Drilling device special for support part

A technology for drilling devices and parts, which is applied in positioning devices, drilling dies for workpieces, metal processing machinery parts, etc. problems such as large land area, to achieve the effect of simple structure, low cost and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

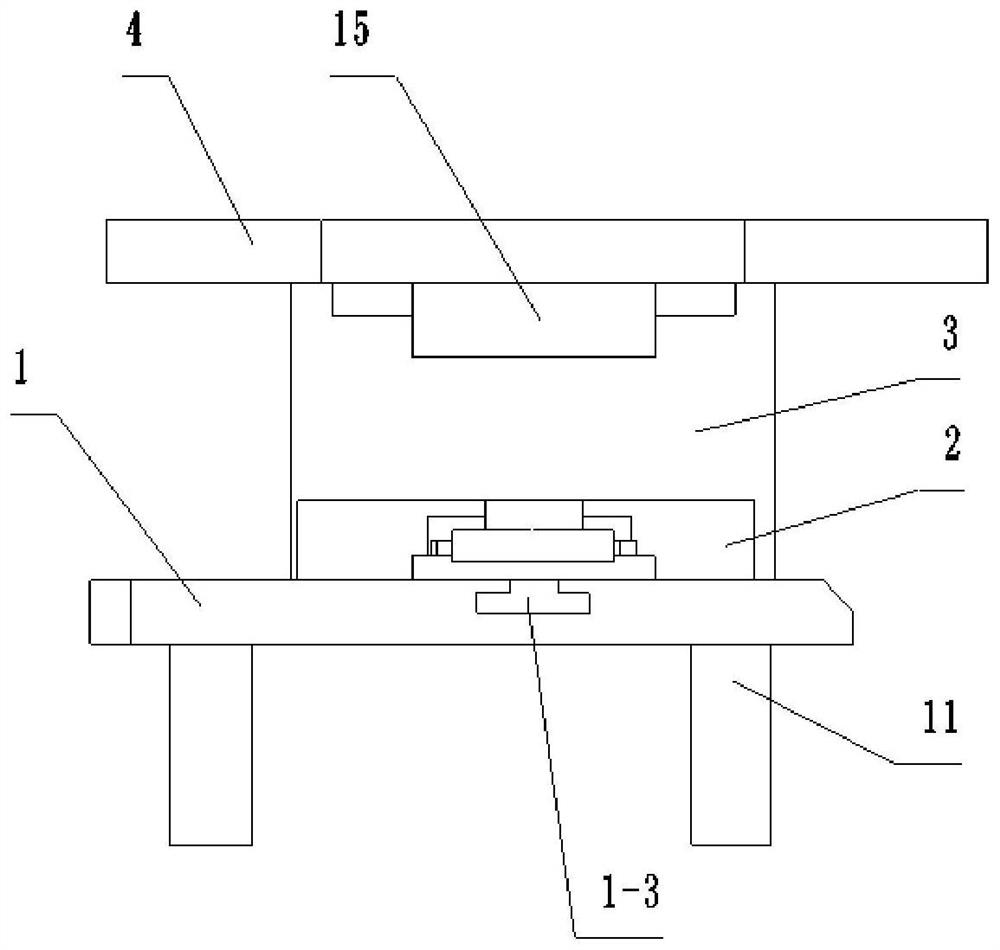

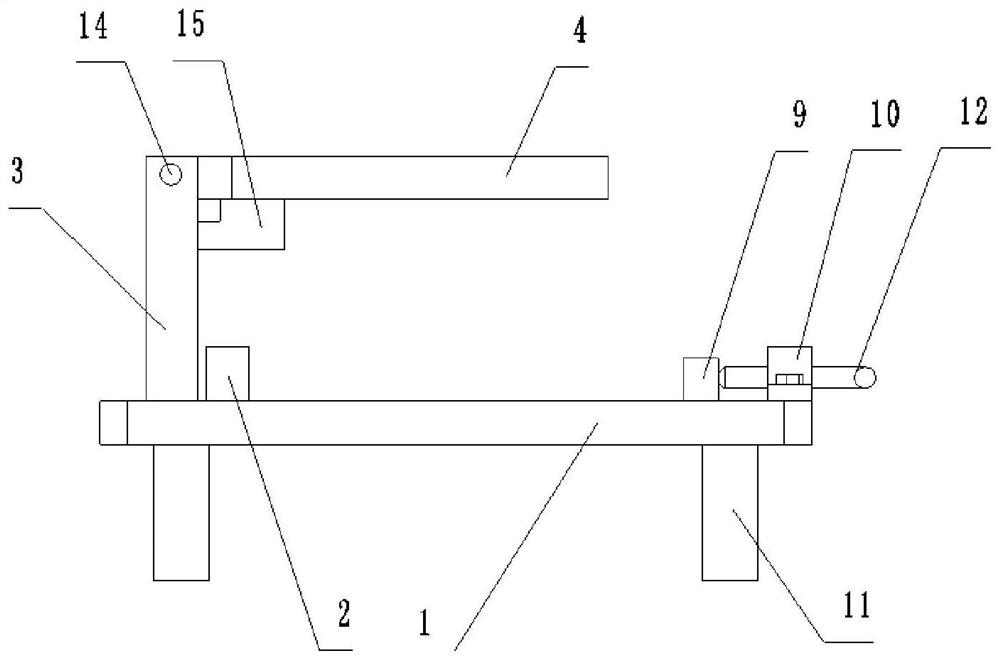

[0026] The specific embodiments of the present invention are further explained below with reference to the embodiments and the accompanying drawings, but are not intended to limit the present invention.

[0027] It should be understood that the appended drawings are not to scale, presenting a suitably simplified representation of various features illustrative of the basic principles of the invention. The specific design features of the invention disclosed herein, including, for example, the specific dimensions, orientations, locations, and profiles will be determined in part by the specific intended application and use environment. In the accompanying figures, the same or equivalent parts (elements) are referenced with the same reference numerals.

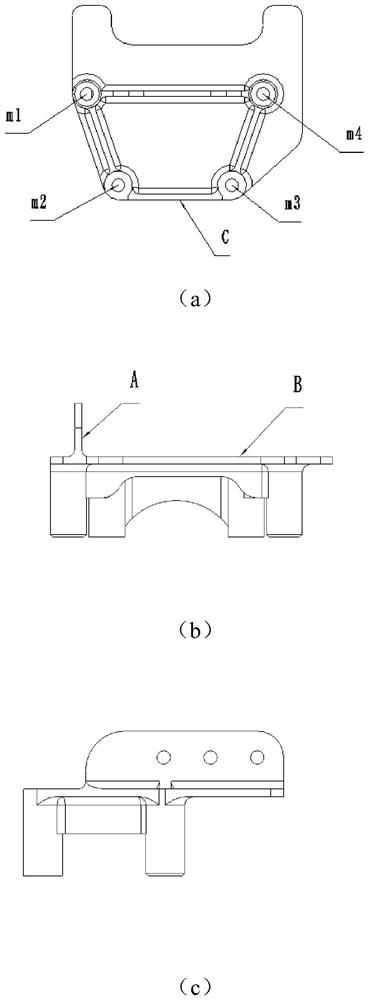

[0028] figure 1 It is a schematic diagram of the structure of the part to be machined, wherein m1, m2, m3, and m4 are the deep blind holes to be machined, A, B, and C are the positioning reference planes, and these three planes ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com