Visual card erasing device

A technology of visible card and erasing unit, which is applied in the direction of erasing devices, inking devices, and information-carrying cards, etc. It can solve the problems of affecting the ticketing speed and slowing down the printing speed, and achieve the goal of reducing operating costs and resource waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

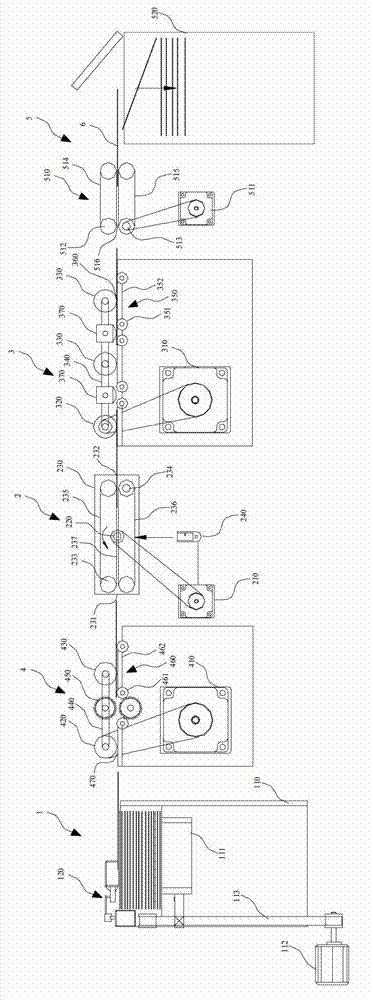

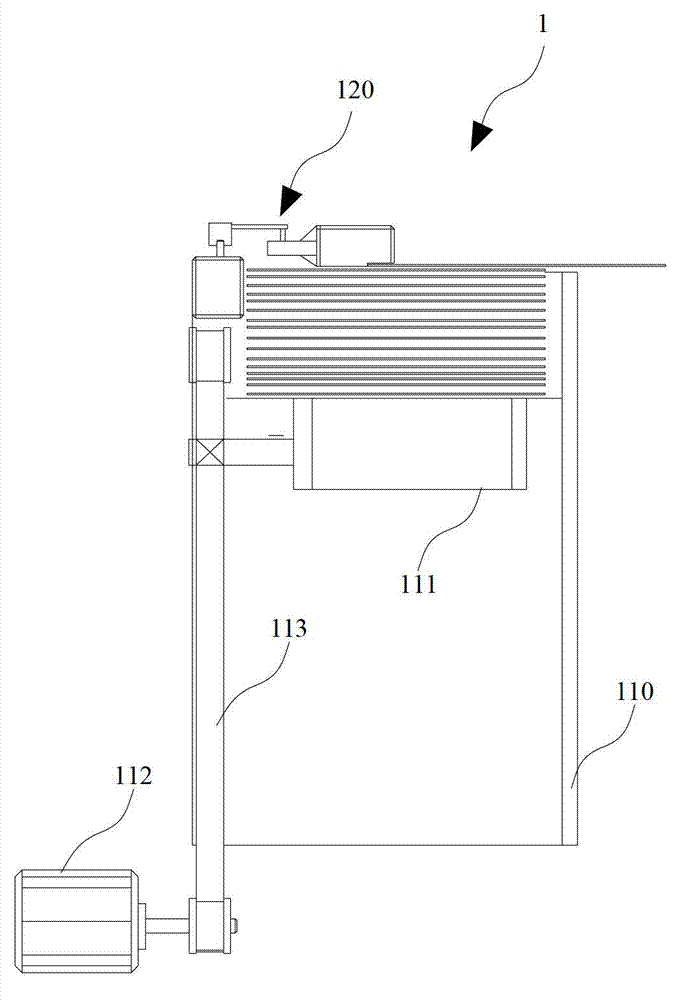

[0026] Such as Figure 1 to Figure 7 Schematically shows a visible card erasing device according to an embodiment of the present invention, which includes a card issuing module 1 , a cleaning unit 4 , a turning mechanism 2 , an erasing mechanism 3 and a card receiving module 5 arranged in sequence. The video card 6 to be erased is sent to the cleaning unit 4 through the card issuing module 1 for cleaning operation. After cleaning, the video card 6 is sent to the turning mechanism 2, and the turning mechanism 2 selectively After turning over, the video card 6 is sent into the erasing mechanism 3 . After the erasing mechanism 3 erases the information on the surface of the video card 6 , the video card 6 is finally sent into the card receiving module 5 .

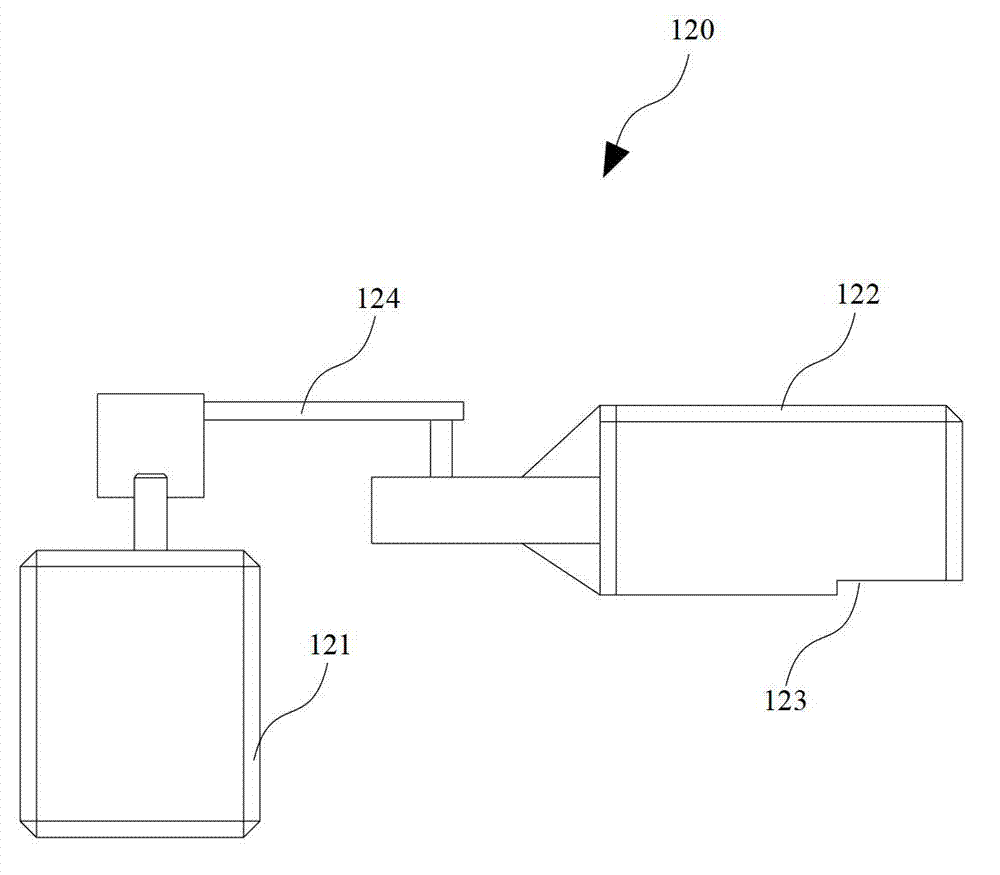

[0027] The card issuing module 1 includes a card box 110 containing the visible card 6 to be erased and a card pushing mechanism 120 located on the top of the card box 110 . The card pushing mechanism 120 includes a sixth mot...

Embodiment 2

[0035] Such as Figure 8 to Figure 9 Schematically shows a visible card erasing device according to yet another embodiment of the present invention, the difference from the first embodiment is that the thermal erasing unit in the second embodiment is a thermal erasing rod 380, and at the same time, the erasing The mechanism 3 also includes a fifth motor 390 , the thermal erasing rod 380 is driven to rotate by the fifth motor 390 , and the thermal erasing rod 380 is located above the first conveying mechanism 350 . The surface of the video card 6 is thermally erased by the rotating thermal erasing rod 380 to eliminate writing on the surface of the video card 6 . Moreover, through the cooperation of the rotating thermal erasing rod 380 and the first transmission mechanism 350, the transmission of the video card 6 can also be realized.

[0036] In addition to the fixed thermal erasing head and the rotating thermal erasing rod, the thermal erasing unit can also have other options...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com