A flexible positioning mechanism

A flexible positioning and positioning mechanism technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor operation convenience, small adjustment amount, difficult to achieve functional requirements, etc., to increase space selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

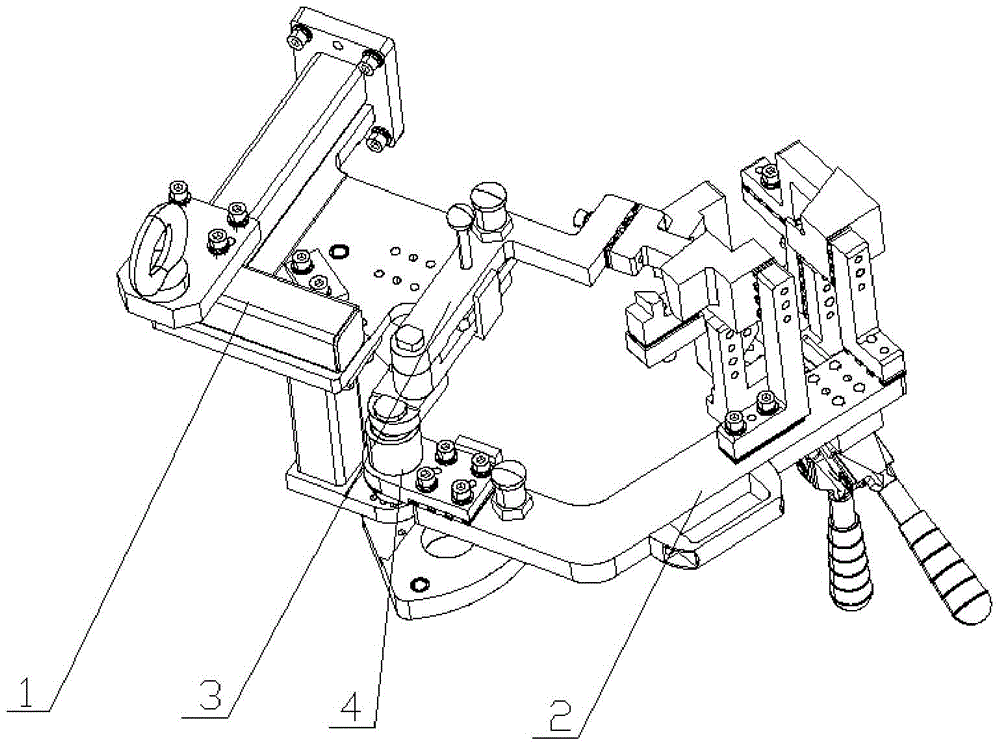

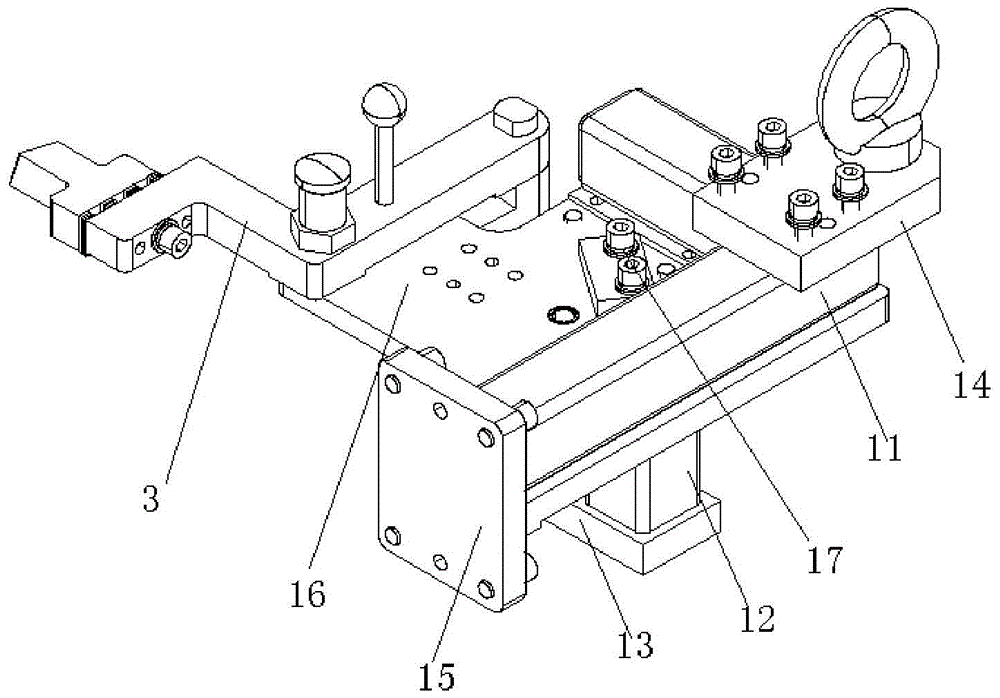

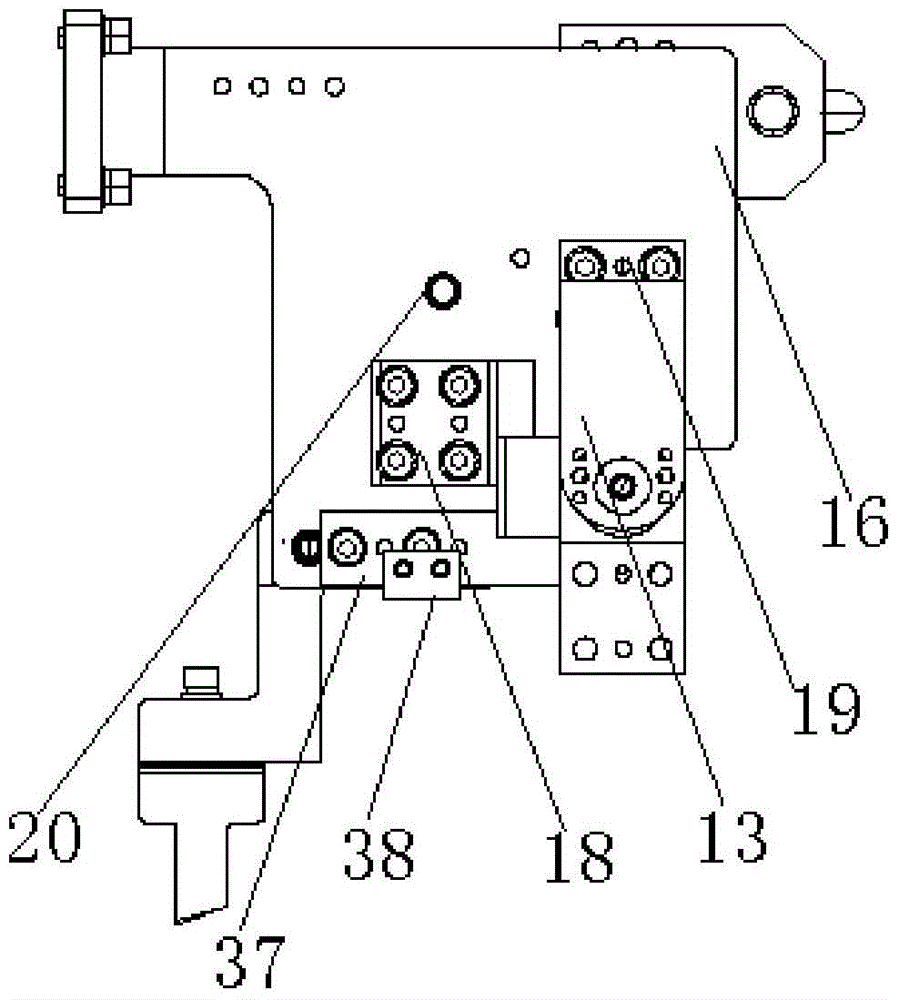

[0051] The invention provides a flexible positioning mechanism, such as Figure 1 to Figure 15 As shown, it includes a frame base 1 , a double rotation positioning mechanism 2 , a rotatable clamping mechanism 3 and a rotating shaft mechanism 4 .

[0052]The rotatable clamping mechanism 3 is connected to the frame base 1; the rotatable clamping mechanism 3 is connected to the double rotation positioning mechanism 2; the double rotation positioning mechanism 2 is connected to the shaft mechanism 4; The rotating shaft mechanism 4 is connected with the frame base 1 .

[0053] The frame base 1 includes an L-shaped frame beam 11, a rectangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com