Device and method for co-production of liquefied natural gas and liquid nitrogen

A technology of liquefied natural gas and liquid nitrogen, which is applied in the direction of gas fuel, nitrogen purification/separation, petroleum industry, etc., can solve the problems of energy consumption, methane gas economy and environmental protection, so as to avoid rollover accidents, improve environmental protection benefits and economy Benefits, the effect of overcoming limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

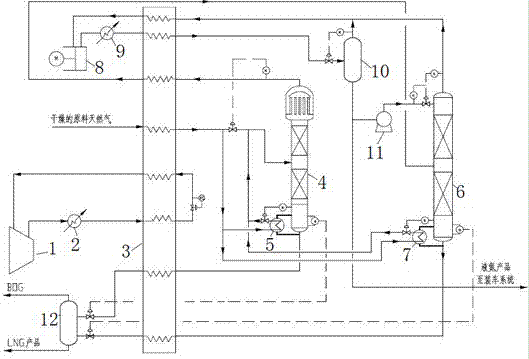

[0031] A device for the co-production of liquefied natural gas and liquid nitrogen, such as figure 1 As shown, it includes: compound refrigerant compressor 1, compound refrigerant cooler 2, main heat exchanger 3, denitrification tower 4, denitrification tower reboiler 5, nitrogen-methane fractionation tower 6, nitrogen-methane fractionation tower Reboiler 7, nitrogen compressor 8, nitrogen cooler 9, liquid nitrogen storage tank 10, liquid nitrogen pump 11 and LNG flash tank 12, etc., wherein:

[0032] The main heat exchanger 3 is connected with the denitrification tower 4, and the liquid phase outlet of the denitrification tower 4, the main heat exchanger 3 and the LNG flash tank 12 are connected in sequence, in order to ensure that the nitrogen content in the LNG product does not exceed the standard and ensure that the LNG For the safe storage of products, a denitrification tower reboiler 5 is installed at the bottom of the denitrification tower 4 to strip the liquid phase ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com