Automatic feeding equipment for LED bulb shells

A technology for automatic feeding and equipment, which is applied to conveyor control devices, stacking of objects, and destacking of objects, etc. It can solve the problems of manpower consumption, low feeding efficiency, and inability to effectively improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

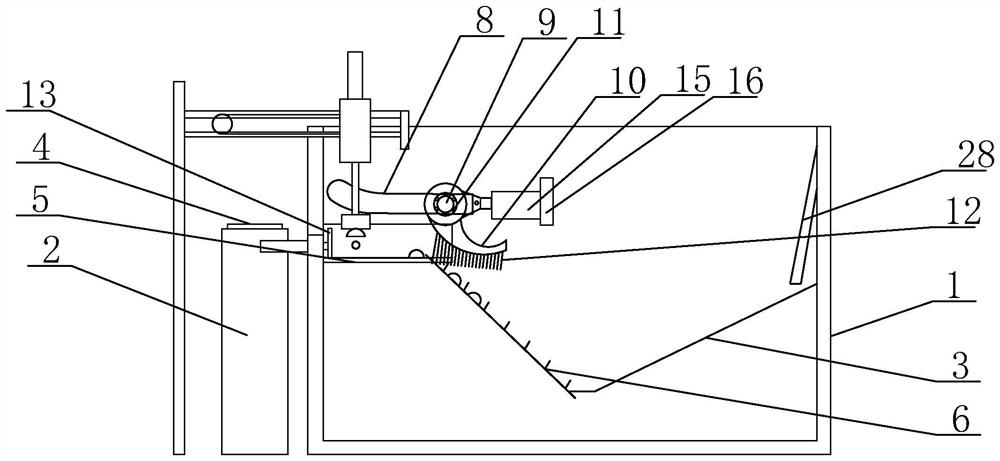

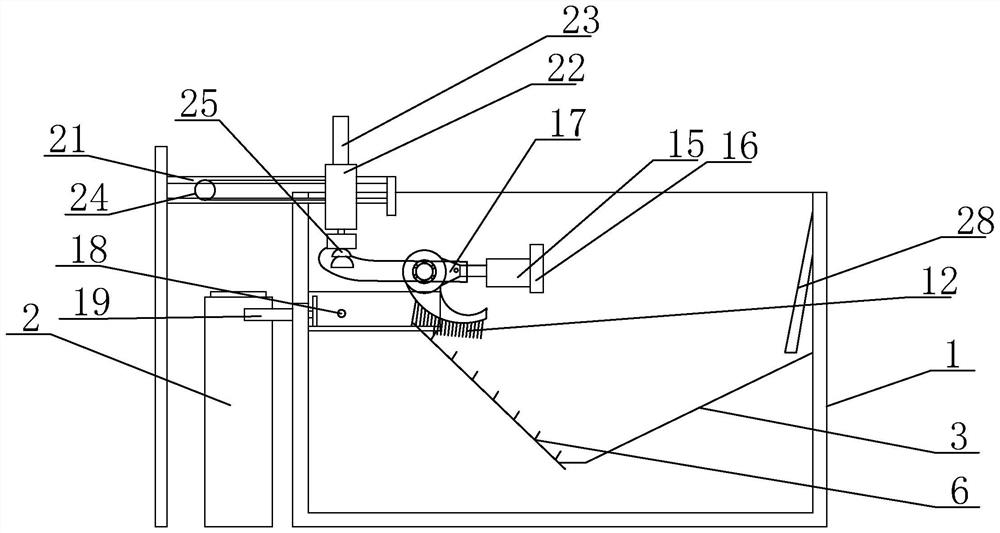

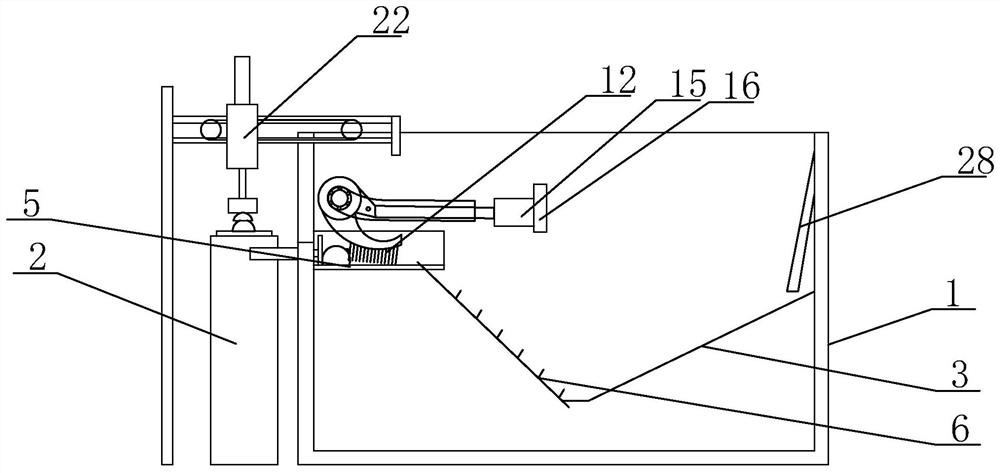

[0026] The present invention is described in further detail below:

[0027] For details, see Figure 1 to Figure 8 :

[0028] An automatic feeding device for LED bulbs, comprising a feeding bin 1, a feeding rack 2 and a transfer device, the feeding rack 2 is arranged on one side of the feeding bin 1, and the transferring device can transfer the LED bulbs from the feeding bin 2 Transfer to the feeding rack 2, the feeding rack 2 is provided with a conveyor belt 4, and the feeding bin 1 is sequentially provided with a hopper 3, a conveyor belt 6 and a feeding platform 5 along the conveying direction of the LED bulb, and the side wall of the hopper 3 There is an installation groove on the top, and a conveyor belt 6 is arranged in the installation groove. The discharge port of the conveyor belt 6 is connected to the side of the feeding platform 5, and the belt body of the conveyor belt 6 is provided with a material blocking plate 7 at intervals. An overturning device capable of o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com