Preparation method of porous concrete for plant growth

A technology of porous concrete and concrete, which is applied in the manufacture of tools, ceramic molding machines, etc., can solve the problems of not considering the important difference of planting porous concrete, not considering the porosity of concrete, the connectivity of pore size and pore, etc., so as to improve the quality of people's life , The preparation method is simple and reasonable, and the effect of high social and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A kind of growing porous concrete preparation method of the present invention, comprises the following steps:

[0043] First, set the porosity range of the plant-grown porous concrete according to the application field of the plant-grown porous concrete; when the application field is bank revetment engineering, set the porosity range as 13% to 26%; when the application field is slope protection engineering, set the porosity range The range is 22% to 35%.

[0044] Then, the aggregate is selected, and the porosity of the vegetated porous concrete prepared from the aggregate is calculated:

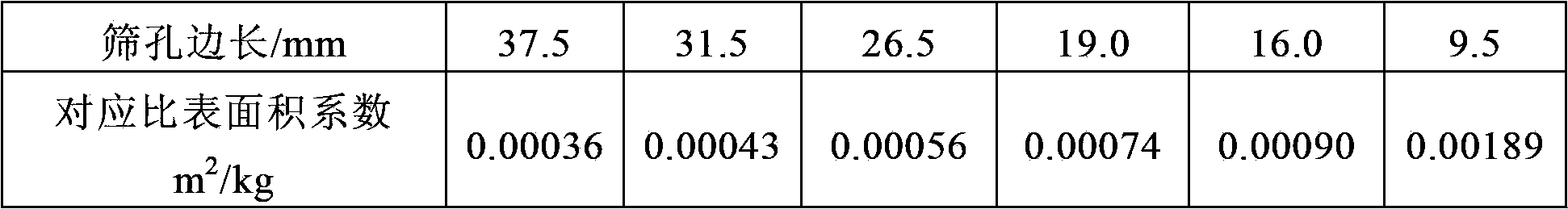

[0045] Establish a corresponding numerical table of the side length of the sieve hole and the corresponding specific surface area coefficient of the aggregate sieve residue;

[0046] Find the corresponding value table and calculate the specific surface area coefficient of the current aggregate;

[0047] The specific surface area coefficient of the current aggregate is the sum of the ...

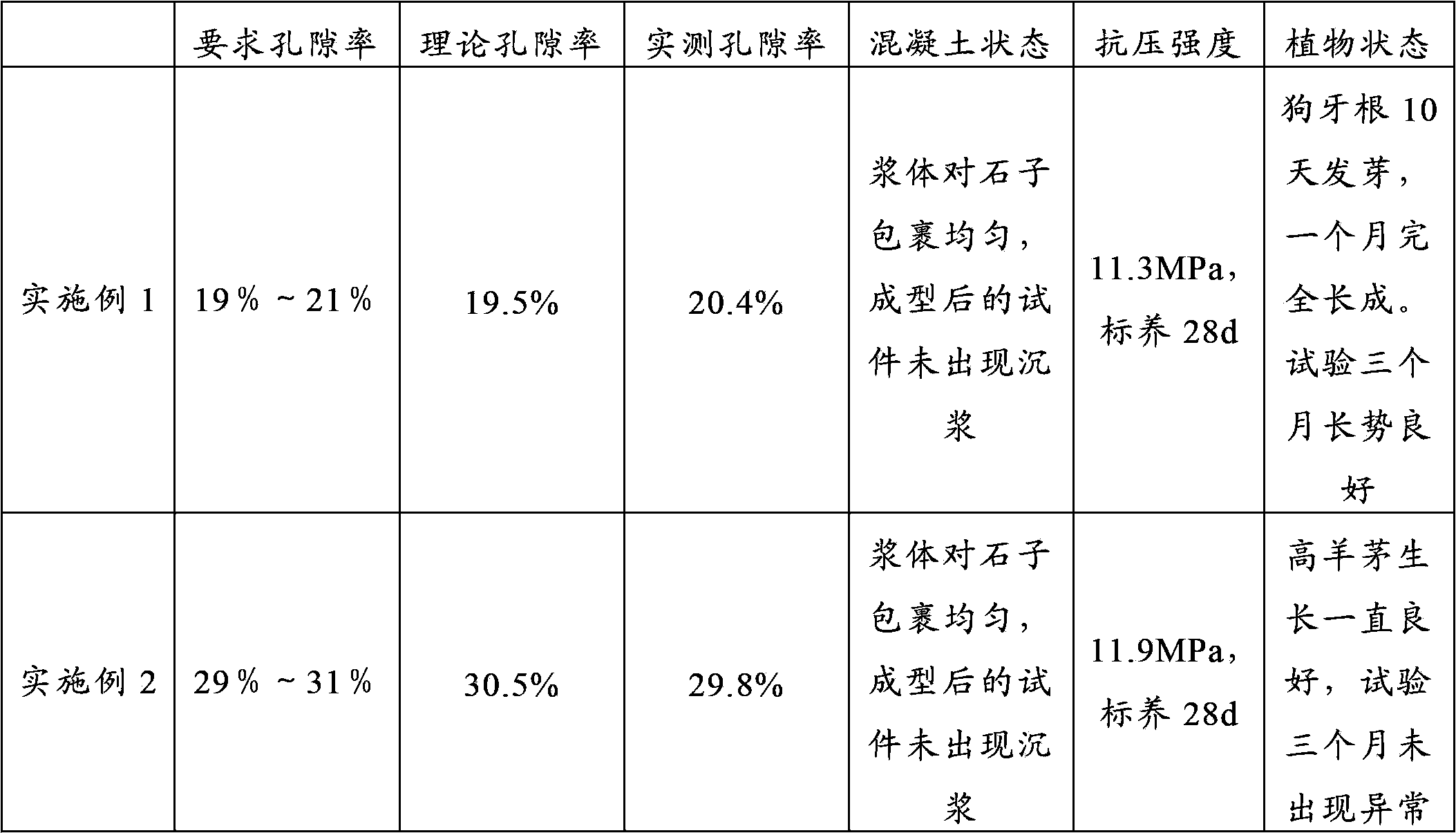

Embodiment 1

[0065] Example 1: Preparation of a plant-growing porous concrete applied to revetment engineering

[0066] First set the range of porosity as 19% to 21%, and then establish a numerical table corresponding to the side length of the sieve hole and the corresponding specific surface area coefficient of the sieved aggregate, see Table 1;

[0067]

[0068] Table 1 Corresponding value table

[0069] Choose 16.0mm ~ 19.0mm single-grade stones as aggregate, and the apparent density of stones is 2720kg / m 3 .

[0070] Stone close packing density 1620kg / m 3 , Porosity 41.5%. The thickness of the cemented slurry wrapping the stone is 1.0mm.

[0071] It can be seen from Table 1 that the specific surface area coefficient corresponding to the sieve residue of the stone is 0.00090m 2 / kg.

[0072] At this time, the specific surface area coefficient of the stone is = 0.00090m 2 / kg×100=0.090m 2 / kg.

[0073] Surface area per unit volume of stones = total mass of stones per unit volum...

Embodiment 2

[0093] Embodiment 2: A kind of planting porous concrete applied to slope protection engineering

[0094] First set the range of porosity as 29% to 31%, and then establish a corresponding value table of the side length of the sieve hole and the corresponding specific surface area coefficient of the sieved aggregate, see Table 1;

[0095] Choose 19.0mm ~ 26.5mm single-grade stones as aggregate, and the apparent density of the stones is 2188kg / m 3 .

[0096] Stone close packing density 1600kg / m 3 , porosity 42.3%. The thickness of the cemented slurry wrapping the stone is 1.0mm.

[0097] It can be seen from Table 1 that the specific surface area coefficient corresponding to the sieve residue of the stone is 0.00074m 2 / kg.

[0098] At this time, the specific surface area coefficient of the stone is = 0.00074m 2 / kg×100=0.074m 2 / kg.

[0099] Surface area per unit volume of stones = total mass of stones per unit volume x specific surface area coefficient of stones = 1600kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com