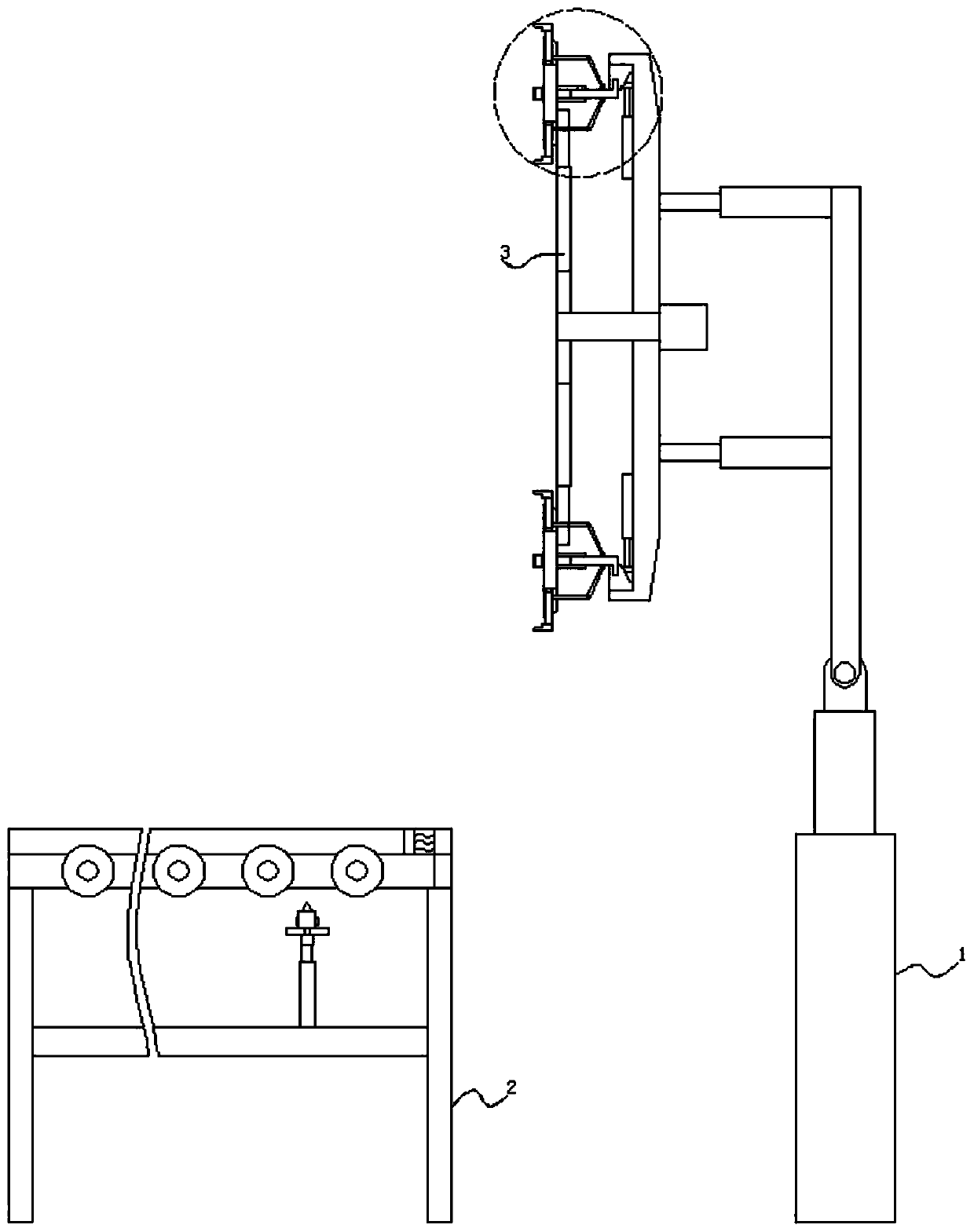

Motor end cover plate machining auxiliary equipment

A technology of motor end cover and auxiliary equipment, applied in the direction of metal processing, etc., can solve the problems of low feeding efficiency, high labor intensity, heavy end cover plate weight, etc., and achieve the effect of low efficiency of change and improvement of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The second driving mechanism 102 adopts a linear module, and the first driving mechanism 302, the third driving mechanism 206 and the fourth driving mechanism 508 adopt any one of a linear motor, an air cylinder, and a hydraulic cylinder;

Embodiment 2

[0042] One end of the rotating rod 104 extending out of the movable plate 103 is fixedly connected with a second motor fixedly connected with the movable plate 103, and one end of the rotating shaft 304 extending out of the support plate 303 is fixedly connected with a third motor fixedly connected with the support plate 303;

Embodiment 3

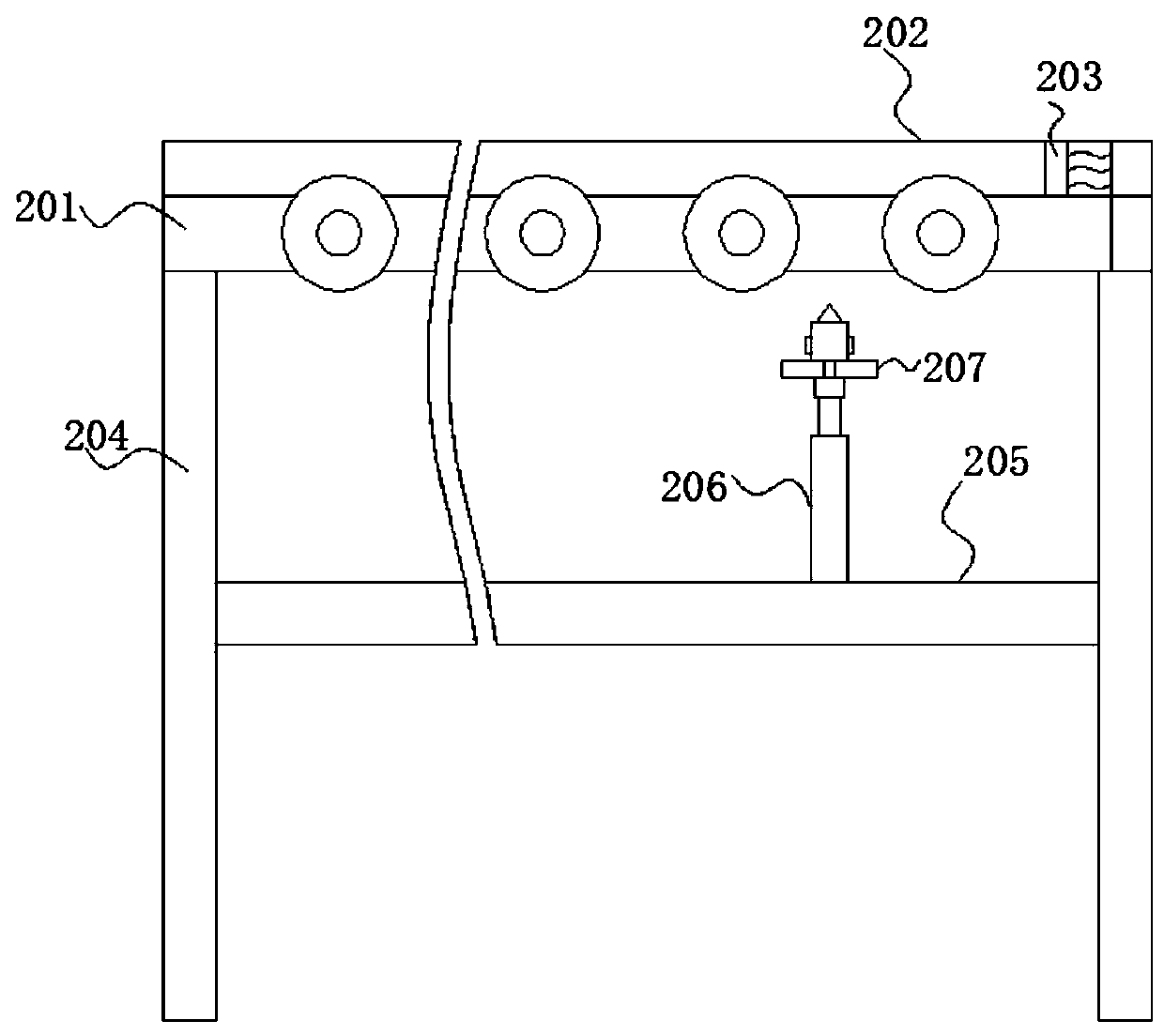

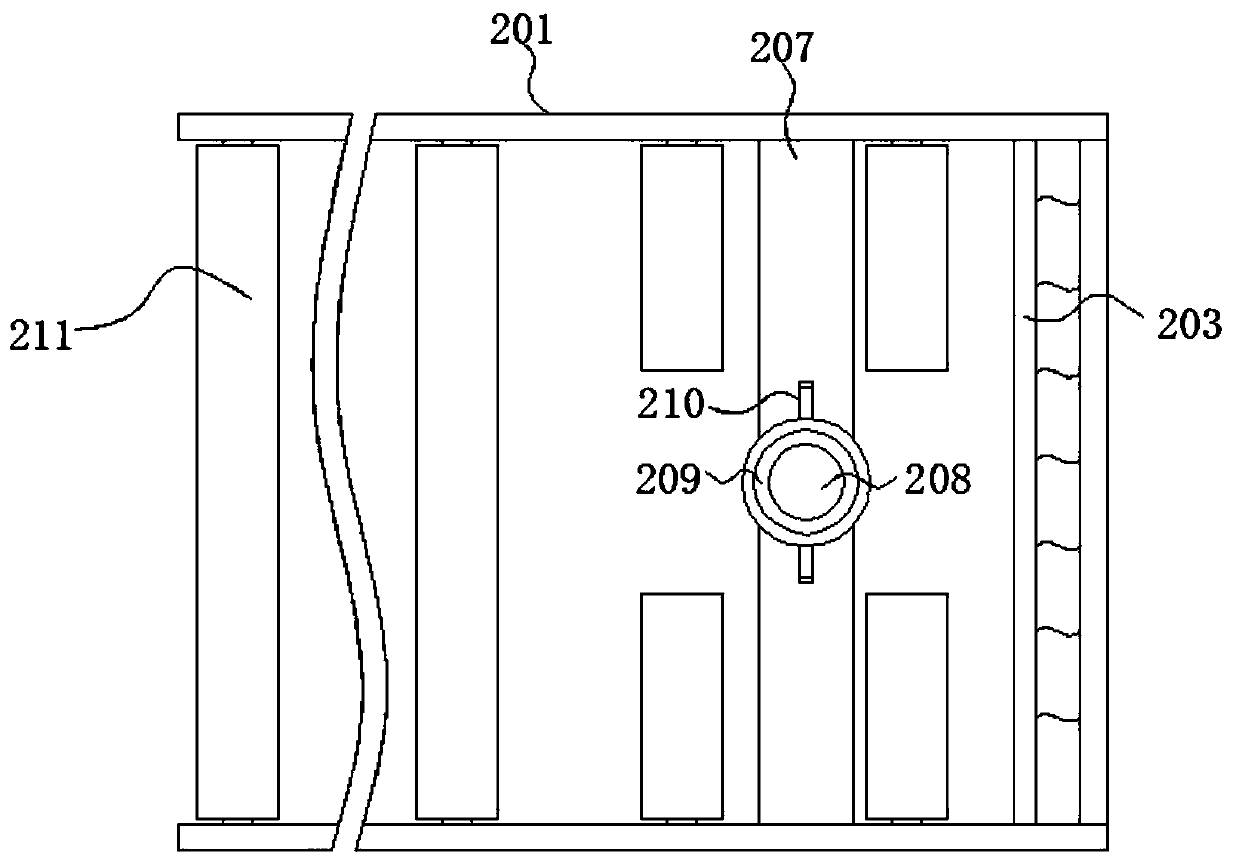

[0044] The transition groove 505 and the extruding block 507 are slidingly connected by means of slider guide rails, and the rollers 211 are connected by means of a chain sprocket, and the inner side walls of both sides of the opening of the blocking frame 202 are fixed with inclined guide rails. The side of the buffer plate 203 close to the push rod 208 is inlaid with a proximity switch, and the side of the push rod 208 away from the buffer plate 203 is equipped with a mechanical switch between adjacent rollers 211;

[0045] Such as Figure 8 Shown is the structural schematic diagram of the existing motor end cover:

[0046] Among them: including the cover plate body 601, the middle position of the cover plate body 601 is provided with a through hole 604, the end outer ring of the cover plate body 601 is provided with a chamfer 602 of circular arc structure, and the chamfer 602 is fixedly connected with a 601 is the edge 605 distributed in an axial array, and the outer ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com