A flexible positioning mechanism

A flexible positioning and clamping mechanism technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor operation convenience, small adjustment amount, and difficulty in realizing functional requirements, and achieve increased space selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

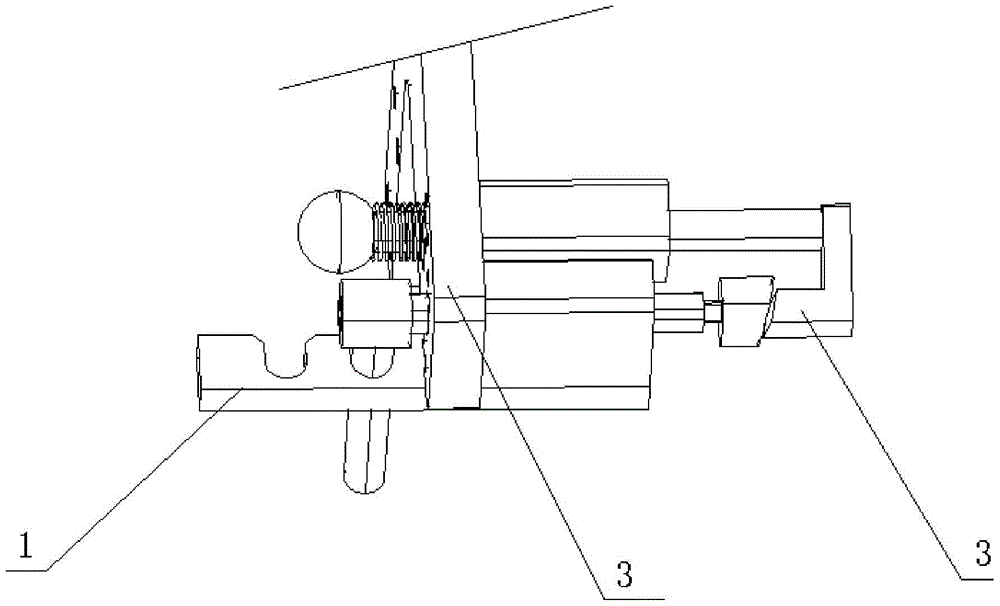

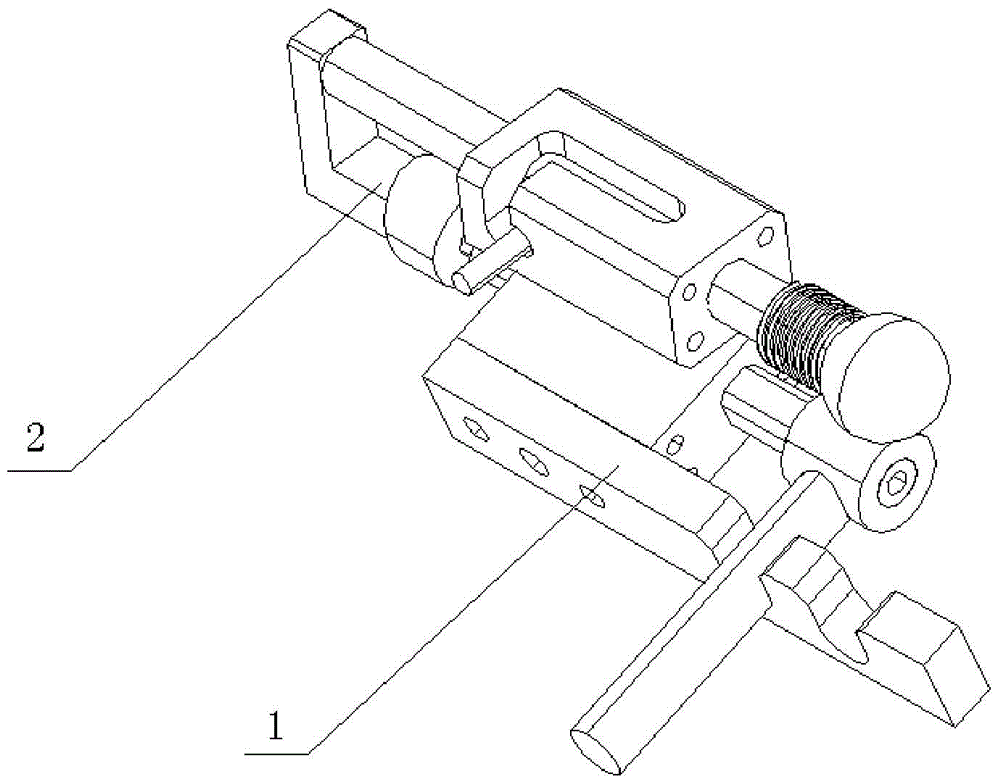

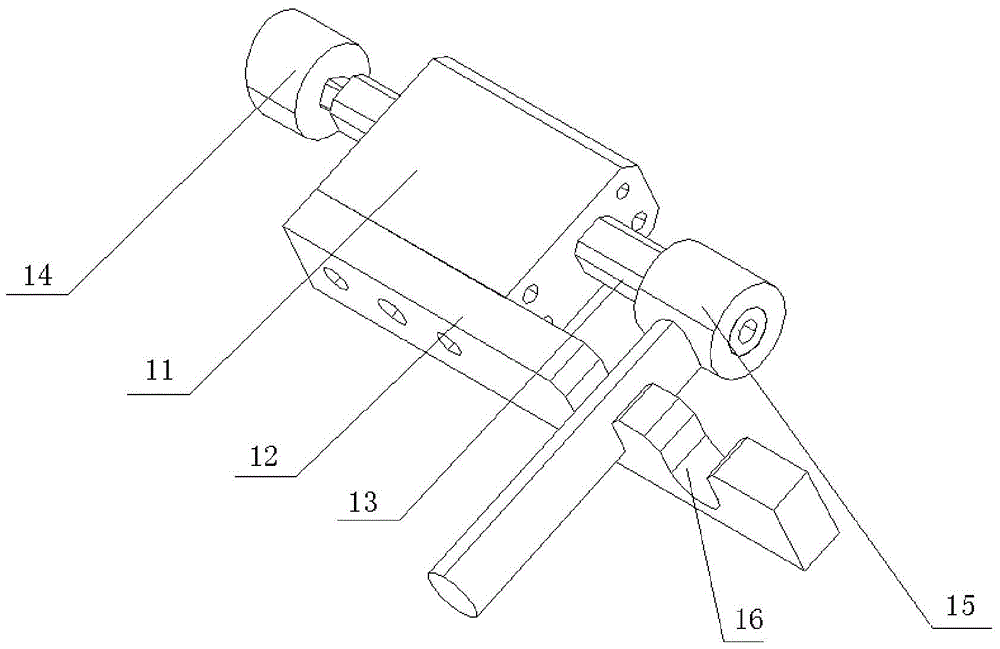

[0032] The invention provides a flexible positioning mechanism, such as Figure 1 to Figure 6 As shown, it includes a telescopic support mechanism 1 , a rotatable sliding clamping mechanism 2 and a connecting fixed plate 3 .

[0033] Both the telescopic supporting mechanism 1 and the rotatable sliding clamping mechanism 2 are fixed on the connecting and fixing plate 3 .

[0034] The connecting and fixing plate 3 is provided with a first through hole, a second through hole and an installation hole 31; through the installation holes, the flexible positioning mechanism is fixed on the tailor welding fixture. In each embodiment of the appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com