Coupler

A coupling, a pair of technology, applied in the direction of electrical components, electromechanical devices, electromechanical transmission devices, etc., can solve the problems of click winding burnt, disciplinary clothing, leakage, etc., to achieve non-contact, prolong service life, and practical functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

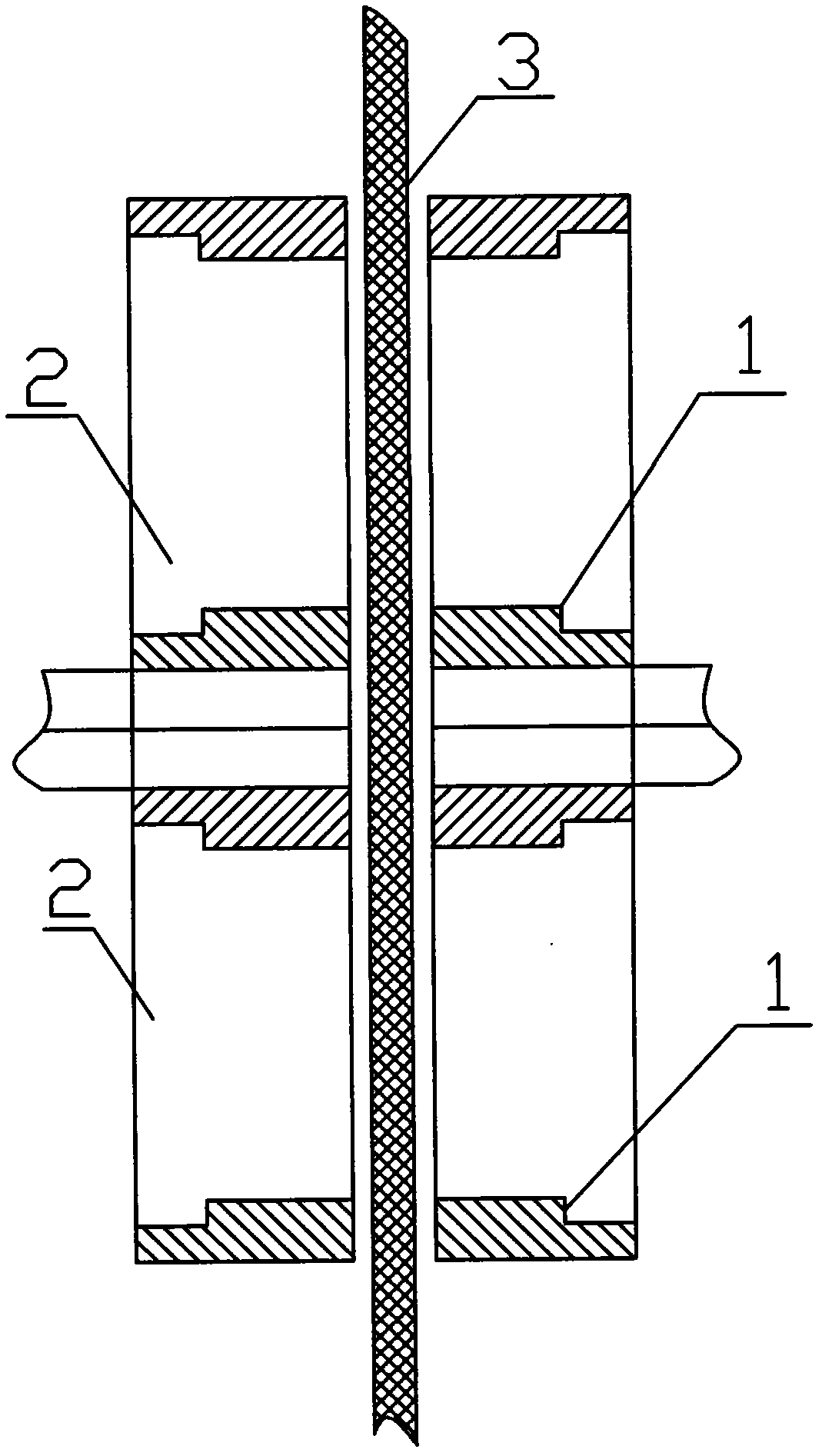

[0010] Such as figure 1 It shows a coupling of the present invention, including a pair of turntables 1, the turntables 1 are installed symmetrically up and down, and a balance magnet 2 is provided inside each turntable 1, and the balance magnets 2 are symmetrically arranged, and in the middle of the turntable 1 There is a magnetic medium casing 3 running through it, and the magnetic medium casing 3 can transmit power to any turntable 1. According to the law that the SN poles of the balance magnet 2 attract each other, the other turntable 1 will rotate accordingly, forming a non-contact of couplings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com