Deep Hole Perpendicularity Laser Measuring System and Measuring Method

A laser measurement system and verticality technology, applied in the field of deep hole verticality measurement system, can solve the problems of measurement length limitation, large error, inability to facilitate deep hole verticality measurement, etc., to achieve accurate measurement work and reduce human errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

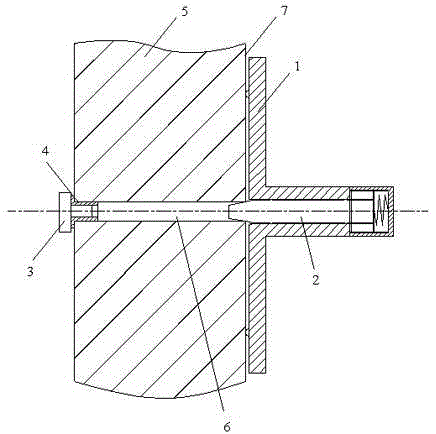

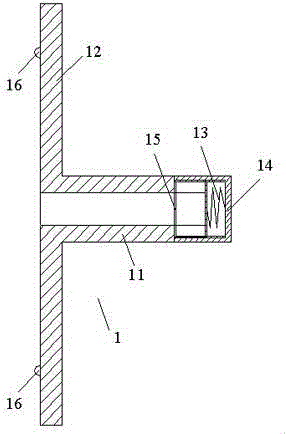

[0025] The following combination Figure 1 ~ Figure 3 , a preferred embodiment of the present invention is described in detail.

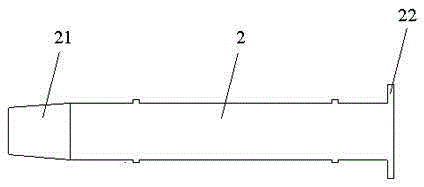

[0026] Such as figure 1 As shown, the deep hole verticality laser measurement system provided by the present invention comprises: a hand-held vertical support 1; a laser emitter 2, which is arranged inside the hand-held vertical support 1, and the front end of the laser emitter 2 emits The head 21 is exposed outside the hand-held vertical support 1; the front-end emission head 21 of the laser transmitter 2 is inserted into one end of the measured depth hole 6 on the steam generator tube plate 5, so that the hand-held vertical support 1 and the steam The measured datum surface 7 on the generator tube plate 5 is in contact; the transition sleeve 4 is arranged in the other end of the measured depth hole 6 on the steam generator tube plate 5; the laser position detection device 3 is arranged on the In the above-mentioned transition sleeve 4, the laser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com