Automatic high-efficiency cane straw binding machine

A strapping machine, high-efficiency technology, applied in the direction of hand tools, agricultural machinery and implements, applications, etc., to overcome the lag of technical performance, save production efficiency, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

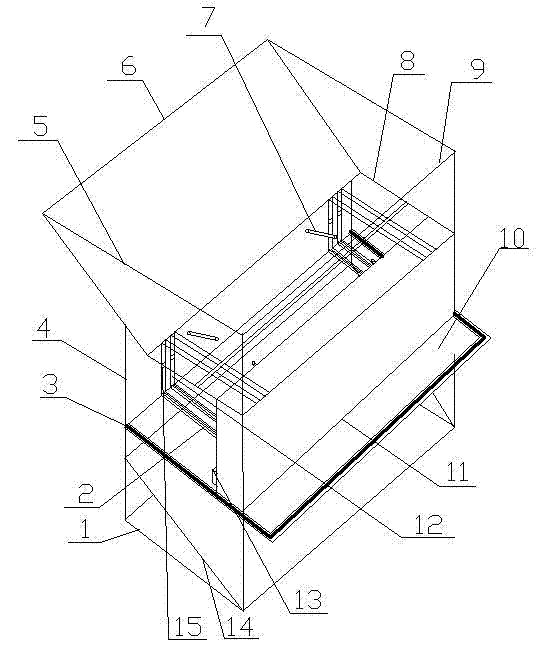

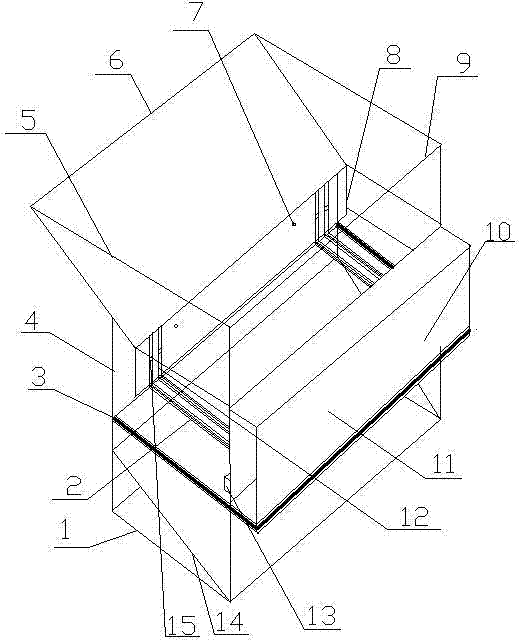

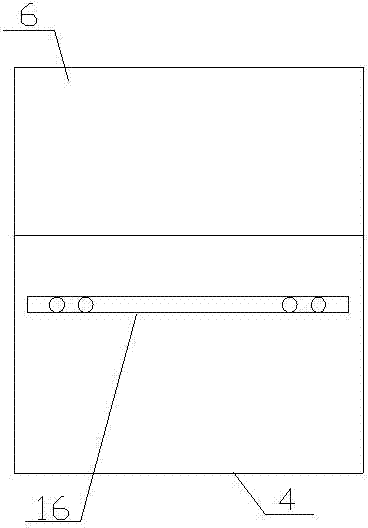

[0035] The automatic and high-efficiency sugarcane stalk binding machine of the present invention is separately installed and arranged on the relevant machinery, and the power supply of the sensor control device 13 in the baler 11 is turned on, when a cane stalk plant slides from the inclined bucket plate 6 and reach the predetermined weight, figure 2 As shown, under the action of gravity, the inclined support rod 7 is compressed to the upper end of the inner side of the lower support plate 4 and the upper end of the inner side of the baler 11, and the two joint working self-unloading plates 8 are opened on both sides of the lower side, and the sugarcane stalks Unload it to the left and right transverse branch grooves 2. When the sensing probe arranged on the inner side of the baler 11 senses the predetermined weight and measures the predetermined data, the automatic controller is instructed to open the sensing control device 13 in the baler 11, figure 1 As shown, at this ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com