Turning mechanism

A frame and organic technology, which is applied in the field of solid glue U-turn mechanism, can solve the problems of difficult solid glue, the inability to realize the uniform orientation of solid glue, and the high cost of manual feeding, so as to achieve the effect of consistent orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

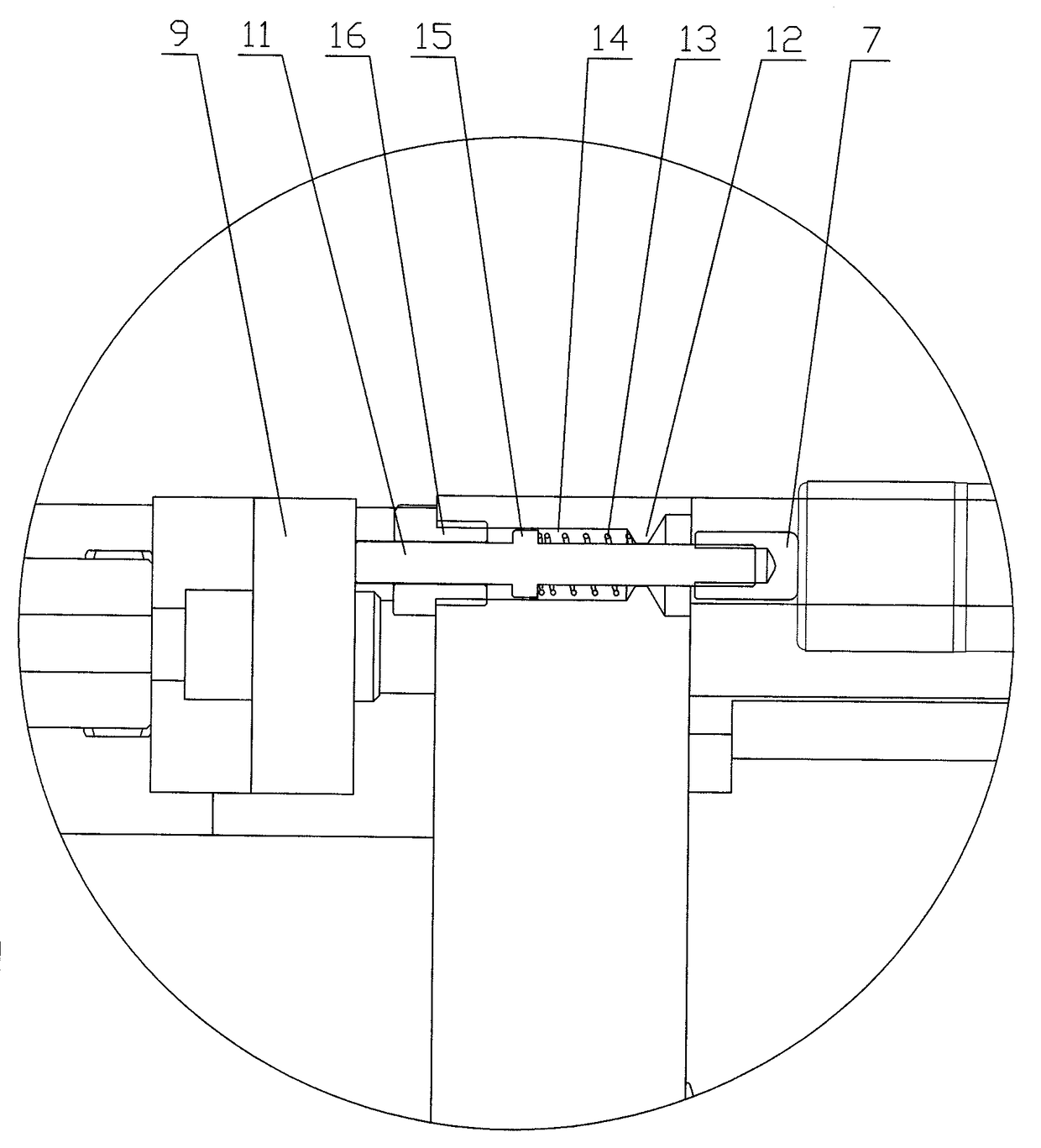

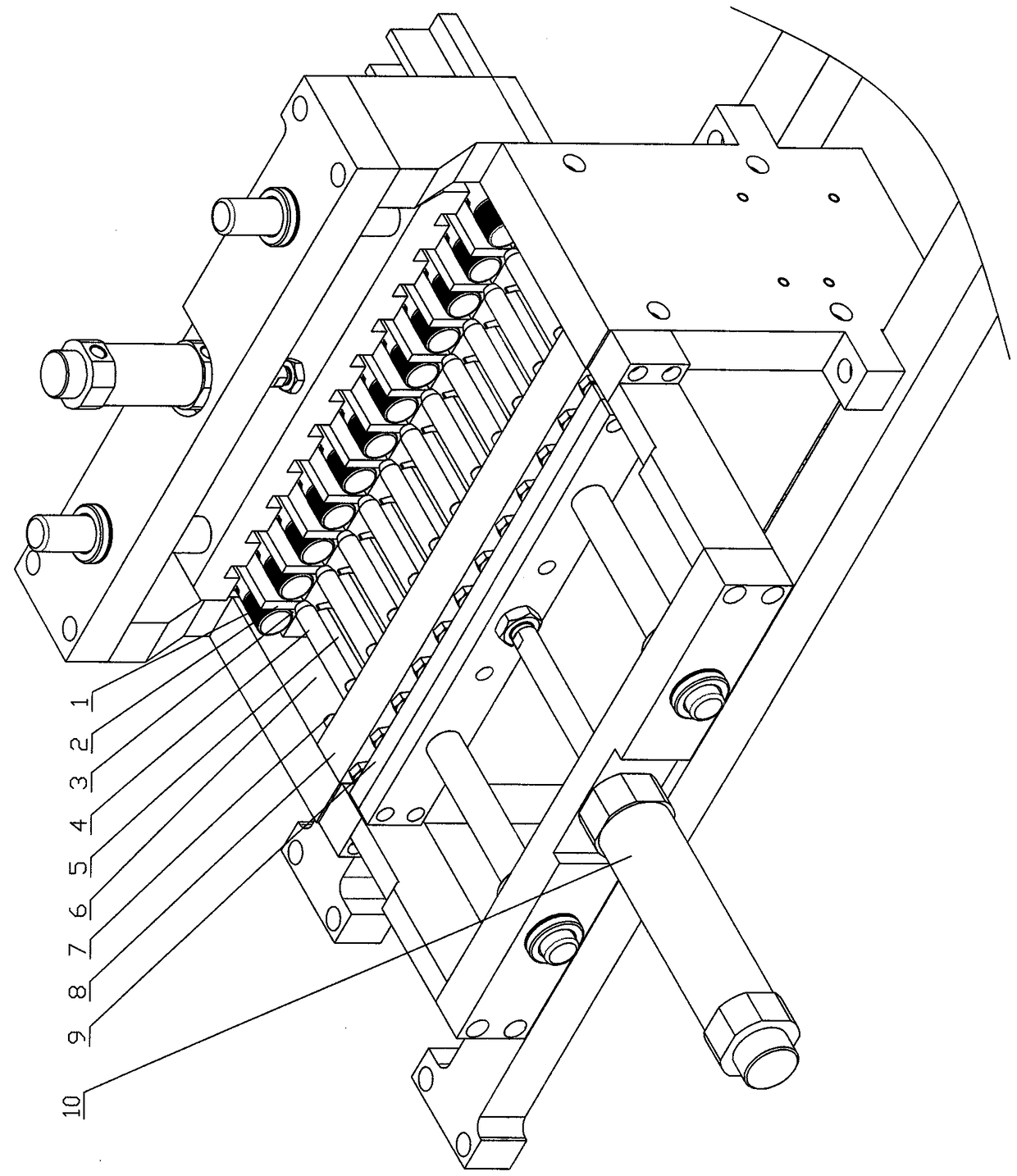

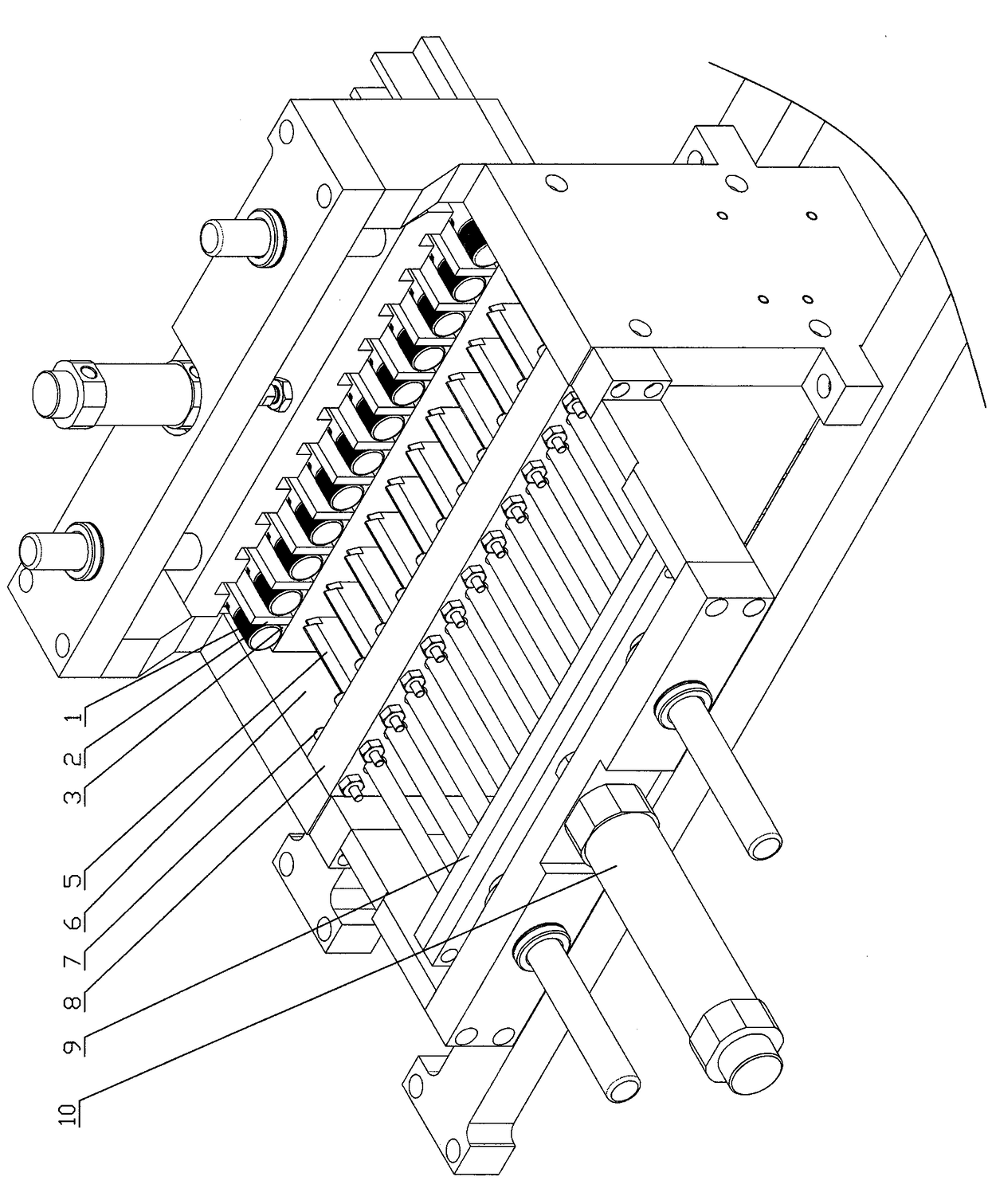

[0020] The details and working principles of the implementation modes and examples of the present invention will be described below with reference to the accompanying drawings. In this embodiment, the material conveying direction is the front, the front-back direction is the length direction, and the left-right direction is the width direction. One end of the material 1 is a plane, which is named as a plane end, and the other end has a groove, which is named as a groove end; this kind of U-turn The mechanism includes a frame, the frame is provided with a feed channel 3 and a guide channel 6, the length of the upper end of the guide channel matches the length of the material, and the lower end of the guide channel has a discharge port 17, The guide channel 6 is wide at the top and narrow at the bottom, and its vertical section is roughly Y-shaped; a stopper part that cooperates with the material 1 is provided in front of the feed channel 3, and the stopper part includes a push r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com