Automatic switch-over shifting device and operation method thereof

A shifting device and automatic transfer technology, which is applied in the direction of transportation, packaging, roller table, etc., can solve the problem that the center of gravity of the vehicle cannot meet the requirements of transfer and transportation, and achieve the effects of reducing safety hazards, labor costs, and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

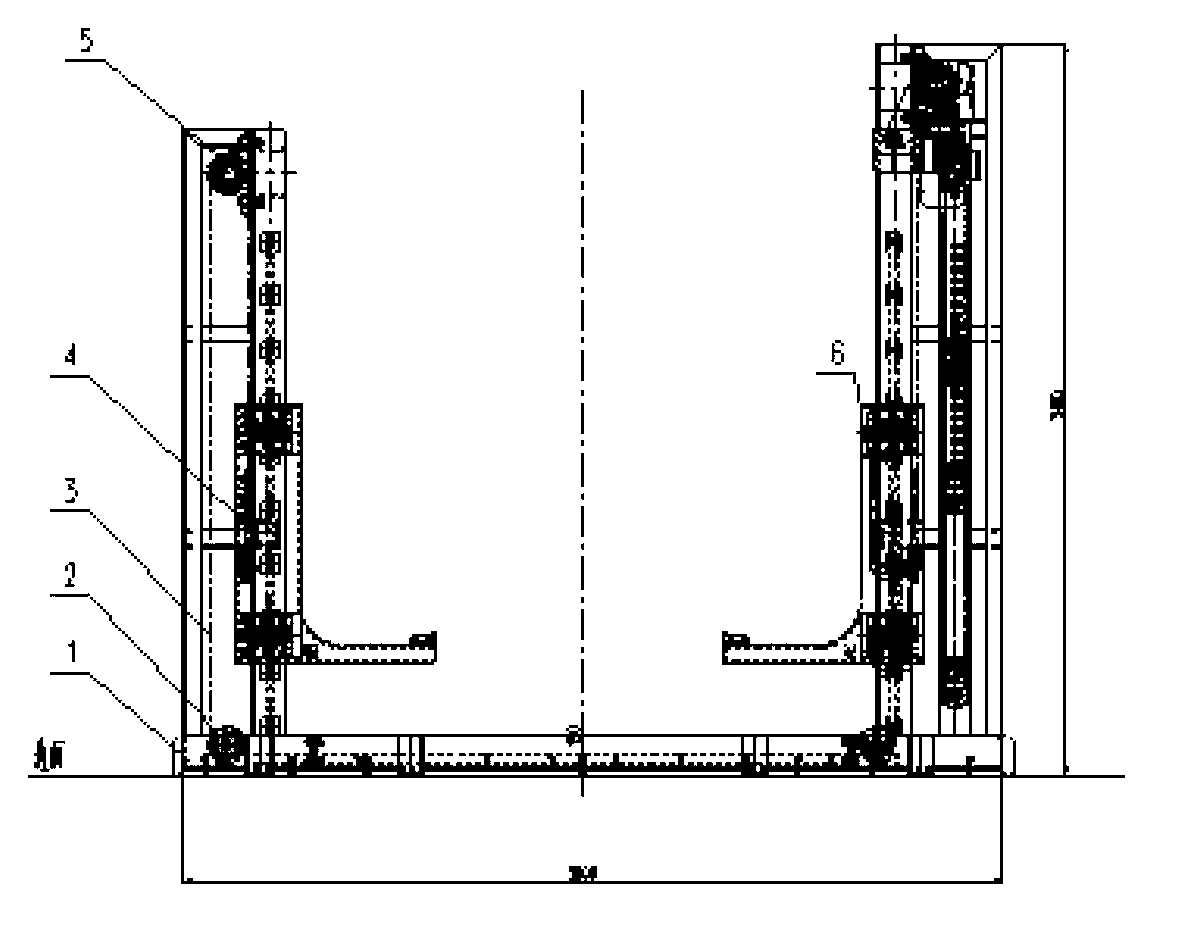

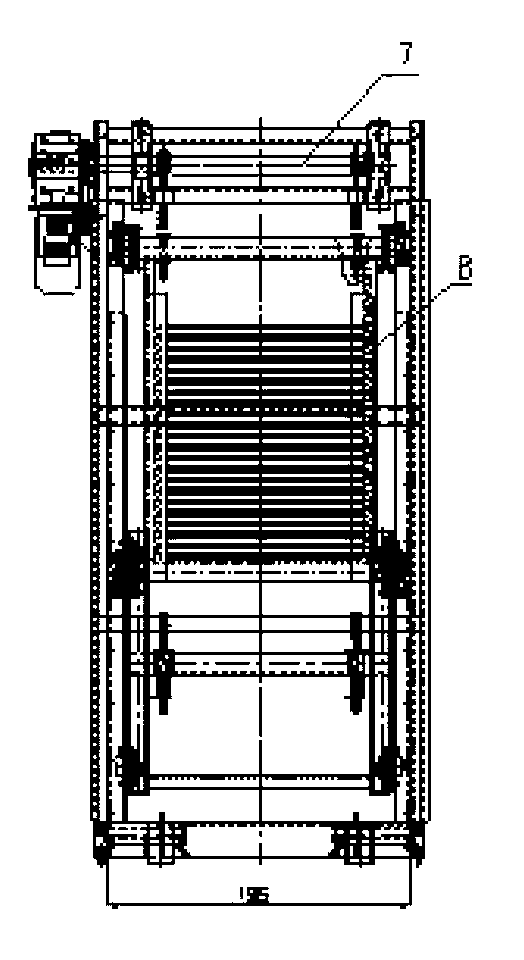

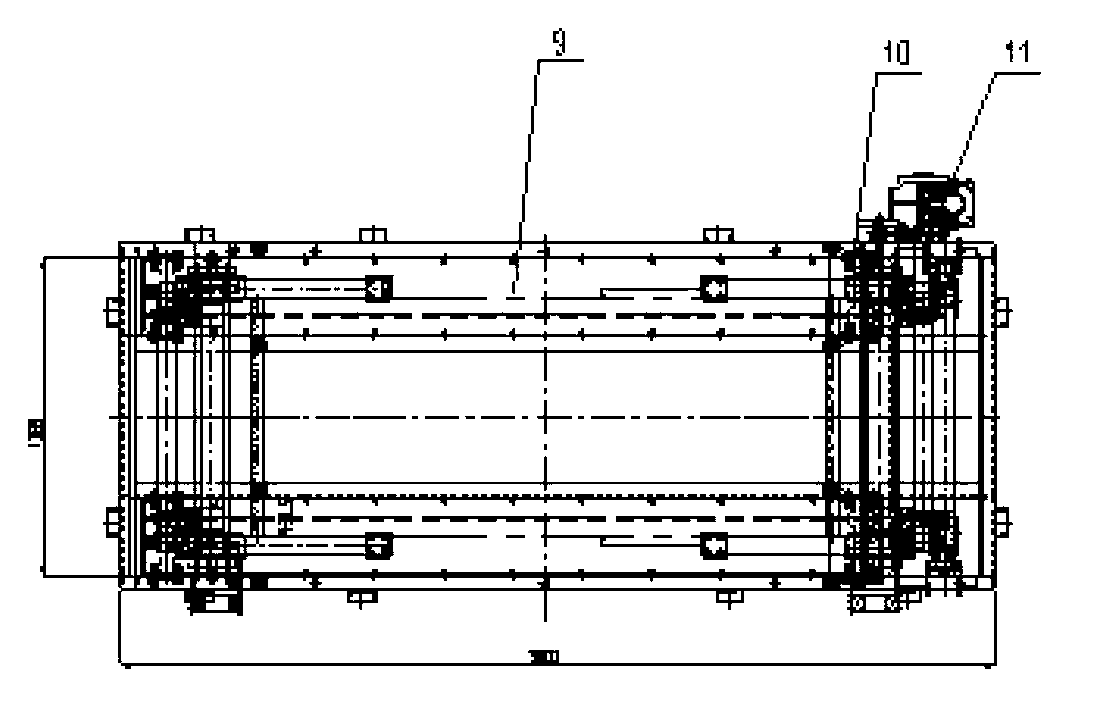

[0033] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

[0034] Use the supporting arm (16) to support the lower skirt of the vehicle body, and adjust the overall height of the supporting arm and the vehicle body through the lifting device (12); 14) A corresponding stop device (13) is arranged on the upper part to realize the position adjustment of the body relative to the skid in the horizontal direction.

[0035] At present, the structure of the roller bed conveying equipment in the painting workshop is as follows: the roller bed conveying line process skid (15) realizes the support for the skid through the fixed roller bed (14) and meets the purpose of walking on the conveying roller bed. The vehicle body is constrained by the positioning pins (17) during the conveying process, which will cause the corresponding positioning pins to be unabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com