A Flexible Lifting Positioning Clamping Device for a Wire Rope Drum

A positioning clamping and wire rope technology, which is applied in the direction of hoisting device, hoisting device, spring mechanism, etc., can solve the problems of the main shaft damage of the clamping mechanism, the damage of the clamping shaft wire rope disc, and complex structure, etc., and achieve the protection of the clamp. Tightening mechanism, improving clamping efficiency and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

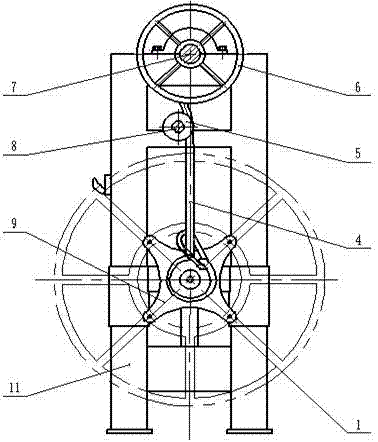

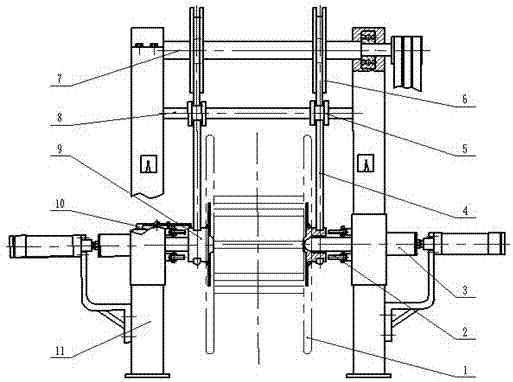

[0014] Such as figure 1 As shown, a wire rope reel flexible lifting positioning clamping device, the main structure includes an upper horizontal shaft 7, a lower horizontal shaft 8, a rope wheel 6, a lifting wire rope 4, a guide wheel 5, a fastening disc 9, a travel switch 10, and a column 11 , Clamping mechanism 3 and unloading mechanism 2. The sheave 6 is installed on the upper horizontal shaft 7, the lower horizontal shaft 8 is installed between the clamping mechanism 3 and the upper horizontal shaft 7, and the guide wheel 5 is installed on the On the lower horizontal axis 8 of the above, the fastening disc 9 is installed on the central position of the wire rope disc 1 . The clamping mechanism 3 is installed on the center of the upper longitudinal beam of the column 11, the travel switch 10 is installed on the top of the clamping mechanism 3, and the unloading mechanism 2 is installed on the clamping mechanism 3 inside. One end of the hoisting wire rope 4 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com