Female terminal

A female terminal and terminal technology, applied in the field of female terminals, can solve the problems of higher insertion force and increased sliding resistance, and achieve the effect of preventing the increase of insertion force, preventing the increase of insertion force and reliable electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] One embodiment of the present invention will be described below based on the drawings.

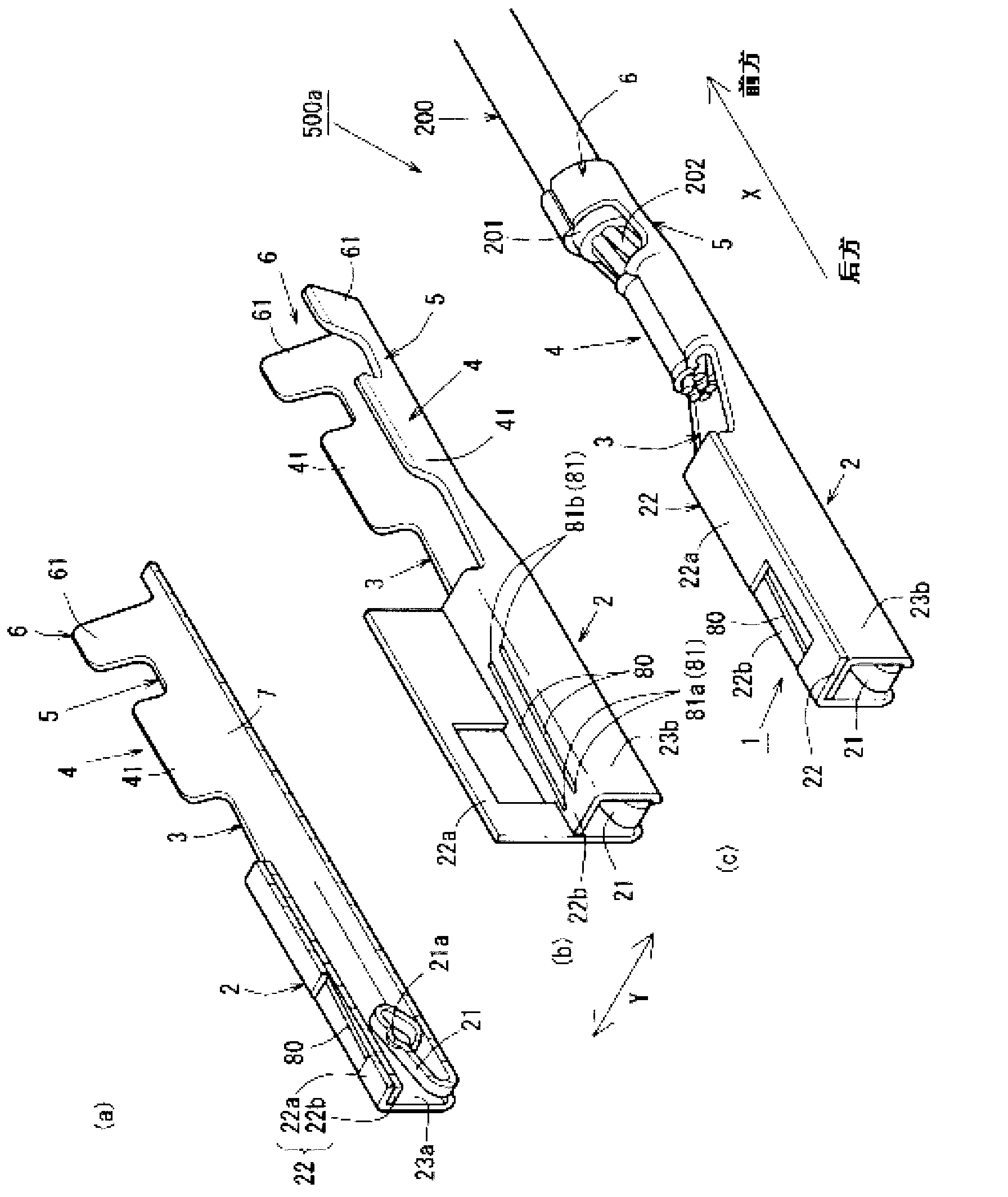

[0072] in addition, figure 1 and figure 2 This is an explanatory diagram showing the male crimp terminal 1. here, figure 1 (a) in (a) shows a cross-sectional perspective view of the female crimp terminal 1 divided in the center of the width direction Y, figure 1 (b) is a perspective view showing the female crimp terminal 1 in the middle of assembly, figure 1 (c) is a perspective view of the female crimping terminal 1 in a state where the covered electric wire 200 is crimped to the core wire crimping portion 4 .

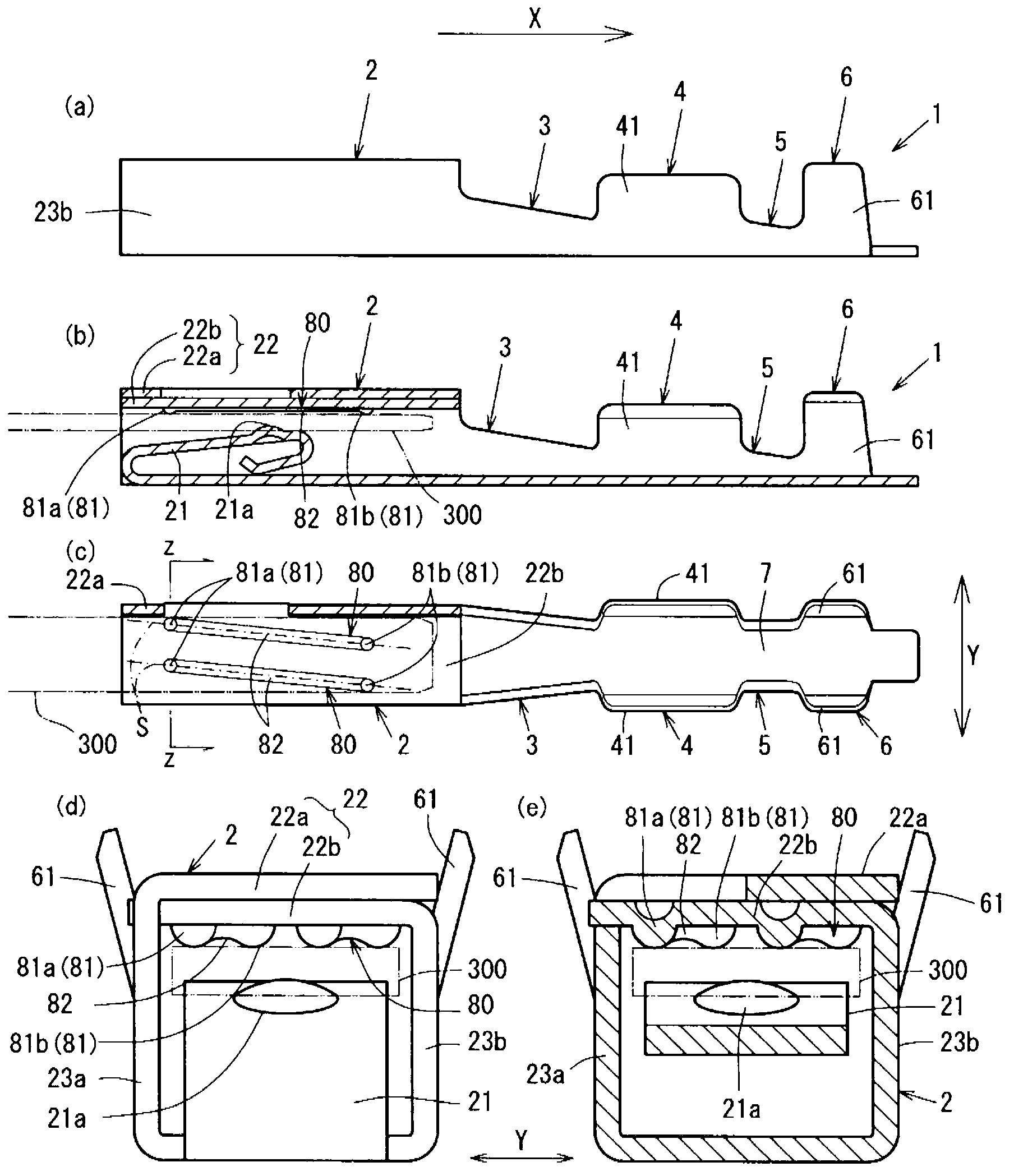

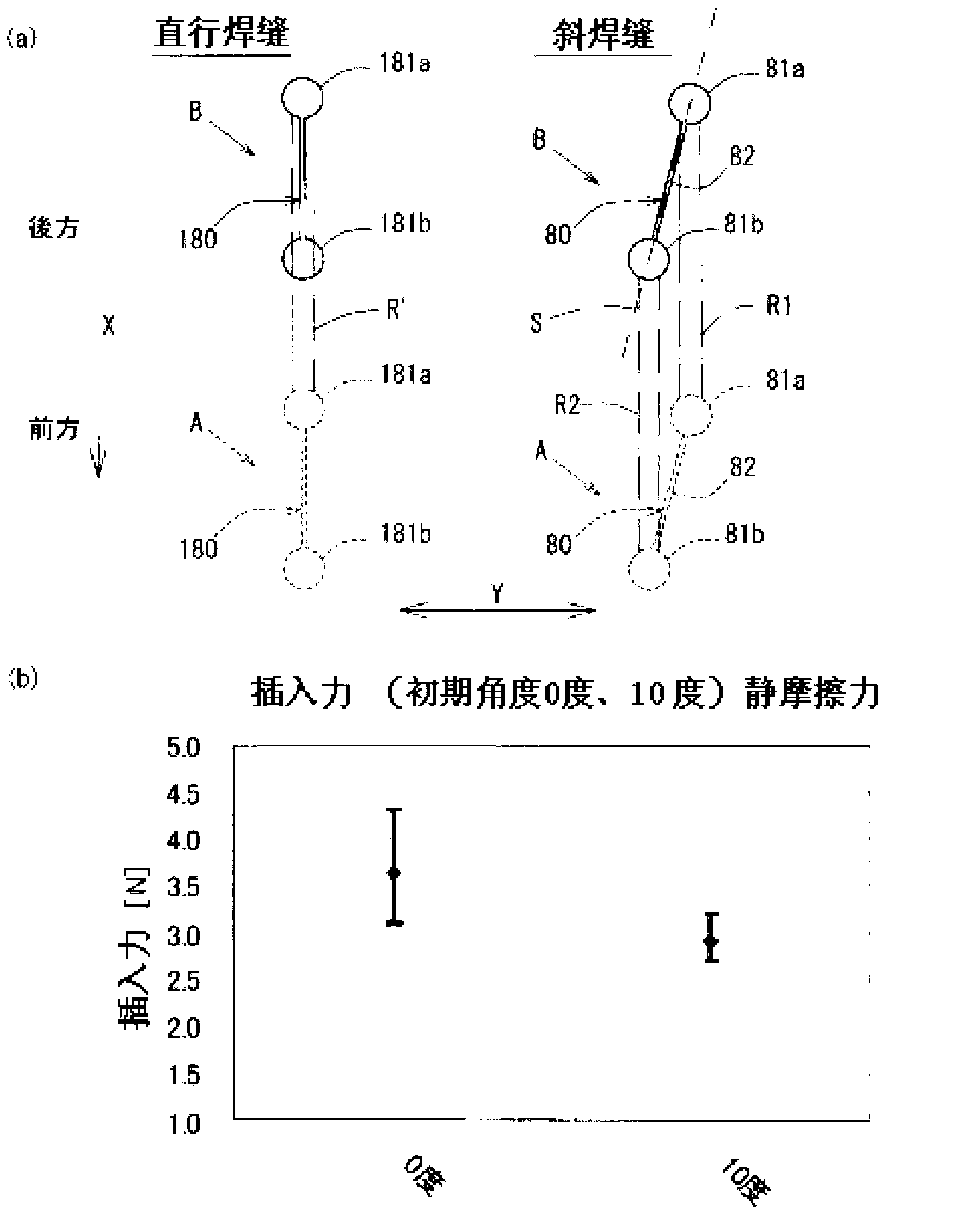

[0073] also, figure 2 (a) in the figure shows the side view of the female crimp terminal 1, figure 2 (b) is a cross-sectional view of the female crimp terminal 1 at the central position in the width direction Y, figure 2 (c) in means figure 1 (b) is a plan view of the female crimp terminal 1 before assembly. and, figure 2 (d) in represents the front view of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com