Transformer easy to assemble and position

A transformer and positioning part technology, applied in the field of transformers, can solve problems such as small application range, pin drop-off, and troublesome positioning of magnetic cores, and achieve the effects of ingenious and reasonable structural design, guaranteed strength and stability, and improved connection firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

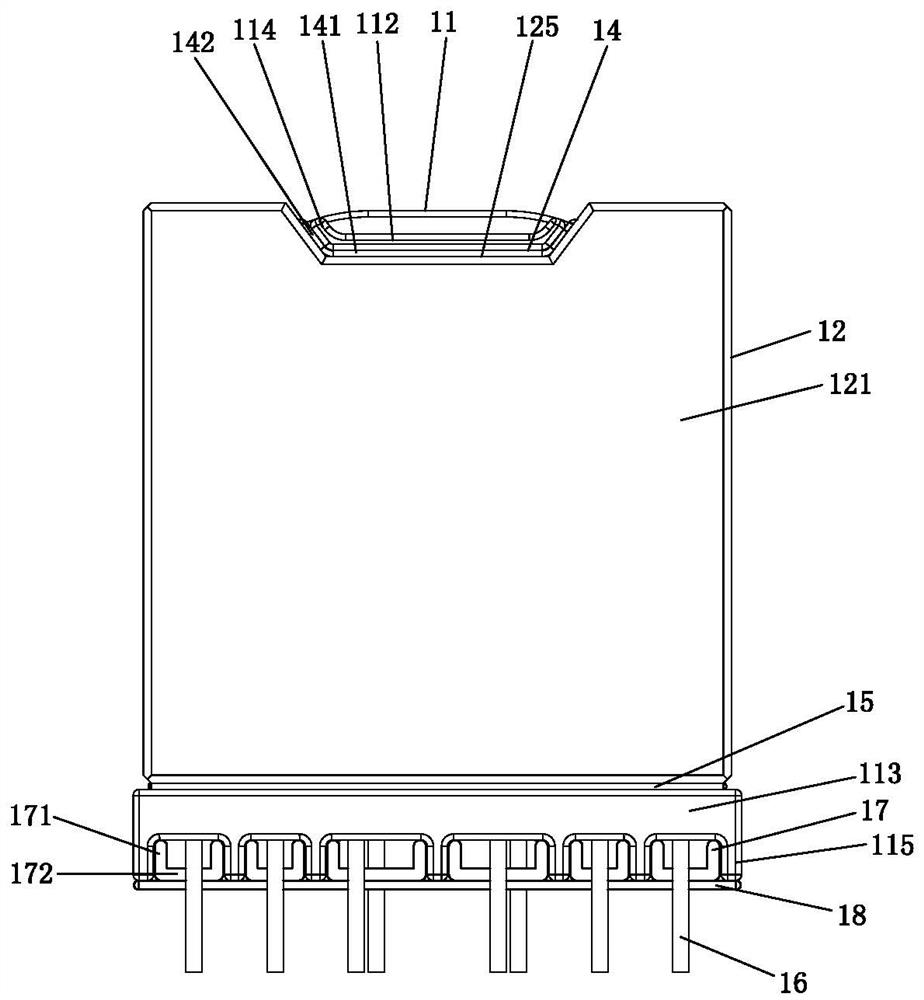

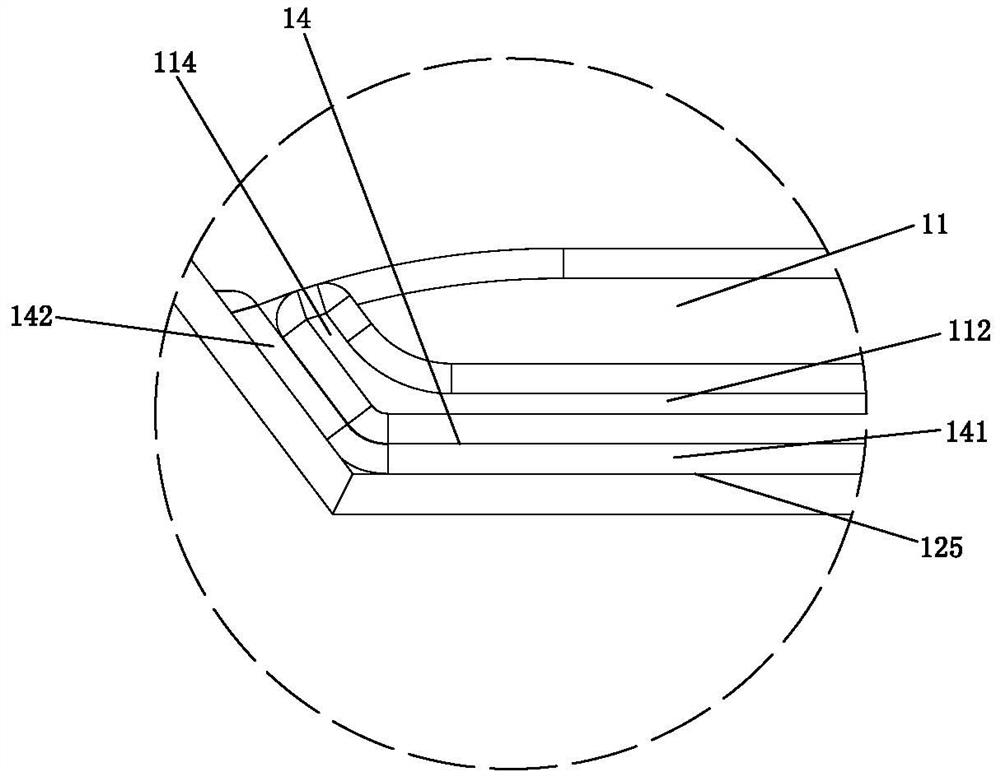

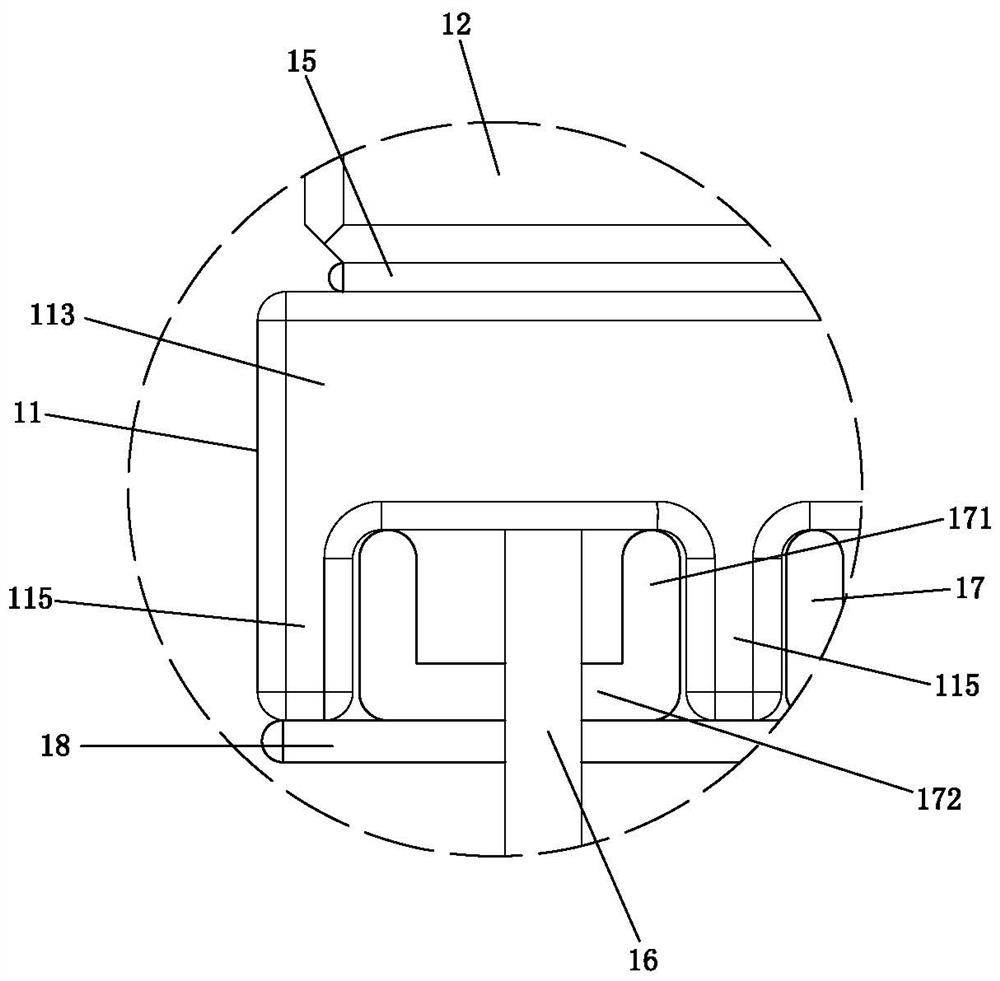

[0036] Please refer to Figure 1 to Figure 6 shown, which show the specific structure of an embodiment of the present invention.

[0037] A transformer that is easy to assemble and locate, comprising a bobbin 11, a magnetic core 12 and a coil (not shown in the figure); wherein:

[0038] The skeleton 11 has a winding slot, and the coil is wound in the winding slot;

[0039] The magnetic core 12 includes two E-shaped magnetic core pieces 121 spliced to each other front and rear, the skeleton 11 is arranged between the two E-shaped magnetic core pieces 121 , and the E-shaped magnetic core piece 121 includes a core body 122 . and the side edges 123 and the center column 124 arranged on the core body, the side edges 123 are respectively arranged on the left and right sides of the core body 122, and the center column 124 is arranged in the middle part of the core body 122 and located on the left and right sides Between the side edges 123 of the skeleton 11 , a through hole 111 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com