Localizable electric wire guiding pulley

A technology of guiding pulleys and wires, applied in the directions of overhead lines/cable equipment, the use of reels/photosensitive drums, etc., can solve the problems of insecurity, rapid wire rewinding, and no braking device, and achieve low cost , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

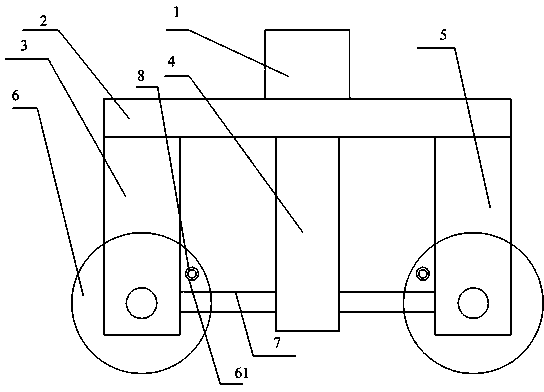

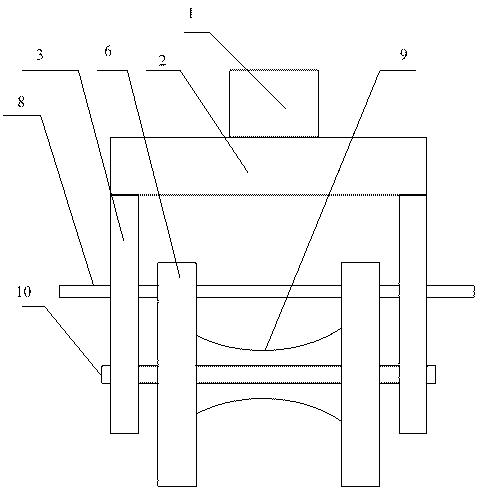

[0015] Such as Figure 1-Figure 2 shown.

[0016] Positionable wire guide pulley, including 2 pulley bodies, each pulley body is mainly composed of 2 chucks 6, 1 grooved roller 9, and 1 through shaft 10, and the 2 chucks 6 are respectively installed on the grooved roller 9 The two ends of the side, the through shaft 10 runs through the center of the chuck 6 and the center of the end face of the grooved roller 9, and the end faces of the two chucks 6 are provided with positioning through holes 61; it also includes a pulley frame body, which includes a hanging plate 1 , the lower side of the hanging plate 1 is connected with the main body block 2, and the lower side of the main body block is connected with 2 first splints 3, 2 middle limit splints 4, 2 second splints 5, and the 2 first splints 3 are respectively connected to the second splint On the two ends of the through shaft 10 of one pulley body, two second splints are respectively connected to the two ends of the through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com