Rotating crane

A technology of slewing arms and columns, which is applied in the field of slewing cranes, can solve the problems of expensive slewing bearings, high machining accuracy requirements, and high maintenance costs, and achieve the effects of large overturning moment, easy maintenance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

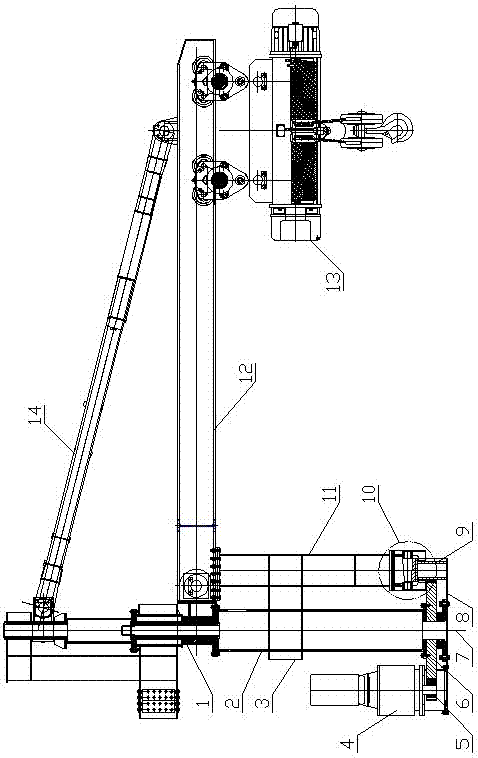

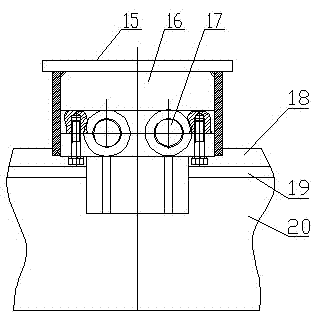

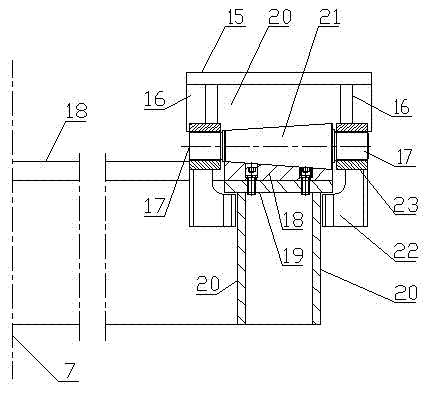

[0026] Depend on Figure 1-Figure 11 The slewing crane shown includes a vertical slewing column 2 driven by a power device 4. The power device 4 is a three-in-one deceleration device composed of a motor, a reducer and a brake connected in sequence. The three-in-one deceleration device passes through The gear transmission drives the rotary column 2, the gear transmission includes a pinion 5 and a large gear 6, the large gear 6 is fixed at the bottom of the rotary column 2, that is, the power device 4 transmits the large gear 6 at the bottom of the rotary column 2 through the small gear 5, The bull gear 6 drives the rotary column 2 to rotate again. The vertical central axis of the revolving column 2 is the revolving centerline 7 .

[0027] The top of the slewing column 2 is fixedly connected with the slewing arm 12 through the slewing bracket 1, the slewing bracket 1 extending vertically upwards is fixed on the top of the slewing column 2, the slewing arm 12 extends horizontall...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap