Neglected loading preventive tooling for crankshaft thrust piece

A technology of thrust plate and leak-proof installation, which is applied in the direction of metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of low installation efficiency, wrong installation, missing installation, monotonous installation action, etc., and achieve low manufacturing cost and solve the problem of The effect of missing installation and enhancing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

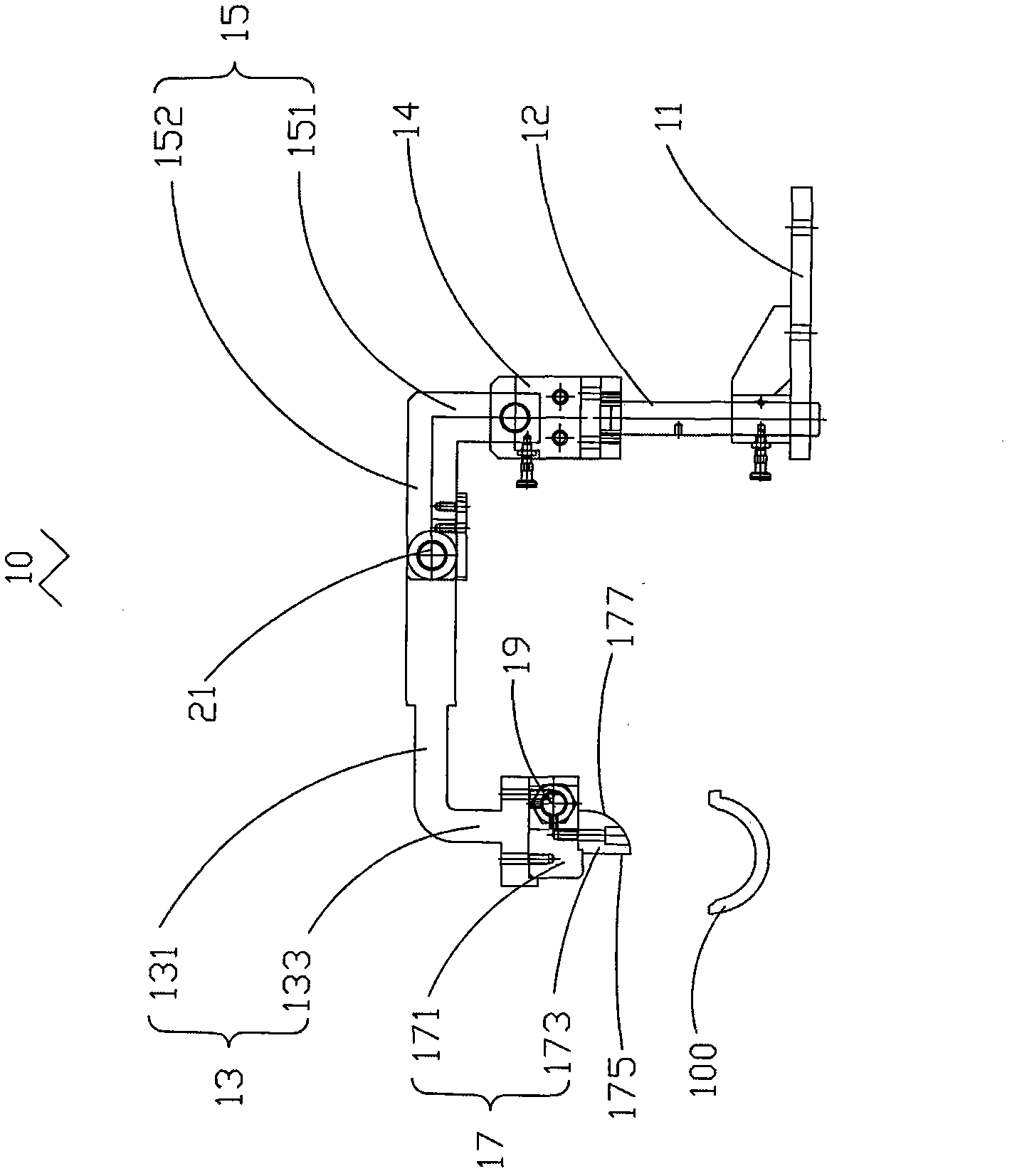

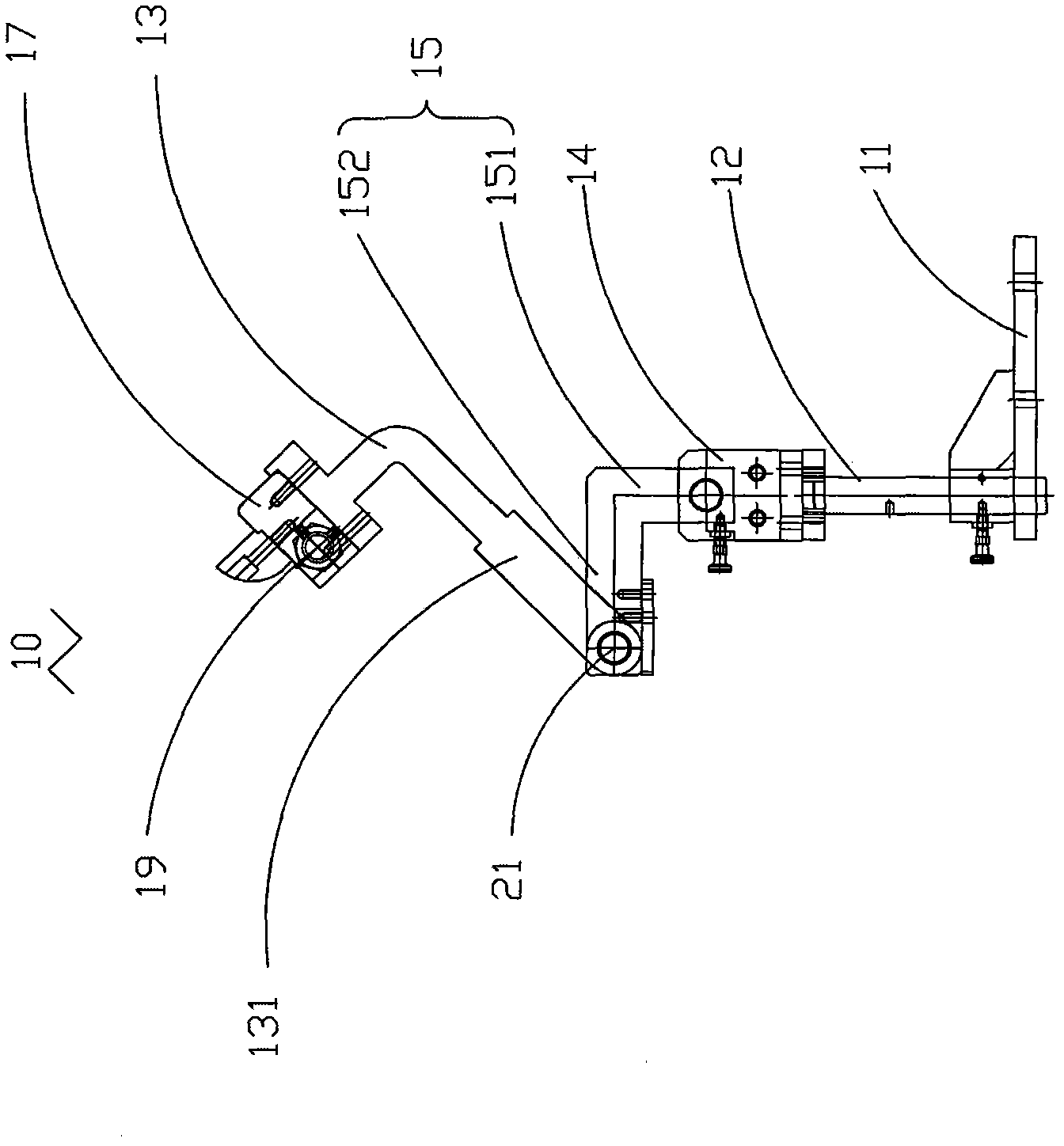

[0020] see figure 1 and figure 2 , The present invention provides a crankshaft thrust plate leakage prevention tooling 10, including a base 11, a support frame 12, a moving arm 13, a connecting block 14, a connecting bracket 15, a positioning block 17, a sensor 19 and a pivot 21. It is used to prevent missing installation of the thrust plate 100.

[0021] The base 11 is placed on the level ground, the support frame 12 is fixedly connected to the base 11, the support frame 12 is arranged perpendicular to the base 11, the connection block 14 is arranged between the support frame 12 and the connection bracket 15, the movable arm 13 includes a main body 131 and a The mounting part 133 of 131, the connecting bracket 15 includes a first connecting part 151 and a second connecting part 152 perpendicular to each other, the main body 131 of the movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com