A method for monitoring the accuracy of measuring scales in the production process

A technology of production process and measuring scales, which is applied in the field of monitoring the accuracy of measuring scales, and can solve problems such as increasing production costs and not being suitable for real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

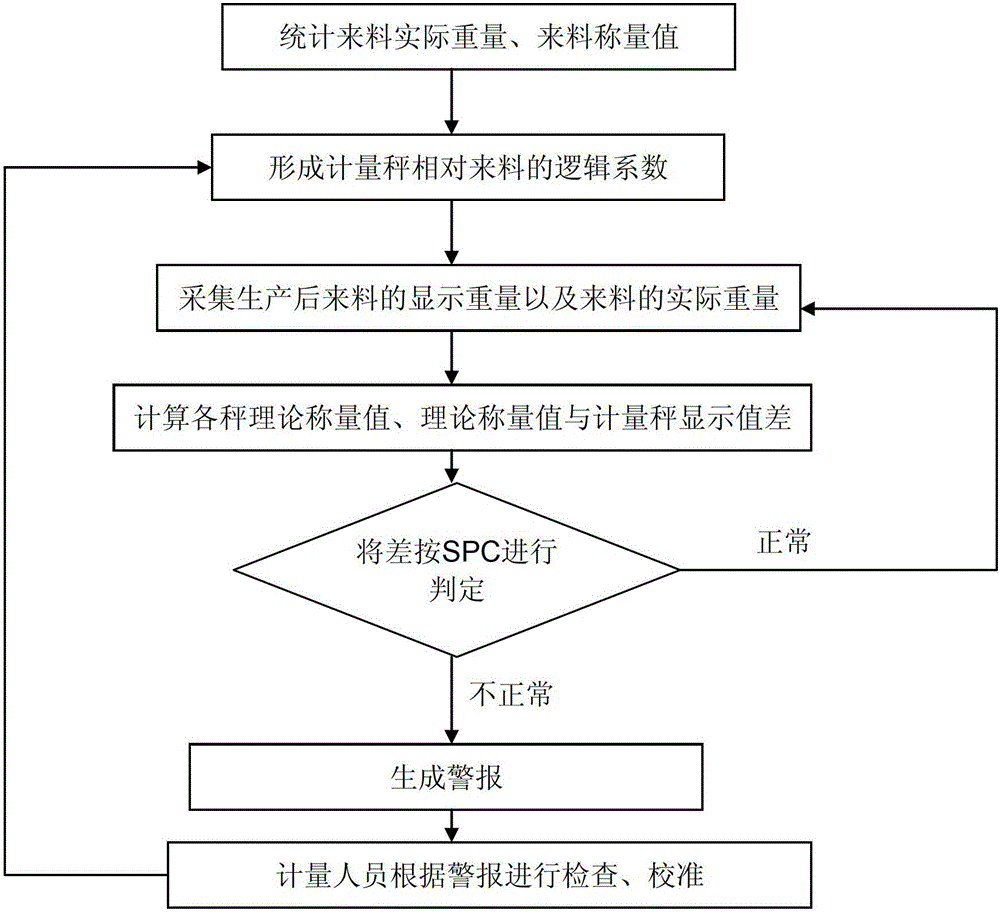

[0022] A specific implementation of the monitoring method of weighing scale accuracy in the production process of the present invention is provided below, comprising the steps:

[0023] (1) Before the start of this batch of production, use the weighing scale to be inspected to weigh the weight of the incoming material before production, and obtain the weighing value A of the incoming material before production 1 ; Here you can choose the calibrated weighing scale to weigh. The calibrated measuring scale has better measurement accuracy and improves the weighing accuracy in the production process. Of course, if there is a slight error in the measuring scale here, it will not affect the method for monitoring the accuracy of the measuring scale in the whole process.

[0024] (2) Calculate the weighing value A of incoming materials before production 1 Compared with the actual weight A of the incoming material before production 0 The ratio of , as the logical coefficient B, B=A 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com