Fuzzy-control-based soft abrasive grain flow processing method and device thereof

A processing method and fuzzy control technology, applied in the direction of manufacturing tools, adaptive control, general control system, etc., can solve the problems of low processing efficiency and low accuracy of flow rate control, and achieve improved processing quality, uniform dynamic pressure distribution, and improved uniformity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

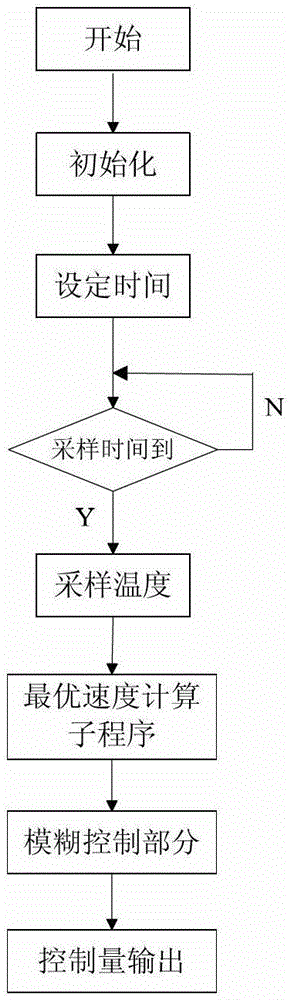

[0032] refer to Figure 1 to Figure 5 , a soft abrasive flow processing method based on fuzzy control, the specific process of the processing method is as follows:

[0033] (1) The temperature sensor in the liquid storage tank measures the current temperature of the soft abrasive particles, and calculates the optimal speed at the current temperature by the temperature-optimal speed formula;

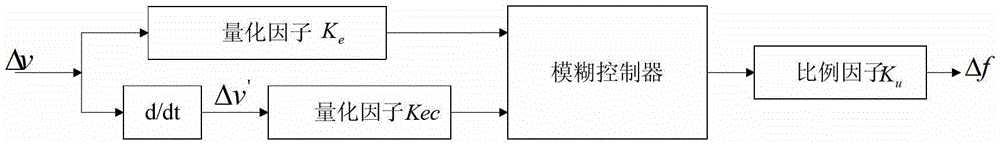

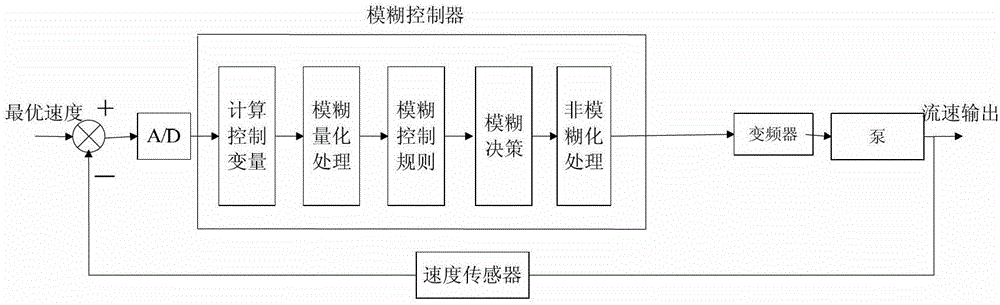

[0034] (2) Input into the fuzzy controller, the optimal speed is used as the speed given value of the fuzzy controller, and the current velocity measured by the speed sensor is input as the feedback quantity of the fuzzy controller; the difference between the optimal speed and the current speed is The input quantity of the system; in the fuzzy controller, after the input quantity is processed through fuzzification-fuzzy control rules-fuzzy decision-refinement treatment, the precise output quantity is output, and the output quantity is the variation of voltage frequency, and the actuator ...

Embodiment 2

[0052] refer to Figure 1~Figure 5 , a soft abrasive flow processing device based on fuzzy control, including a soft abrasive flow processing experimental platform, the soft abrasive flow processing experimental platform includes a liquid storage tank, and a pump and a pipeline are installed in the liquid storage tank , the pump is connected to a frequency converter, the frequency converter is connected to a RS232 / RS485 converter, the RS232 / RS485 converter is connected to a processing controller, a temperature sensor and a flow sensor are installed in the pipeline, and the temperature sensor and The flow sensor is connected to an A / D converter which is connected to the process controller.

[0053] The system block diagram is attached image 3 As shown, the flow chart is as figure 1 shown.

[0054] In the system, the temperature sensor measures the current temperature, and the mathematical model set inside the system calculates the optimal speed at the current temperature, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com