Telescopic overall hoisting derrick device and hoisting method thereof

An overall hoisting and telescopic technology, applied in the direction of supporting devices, hoisting devices, drilling equipment, etc., can solve the problems of easy collision damage, potential safety hazards, labor and other problems of components, and achieve fast and convenient installation and lifting, improved use and economical use Effects on costs and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

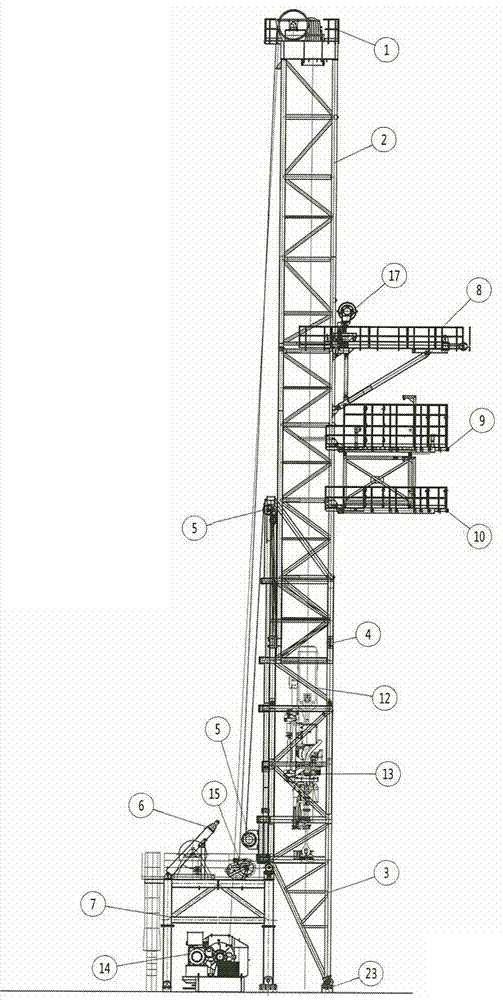

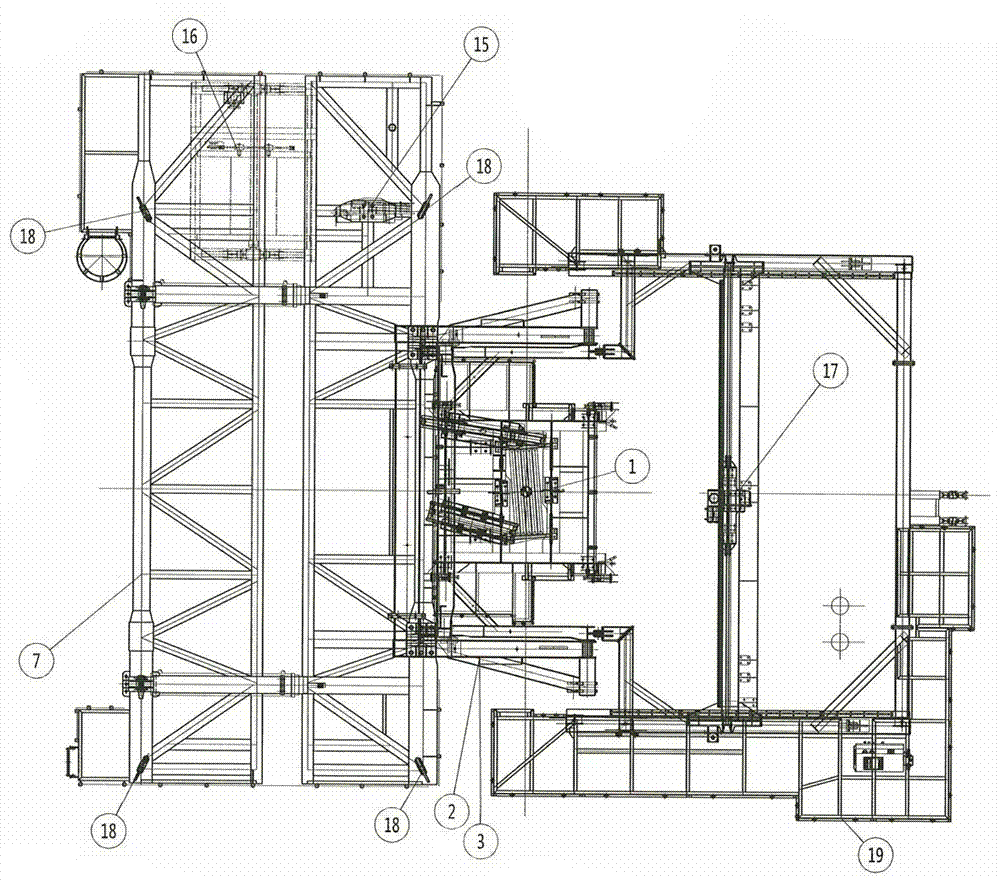

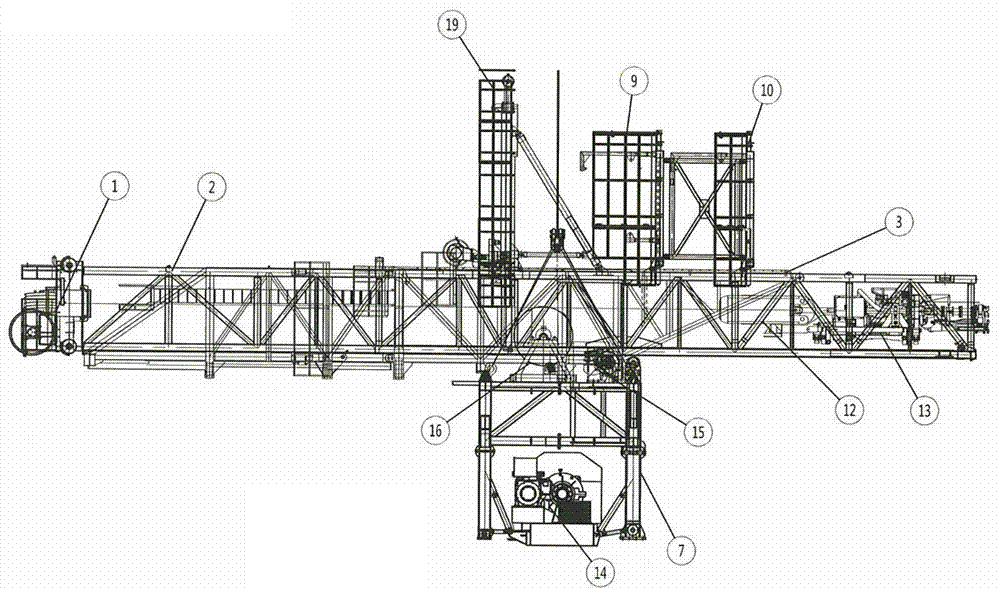

[0051] figure 1 , figure 2 It shows a telescopic overall hoisting type derrick device, which includes a derrick support platform 7 detachably fixedly connected with the drilling platform, a derrick body arranged on the support platform 7, a pipe row machine platform 8, a second floor platform 9, a sleeve The pipe platform 10, crown block 1 and root service platform 22, the main drawworks 14 are detachably fixedly installed on the lower part of the derrick support platform 7, and the base of the main winch and the derrick support platform 7 are hinged with small beams. The main drawworks 14 can be hoisted together with the derrick, and as the crane is overweight, the main drawworks 14 can also be separated from the derrick support platform 7 for separate hoisting. The derrick body is divided into an upper section 2 of the derrick body and a lower section 3 of the derrick body; one side of the lower end of the lower section 3 of the derrick body is hinged to one side of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com