Rotating structure of lamp holder of track lamp

A technology of rotating structure and track lights, applied in the field of track lights, can solve the problems of uneven contact surface, damage to the overall appearance, sticking, etc., and achieve the effect of simple overall structure, strong manufacturability, and easy assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

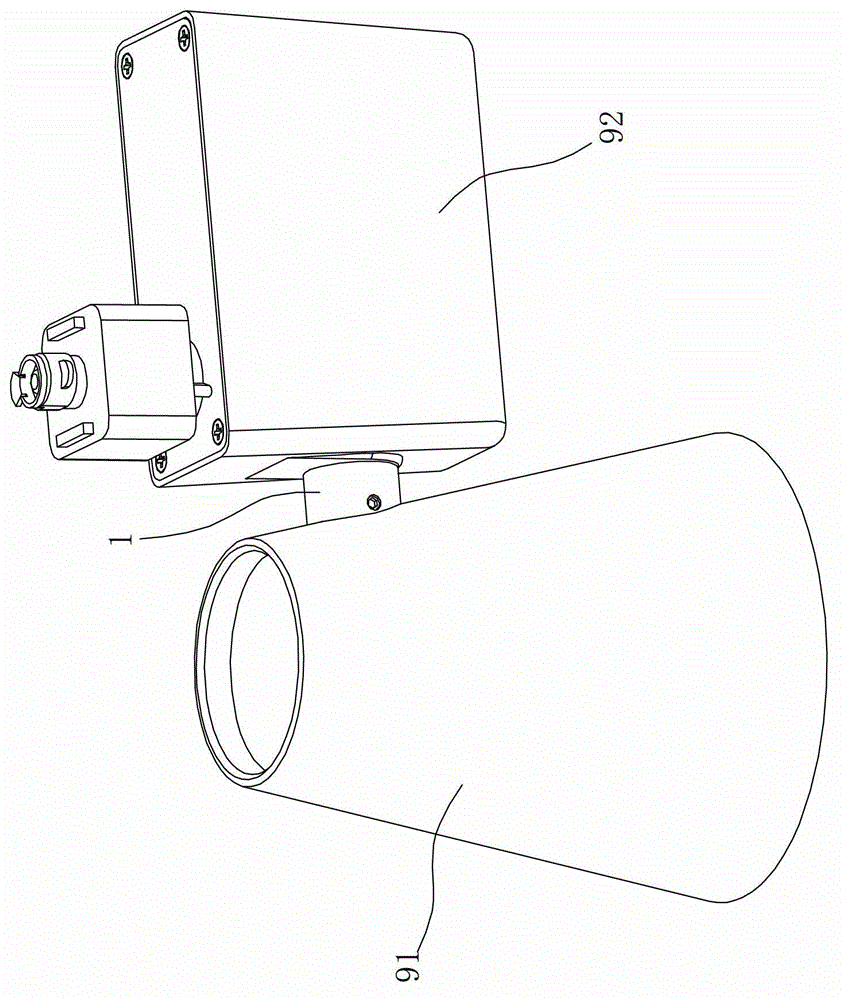

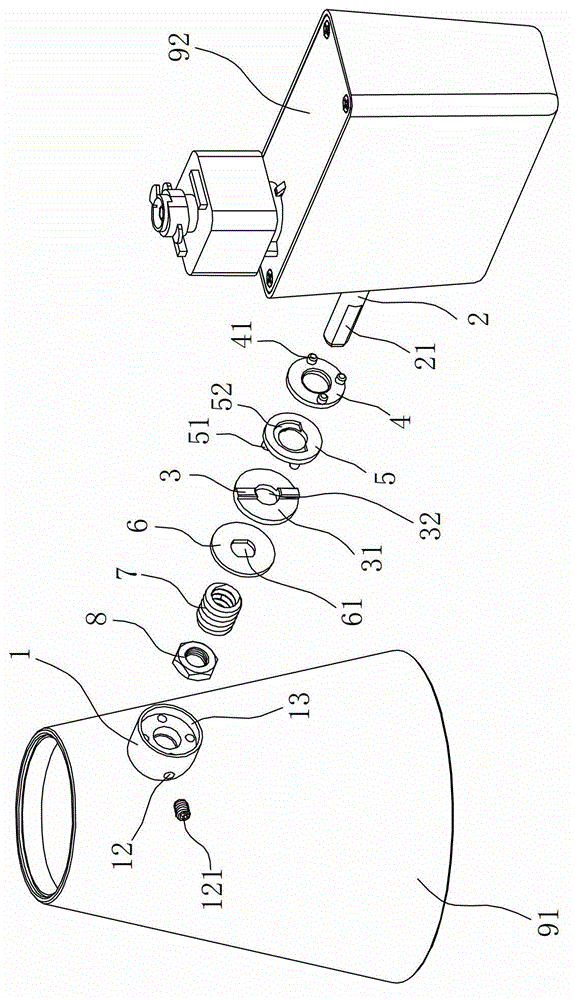

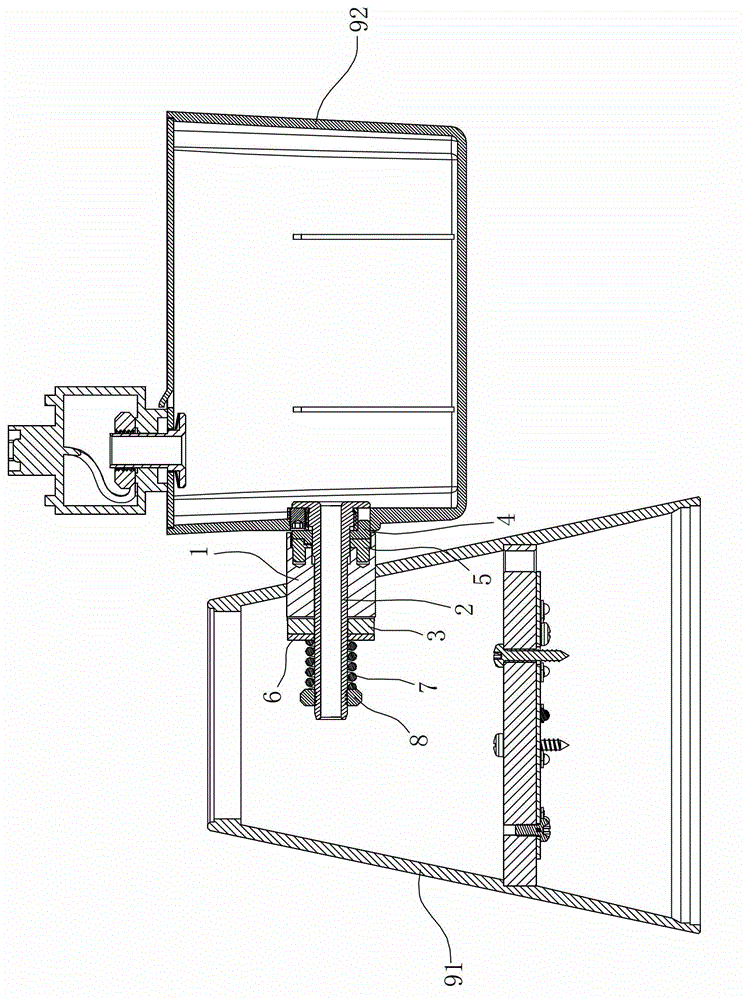

[0026] Such as Figure 1 to Figure 7 As shown, this embodiment is a rotating structure of the lamp head 91 of a track light, and the rotating structure of the lamp head 91 includes a shaft sleeve 1, a connecting shaft 2, a first stop disc 3, a second stop disc 4, and a limiting device 5 , Stop washer 6, elastic member 7 and lock nut 8.

[0027] Wherein, the lamp cap 91 of the track light has a shaft hole on the side wall, and a shaft sleeve 1 is fixedly arranged in the shaft hole. There is no relative rotation between the shaft sleeve 1 and the lamp cap 91, and the two can be fixed by welding or threaded connection; One end of the shaft 2 is inserted into the shaft sleeve 1 and is rotatably matched with the shaft sleeve 1. The other end of the connecting shaft 2 is fixedly connected to the bracket 92 (or power module) of the track light. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com