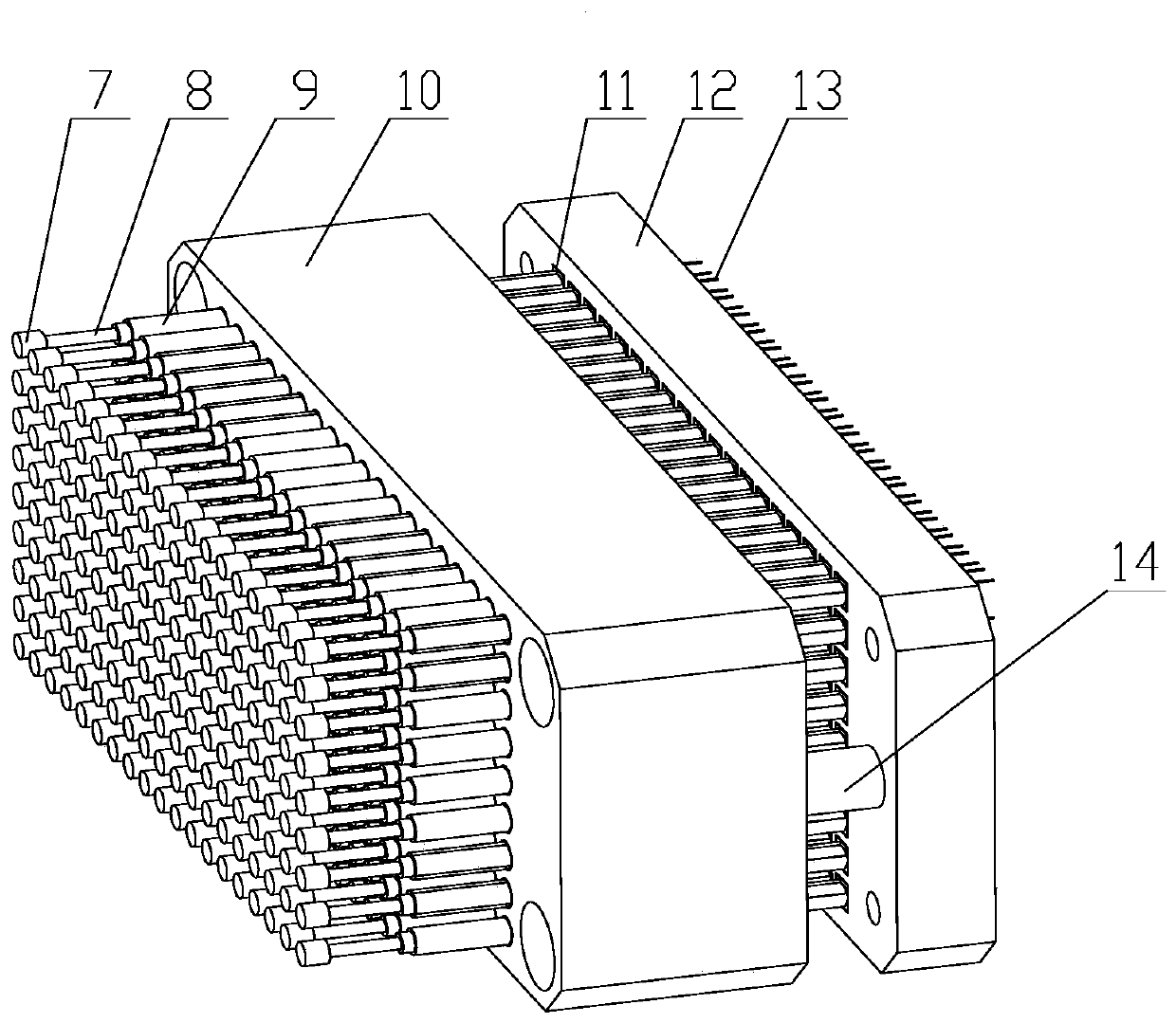

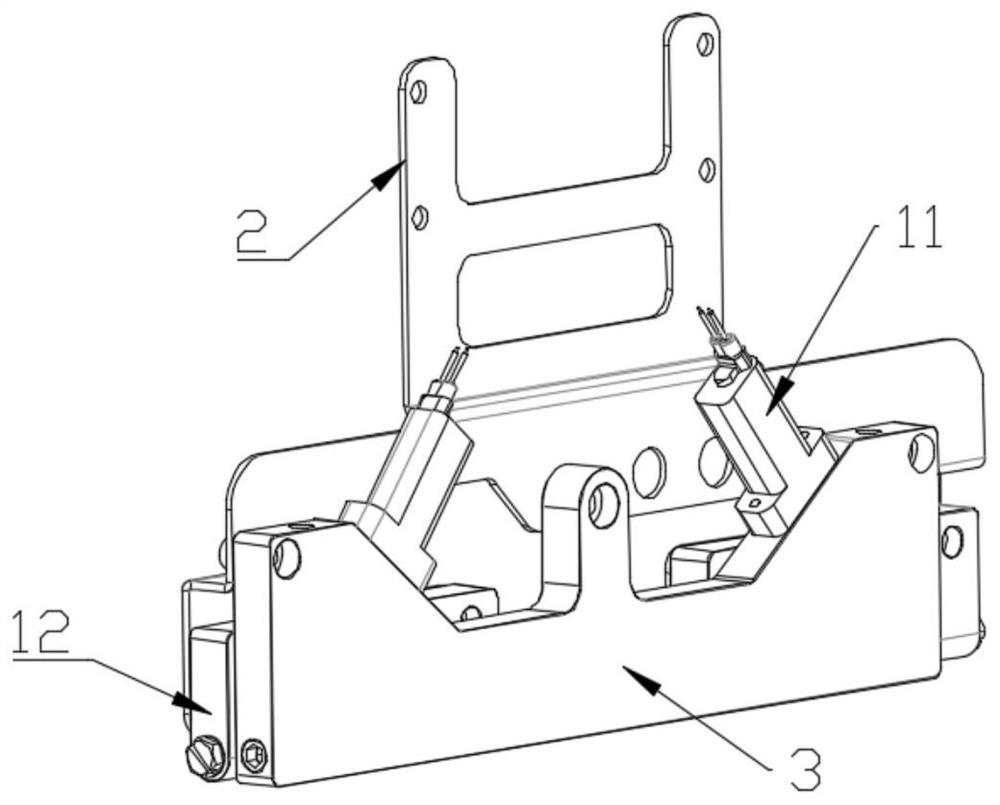

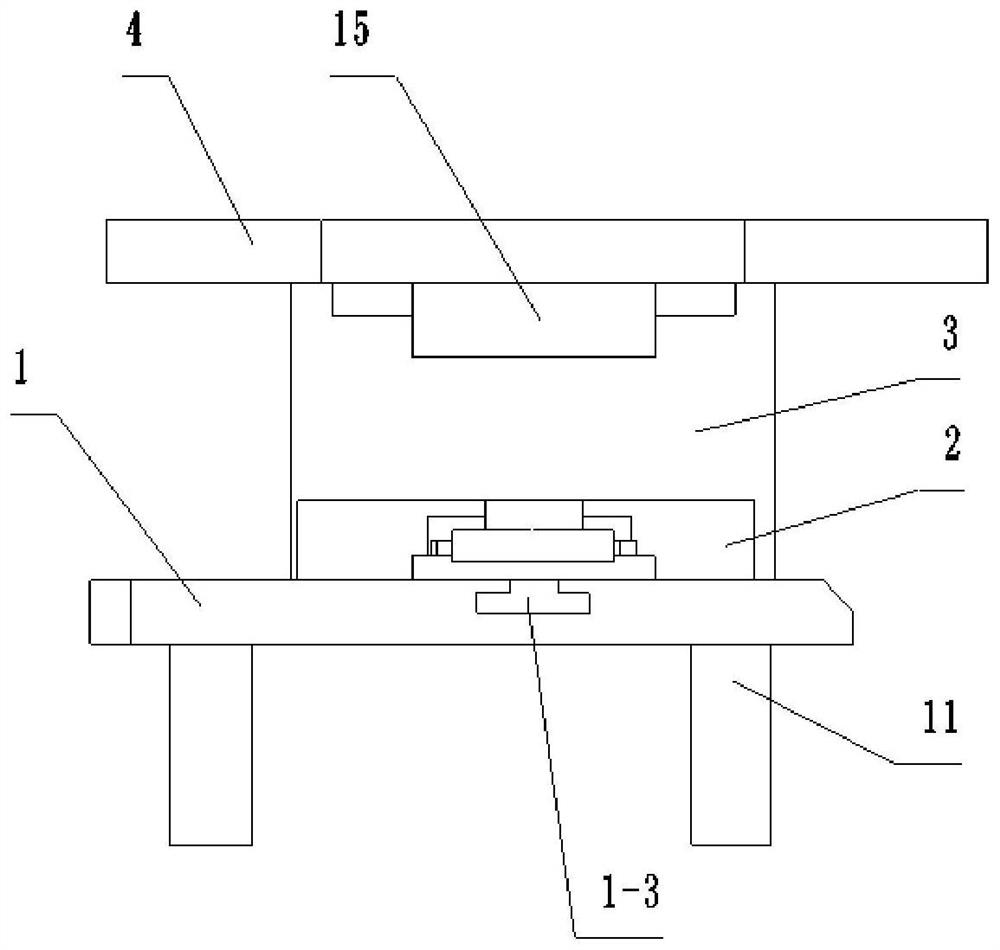

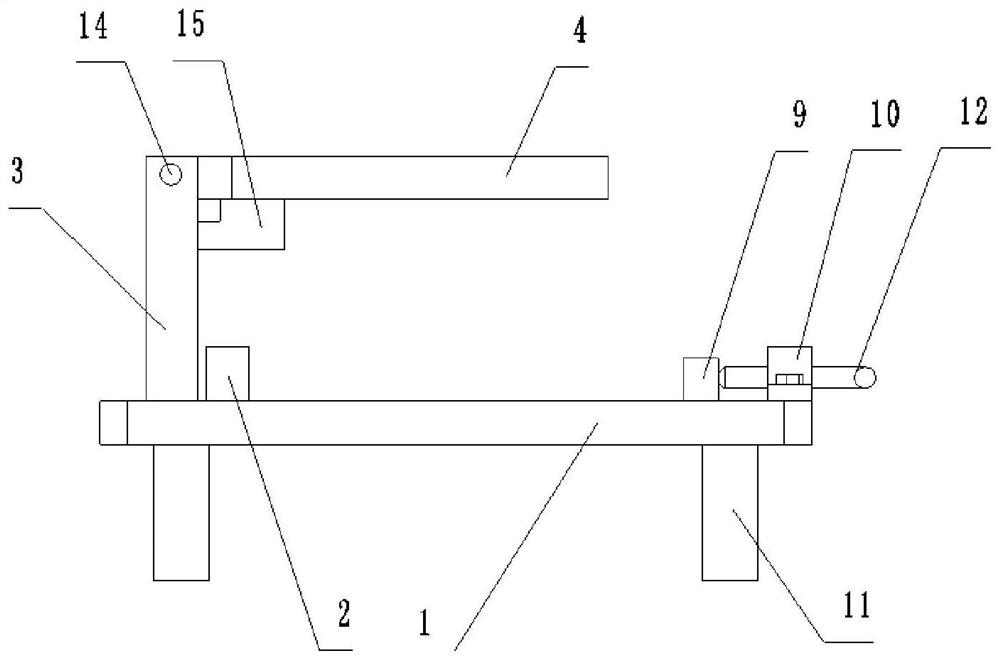

Product positioning device and method

ActiveCN108381415AImplement positioning operationsHigh positioning accuracyWork holdersApparatus for force/torque/work measurementControl systemResistor

The invention provides a product positioning device and method. The product positioning device comprises a bottom plate, a product placement seat arranged on the bottom plate, and at least two groupsof pushing assemblies located on the periphery of the product placement seat, and a product to be positioned is placed on the product placement seat; each pushing assembly comprises a pushing air cylinder fixed on the bottom plate and a dense pin module arranged on the corresponding pushing air cylinder; each dense pin module comprises a rod pin fixing block and a resistor fixing block fixedly connected with the rod pin fixing block, rod pins which are regularly distributed are arranged on the rod pin fixing blocks, and force sensitive resistors which are fixedly connected with the rod pins are arranged on the resistor fixing blocks; the pushing air cylinders are used for pushing the dense pin modules to move towards the side close to the product to be positioned, and the product to be positioned is limited and fixed through the rod pins; and the force sensitive resistors are used for detecting the deformation amount when the rod pins are in contact with the product to be positioned, and an external control system determines the current positioning position of the product to be positioned through the deformation amount information. By using the device and the method, universal typeaccurate positioning of the product can be realized.

Owner:GOERTEK INC

Automatic positioning and welding integrated production equipment for machining of diodes

InactiveCN112077492ARealize automatic pinch operationFor automatic homingWelding/cutting auxillary devicesAuxillary welding devicesKinematic pairVisual inspection

The invention discloses automatic positioning and welding integrated production equipment for machining of diodes. The automatic positioning and welding integrated production equipment comprises a main body frame, a conveying belt is installed on the lower portion of the interior of the main body frame, pins are installed on the upper portion of a support, a first servo motor is installed on the left side of the upper portion of the interior of the main body frame, and a first kinematic pair is connected to the right side of a first connecting rod in a screwed mode. Compared with existing common visual inspection equipment, the automatic positioning and welding integrated production equipment for machining of the diodes is provided with a groove, the first servo motor rotates to drive thefirst connecting rod, the first connecting rod rotates through the first kinematic pair, the first kinematic pair drives a second kinematic pair to move through a second connecting rod, the second kinematic pair drives a third kinematic pair to move through a first moving plate, a transverse limiting plate drives the first moving plate to slide through the third kinematic pair, a longitudinal limiting plate drives a lifting rod to stretch out and draw back through the third kinematic pair, and automatic clamping and conveying operation of a clamping frame is achieved.

Owner:广州市金点子机电科技发展有限公司

Endoscopic positioning device and positioning method for digestive tract lesion treatment operation

ActiveCN110089991AUse stableImprove clarityEndoscopesDiagnostic recording/measuringEngineeringActual use

The invention discloses an endoscopic positioning device and positioning method for digestive tract lesion treatment operation, wherein the endoscopic positioning device comprises a shell. The top ofthe inner wall of the shell is fixedly connected with a first camera, the inner wall of the shell is provided with a groove and fixedly connected with a lighting lamp through the groove, and the bottom of the inner wall of the shell is fixedly connected with a fixed seat; the upper surface of the fixed seat is fixedly connected with a motor, and the top of an output shaft on the motor is fixedly connected with a rotating shaft; the surface, close to the top, of the rotating shaft is fixedly sleeved with a turntable; the lower surface of the turntable is provided with a spiral groove, the innerwall of the spiral groove is slidingly connected with a sliding column, and the bottom of the sliding column is fixedly connected with a positioning column. Through cooperative use of the structures,the problems of inconvenient use and reduction of work efficiency caused because a traditional endoscope cannot position quickly and accurately in an actual use process and the endoscope difficultlytakes effective monitoring pictures are solved.

Owner:南通市传染病防治院

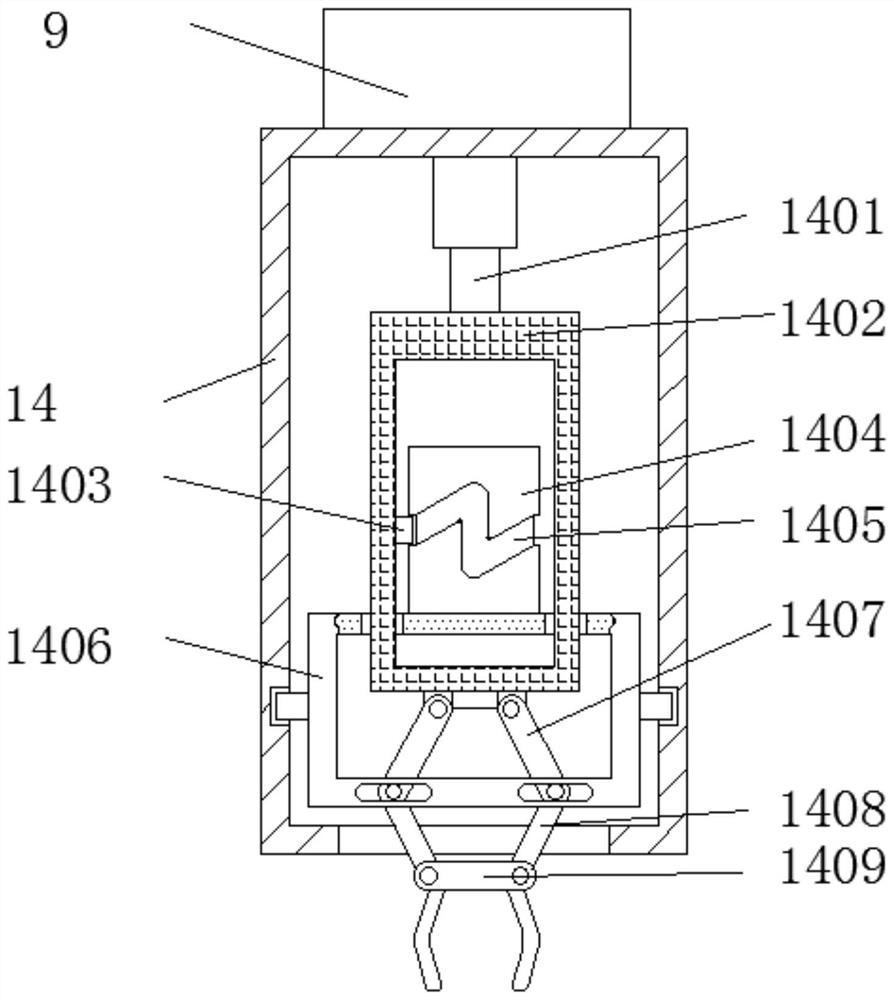

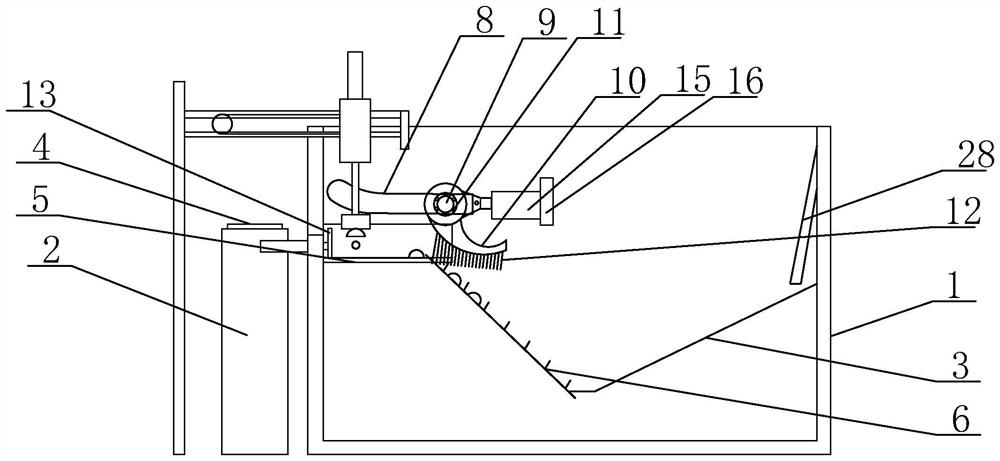

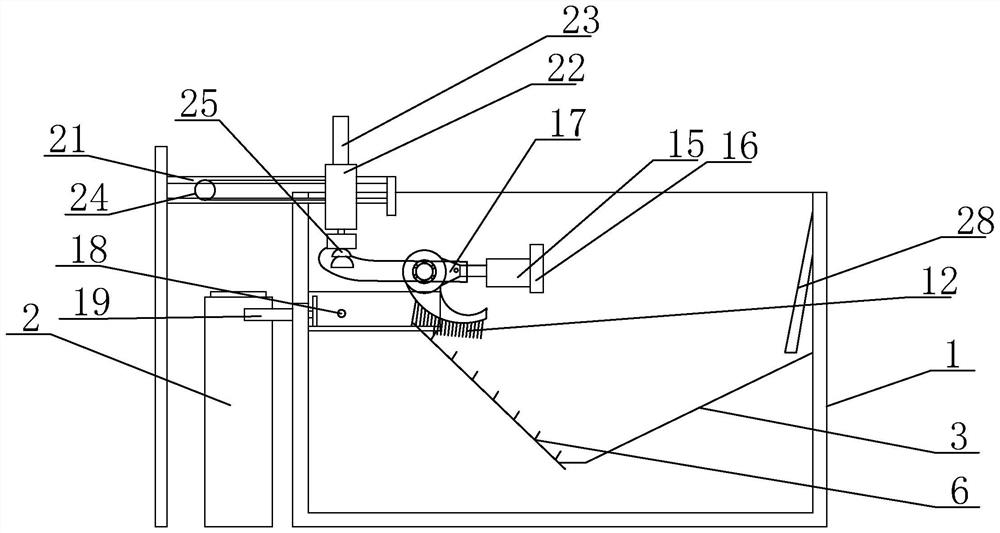

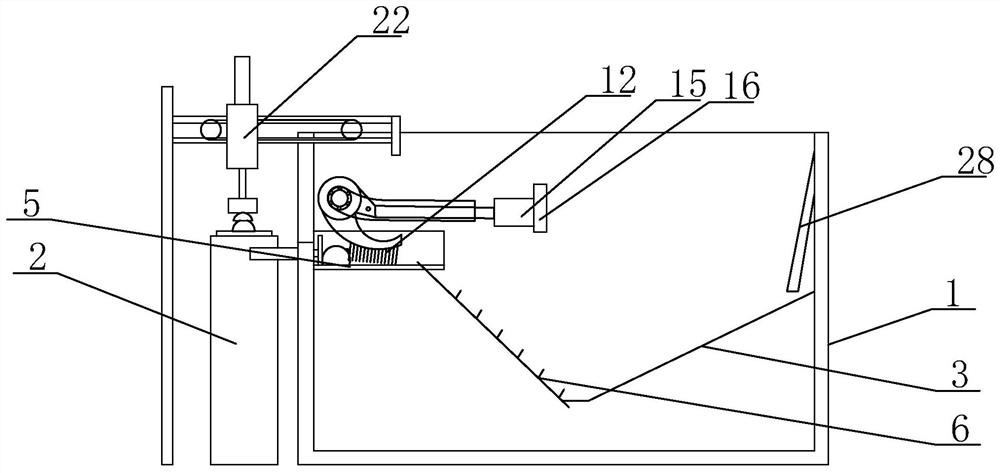

Waste needle head bending equipment

InactiveCN113058114AImplement positioning operationsPrevent outflowInfusion needlesPhysicsEngineering

The invention relates to the technical field related to medical treatment, in particular to waste needle head bending equipment. The waste needle head bending equipment comprises a box body, a needle head positioning assembly used for positioning a needle head is fixedly connected to the surface of the box body, a bending space is formed in the box body, and a movable fixing assembly used for fixing the needle head when the needle head is bent is arranged in the bending space; a fixing assembly used for fixing the needle head when the needle head is bent is arranged in the side wall, close to the movable fixing assembly, of the bending space, a bending mechanism used for bending the needle head is arranged in the front wall of the bending space, and a needle head clamping assembly used for clamping and fixing the needle head is arranged at the rear end of the bending mechanism. After the needle head is bent into the spiral shape, the needle point part can be well hidden in the center of the spiral shape, so the possibility that a bag is punctured during transportation in the garbage bag basically does not exist, the problems that dirty liquid in the bag flows out, virus sensing is caused and the like are avoided, and accidental injury to personnel is also avoided.

Owner:深圳德朗美科技有限公司

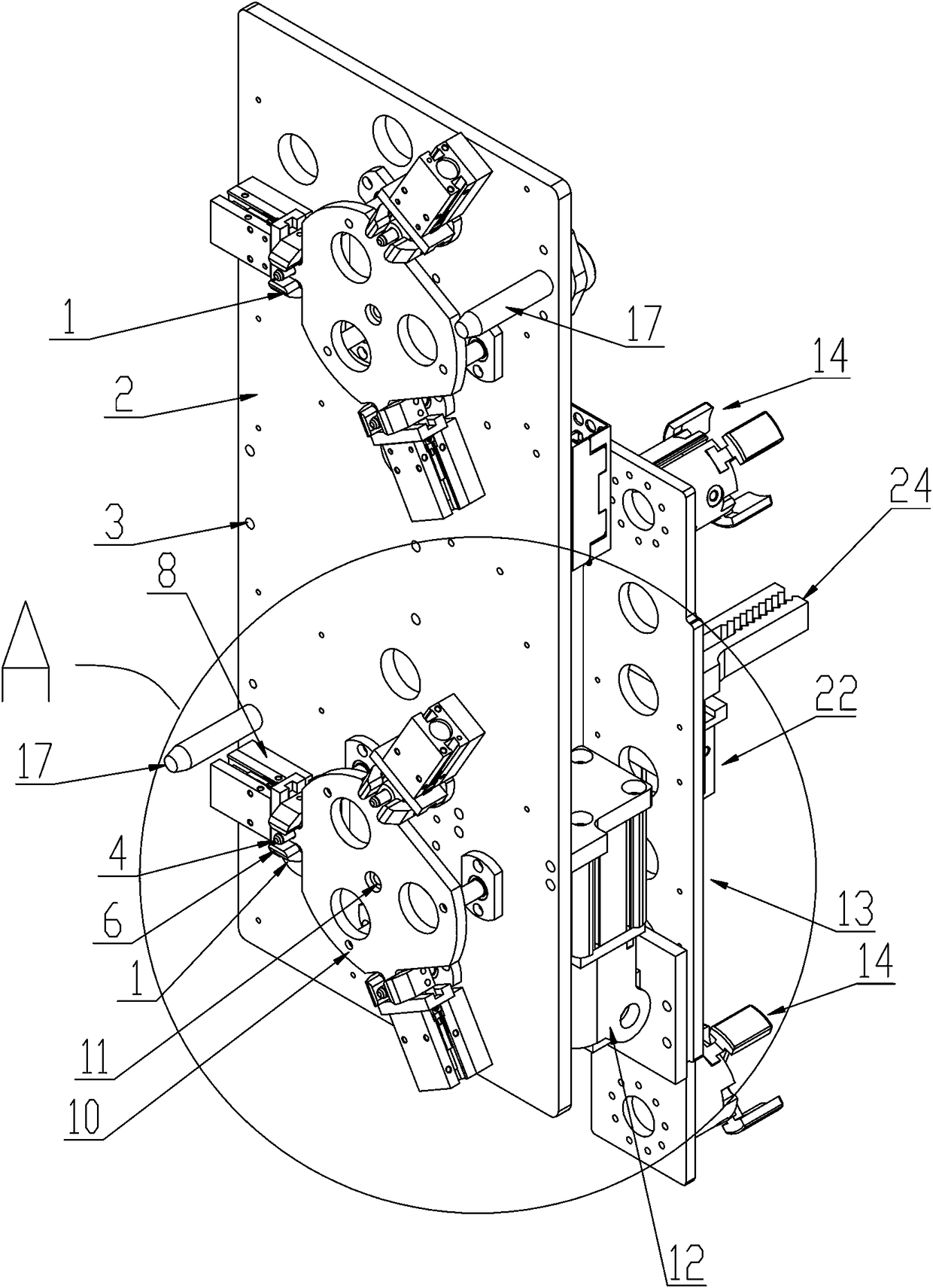

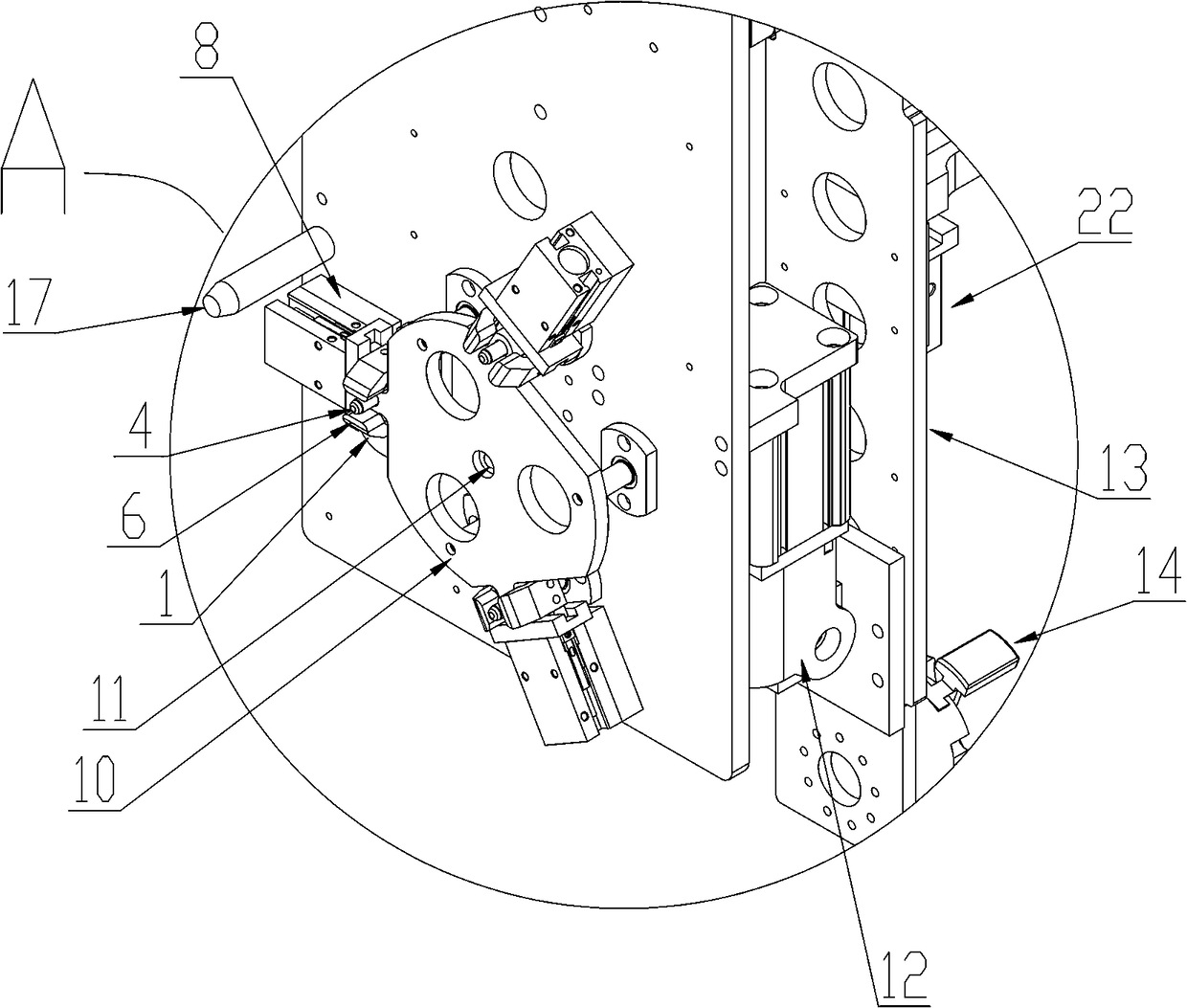

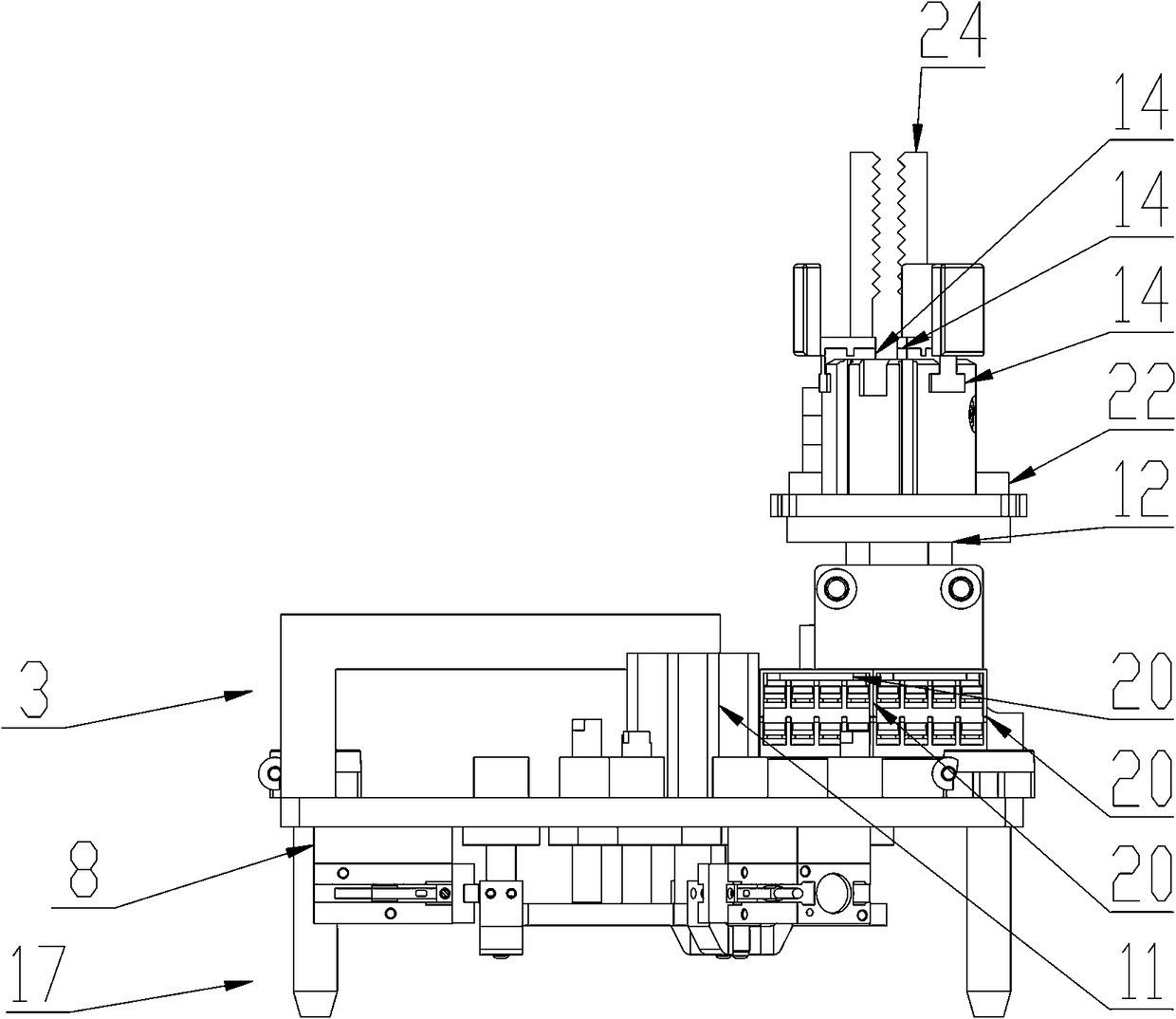

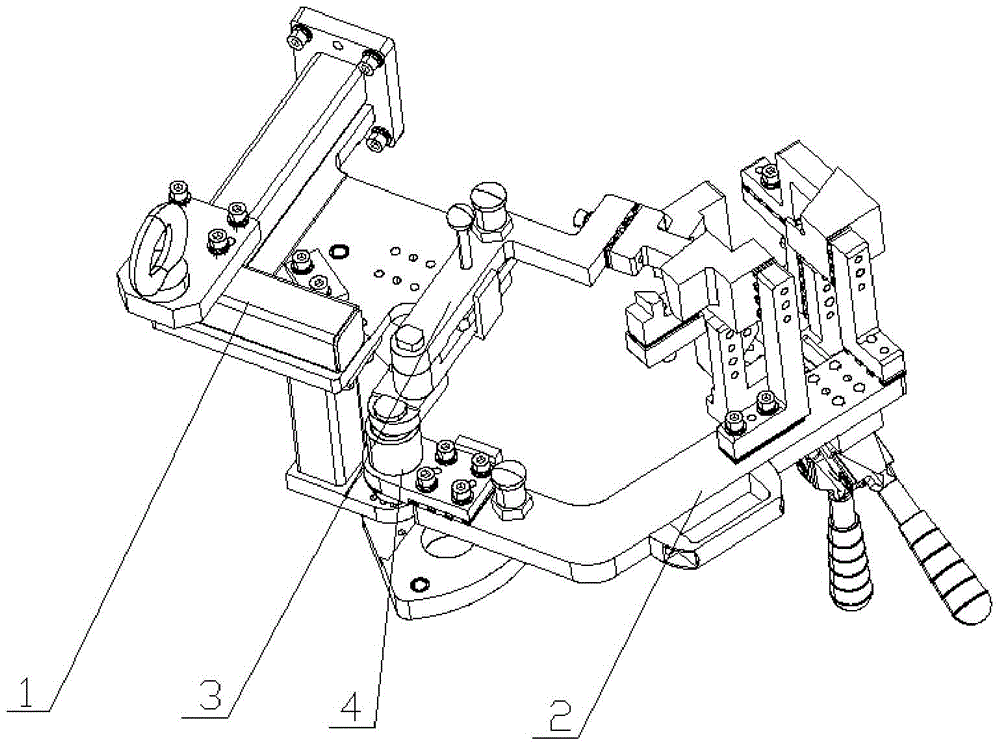

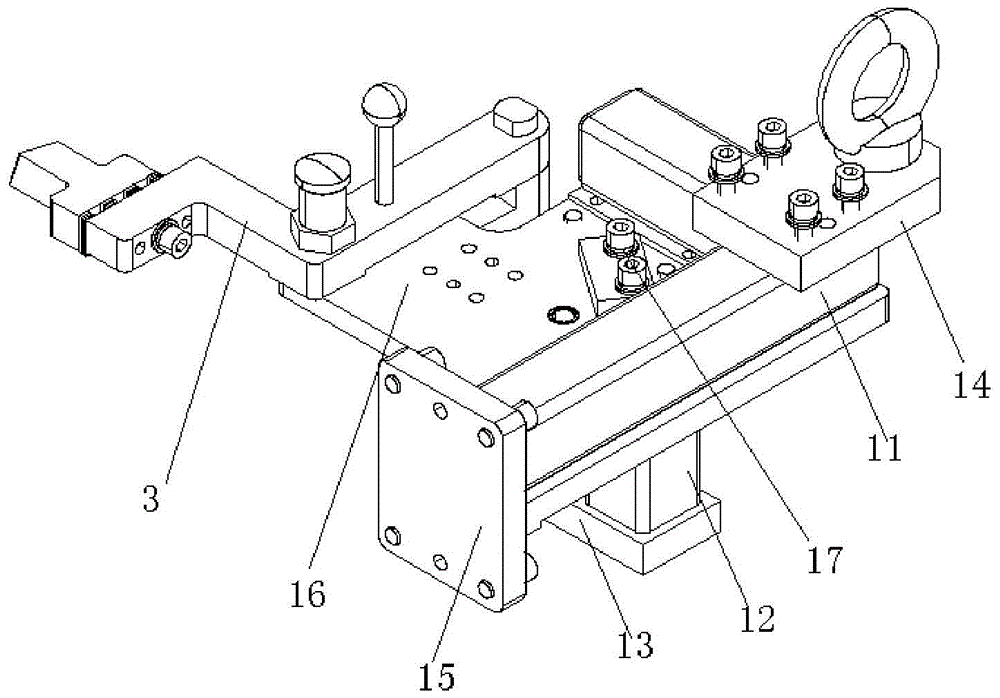

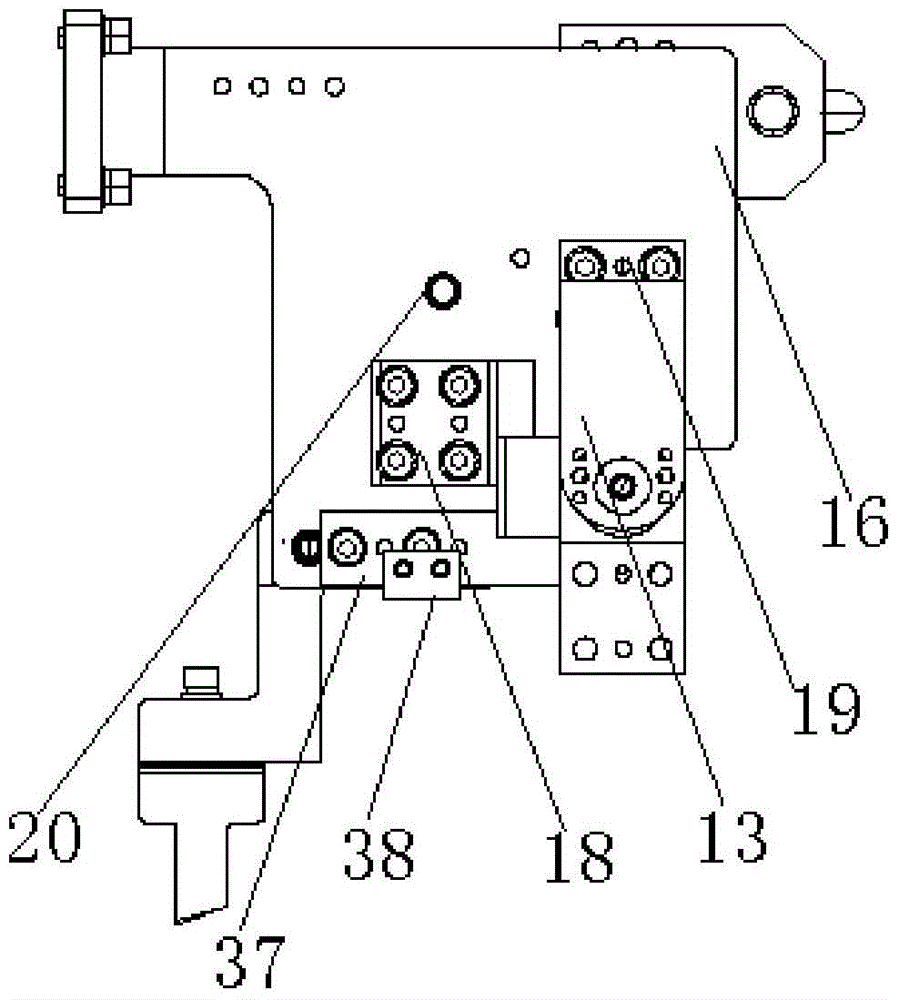

Positioning inserting and overturning removing jig for hexagonal cap

PendingCN108620848ARealize the pushing effectImplement positioning operationsWork holdersMetal working apparatusEngineeringControllability

The invention provides a positioning inserting and overturning removing jig for a hexagonal cap. The positioning inserting and overturning removing jig for the hexagonal cap comprises a jig plate, wherein a hexagonal cap positioning device is arranged on one surface of the jig plate, and an overturning mechanism and jacking cylinders are arranged on the other surface of the jig plate; one end of the overturning plate is fixedly connected to the jig plate, and the other end of the overturning mechanism is connected to one surface of a mounting plate of the overturning mechanism; a first clamp for removing a workpiece and a second clamp are correspondingly arranged on the other surface of the mounting plate of the overturning mechanism; the hexagonal cap positioning device comprises a plurality of cap clamps for clamping the caps; telescoping positioning columns are arranged in the middle parts of the cap clamps; each telescoping positioning column penetrates a jacking plate; the jackingcylinders are connected to the middle parts of the jacking plates; and a plurality of jacking columns are arranged on the jacking plates. The positioning inserting and overturning removing jig for the hexagonal cap is high in stability, high in safety coefficient, and convenient to operate, and the controllability is effectively improved.

Owner:苏州华吉威自动化设备有限公司

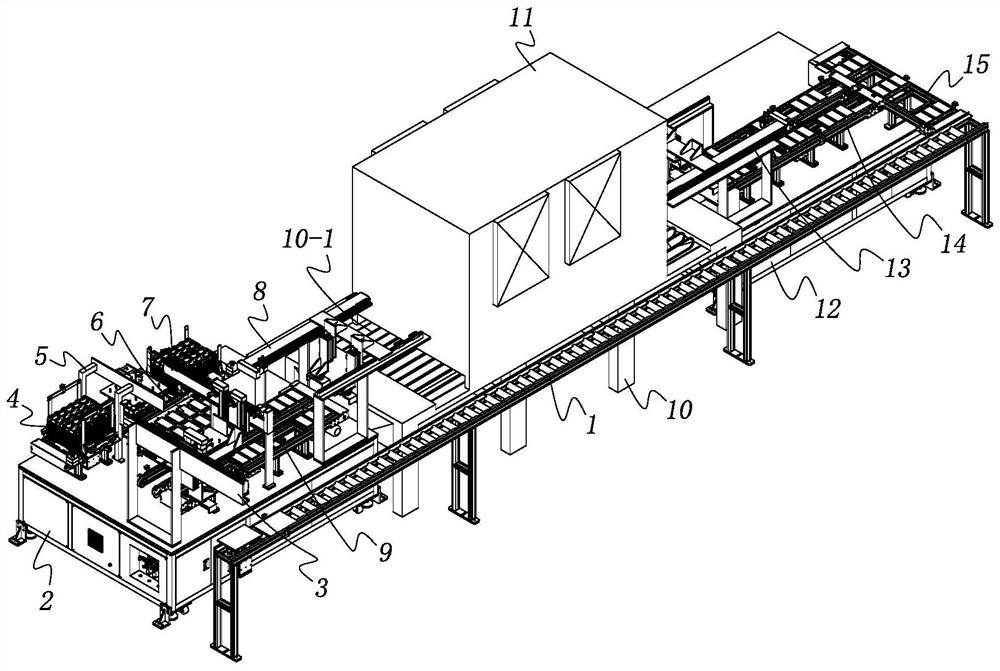

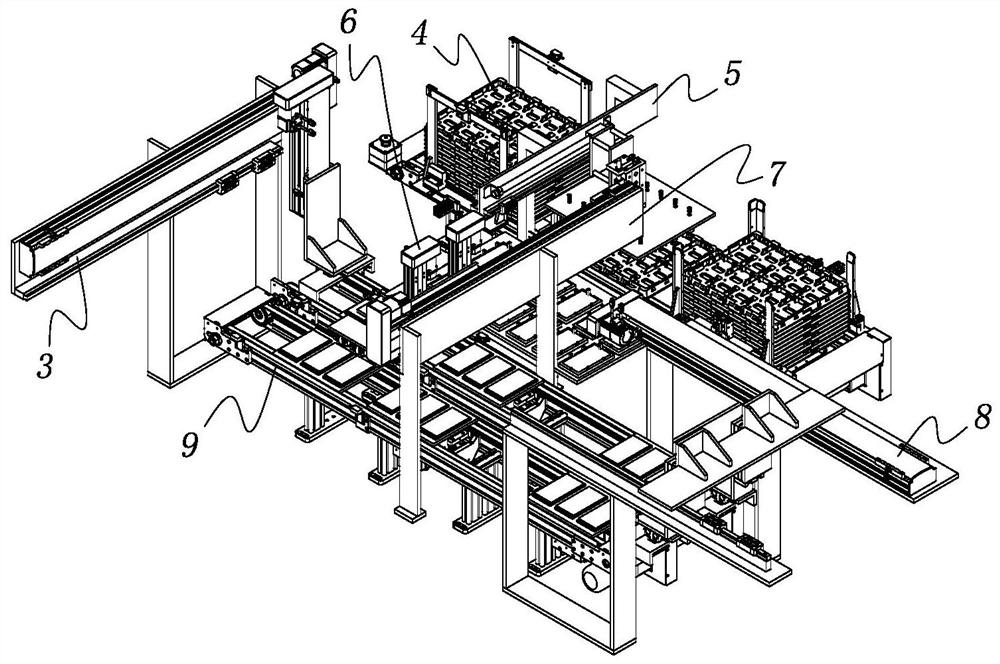

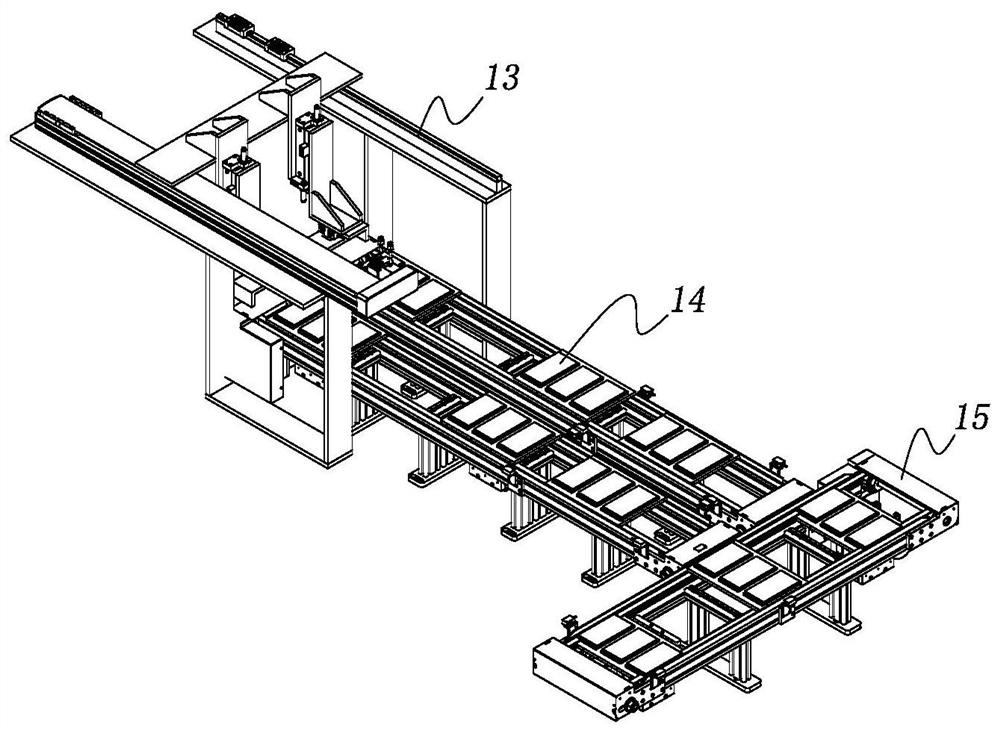

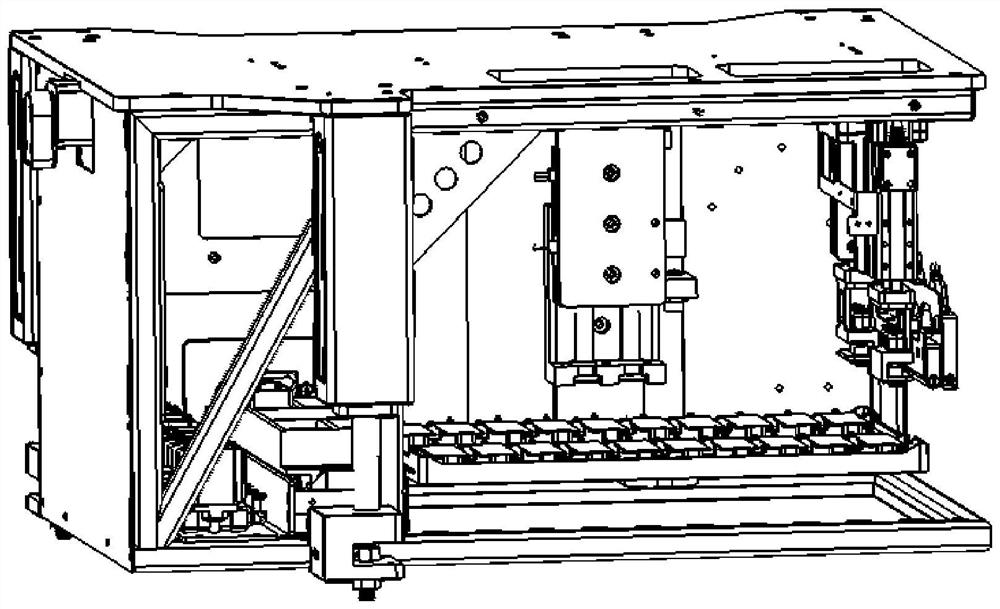

Sand blasting machining equipment with automatic feeding and discharging function

InactiveCN113305745AReasonable structural designImprove processing efficiencyAbrasive machine appurtenancesAbrasive blasting machinesSand blastingStructural engineering

The invention relates to sand blasting machining equipment with an automatic feeding and discharging function. The sand blasting machining equipment comprises a sand blasting support located in the middle, a sand blasting device is installed on the sand blasting support, a feeding support is arranged in front of the sand blasting support, a discharging support is arranged behind the sand blasting support, and supporting plate conveyors used for conveying supporting plates are arranged on the side portions of the sand blasting support, the feeding support and the discharging support. A positioning device is arranged in the middle of the feeding support, a feeding conveying device is arranged on the inner side of the positioning device, a tray separating device is arranged on the outer side of the positioning device, a workpiece transferring device is arranged in the middle of the tray separating device, a supporting plate transferring device is arranged on the front portion of the feeding conveying device, a feeding transverse moving device is arranged in the middle of the feeding conveying device, and a feeding longitudinal moving device is arranged on the middle rear portion of the feeding conveying device. A discharging conveying device is installed on the discharging support, a discharging longitudinal moving device is arranged on the middle front portion of the discharging conveying device, and a discharging transverse moving device is arranged at the tail of the discharging conveying device. The sand blasting machining equipment is reasonable in structural design, continuous sand blasting machining is achieved, and the workpiece machining efficiency is improved.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

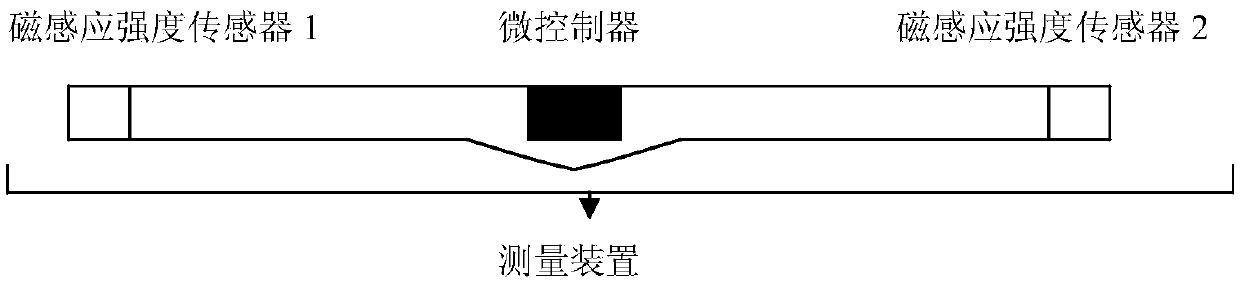

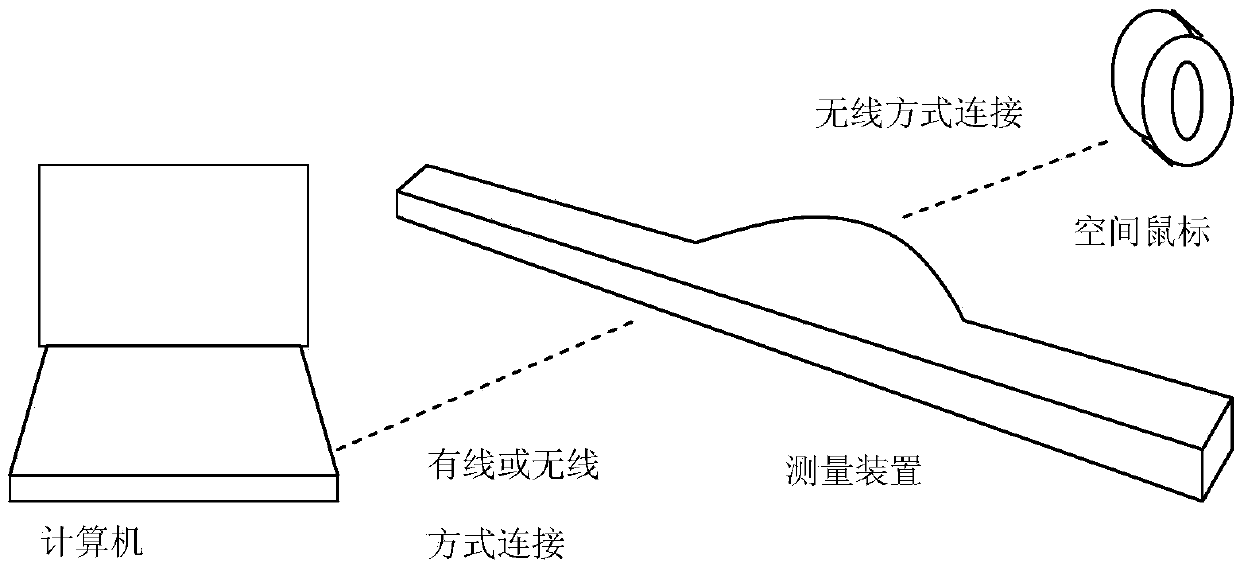

Space mouse used for human-computer interaction, and electromagnetic positioning method

InactiveCN108710442AA large amountLow costInput/output processes for data processingHuman system interactionHuman machine interaction

Owner:UNIV OF SCI & TECH BEIJING

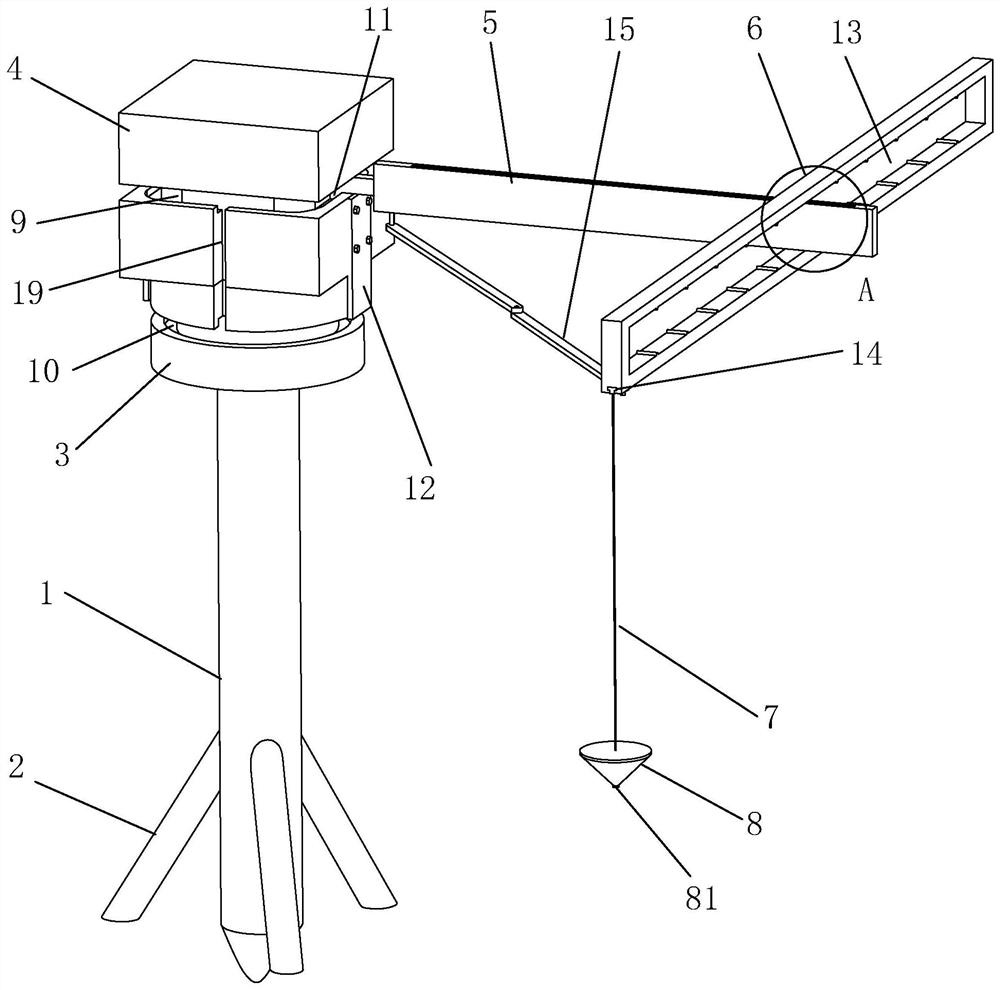

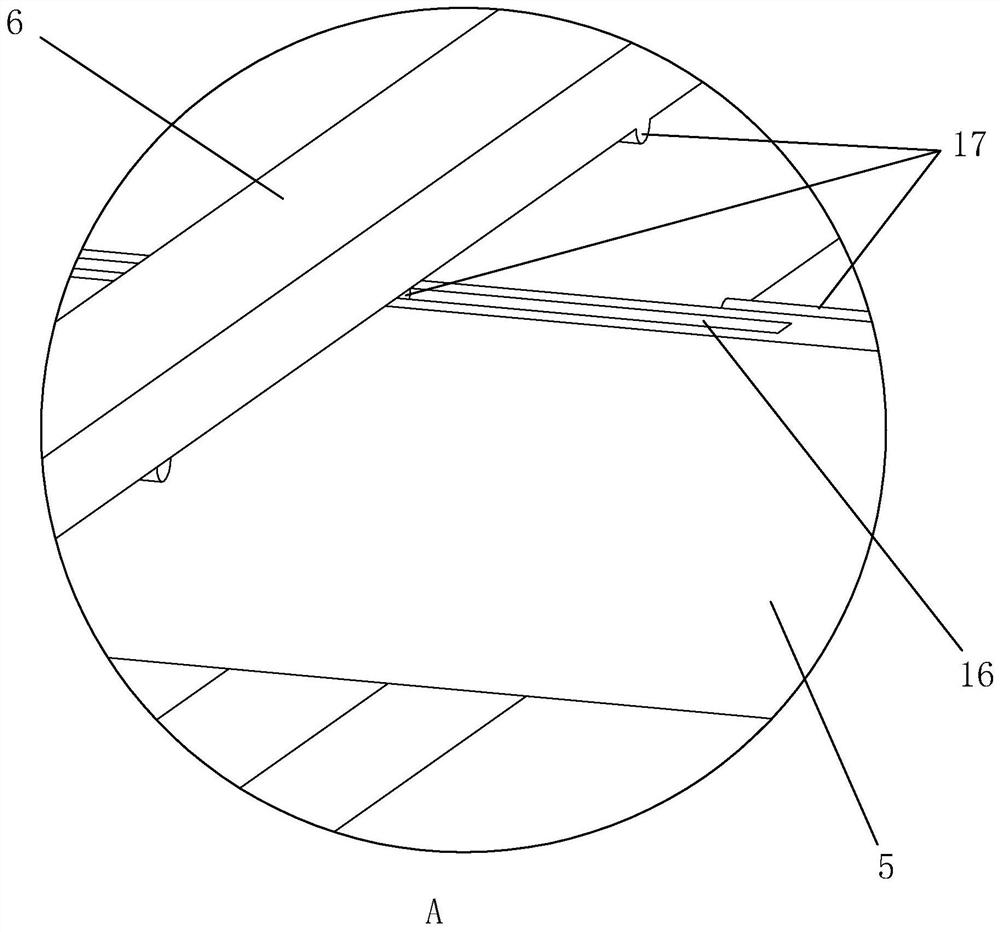

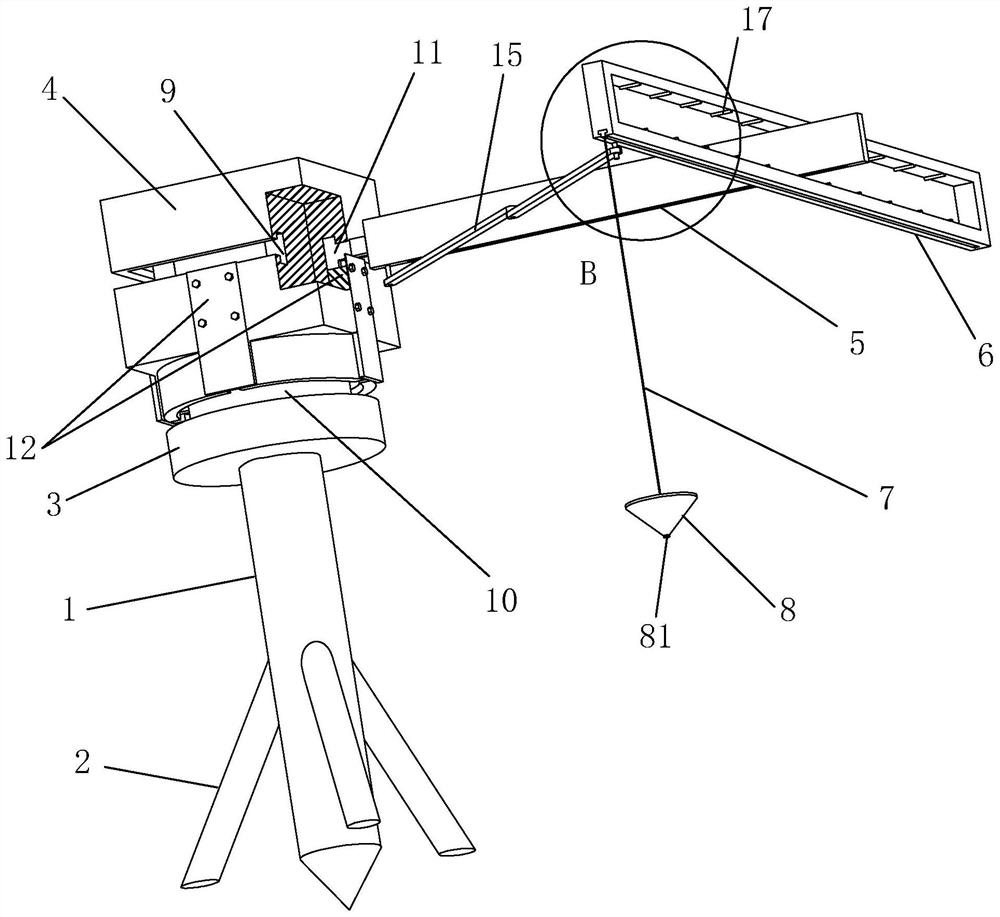

Localizable electric wire guiding pulley

InactiveCN104037655AImplement positioning operationsSimple structureArrangements using take-up reel/drumApparatus for overhead lines/cablesEngineeringElectric wire

The invention discloses a localizable electric wire guiding pulley. The localizable electric wire guiding pulley comprises two pulley bodies and a pulley rack, wherein each pulley body mainly comprises two chucks, a groove-shaped roller and a through shaft; the two chucks of each pulley body are respectively arranged on side surfaces of two ends of the corresponding groove-shaped roller; each through shaft penetrates in the circle centers of the corresponding chucks and the circle centers of end surfaces of the corresponding groove-shaped roller; positioning through holes are formed in end surfaces of the two chucks of each pulley body; the pulley rack comprises a hanger plate; the lower side surface of the hanger plate is connected with a main body block; the lower side surface of the main body block is connected with two first clamping plates, two intermediate limiting clamping plates and two second clamping plates; the two first clamping plates are respectively connected to two ends of the through shaft of the first pulley body; the two second clamping plates are respectively connected to two ends of the through shaft of the second pulley body; the intermediate limiting clamping plates are respectively connected with the first clamping plates and the second clamping plates through connecting columns; and positioning columns are inserted in the positioning through holes. The guiding pulley can be located.

Owner:STATE GRID SICHUAN ELECTRIC POWER

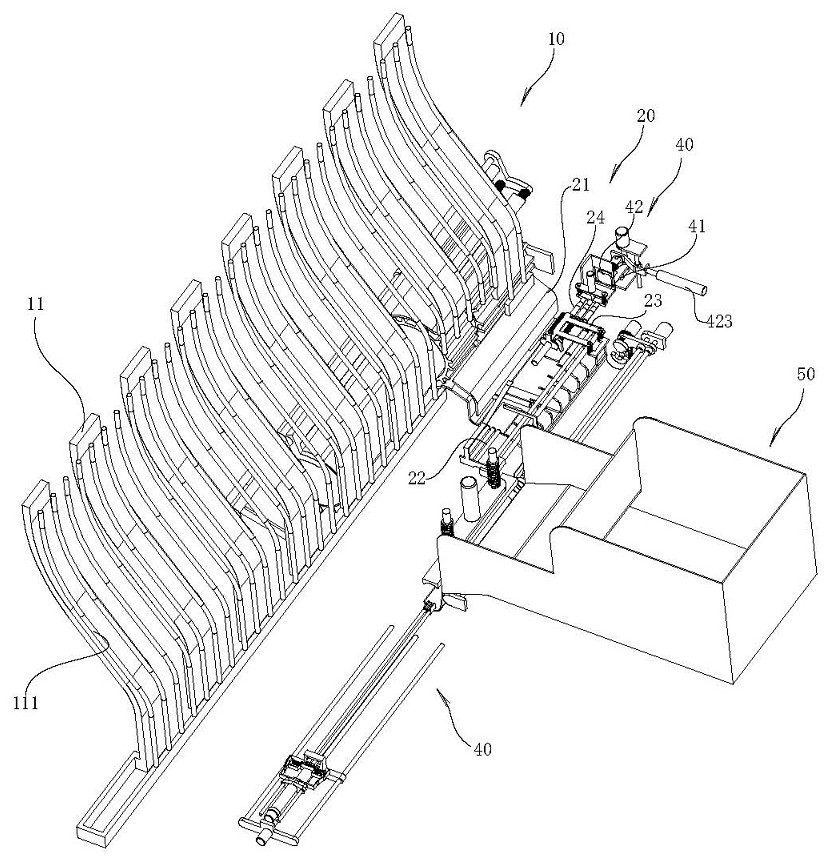

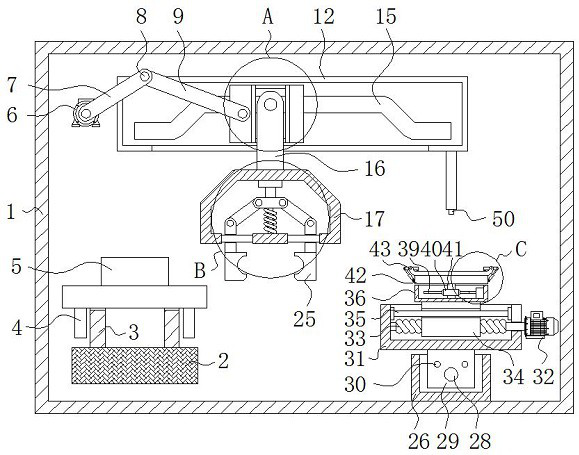

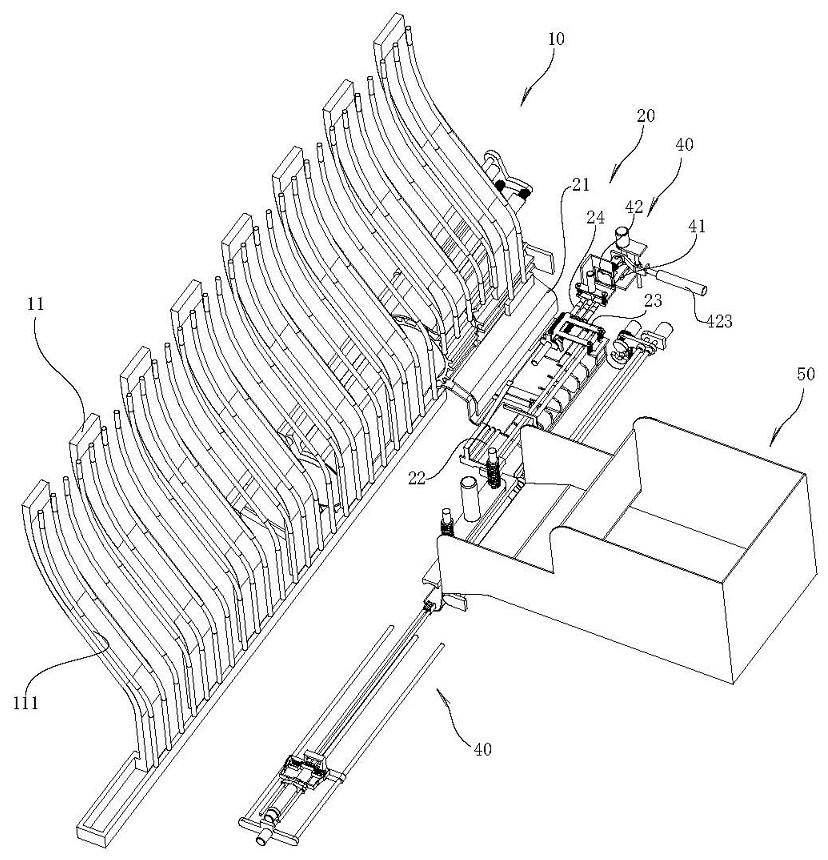

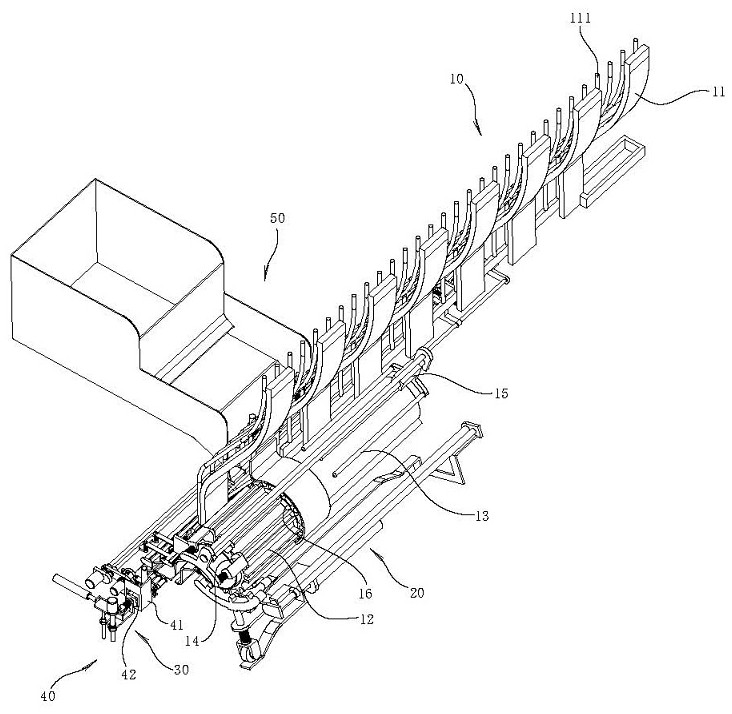

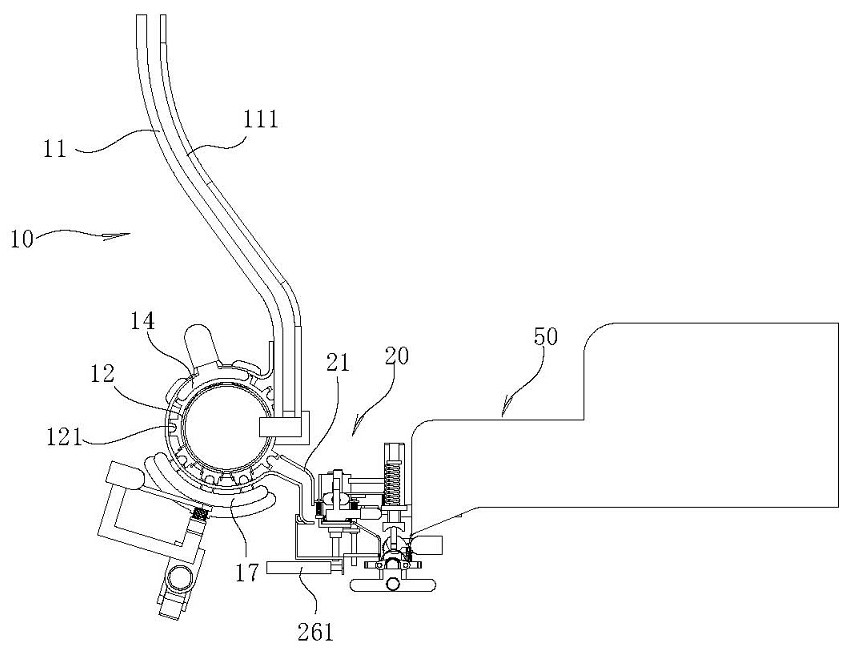

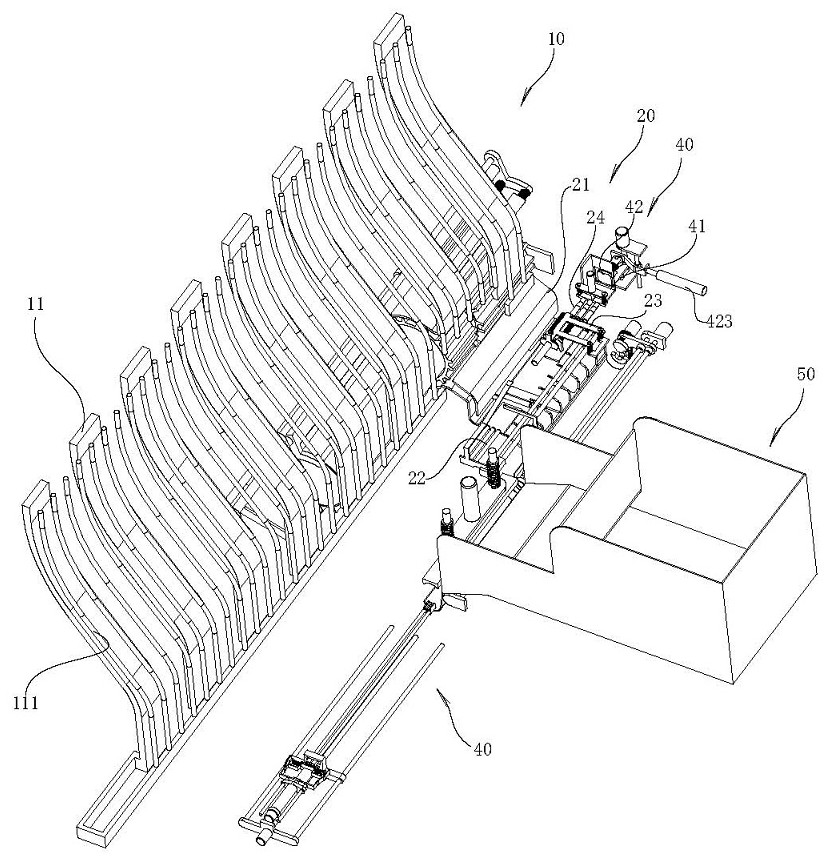

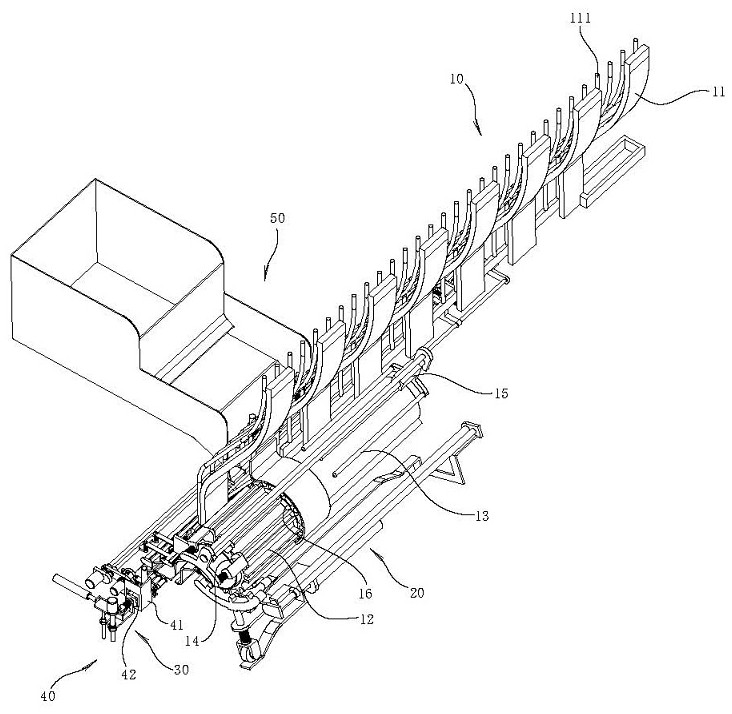

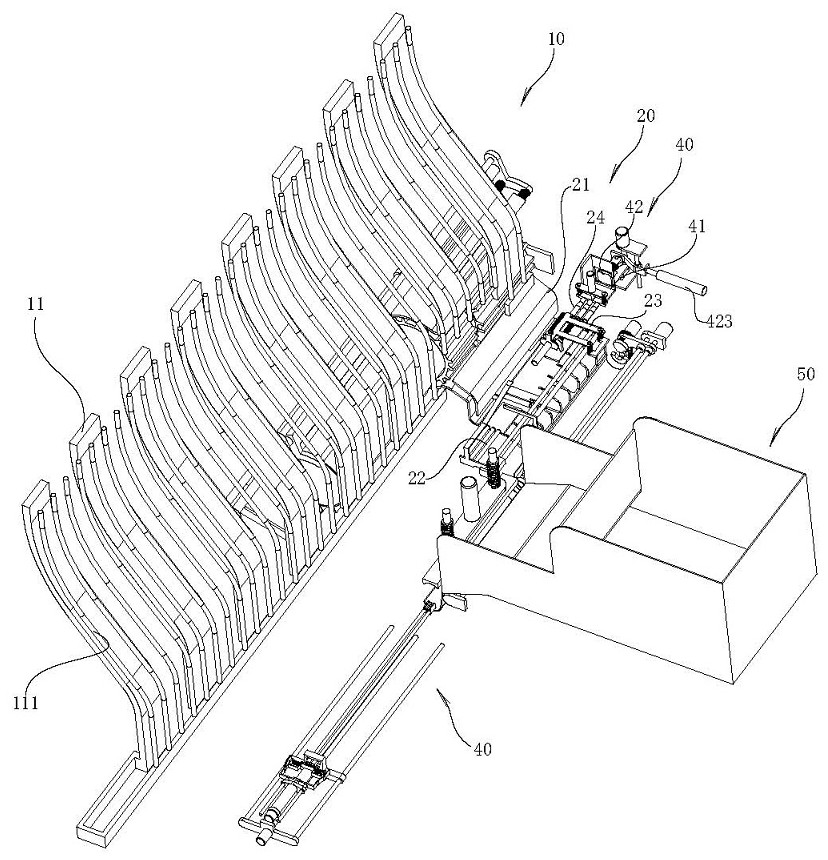

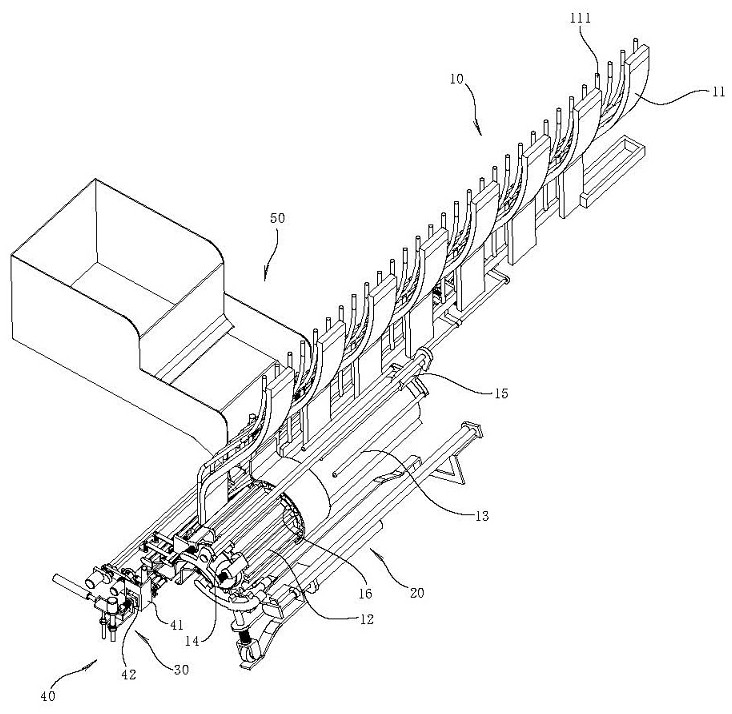

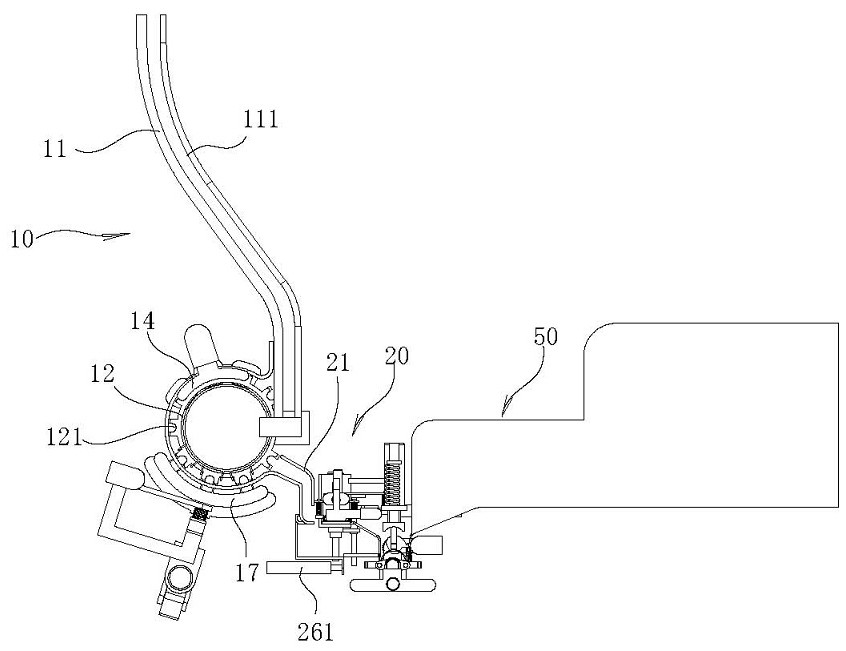

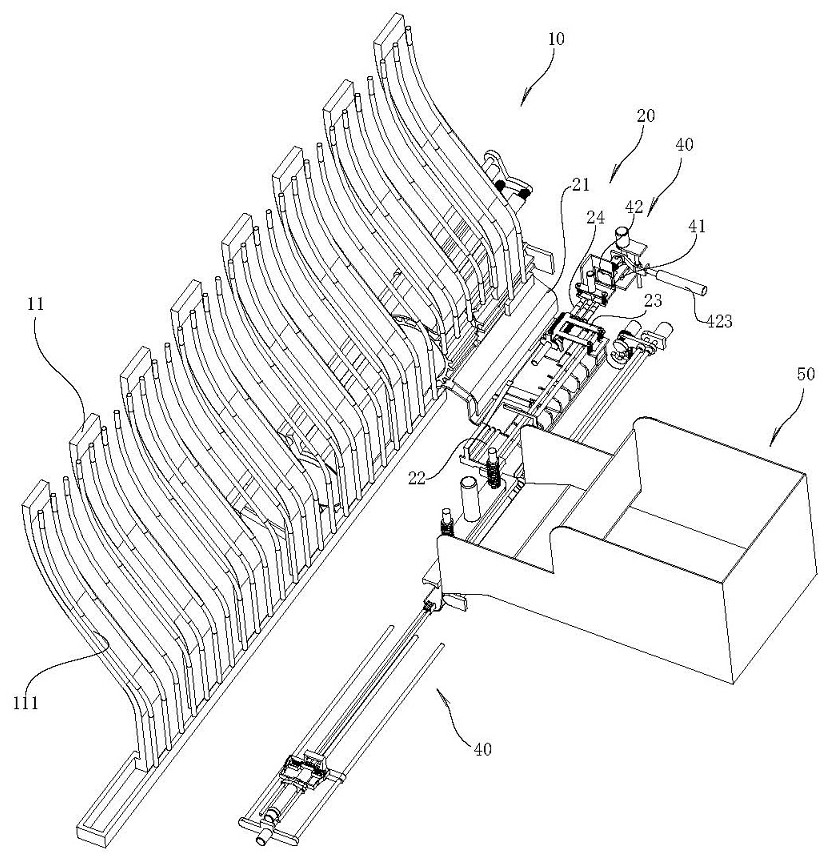

Electric appliance wire production system

ActiveCN111884009ARealize plug-in production operationsGuarantee product qualityContact member assembly/disassemblyProcess engineeringProduction quality

The invention relates to an electric appliance wire production system which comprises a wire harness leading-out device, a wire harness plugging device is arranged at an outlet of the wire harness leading-out device, a plug feeding device is arranged beside the wire harness plugging device, and a plug positioning device is arranged at an outlet of the plug feeding device. The wire harness pluggingdevice is used for enabling a wire harness wiring needle to be in plugging fit with a positioning hole in a plug. When an electric appliance wire is produced, the wire harness is led out to the position of the wire harness inserting device through the wire harness leading-out device, then the plug feeding device is started, a single plug is led out to the position of the plug positioning device,thus positioning operation of the single plug is realized, then the wire harness plugging device is started, multiple groups of wire harnesses are plugged into the positioning holes of the plug, plug-in production operation of the wire harnesseses is further realized, and the production efficiency of the wire harnesses can be effectively improved while the production quality of the wire harnessesis ensured.

Owner:YJH ELECTRICAL EQUIP

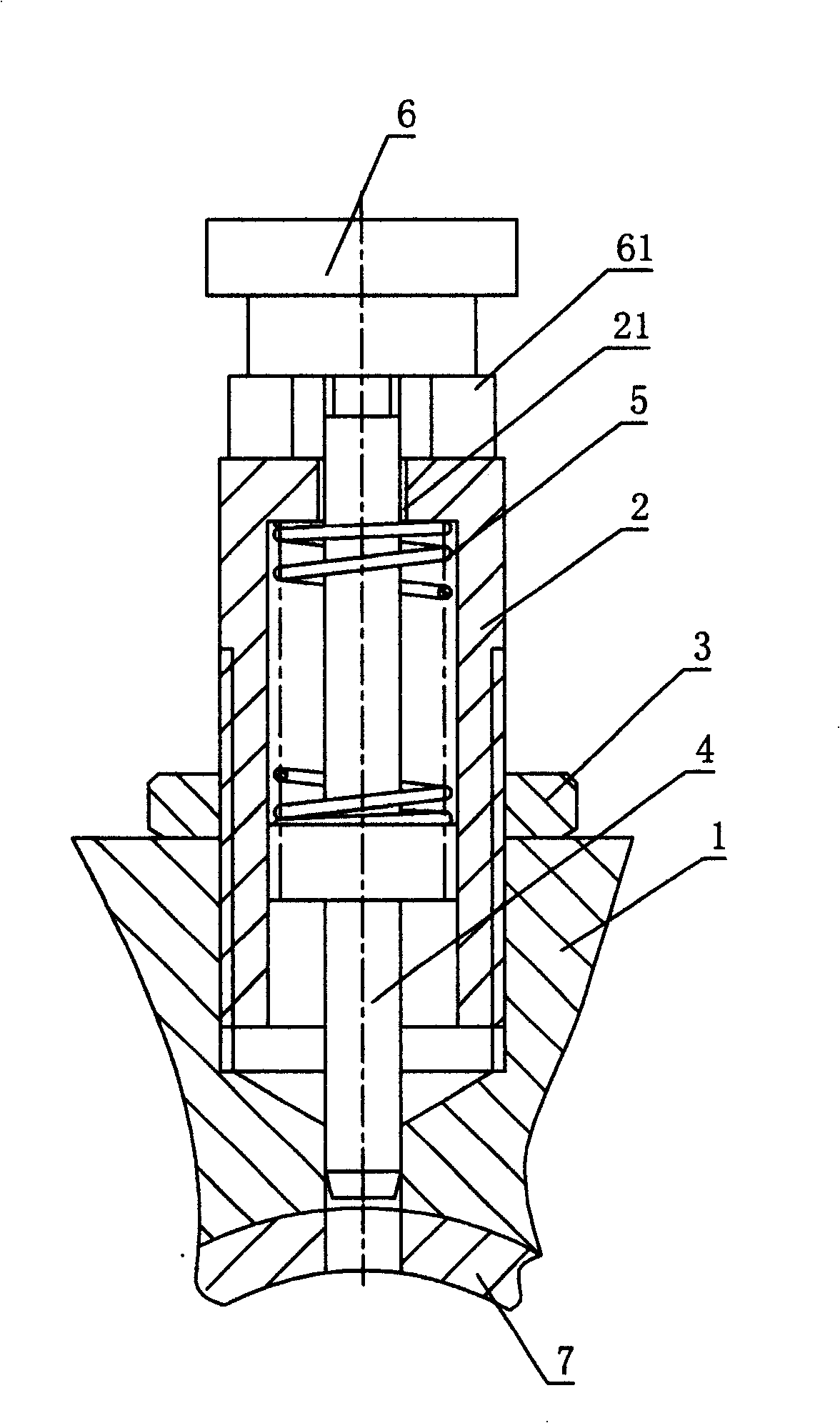

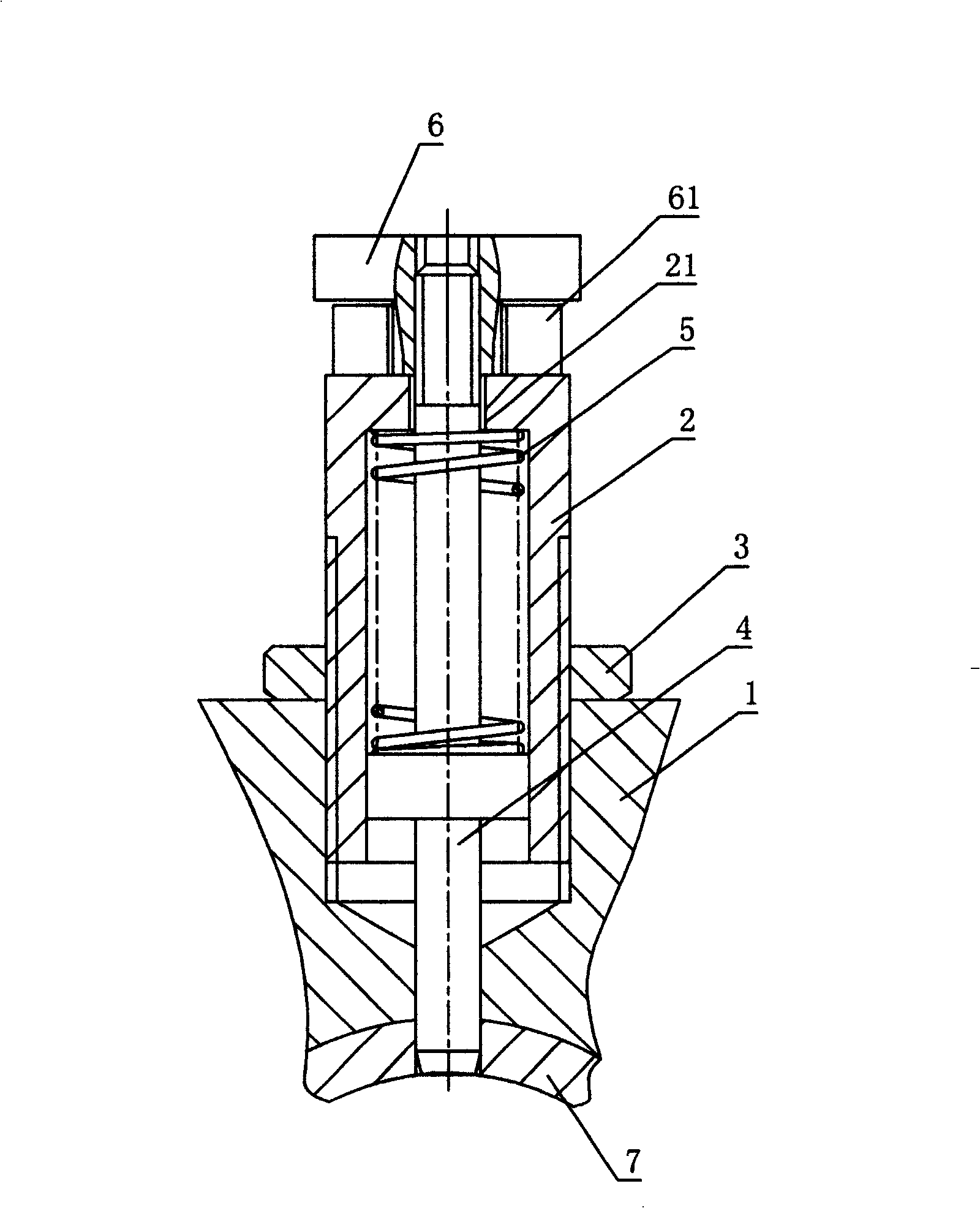

Manual positioning device of moving component

InactiveCN101244522AMeet the requirements of machining accuracyEconomicalPrecision positioning equipmentWork holdersEngineeringMachining

The invention discloses a manual positioning device for a moving element, comprising a body which is provided with a locating hole, a tubular bearing is fixedly arranged on the locating hole of the body through a fixing device, a locating pin which one end can extend out of the locating hole of the body is arranged in the lumen traversing the bearing, the other end of the locating pin is provided with a handle; between the locating pin and the bearing is provided with a promoting device for promoting the locating pin to extend out of the locating hole of the body; between the handle and the bearing is provided with a control device for controlling the locating pin to extend out of the locating hole of the body. The positioning device has the advantages that the location operation of moving element can be achieved in the small batch machining production, not only meet the requirement of processing precision, but also has a better economy.

Owner:WEICHAI POWER CO LTD

Product positioning device and method

ActiveCN108381415BImplement positioning operationsHigh positioning accuracyWork holdersApparatus for force/torque/work measurementControl systemStructural engineering

The invention provides a product positioning device and method. The product positioning device comprises a bottom plate, a product placement seat arranged on the bottom plate, and at least two groupsof pushing assemblies located on the periphery of the product placement seat, and a product to be positioned is placed on the product placement seat; each pushing assembly comprises a pushing air cylinder fixed on the bottom plate and a dense pin module arranged on the corresponding pushing air cylinder; each dense pin module comprises a rod pin fixing block and a resistor fixing block fixedly connected with the rod pin fixing block, rod pins which are regularly distributed are arranged on the rod pin fixing blocks, and force sensitive resistors which are fixedly connected with the rod pins are arranged on the resistor fixing blocks; the pushing air cylinders are used for pushing the dense pin modules to move towards the side close to the product to be positioned, and the product to be positioned is limited and fixed through the rod pins; and the force sensitive resistors are used for detecting the deformation amount when the rod pins are in contact with the product to be positioned, and an external control system determines the current positioning position of the product to be positioned through the deformation amount information. By using the device and the method, universal typeaccurate positioning of the product can be realized.

Owner:GOERTEK INC

Electric wire production system

ActiveCN111884009BRealize plug-in production operationsGuarantee product qualityContact member assembly/disassemblyProcess engineeringCable harness

The invention relates to an electrical wire production system, comprising a wire harness exporting device, a wire harness plugging device is provided at the outlet of the wire harness exporting device, a plug feeding device is arranged on the side of the wire harness plugging device, and the plug feeding device The outlet of the plug is provided with a plug positioning device. The wire harness plug-in device is used to form a plug-in fit between the wiring harness pin and the positioning hole on the plug. Then the plug feeding device is started, and the single plug is exported to the position of the plug positioning device, so as to realize the positioning operation of a single plug, and then the wiring harness insertion device is started, and multiple sets of wiring harnesses are inserted into the positioning holes of the plug. In order to realize the plug-in production operation of the wire harness, the system can effectively improve the production efficiency of the wire harness while ensuring the quality of the wire harness production.

Owner:YJH ELECTRICAL EQUIP

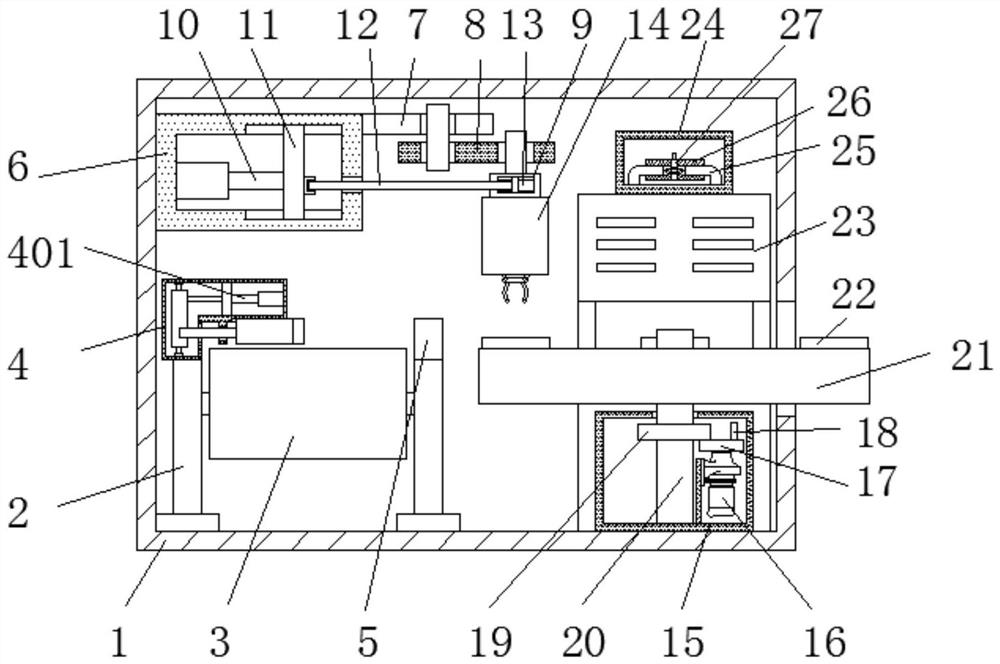

Production equipment with reaction liquid flow rate control function for microwave reactor processing

InactiveCN112588223AImplement positioning operationsRealize the pinch operationProcess control/regulationEnergy based chemical/physical/physico-chemical processesControl engineeringEngineering

The invention discloses production equipment with a reaction liquid flow rate control function for microwave reactor processing. The equipment comprises a main body frame, a bracket is fixedly mountedat the bottom end of the inner wall of the main body frame, a conveyor belt is mounted on the inner wall of the bracket, a positioning frame is welded at the top end of the bracket, the inner wall ofthe positioning frame is fixedly connected to a fixed positioning block which is located at the top end of the bracket and away from the main body frame, a clamping and conveying frame is welded to the position, located on the inner wall of the main body frame, of the upper portion of the positioning frame, and a rotating plate is welded to the outer wall of the clamping and conveying frame. According to the production equipment with a reaction liquid flow rate control function for microwave reactor processing, by arranging a special-shaped cam, a first pneumatic push rod in the positioning frame works to drive a first push plate to move, the first push plate drives the special-shaped cam to rotate through a first connecting rod, the special-shaped cam drives a movable positioning block to move through a second connecting rod, and the movable positioning block is of a concave design. Through cooperation of the fixed positioning block, the positioning operation on a machined workpieceis realized.

Owner:嘉兴惠韫智能科技有限公司

Transformer easy to assemble and position

PendingCN114823095AReasonable and ingenious structural designStable qualityTransformers/reacts mounting/support/suspensionTransformers/inductances coils/windings/connectionsMagnetic coreStructural engineering

The invention discloses a transformer easy to assemble and position. The transformer comprises a framework, a magnetic core and a coil, the magnetic core comprises two E-shaped magnetic core parts which are mutually spliced front and back, the framework is arranged between the two E-shaped magnetic core parts, each E-shaped magnetic core part comprises a core body, a side edge and a middle column, the side edge and the middle column are arranged on the core body, a through hole is formed in the framework, the middle columns of the two E-shaped magnetic core parts are connected through the through hole, and a positioning edge extending towards the core body is arranged at the upper end of the framework. A positioning groove matched with the positioning part is formed in the core body, the positioning part is arranged at the lower end of the framework, and the lower end of the core body is limited by the upper end of the positioning part; thus, through the design of the framework and the magnetic core, the positioning grooves are connected with the positioning edges in a matched mode, and the positioning portions are connected with the lower end of the magnetic core in a matched mode, so that positioning operation of the magnetic core on the framework is achieved, assembling is firm, follow-up operation of fixing the magnetic core and the framework through glue is facilitated, structural design is ingenious and reasonable, and quality is stable and consistent; the production efficiency of the transformer is improved, the cost is low, and the application range is wide.

Owner:东莞市慧创电子有限公司

A kind of electric wire and its production method

ActiveCN111884013BRealize plug-in production operationsGuarantee product qualityContact member assembly/disassemblyElectric wireProduction quality

The invention relates to an electric wire and its production method, so that a single wire harness is arranged in an alignment groove on an alignment roller of a wire harness lead-out device, and a wire harness wiring pin alignment mechanism is used to perform an alignment operation on multiple wire harnesses; The single wire harness in the slot moves, and the wire harness wiring pin is plugged into the positioning hole of the plug on the plug positioning device; the plug on the plug positioning device is pushed out into the protective sleeve threading device; the protective sleeve threading mechanism is activated, so that The protective sheath is put on multiple sets of tightened wire harnesses, and then the sheathing operation of the protective sheath is completed. This method can effectively improve the production efficiency of the wire harness while ensuring the production quality of the wire harness.

Owner:YJH ELECTRICAL EQUIP

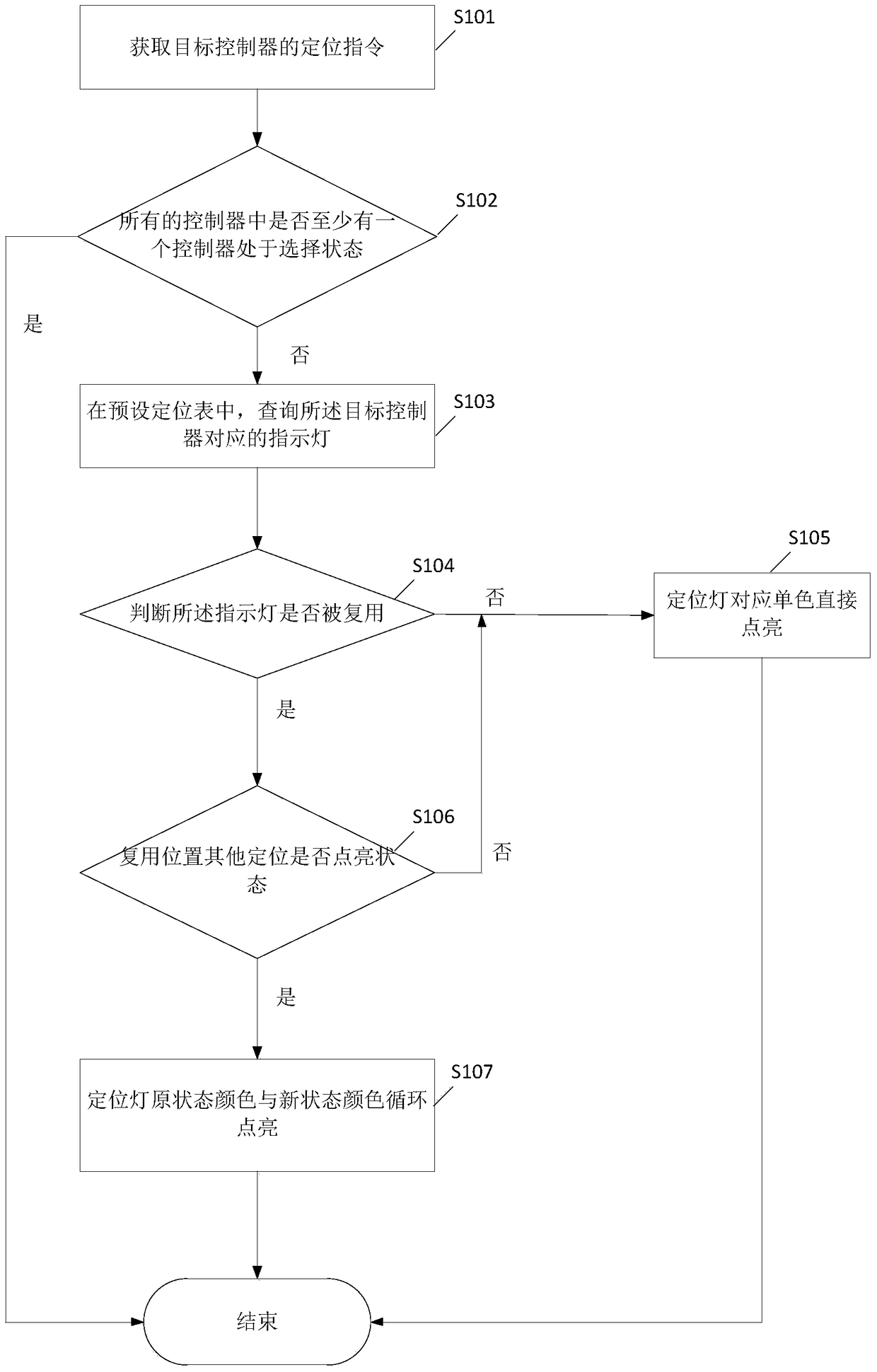

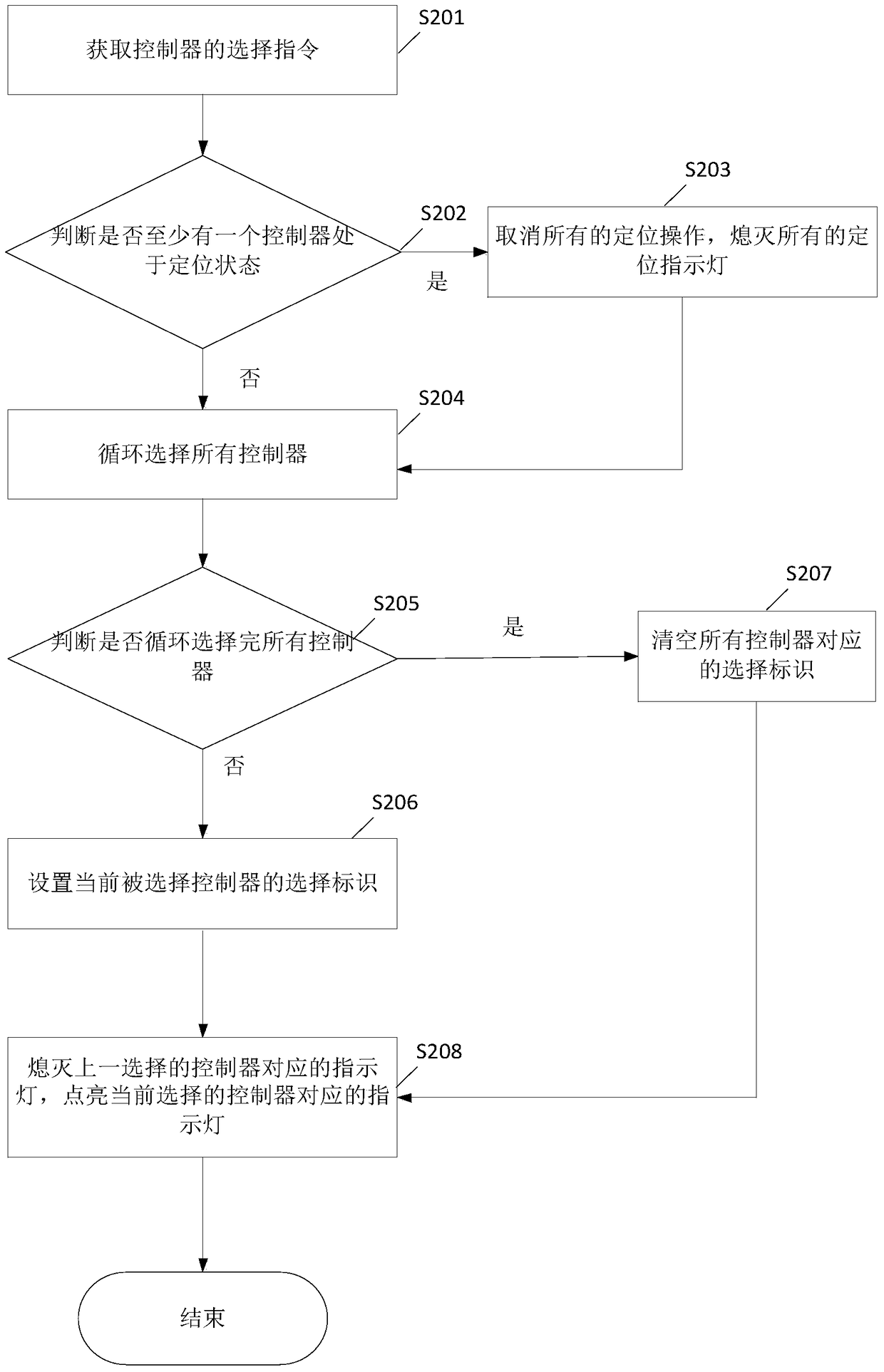

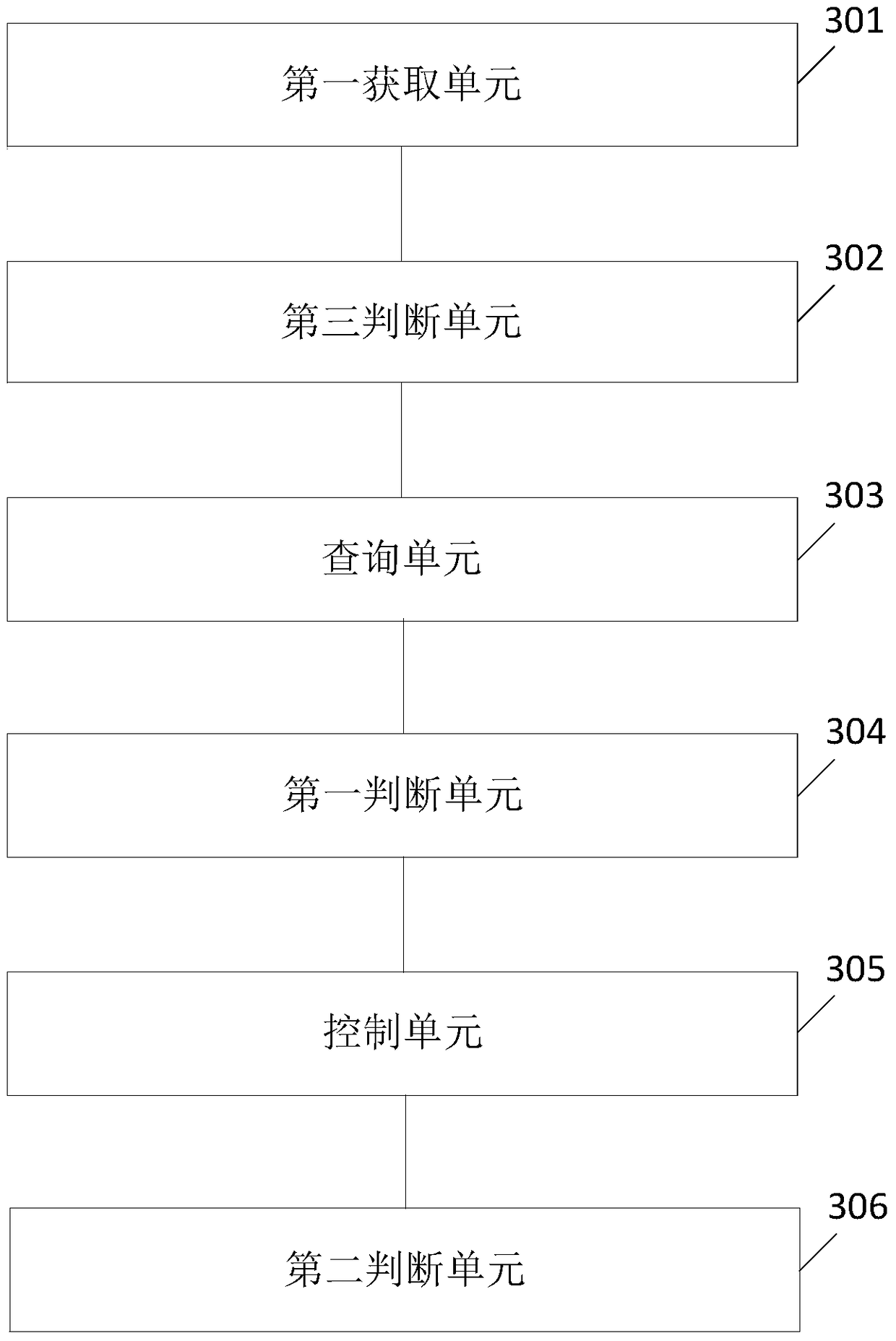

A multi-controller positioning control method and system

ActiveCN105242581BImplement positioning operationsReduce usageProgramme control in sequence/logic controllersTarget controlPosition control

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

Electrical wiring harness and plug installation

ActiveCN111884010BRealize plug-in production operationsGuarantee product qualityContact member assembly/disassemblyCable harnessElectrical wiring

The invention relates to an electrical wire harness and plug installation device, comprising a wire harness lead-out device, an outlet of the wire harness lead-out device is provided with a wire harness plug-in device, and a plug feeding device is arranged beside the wire harness plug-in device, and the plug The outlet of the feeding device is provided with a plug positioning device, and the wire harness plug-in device is used to form a plug-fit between the wire harness terminal pin and the positioning hole on the plug. To the position of the wiring harness insertion device, and then the plug feeding device is activated, and a single plug is exported to the position of the plug positioning device, so as to realize the positioning operation of a single plug, and then the wiring harness insertion device is activated to insert multiple groups of wire harnesses into the plug. The system can effectively improve the production efficiency of the wire harness while ensuring the production quality of the wire harness.

Owner:YJH ELECTRICAL EQUIP

Self-debugging placing frame for Chinese zither teaching

InactiveCN114596830ARealize height adjustment operationRealize control operationMusical supportsEngineeringLever pressing

Owner:WEIFANG ENG VOCATIONAL COLLEGE

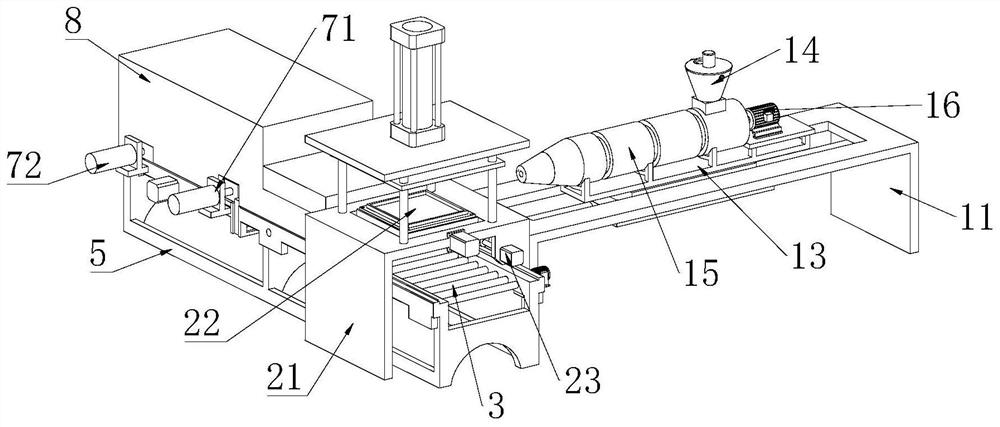

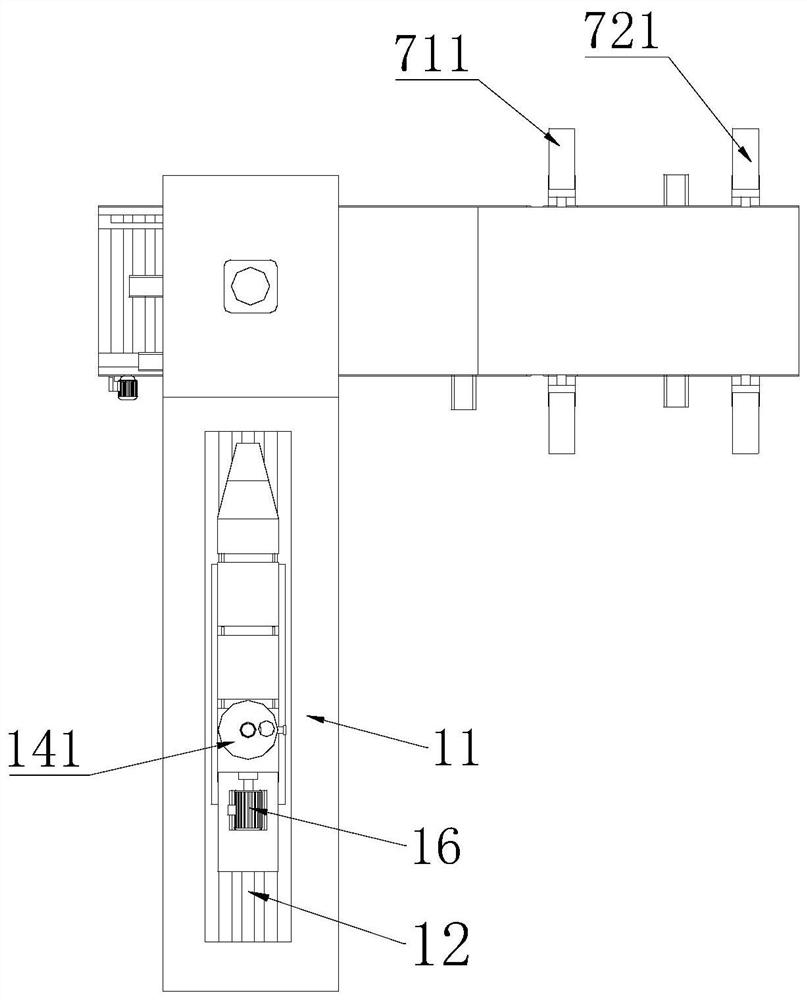

Glass injection molding mold and molding machine tool

ActiveCN113732866AMass productionRealize pressing automatic forming operationEdge grinding machinesGrinding drivesMolding machineSpiral blade

The invention relates to the technical field of glass processing, and provides a glass injection molding mold and molding machine tool. The glass injection molding mold and molding machine tool comprises a feeding mechanism, a molding mechanism, a conveying roller machine, a transition conveying mechanism, a support frame, a turn-over mechanism and a processing mechanism, wherein the feeding mechanism is arranged on one side of the molding mechanism; the conveying roller machine and the support frame are covered with a mounting cover plate; the feeding mechanism comprises a bearing table, a lead screw sliding table, a mounting support, a mixing assembly and an injection molding barrel; the bearing table is transversely arranged on one side of the molding mechanism; the lead screw sliding table is mounted at the inner top of the bearing table; the bottom of the mounting support is connected with the moving end of the lead screw sliding table; the injection molding barrel is fixed to the mounting support; a driving motor is arranged on the mounting support; a heater, a screw rod and a spiral blade are arranged in the injection molding barrel; the output end of the driving motor is connected with one end of the screw rod through a coupler; and the spiral blade is fixed to the screw rod.

Owner:JIANGSU HUIDA MEDICAL INSTR CO LTD

Auxiliary equipment for motor end cover processing

ActiveCN110524300BImplement positioning operationsEnsure consistencyMetal working apparatusElectric machineryControl theory

The invention belongs to the technical field of motor processing, specially relates to motor end cover plate machining auxiliary equipment that comprises a conversion assembly with a swing plate; oneside of the swing plate is fixedly connected with a first driving mechanism perpendicular to the swing plate; the output end of the first driving mechanism is fixedly connected with a supporting discparallel to the swing plate. A switching mechanism used for switching and clamping the motor end cover plate is fixedly connected to the outer ring of the side, away from the swing plate, of the supporting disc; the center of the supporting disc is movably sleeved with a rotating shaft; extending plates distributed along the axis of the rotating shaft in an array mode are fixedly connected to theouter ring of the end, away from the swing plate, of the rotating shaft, and U-shaped connecting plates are fixedly connected to the ends, away from the rotating shaft, of the extending plates. According to the motor end cover plate machining auxiliary equipment, positioning, feeding and discharging operation during motor end cover plate machining is achieved, continuous production can be achievedin cooperation with a machine tool, the situations that a traditional manual feeding mode is low in efficiency and high in labor intensity, and potential safety hazards exist are changed, and the motor end cover plate machining efficiency is improved.

Owner:中擎电机有限公司

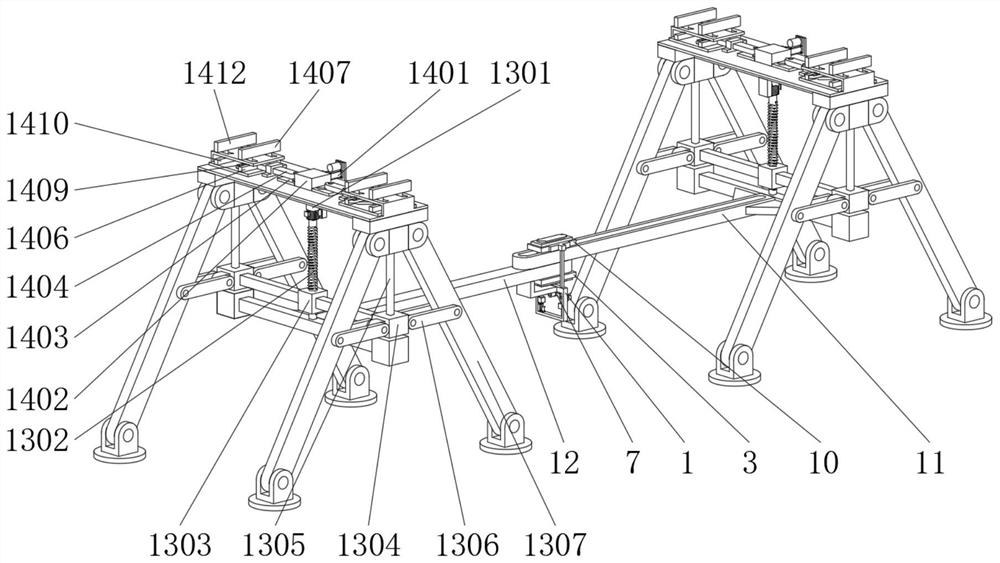

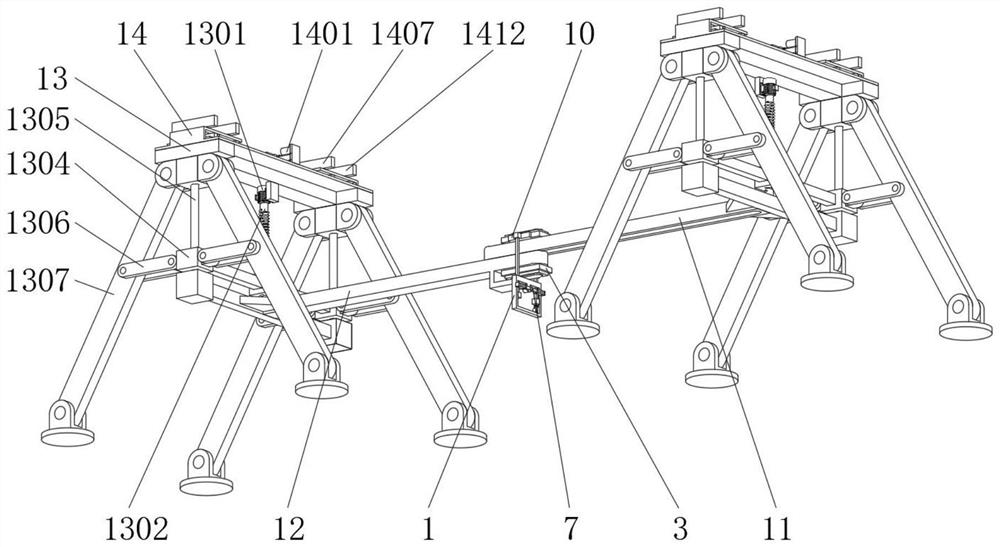

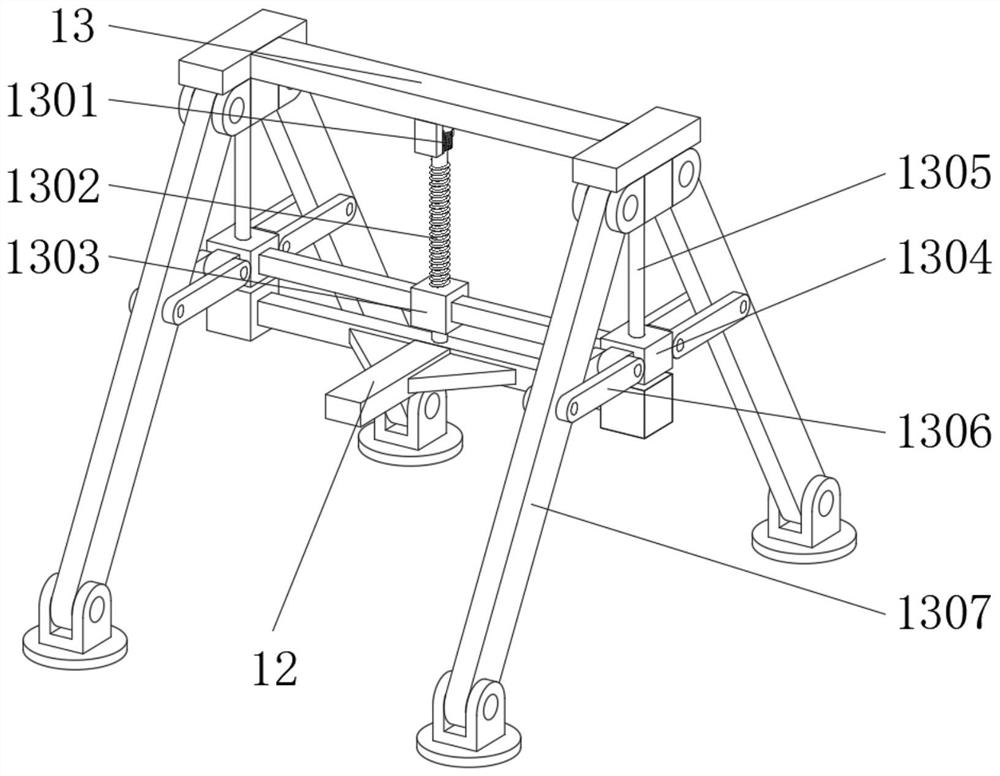

A Multipurpose Concrete Column Form Positioning Device

ActiveCN110857590BImplement positioning operationsReduce positioning workloadForms/shuttering/falseworksBuilding material handlingStructural engineeringMechanical engineering

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Automatic tissue slice sealing box

ActiveCN112747990AEasy to operateImprove adaptabilityPreparing sample for investigationMachiningAutomation

The invention discloses an automatic tissue slice sealing box. The automatic tissue slice sealing box comprises a box body fixed to a rack, a liquid dropping assembly, a slide dragging assembly, a first moving assembly and a second moving assembly. The liquid dropping assembly comprises a base body, the base body is provided with a liquid inlet, a liquid dropping opening and a liquid dropping pipeline, the slide dragging assembly comprises a suction cup with a downward opening and a negative pressure formed in the opening, the first moving assembly comprises a first guide rail and a first driving device, and the first driving device drives a moving frame to move in the horizontal direction of the first guide rail; the second moving assembly comprises a second driving device, and the second driving device drives the first guide rail to move in the vertical direction. The base body of the liquid dropping assembly is provided with the liquid inlet, the liquid dropping opening and the liquid dropping pipeline in an integrated machining mode, the liquid dropping assembly and the slide dragging assembly are controlled by the first moving assembly and the second moving assembly to move together, the liquid dropping and slide covering processes are completed, operation is easy and convenient, and the automation control degree is high.

Owner:SHANDONG JUNTENG MEDICAL TECH CO LTD

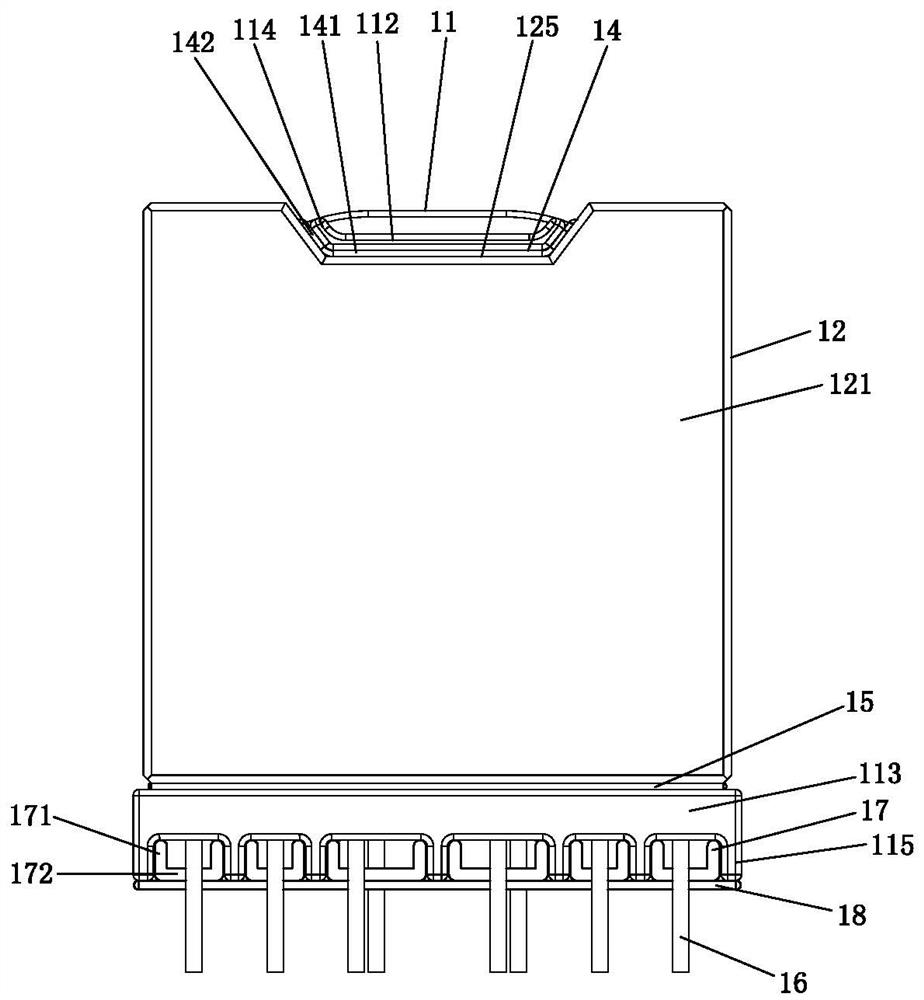

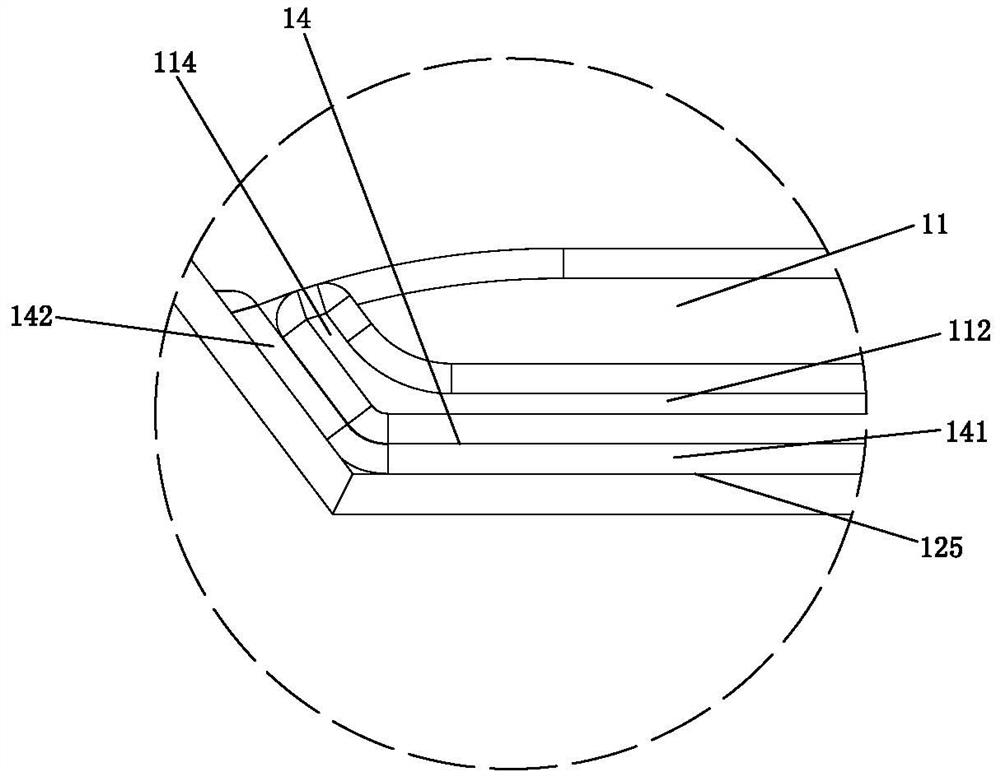

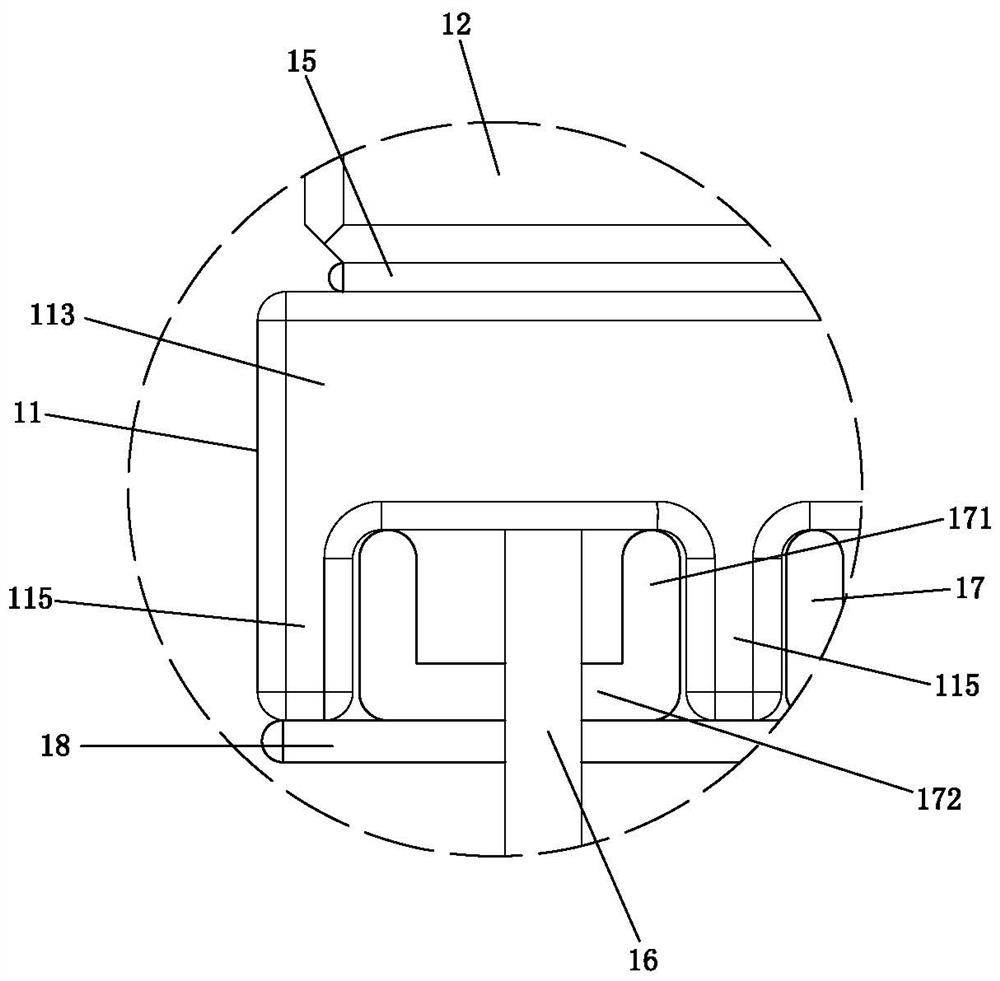

Automatic feeding equipment for LED bulb shells

ActiveCN113942812AGuaranteed towards unityPrecise positioningConveyorsControl devices for conveyorsEngineeringEquipment use

The invention aims to provide automatic feeding equipment for LED bulb shells. By means of the feeding device, efficient feeding of the LED bulb shells can be achieved, manpower is saved, and the feeding quality is guaranteed. The automatic feeding equipment comprises a supply bin, a feeding frame and a transferring device. The feeding frame is arranged on one side of the supply bin and provided with a conveying belt. A hopper, a conveying belt and a feeding platform are arranged in the supply bin. An installing groove is formed in the side wall of the hopper. The conveying belt is arranged in the installing groove. A discharging port of the conveying belt is connected with the side face of the feeding platform. Material baffles are arranged on a belt body of the conveying belt at intervals. An overturning device is further arranged in the supply bin.

Owner:海宁市海金照明有限公司

A flexible positioning mechanism

ActiveCN105499894BRealize flexible positioningImplement positioning operationsWelding/cutting auxillary devicesWork holdersFrame basedEngineering

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Pressure device with positioning structure for mechanical production and using method of pressure device

InactiveCN112792283ARealize clamping and fixingImplement positioning operationsForging/hammering/pressing machinesPhysicsElectric machinery

The invention discloses a pressure device with a positioning structure for mechanical production and a using method of the pressure device. The pressure device comprises a device main body, a motor and an engine; a pressing seat is arranged above the device main body; the motor is fixedly mounted on the outer surface of the right side of the device main body; and a clamping and fixing mechanism is fixedly mounted on the upper surface of the pressing seat. According to the pressure device, by installing a clamping and fixing mechanism, a rotating mechanism, a pressing plate, a telescopic mechanism and a sliding mechanism, after a plate is placed on the upper surface of the pressing seat, a second gear rotates through connection of a rubber belt, and at the moment, a first meshing plate and a second meshing plate jointly do telescopic movement in the horizontal direction, so that horizontal telescopic control is performed on sliding blocks, and at the moment, through meshed connection of rack plates and first gears, positioning wheels conducts rotation control by installing transmission mechanisms, so that the periphery of a steel plate is clamped and fixed, and auxiliary positioning control over the steel plate is realized.

Owner:肖霜梅

Drilling device special for support part

PendingCN114769676AImplement positioning operationsPrecise positioningPositioning apparatusDrill jigsMachined surfaceEngineering

The invention provides a drilling device special for a support part, and belongs to the technical field of machining. The drilling device comprises a base, a positioning block, a supporting plate, a drilling plate, a drilling sleeve, a pressing sliding block, a support, an adjusting bolt and a J-shaped supporting block. When the drilling device is used for drilling a bracket part on a common drilling machine, the quick positioning operation of the part can be realized, and the positioning surface is a finish machining surface, so that the positioning precision is high; according to the device, positioning can be rapidly achieved through the finish machining surface of a part, clamping is rapidly achieved through the pressing sliding block, and the device is simple and convenient to use; meanwhile, the drilling device is made of common materials, and each part is simple in structure, convenient to machine, low in manufacturing cost, low in maintenance cost and suitable for mass production.

Owner:SHENYANG AIRCRAFT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com