Detection screening device and detection screening method thereof

A screening device and screening method technology, applied in sorting and other directions, can solve problems such as accuracy problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

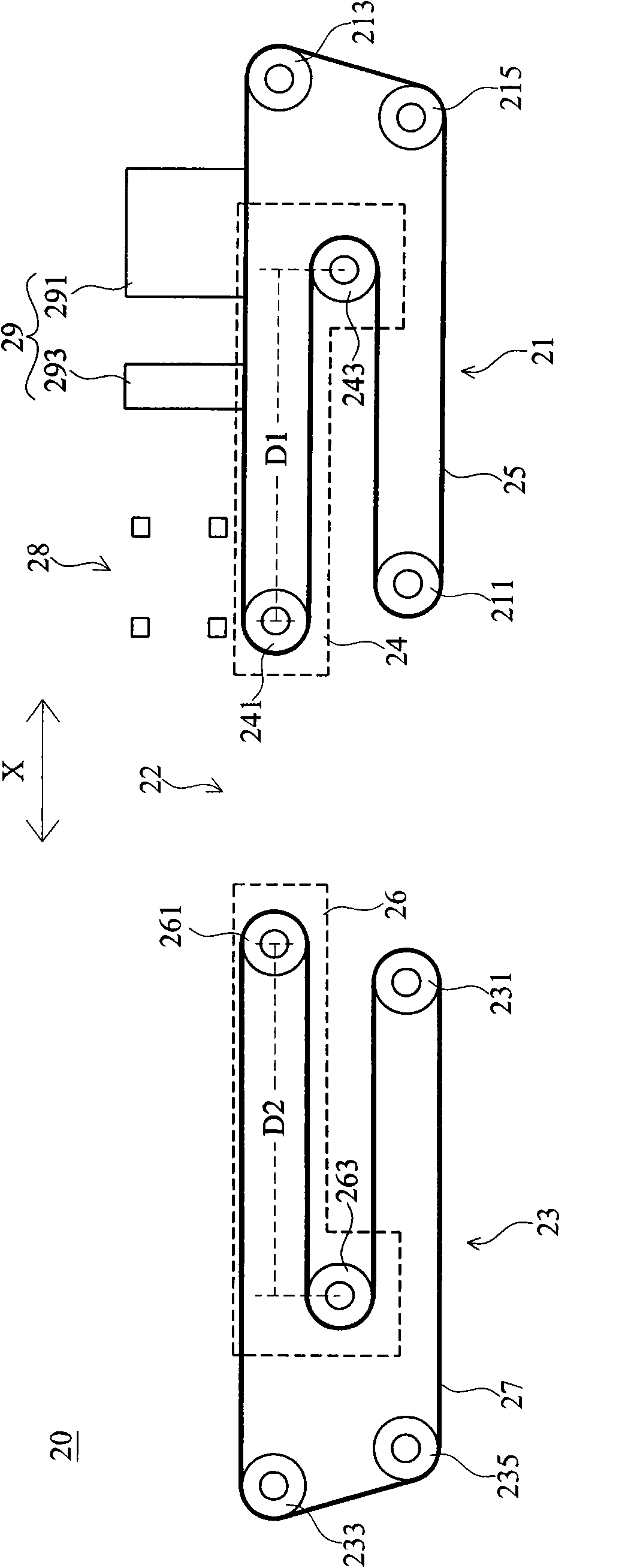

[0065] see figure 2 , is a schematic diagram of the structure of a preferred embodiment of the detection and screening device of the present invention. As shown in the figure, the detection and screening device 20 includes a first transmission unit 21 and a second transmission unit 23, wherein there is a gap 22 between the first transmission unit 21 and the second transmission unit 23, and the first transmission unit 21 and the second transmission unit 23 Part of the components of the second transmission unit 23 are movable to achieve the purpose of changing the size of the gap 22 .

[0066] In one embodiment of the present invention, the first transmission unit 21 includes a first power wheel 211, a first tension wheel 215, a first fixed wheel 213, a first movable wheel set 24 and a first conveyor belt 25, and The first conveyor belt 25 is wound around the first power pulley 211 , the first tension pulley 215 , the first fixed pulley 213 and the first movable pulley set 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com