Effect rod boosting device

An effect and boosting technology, applied in the field of electrolytic aluminum, can solve the problems of difficulty in purchasing effect rods, intensifying efforts to close mountains and afforestation, and hidden dangers in safety production, and achieve the effect of good safety protection, simple structure and reduced use cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

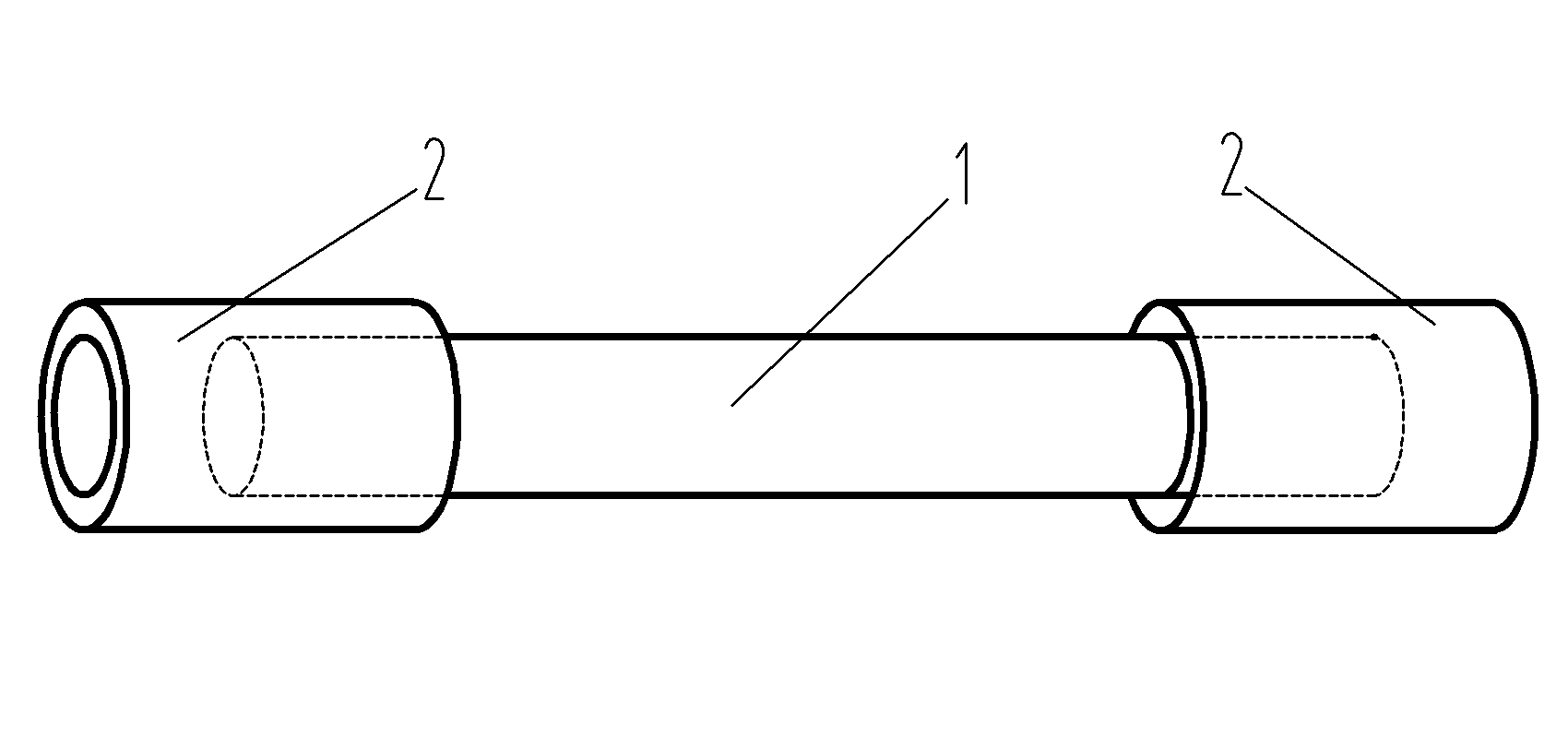

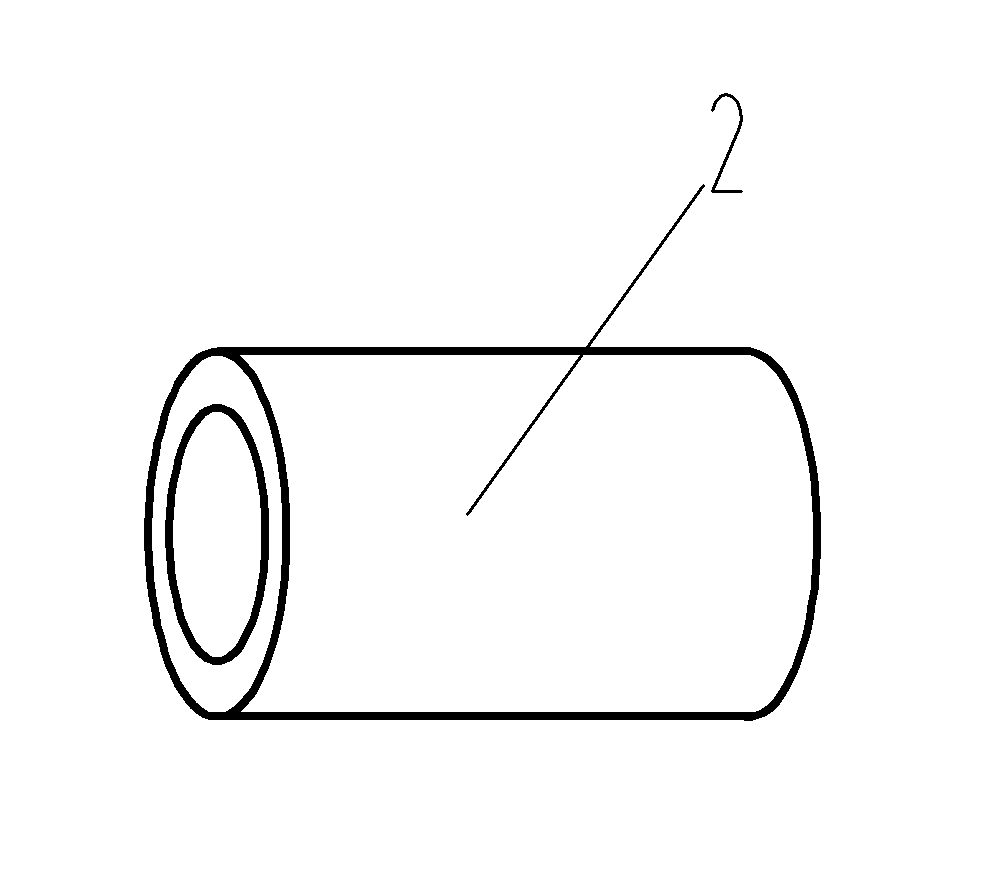

[0016] figure 1 It is a schematic diagram of the overall structure of the effect rod booster. The effect rod booster is mainly composed of a wooden guide rod 1 and two steel pipes 2 respectively sleeved at both ends of the wooden guide rod. The diameter of the cavity of the steel pipe 2 is the same as that of the wooden guide rod. 1 have the same diameter, and the steel pipe 2 is tightly connected to the wooden guide rod 1, the wooden guide rod 1 does not penetrate the cavity of the steel pipe 2, and the ratio of the length of the wooden guide rod 1 inserted into the steel pipe cavity to the steel pipe cavity is 7: 10, figure 2 and image 3 It is a wooden guide rod guide rod 1 and a steel pipe 2, the preferred length of the wooden guide rod is 100cm, and the preferred length of the steel pipe is 10cm.

[0017] When in use, assemble the wooden guide rod and the steel pipe, and connect the effect rod to its end. At this time, the effect rod can be put under the palm of the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com