Monolithic drill pipe and drill pipe composed of it

A drill pipe and monomer technology, applied in drill pipe, drill pipe, drilling equipment and other directions, can solve the problems of inability to work, affect the powder extraction efficiency, collapse and other problems, and achieve the effect of increasing economic benefits and controlling the accident rate of coal mines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

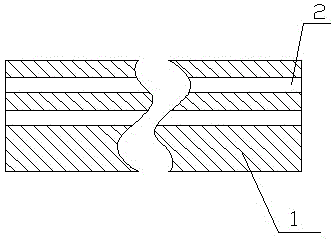

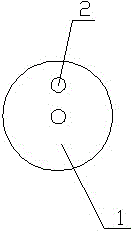

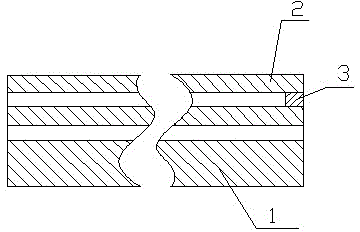

[0039] Such as figure 1 , 2 As shown, a single drill rod includes a rod body 1 and joints at both ends of the rod body. Two axial through holes are arranged in the rod body, one of which is an eccentric through hole 2 . The eccentric through hole is used as a hydraulic oil chamber or a wire rope channel to bend the drill pipe to achieve the purpose of bending drilling operations, and the other axial through holes can be used for other purposes. This monolithic drill pipe is the basis for other monolithic drill pipes. And it can be used as a single drill pipe of the drill pipe of the advancing section or as a single piece of drill pipe forming the hydraulic cavity of the drill pipe of the bending section.

Embodiment 2

[0041] A single-body drill rod, the rod body is a solid rod body, and at least two axial through holes are arranged in the solid rod body, at least one of which is an eccentric through hole. This monolithic drilling rod is a solid monolithic drilling rod, and has the same effect as that of Embodiment 1.

[0042] Other structures are with embodiment 1.

Embodiment 3

[0044] A single-body drill pipe, the rod body is a hollow rod body, and the hollow rod body is provided with a hollow tube with at least two hollow rod bodies through a support plate. The inner hole of the hollow tube is an axial through hole, and at least one of the axial through holes is eccentric through hole. This monolithic drill pipe is a hollow monolithic drill pipe with a lighter weight, and has the same effect as in Embodiment 1.

[0045] Other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com