Measurer for perpendicularity of end face to blind hole axis

A technology of vertical axis and blind hole, which is applied in the field of end-to-face blind hole axis perpendicularity measurer, can solve the problems of complicated and difficult measurement process, and achieve the effects of guaranteed product quality, simple structure and convenient manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

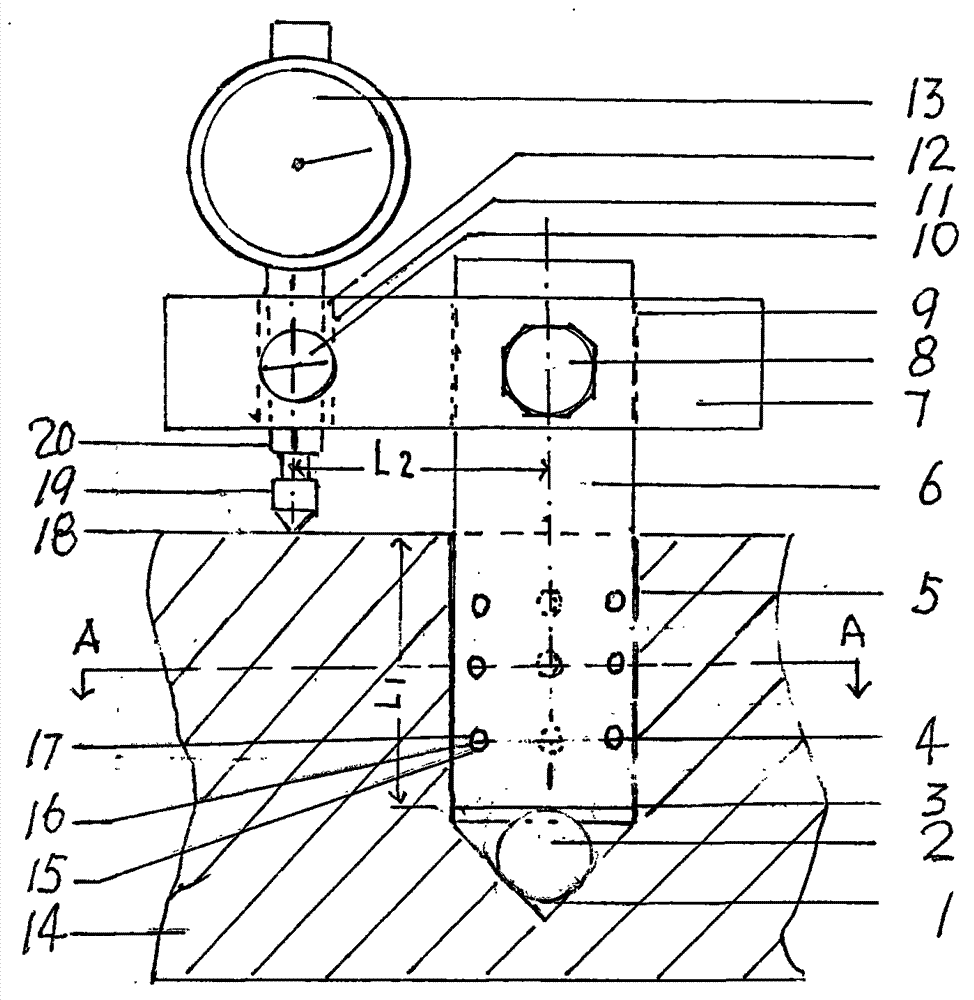

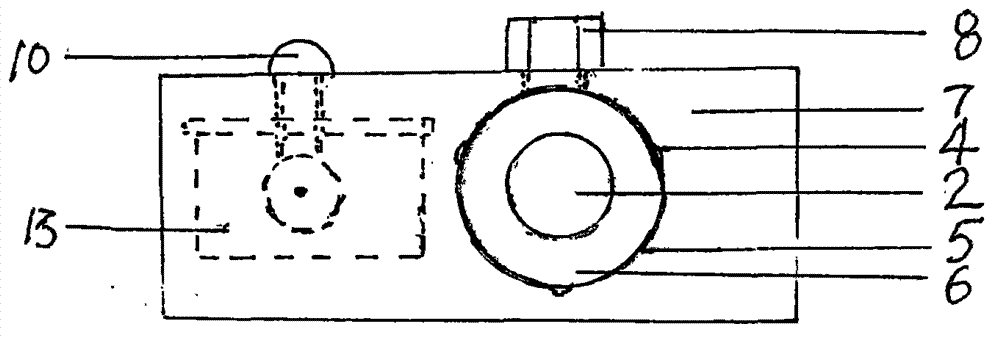

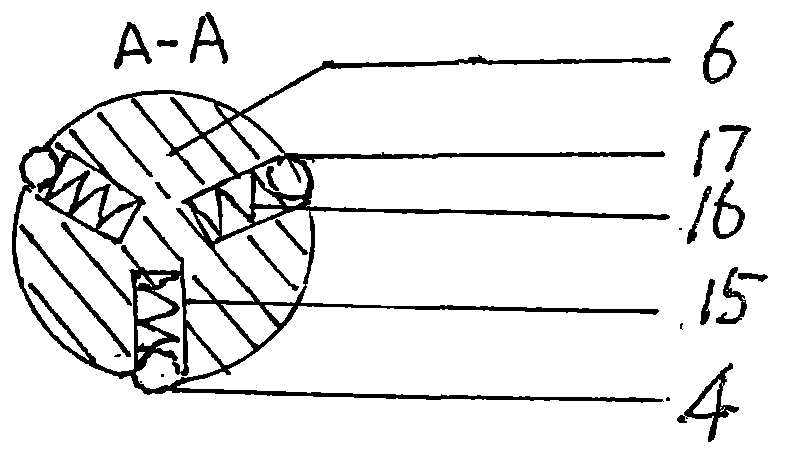

[0013] The accompanying drawing is a measurement structure diagram of the measuring device for measuring the verticality of the axis of the blind hole from the end of the guide post installation hole on the cylinder head of the workpiece 16V240 diesel engine. See attached figure 1 , 2 3. The upper end of the expandable mandrel (6) with a diameter of Φ22-0.17 mm is inserted into the right end inner diameter of the large plane of the horizontal plate (7). ), the axis of the expandable mandrel mounting hole (9) is perpendicular to the large plane under the horizontal plate (7); the lower end of the expandable mandrel (6) with a diameter of Φ22-0.17 mm is inserted into a blind hole with an inner diameter of Φ22.00 mm ( 5) Within the range of effective inner depth L1 equal to 30.00 mm, three expansion bead installation holes (15) with an inner diameter of Φ4.50 mm distributed in an equilateral triangle in the transverse direction, and 3 rows of Φ4. 00 mm expansion ball (4); insta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quenching hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com