High-speed moving parallel mechanical arm with six degrees of freedom

A high-speed motion and degree of freedom technology, applied in the field of robotics, can solve problems such as increasing the mass and inertia of moving parts, making it difficult to achieve high-speed motion, and affecting the dynamic performance of the mechanism, so as to achieve overall structure symmetry, satisfy complex pick-and-place operations, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

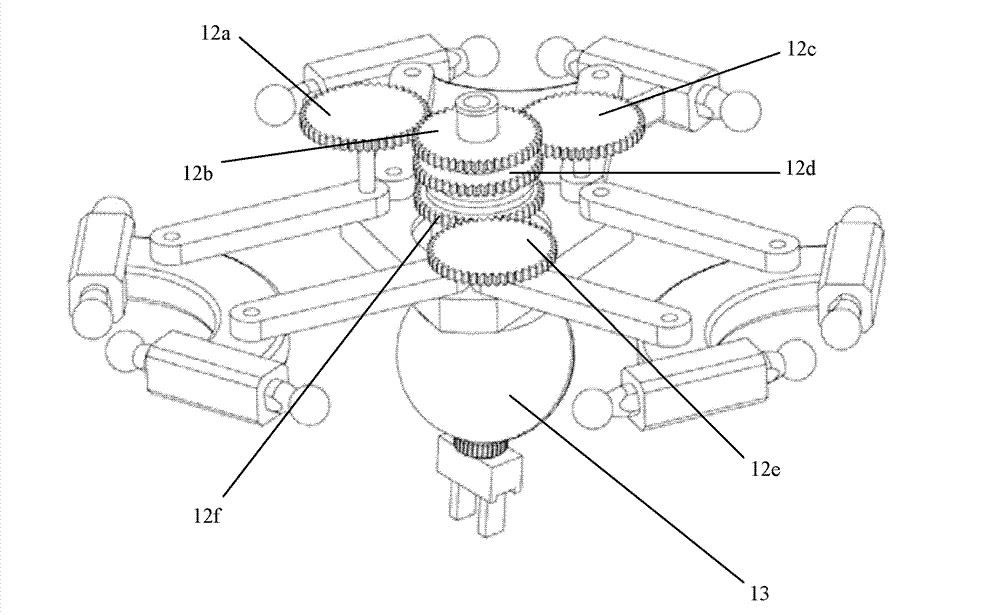

[0025] Each set of gear mechanisms includes a large gear and a small gear, wherein the large gear is fixedly connected to a connecting rod in a set of connecting rods, the rotation axis of the large gear coincides with the rotation axis of the connecting rod on the center plate, and the small gear and One input shaft of the three-degree-of-freedom wrist is fixedly connected, and the rotation axis of the pinion coincides with the axis of one input shaft. Such as image 3 As shown, the three large gears 12a, 12c, 12e are fixedly connected to one of the connecting rods 11a, 11c, 11e in the three sets of connecting rods respectively, and the rotation axis of the large gear and the rotation axis of the fixed connecting rod on the center plate Coincident; the three pinions 12b, 12d, 12f are fixedly connected to an input shaft of the three-degree-of-freedom wrist 13 respectively, and the rotation axis of the pinion coincides with the axis of the fixed input shaft. Three large gears ...

Embodiment approach 2

[0027] The gear mechanism includes a large gear and a small gear, wherein the large gear is affixed to the club base, the pinion is affixed to an input shaft of the three-degree-of-freedom wrist, and the rotation axis of the pinion is connected to one of the three-degree-of-freedom wrists. The axis of the input shaft coincides, and the common vertical segment of the rotation axis of the pinion and the rotation axis of the bull gear is parallel and equal in length to the connecting rod in the parallelogram structure. Such as Figure 4As shown, the three large gears 12a, 12c, 12e are fixedly connected to the three club mounts 8a, 8b, 8c respectively, and the three small gears 12b, 12d, 12f are respectively fixedly connected to an input shaft of the three-degree-of-freedom wrist 13, And the rotation axis of the pinion coincides with the axis of the input shaft of the fixed three-degree-of-freedom wrist 13 . Three bull gears 12a, 12c, 12e and three pinion gears 12b, 12d, 12f form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com