Electrical contact, connector terminal pair, and connector pair

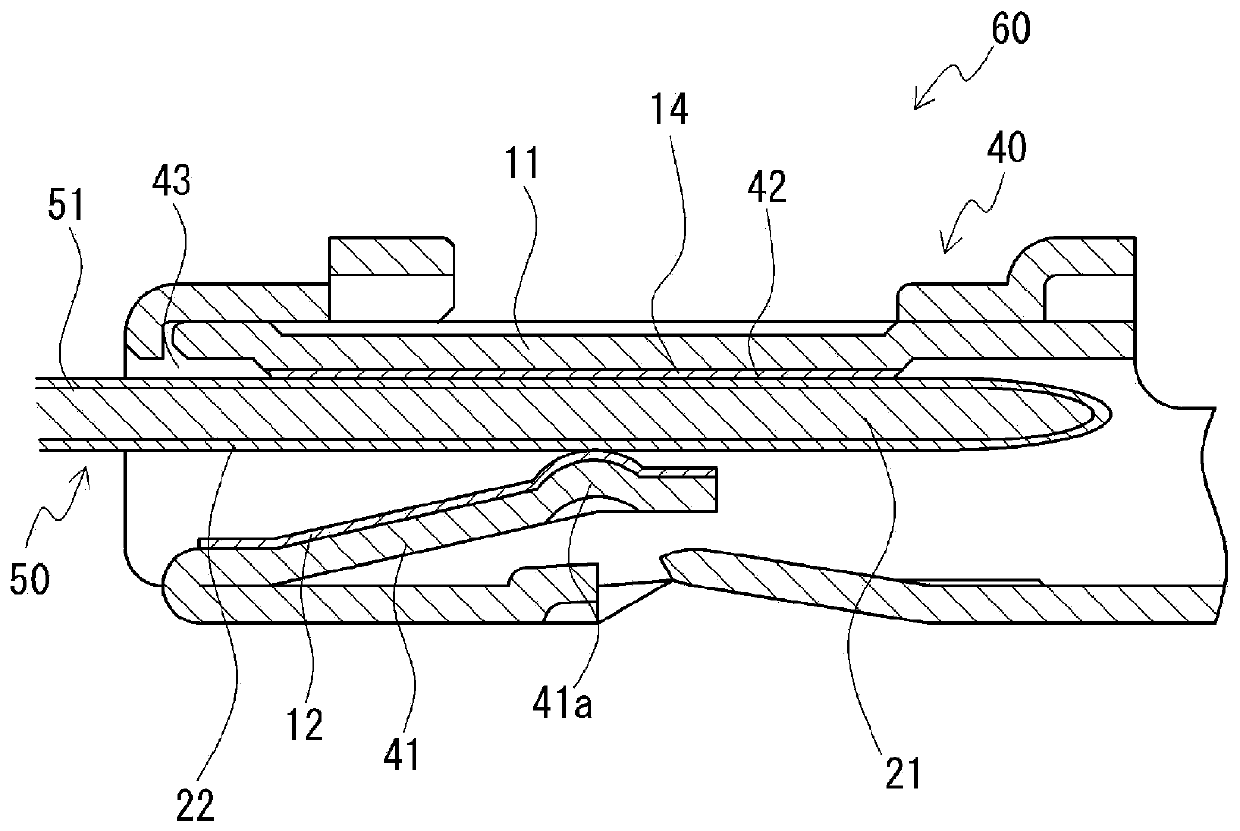

A technology of connector terminals and electrical contacts, applied in the direction of connection, parts and circuits of connecting devices, can solve the problems of increased insertion force, high friction coefficient, condensation, etc., and achieve high connection reliability and low insertion. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0073] Hereinafter, the present invention will be described in detail using examples.

[0074] [Preparation of plating samples]

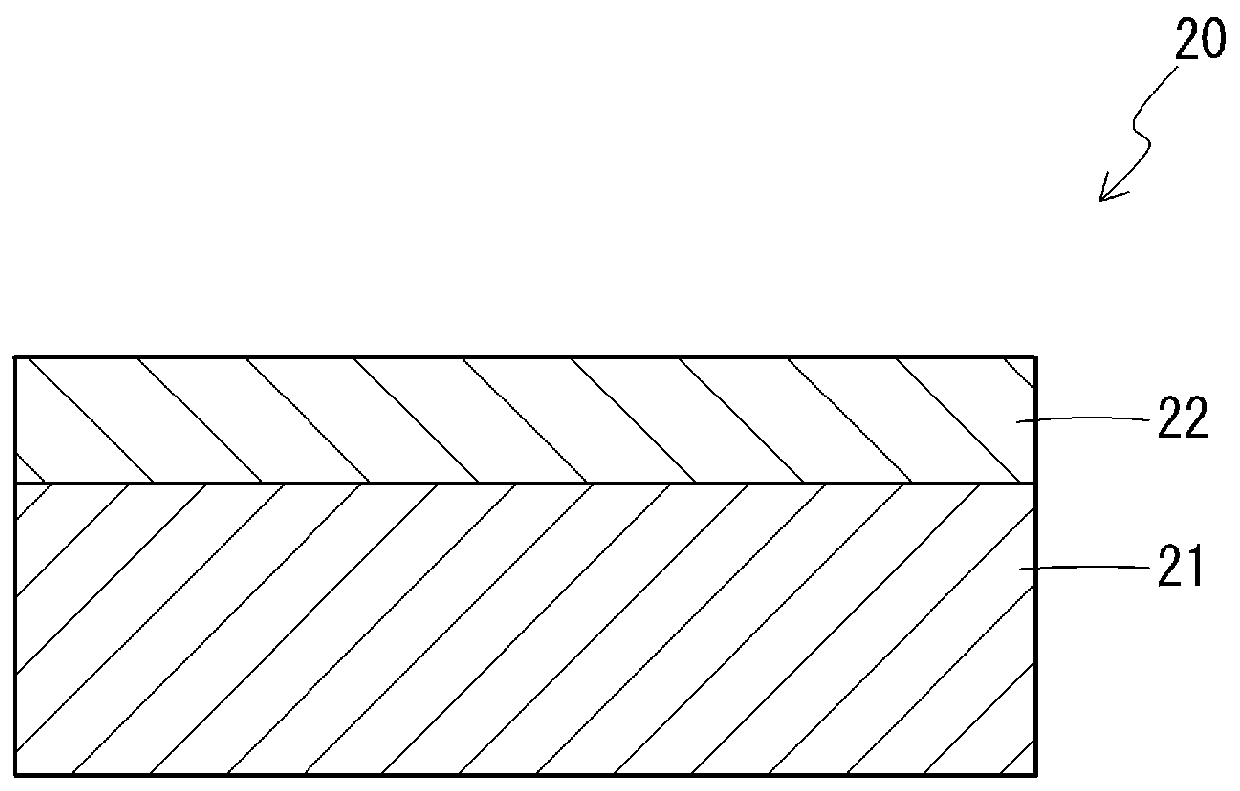

[0075] Tin-plated samples, tin / palladium-plated samples, and nickel-plated samples were produced by electroplating on the surface of a clean copper substrate. Table 1 shows the film thicknesses of the respective plating layers. Regarding the tin / palladium-plated samples, after the nickel-plated layer was formed as the base layer, the palladium-plated layer and the tin-plated layer were sequentially formed with the described film thicknesses.

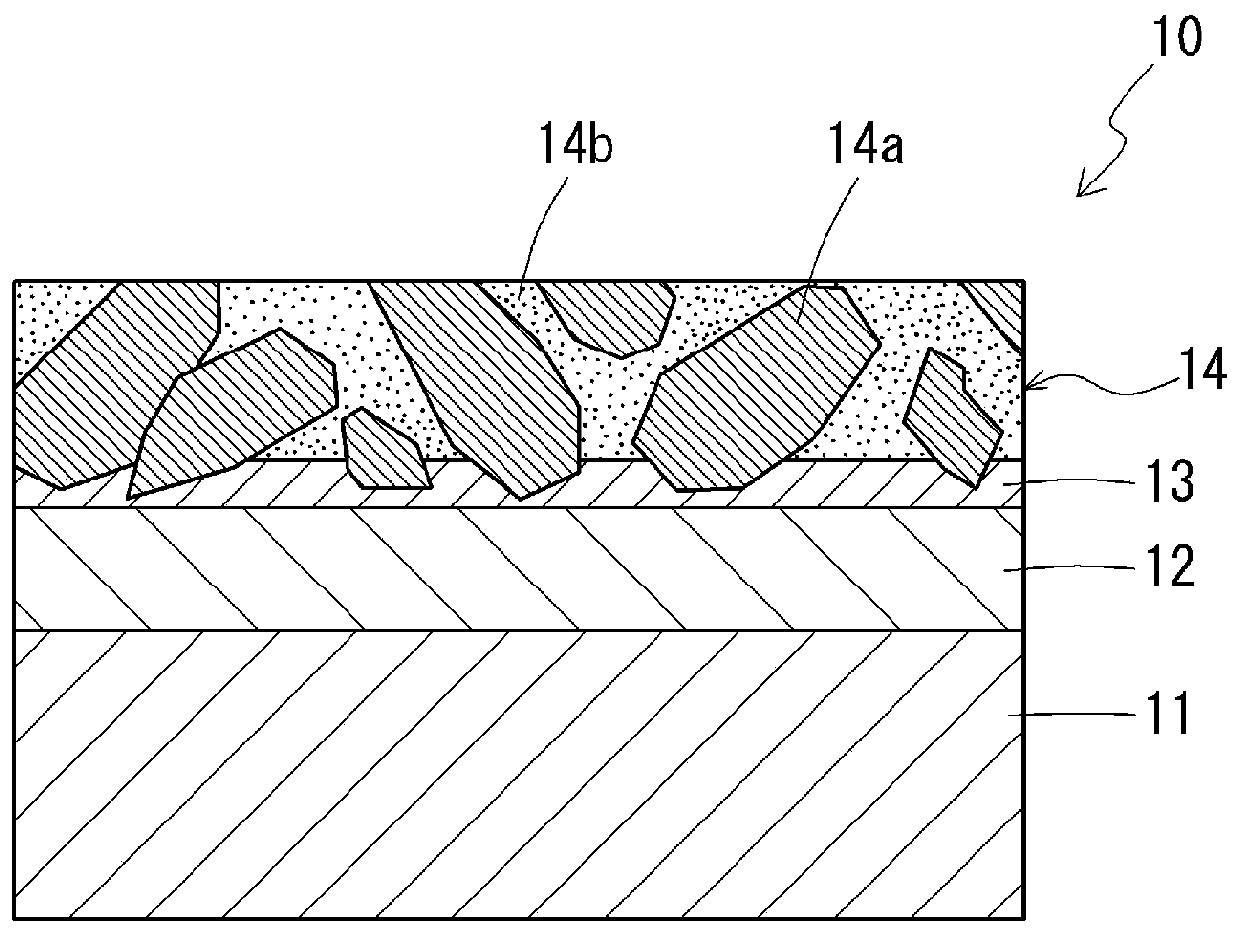

[0076] By further heating the tin / palladium-plated sample at 300° C., an alloy between tin and palladium progressed, and this was used as a tin-palladium alloy sample. By observing the cross-section and surface of the obtained sample with a scanning electron microscope (SEM), it can be confirmed that both the alloy part and the tin part are exposed on the outermost surface of the tin-palladium alloy sample, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com