Hollow cavity member

A cavity and component technology, used in building components, building structures, floor slabs, etc., can solve problems such as poor overall strength and rigidity, and cavity mold shell rupture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below in conjunction with the drawings and embodiments.

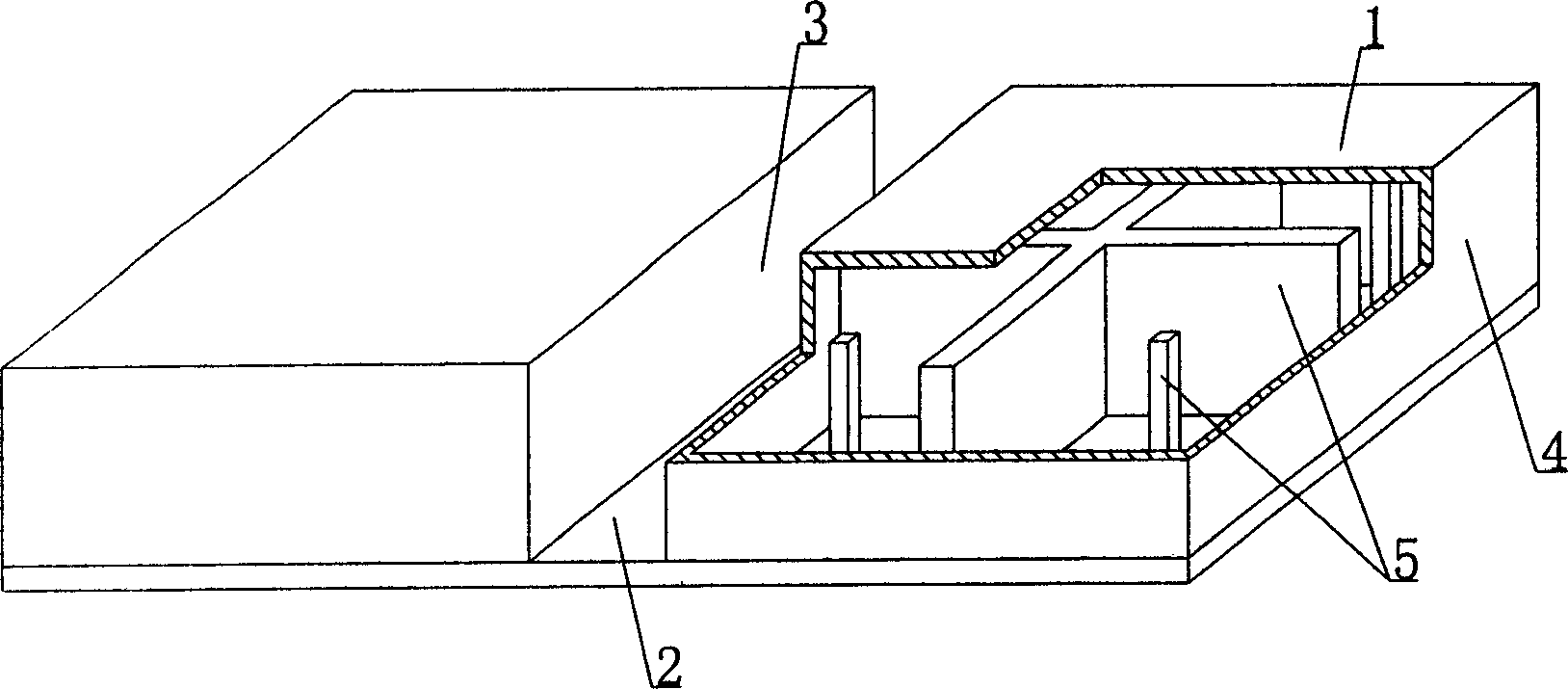

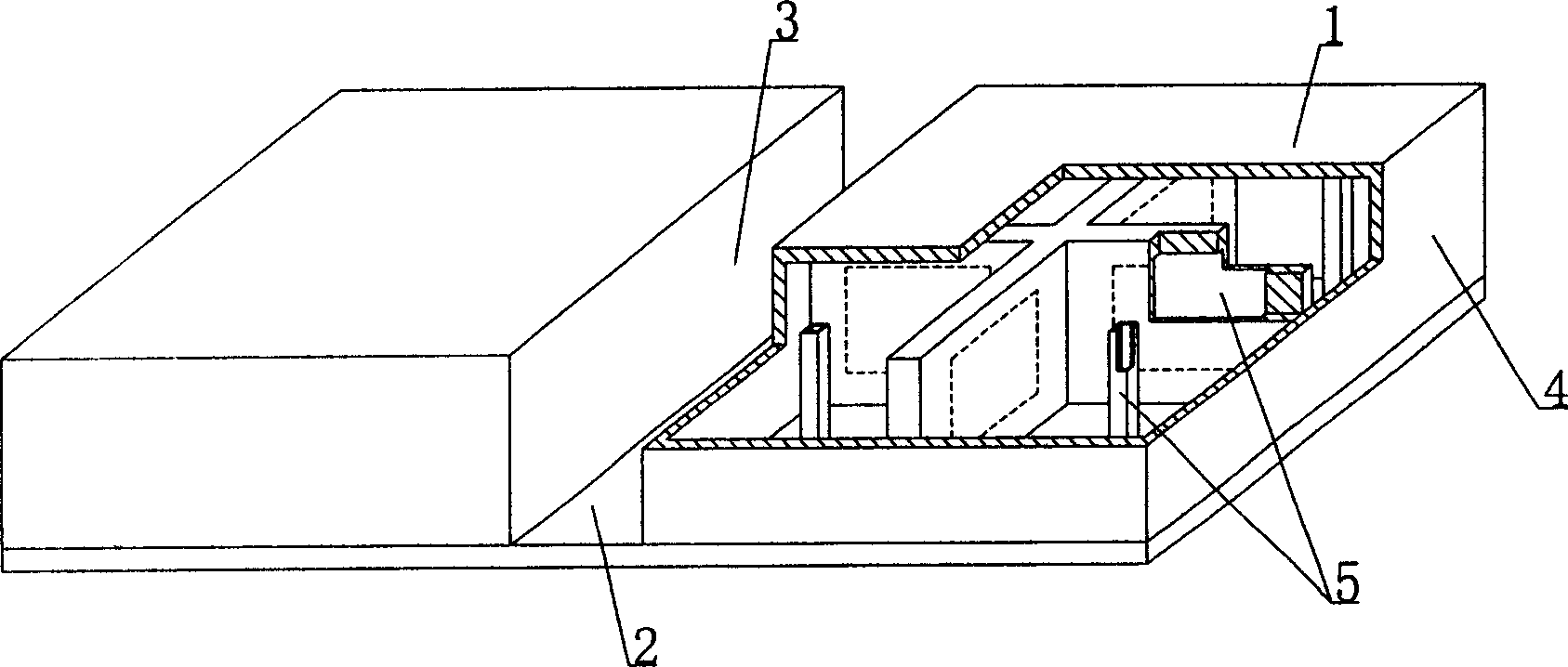

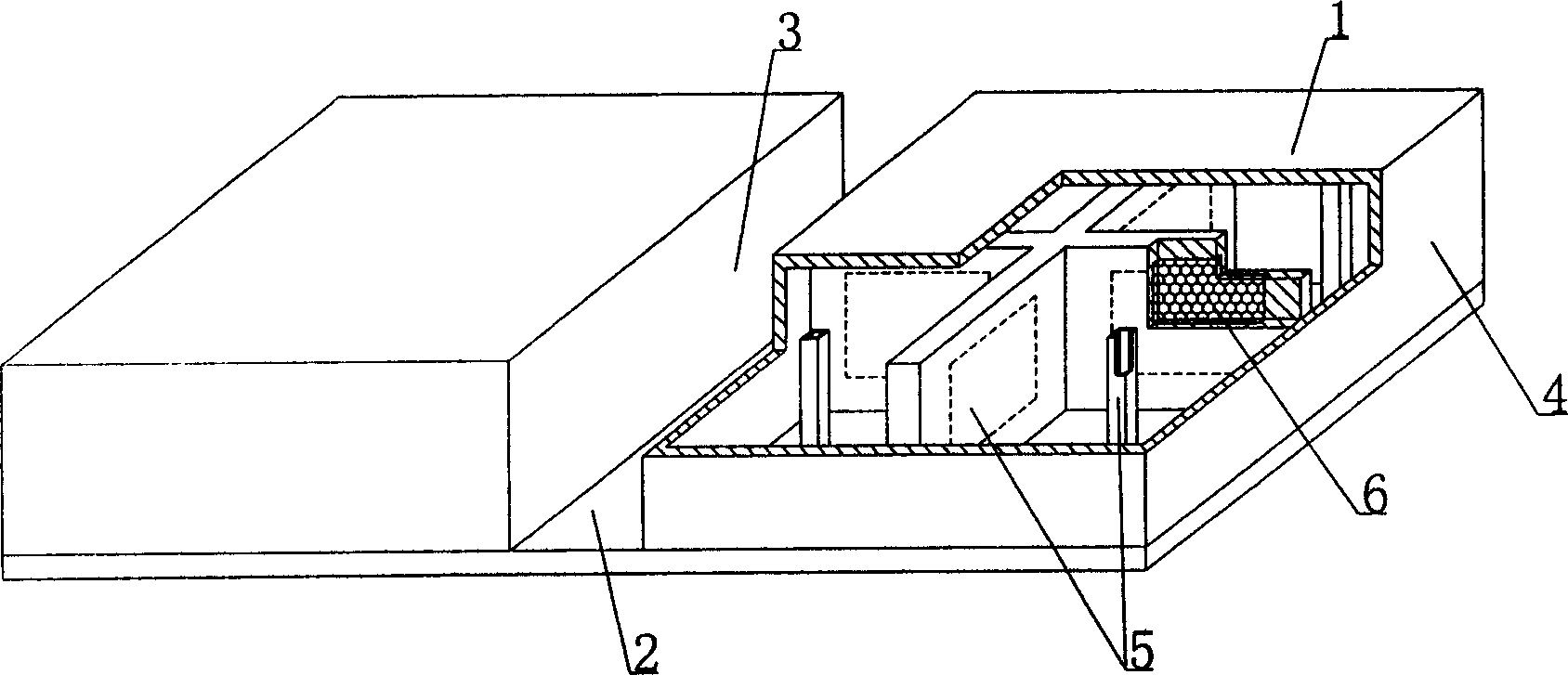

[0077] As shown in the drawings, the present invention includes a cavity mold shell 1 and a bottom plate 2. The cavity mold shell 1 and the bottom plate 2 are connected as a whole. On the bottom plate 2, there are at least two cavity mold shells 1 arranged alternately. 2 constitute at least one cast-in-place structure inner rib mold cavity 3, the other outer side of the cavity mold shell 1 constitutes the side template of the cast-in-place structure outer rib or beam or wall, characterized in that at least one cavity mold shell 1 is provided with At least one reinforcing member 5, the contact part of the cavity mold shell 1 and the bottom plate 2 is a groove 11, and the inner rib mold cavity 3 has at least two parallel bracing members 9. figure 1 It is a schematic diagram of the structure of Embodiment 1 of the present invention. In the drawings, 1 is a cavity mold she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com