Production process of ventilated and anti-velvet fine-denier shell fabric

A production process and fabric technology, which is applied in the field of textile weaving and dyeing to achieve the effects of improving velvet resistance, good fabric feel, and velvet-proof fabric feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

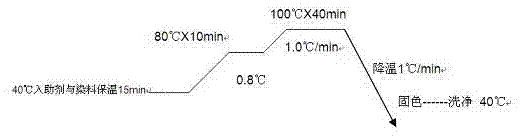

Method used

Image

Examples

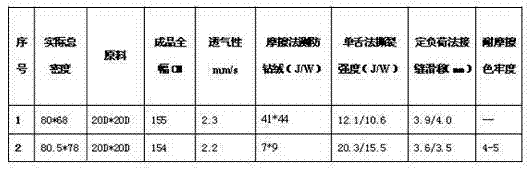

Embodiment 1

[0025] A production process of air-permeable and cashmere-proof fine denier fabric, which is carried out as follows: gray cloth weaving→cold pile treatment→desizing→dyeing→setting→water washing→calendering, in which: the warp and weft of the gray cloth are all made of 20D nylon matting FDY Filament, warp direction density 78 / cm, weft density 78 / cm.

[0026] The cold-stack treatment is to dip the gray cloth in the cold-stack padding liquid in the padding tank for padding treatment, and then wrap and seal it, and stack the sealed cloth rolls on the cold-stack rack for 24 hours, while keeping the cloth The roll rotates slowly at a speed of 16m / min; the padding solution in the padding tank is made of H 2 0 2 , NaOH, and refining agent are mixed at a weight ratio of 10:20:2, and an aqueous solution prepared by adding 30 times the total weight of the three deionized water, wherein the refining agent is refining agent TK-1.

[0027] Loose open-width desizing is used for desizing, a...

Embodiment 2

[0033] A production process of air-permeable and cashmere-proof fine denier fabric, which is carried out as follows: gray cloth weaving→cold pile treatment→desizing→dyeing→setting→water washing→calendering, in which: the warp and weft of the gray cloth are all made of 20D nylon matting FDY Filament, warp direction density 78 / cm, weft density 78 / cm.

[0034] The cold-stack treatment is to dip the gray cloth in the cold-stack padding liquid in the padding tank for padding treatment, and then wrap and seal it, and stack the sealed cloth rolls on the cold-stack rack for 24 hours, while keeping the cloth The roll rotates slowly at a speed of 17m / min; the padding solution in the padding tank is made of H 2 0 2 , NaOH, and refining agent are mixed in a weight ratio of 10:20:2, and an aqueous solution prepared by adding 31 times the total weight of the three deionized water is prepared, wherein the refining agent is refining agent TK-1.

[0035] Loose open-width desizing is used for...

Embodiment 3

[0041] A production process of air-permeable and cashmere-proof fine denier fabric, which is carried out as follows: gray cloth weaving→cold pile treatment→desizing→dyeing→setting→water washing→calendering, in which: the warp and weft of the gray cloth are all made of 20D nylon matting FDY Filament, warp direction density 78 / cm, weft density 78 / cm.

[0042] The cold-stack treatment is to dip the gray cloth in the cold-stack padding liquid in the padding tank for padding treatment, and then wrap and seal it, and stack the sealed cloth rolls on the cold-stack rack for 24 hours, while keeping the cloth The roll rotates slowly at a speed of 16m / min; the padding solution in the padding tank is made of H 2 0 2 , NaOH, and refining agent in a weight ratio of 10:20:2, and add 33 times the total weight of the three deionized water to prepare an aqueous solution, wherein the refining agent is refining agent TK-1.

[0043] Loose open-width desizing is used for desizing, and the speed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com