Patents

Literature

30results about How to "Consistent torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

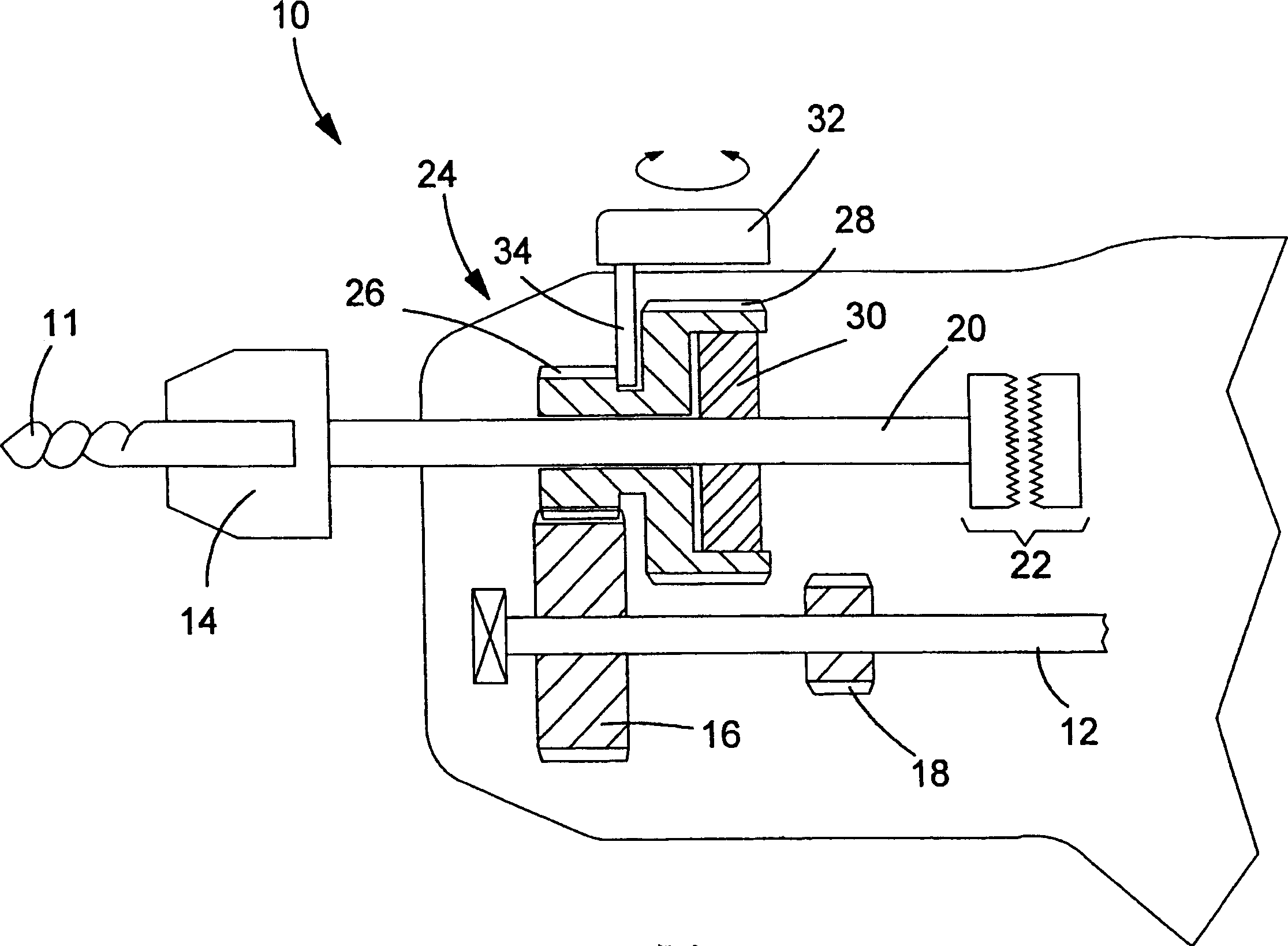

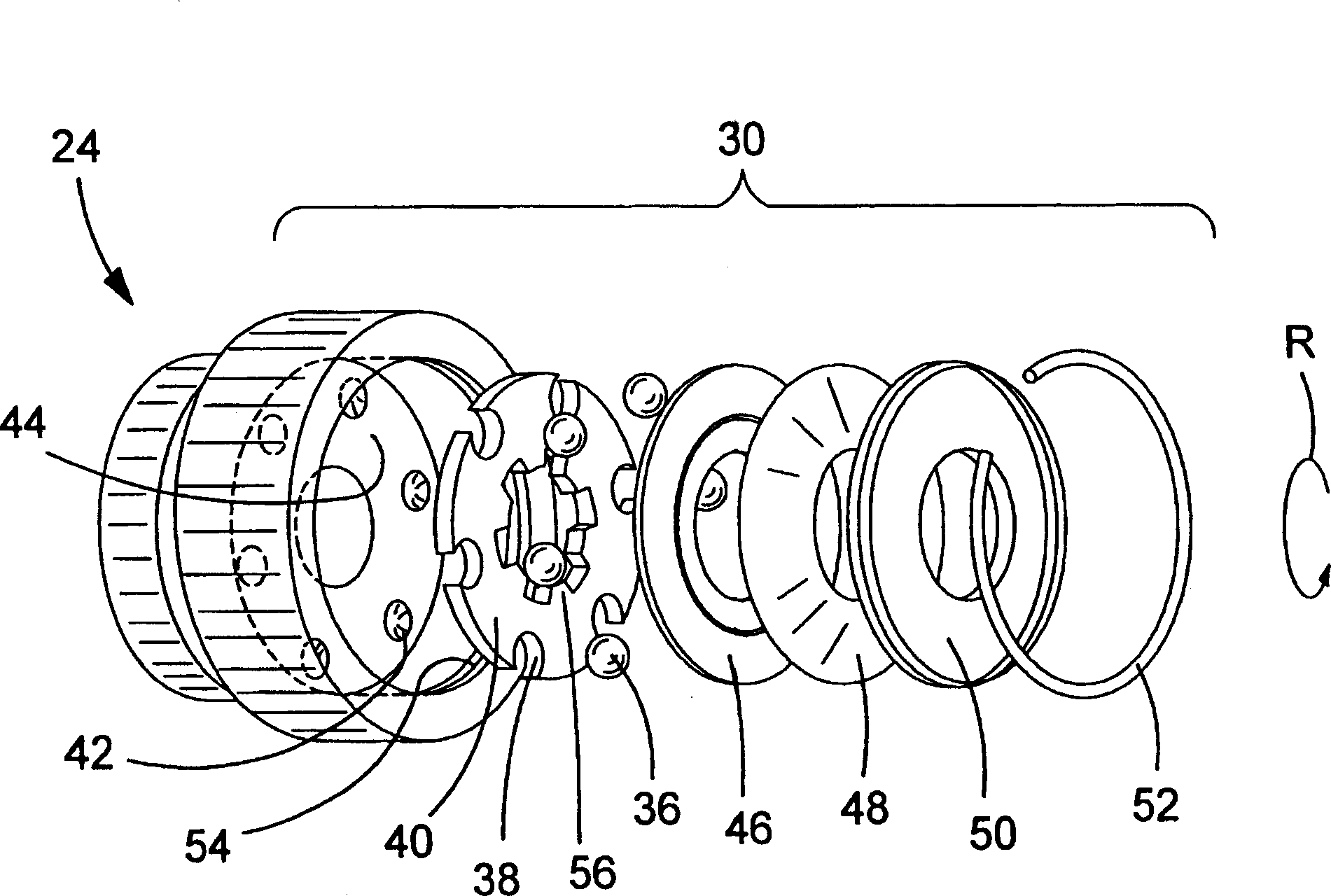

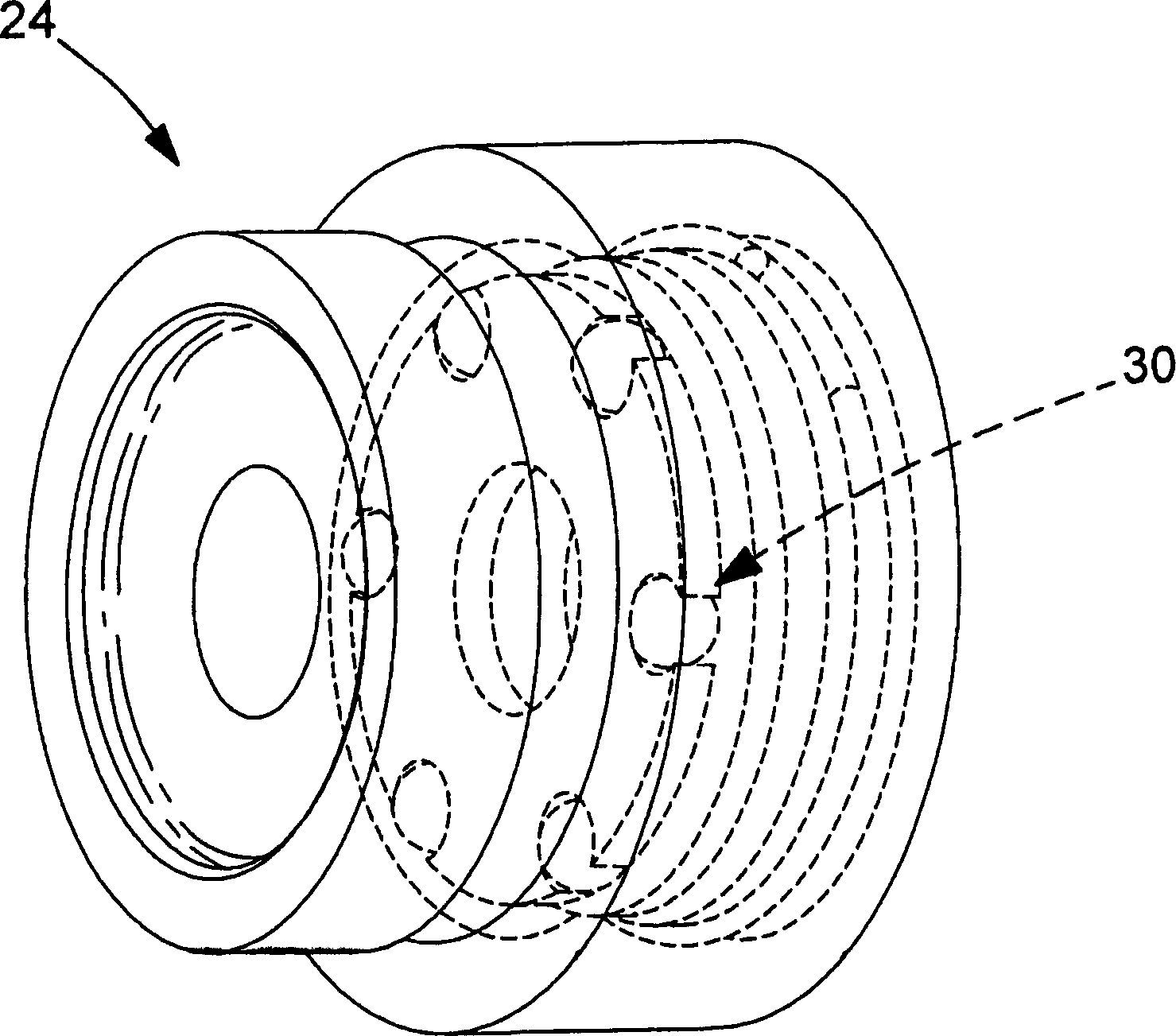

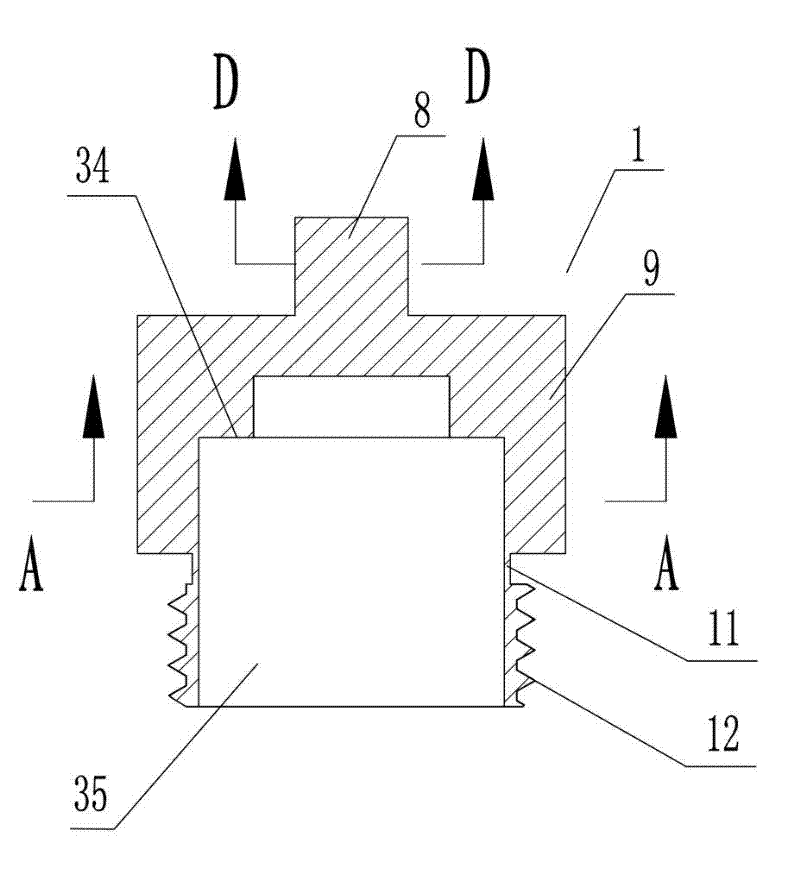

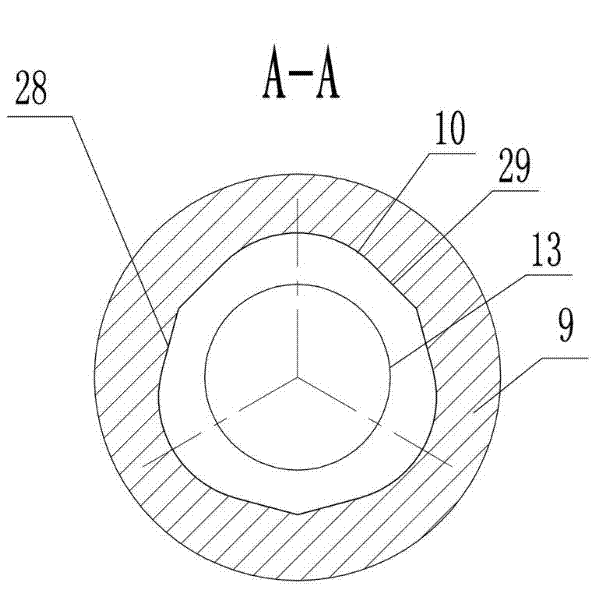

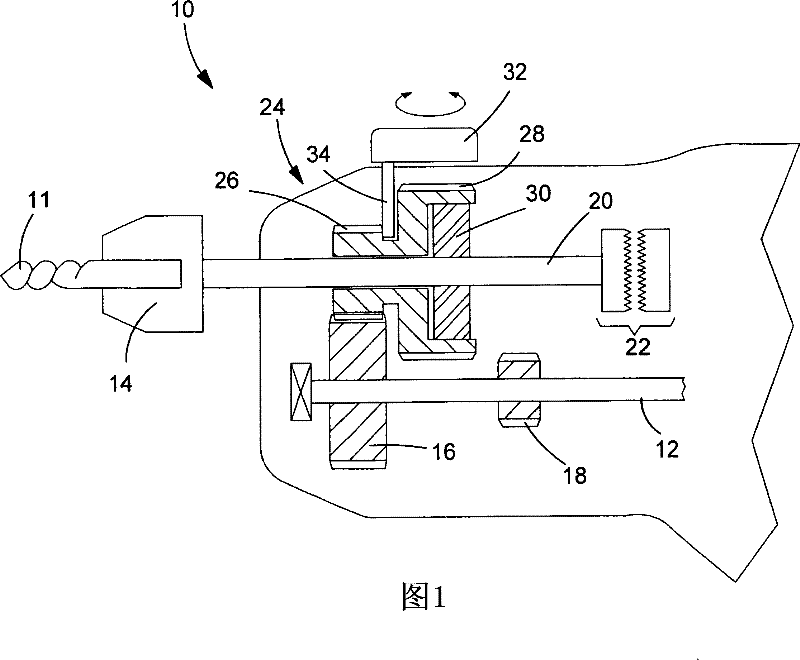

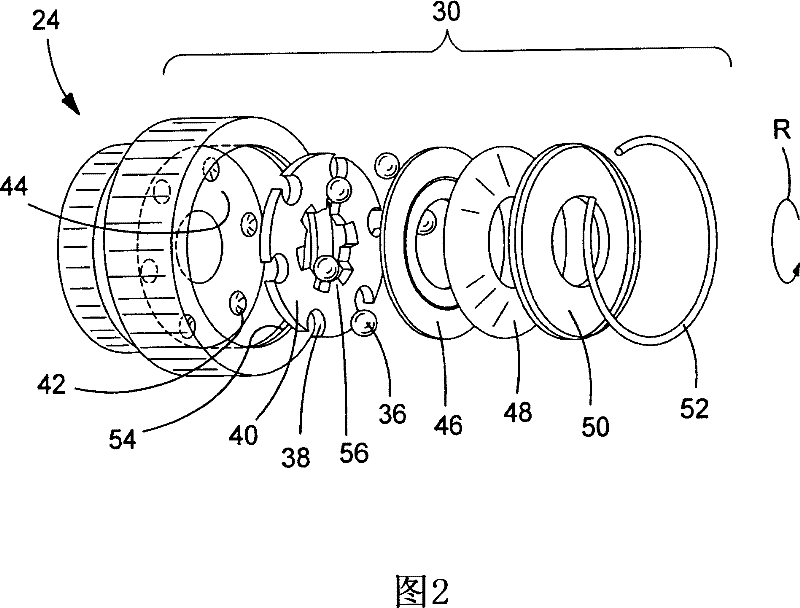

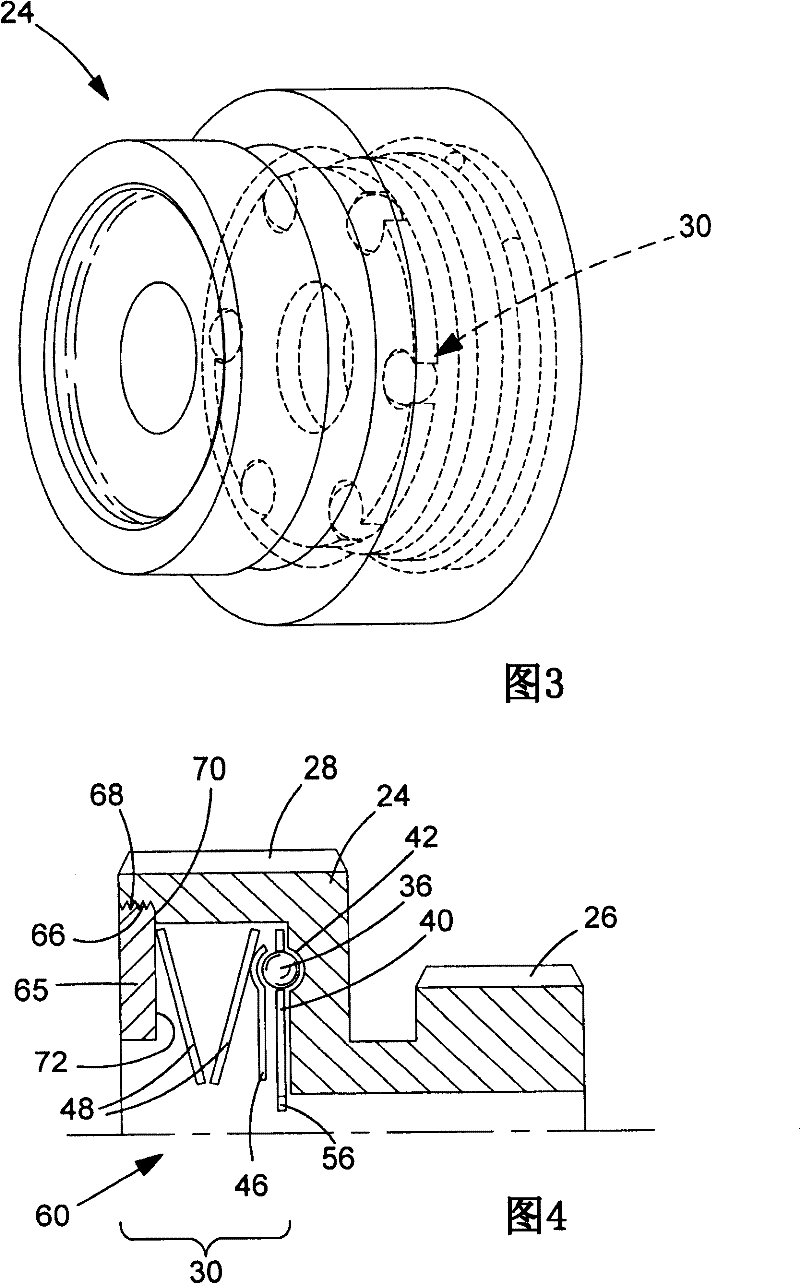

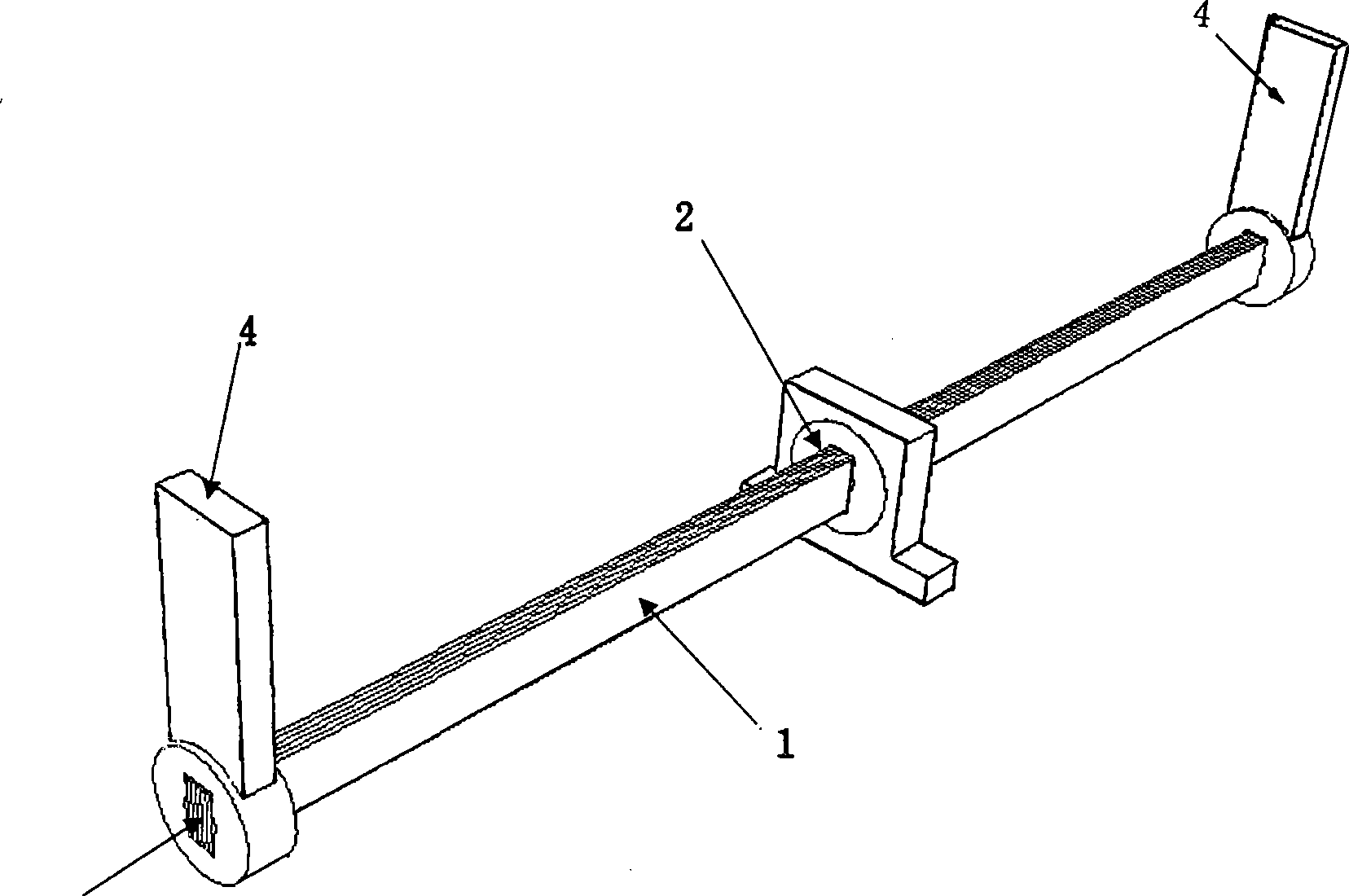

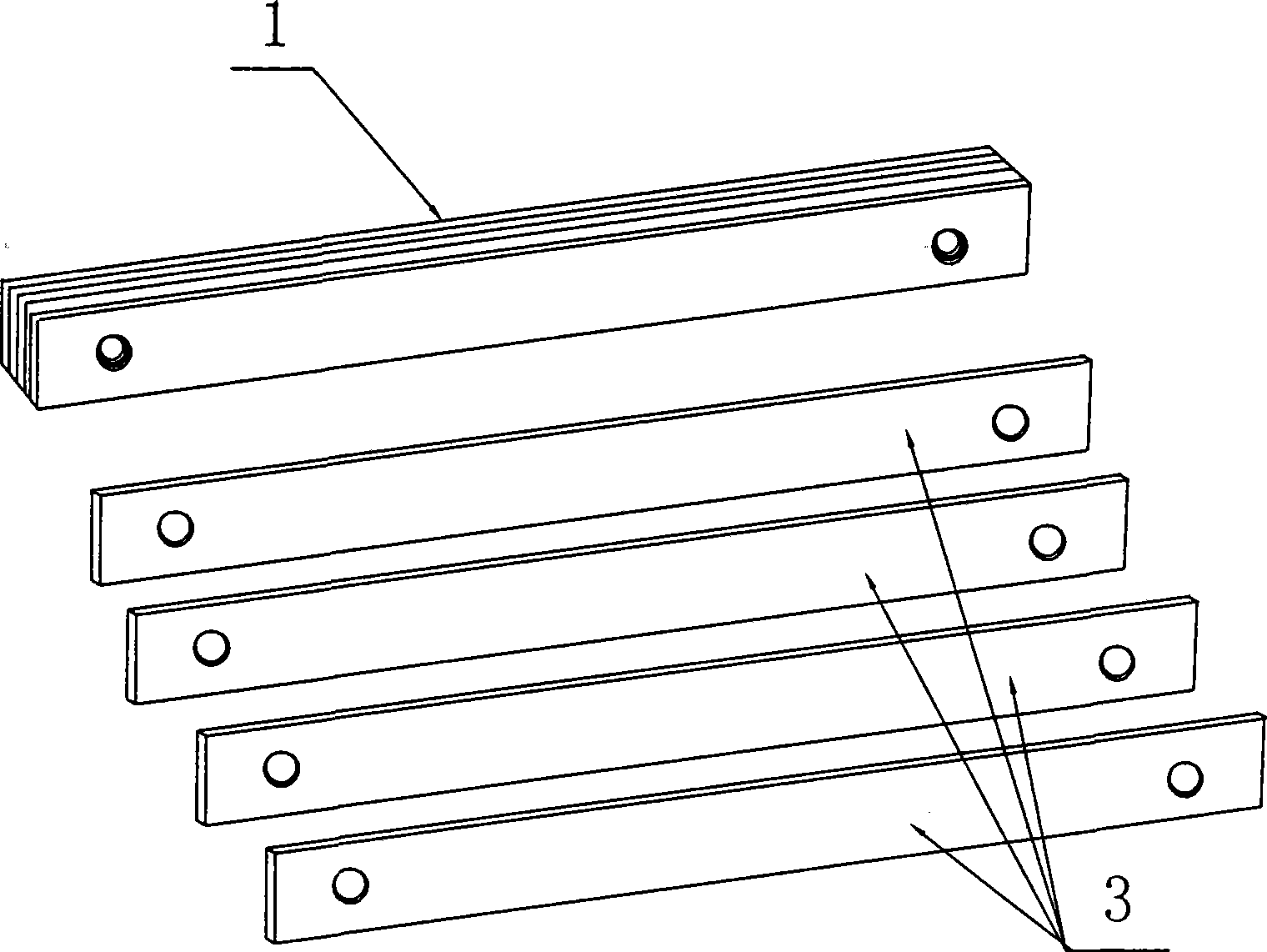

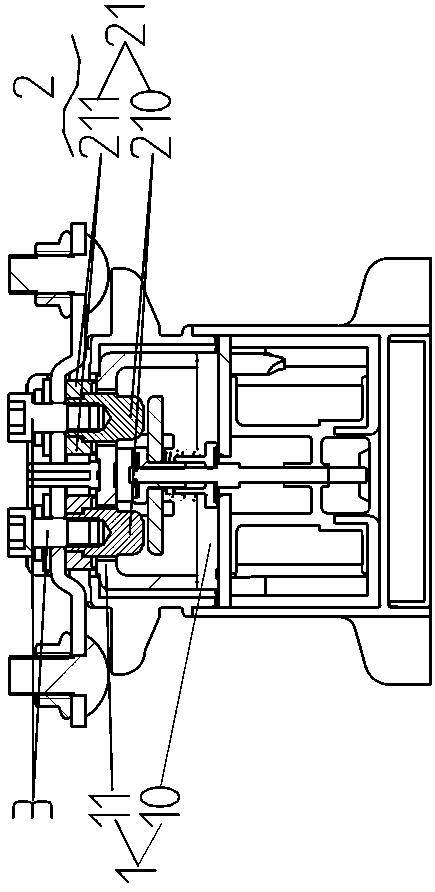

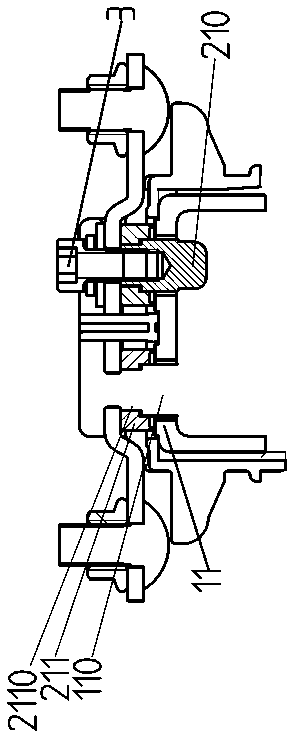

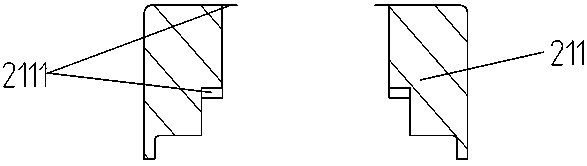

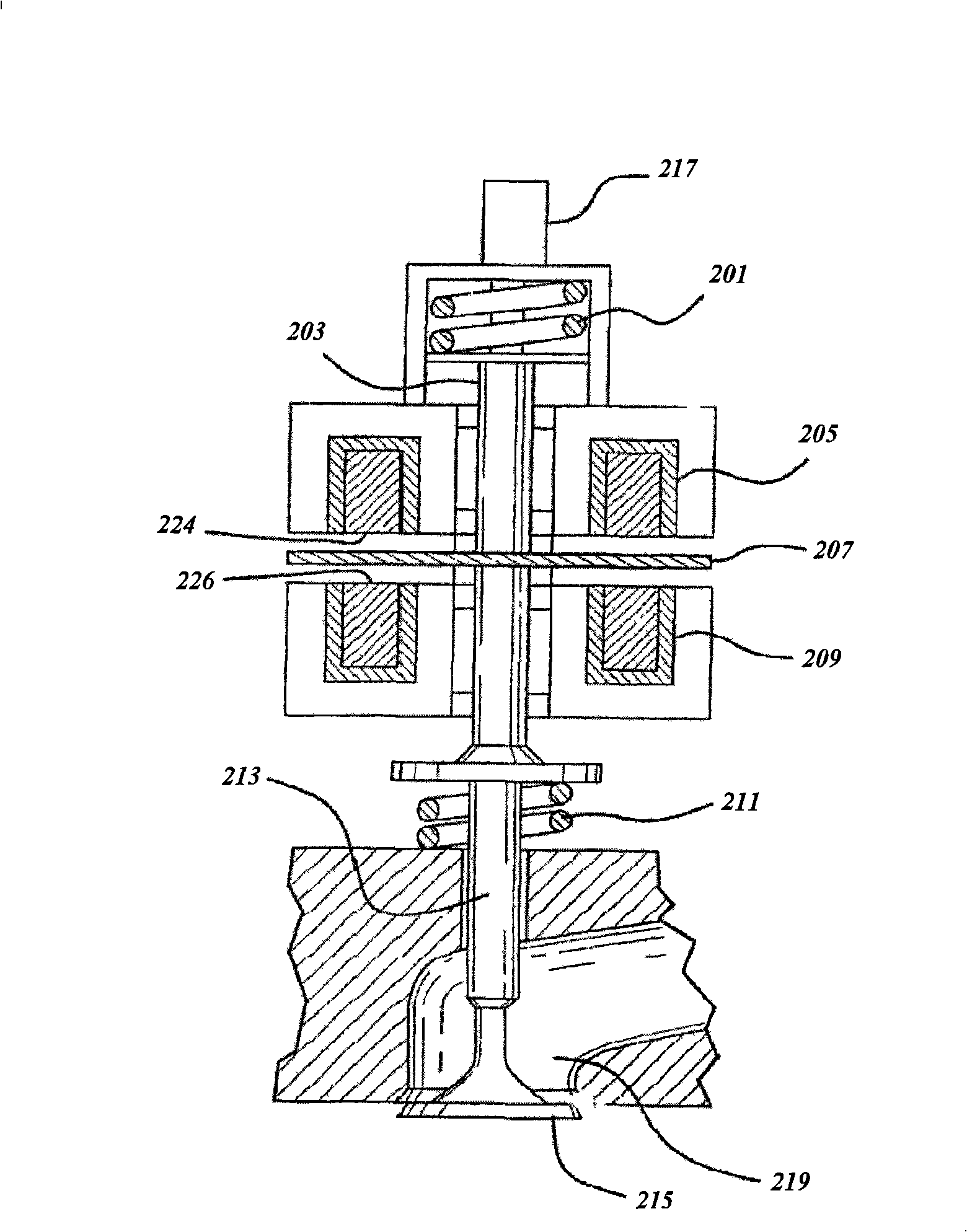

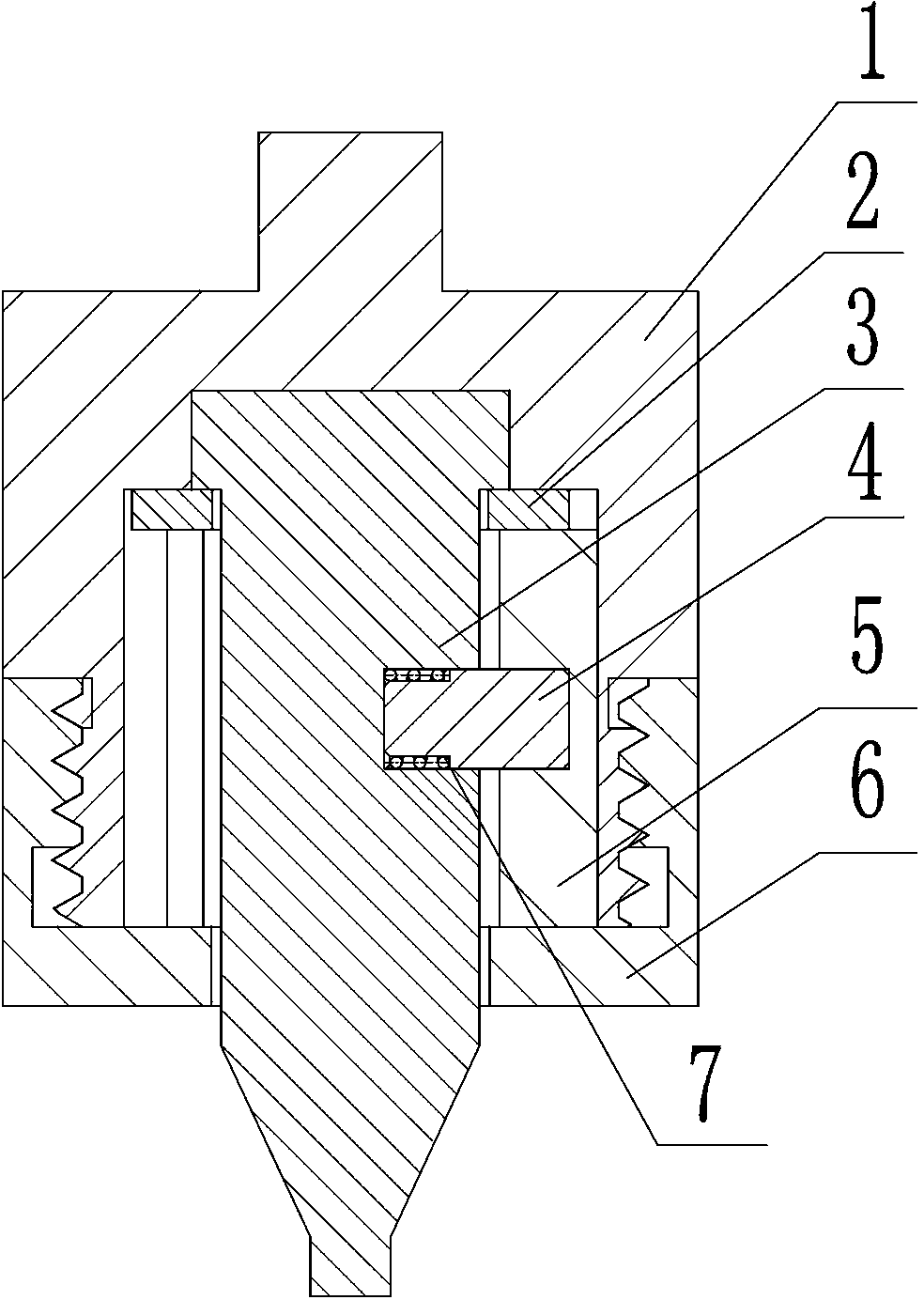

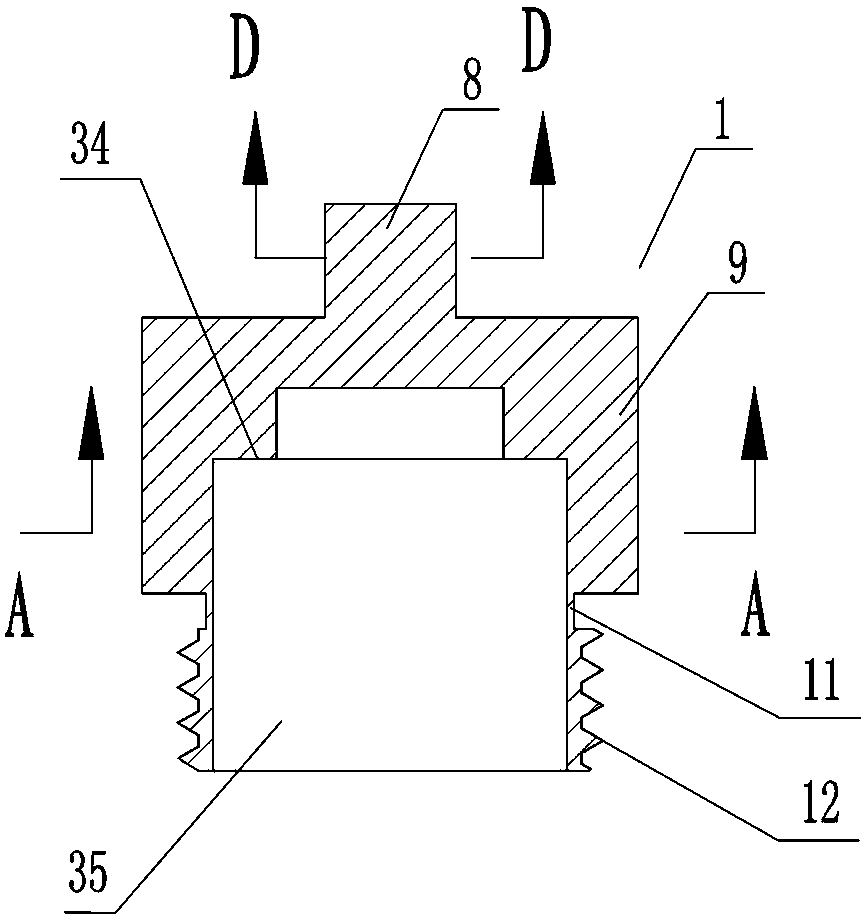

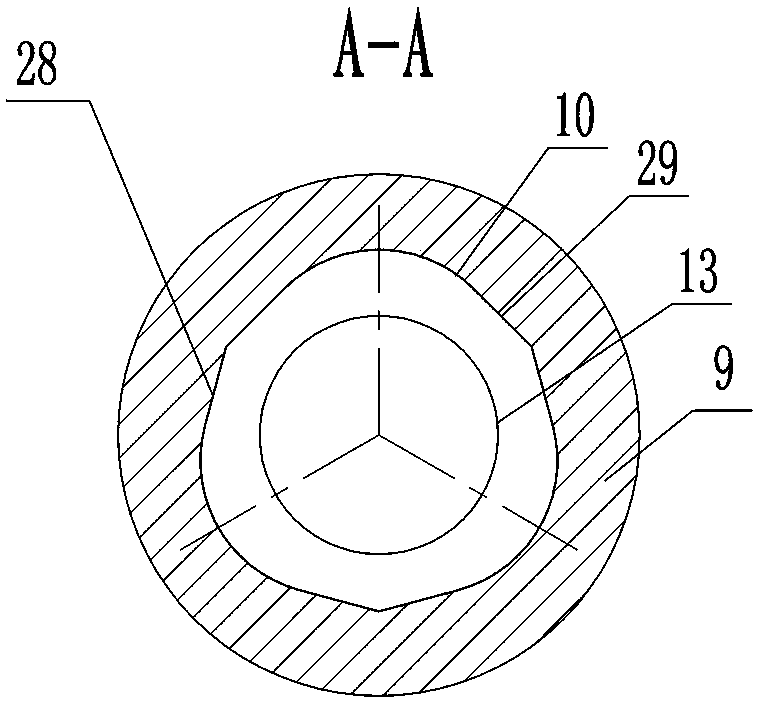

Power tool torque overload clutch

InactiveCN1833826AConsistent torqueEasy to prepareMetal sawing devicesSlip couplingBall bearingDrive shaft

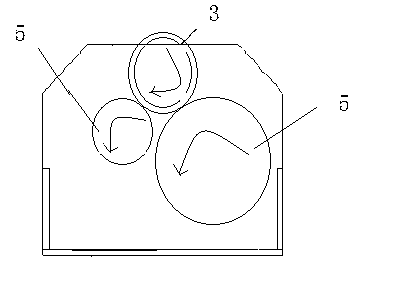

A torque overload clutch for power tools such as hammer drills. The clutch is housed in the cavity of the gear unit. Spring washers are used to push the ball bearings into indentations formed in the bottom of the cavity. Ball bearings are housed within cavities formed in a drive plate that engages the drive shaft of the power tool. The spring washers are held in place by round clips or threaded plates. A threaded plate arrangement is provided for means of compressing spring washers with a constant force through a manufacturing lot. Also disclosed is a manufacturing method of the clutch.

Owner:BLACK & DECKER INC

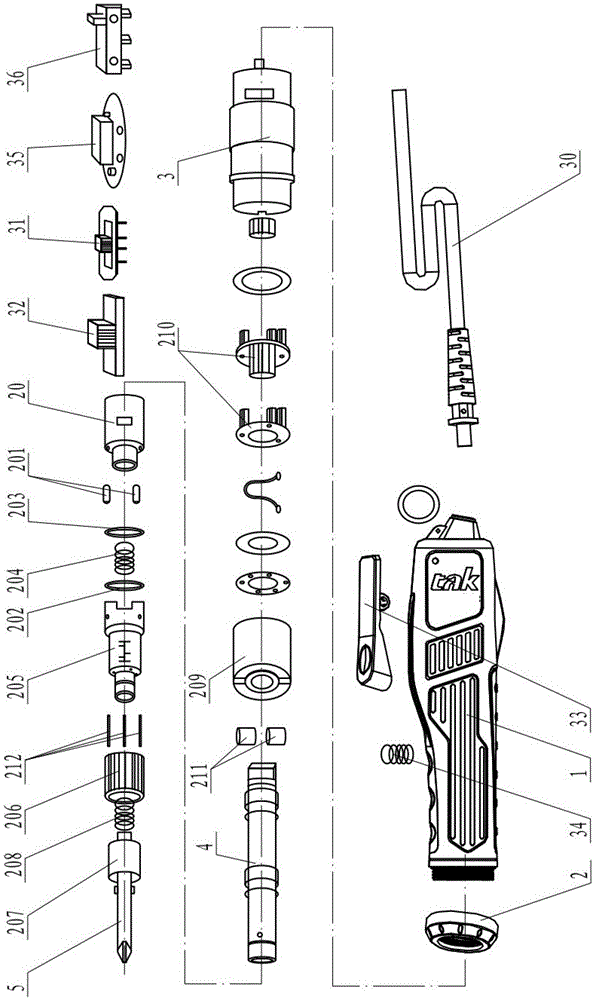

electric screw driver

Owner:佛山市速可达科技有限公司

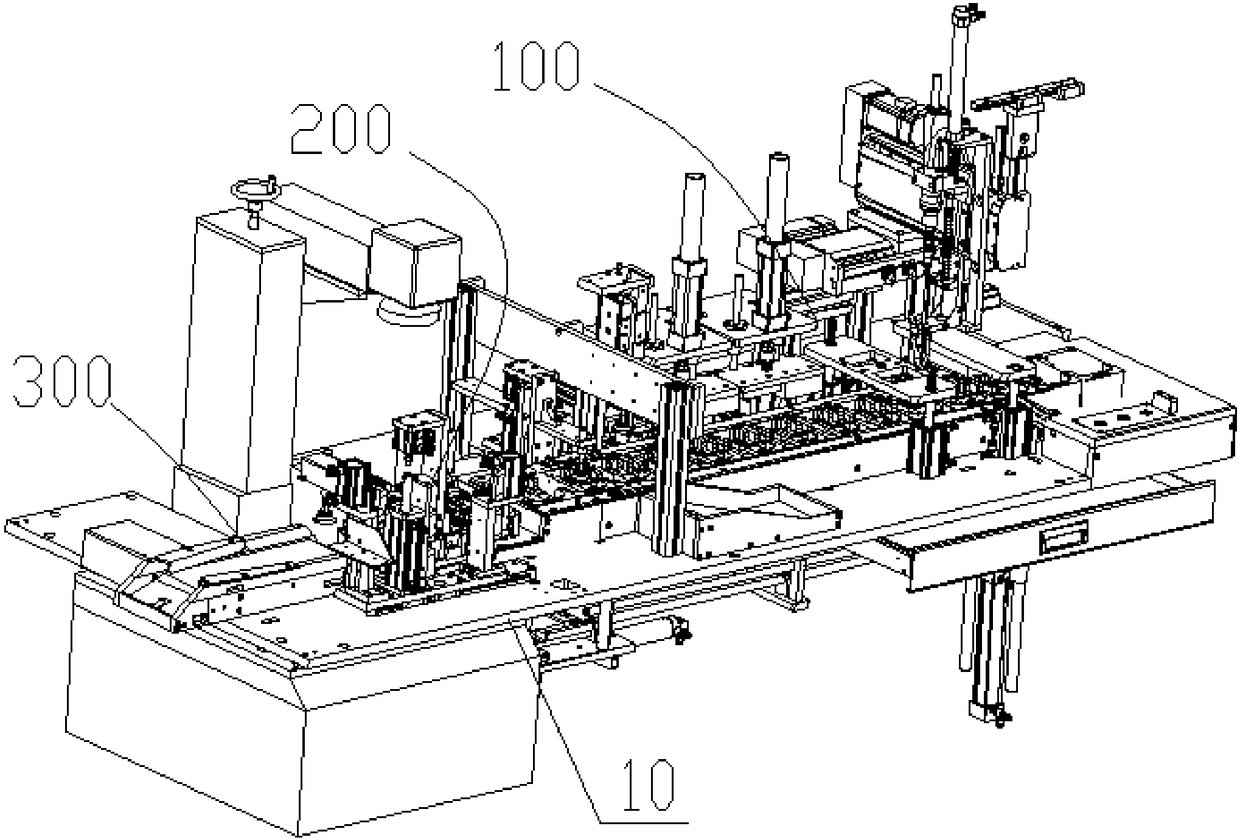

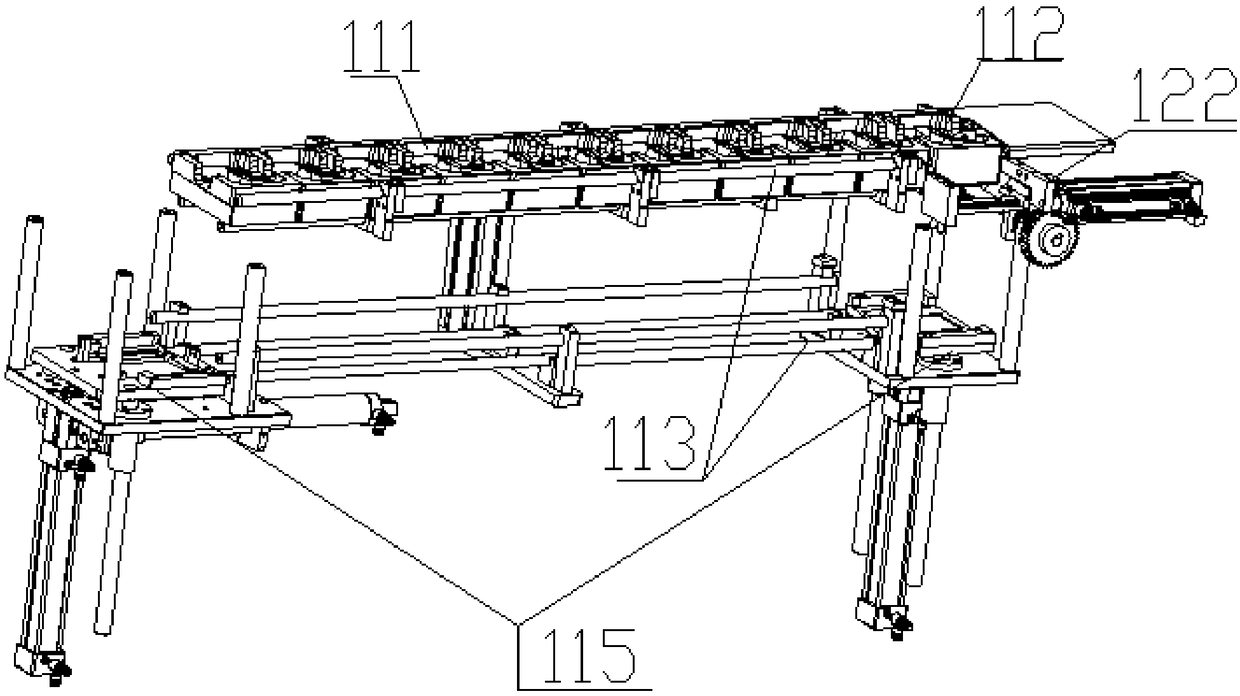

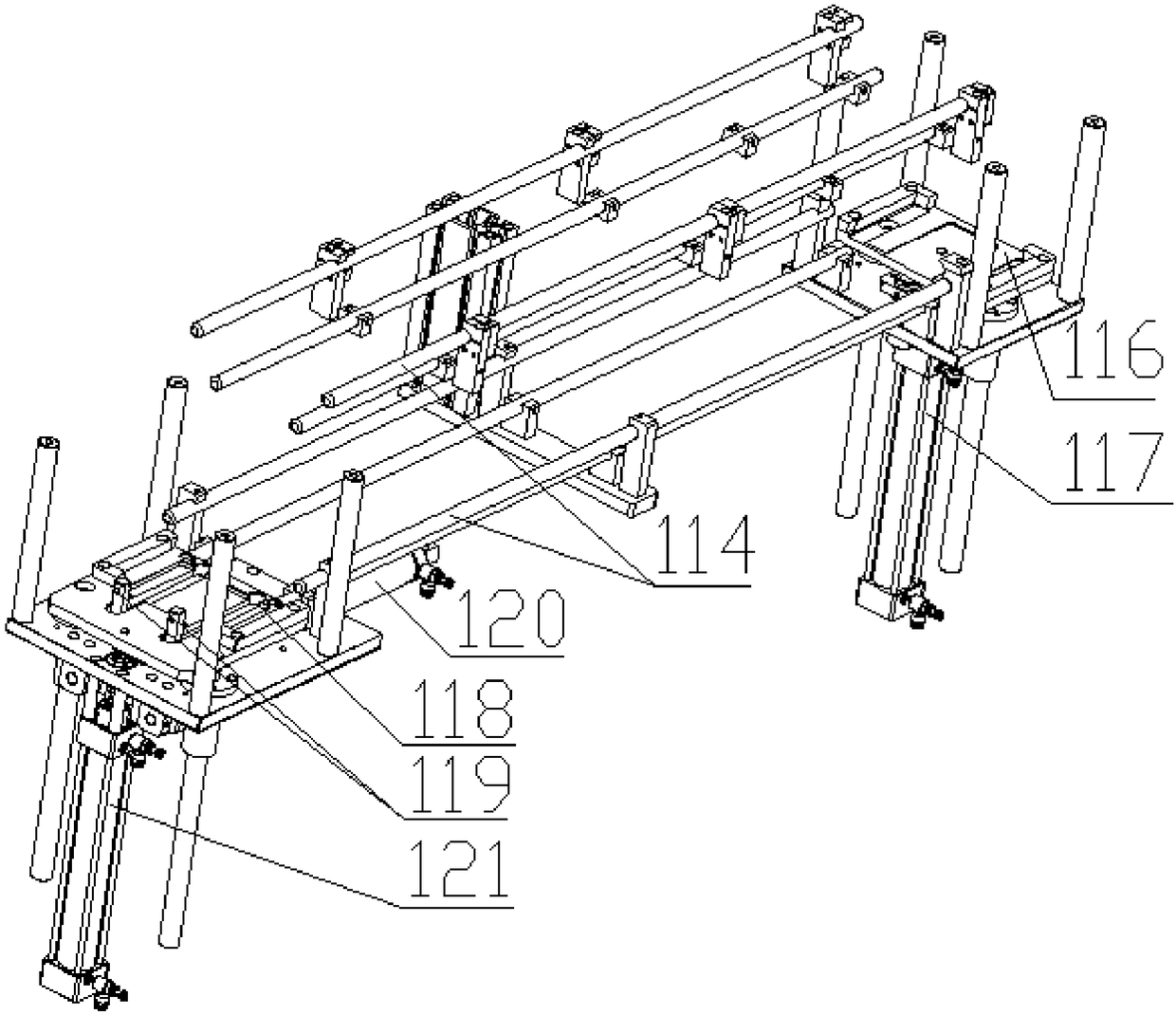

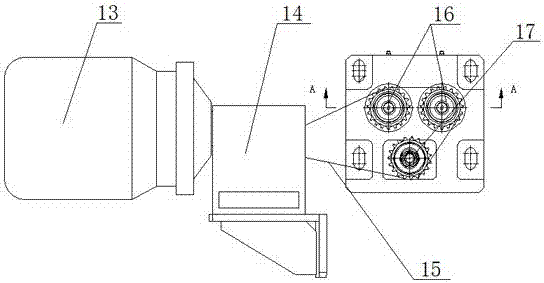

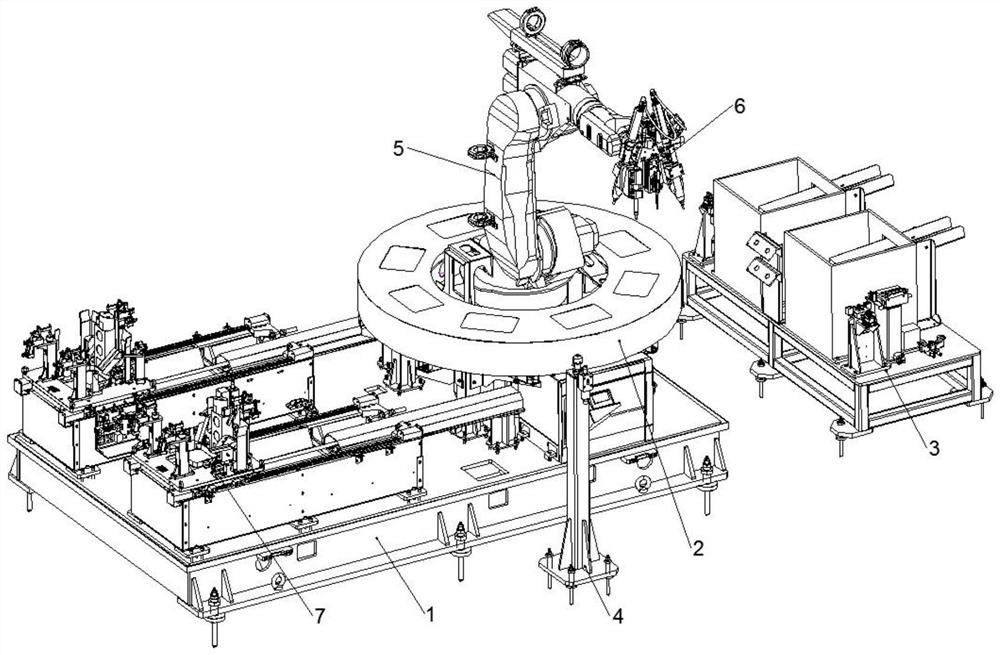

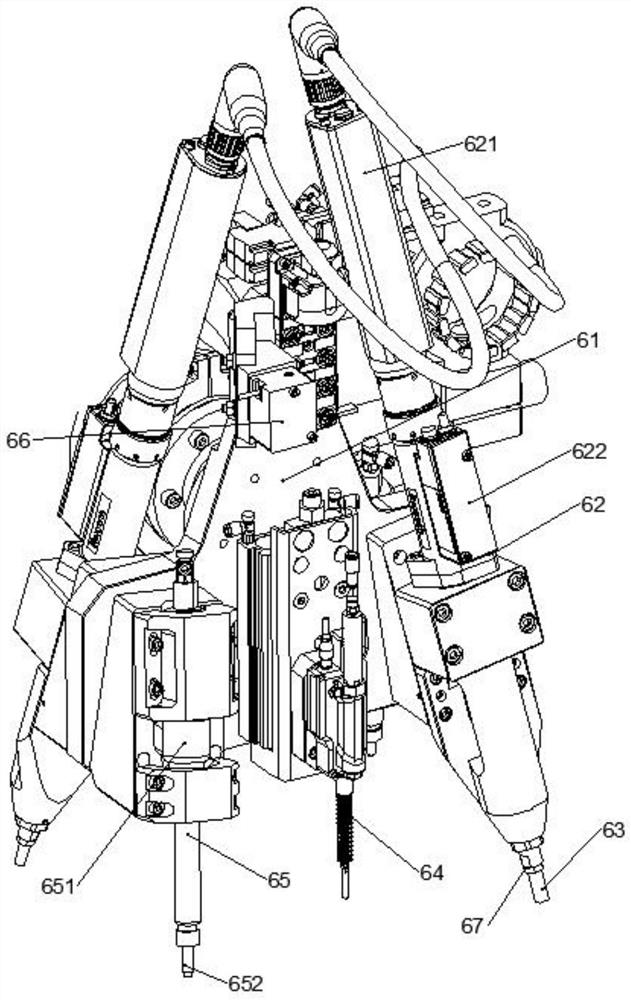

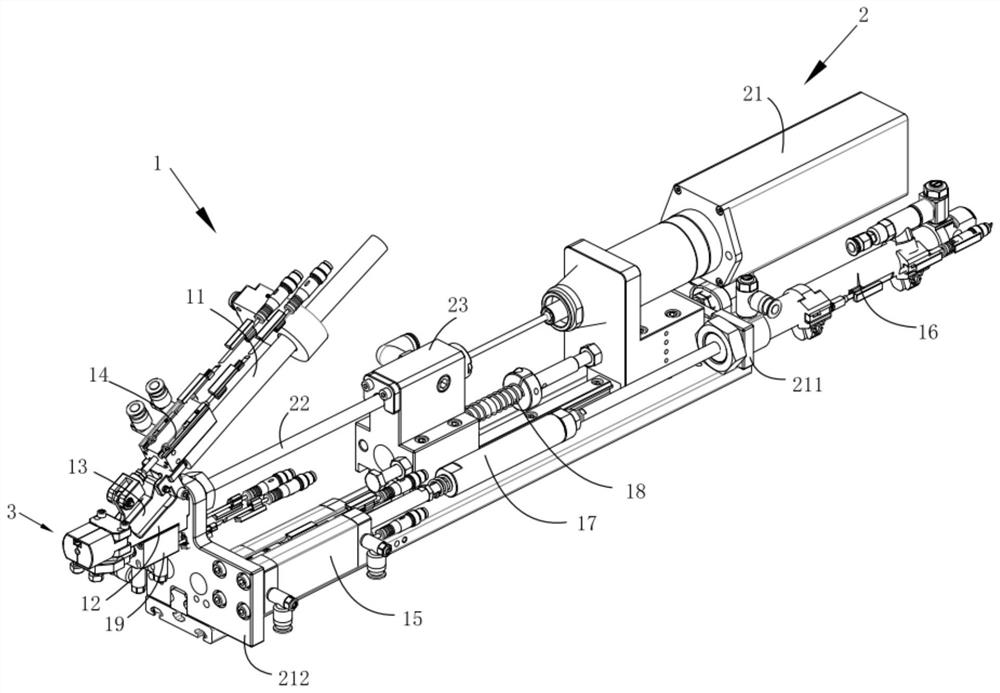

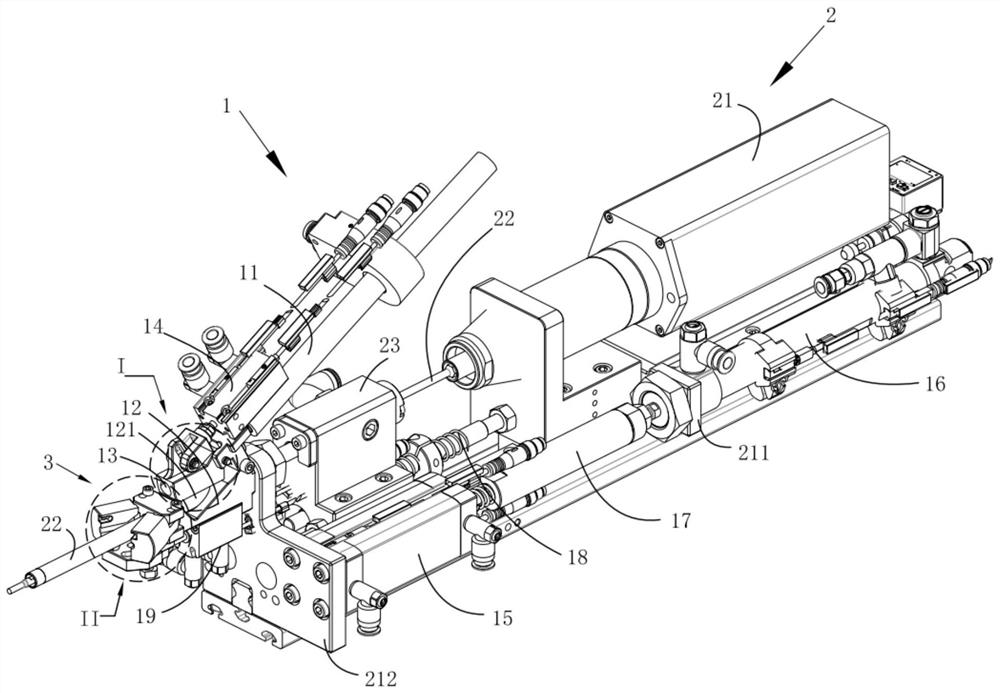

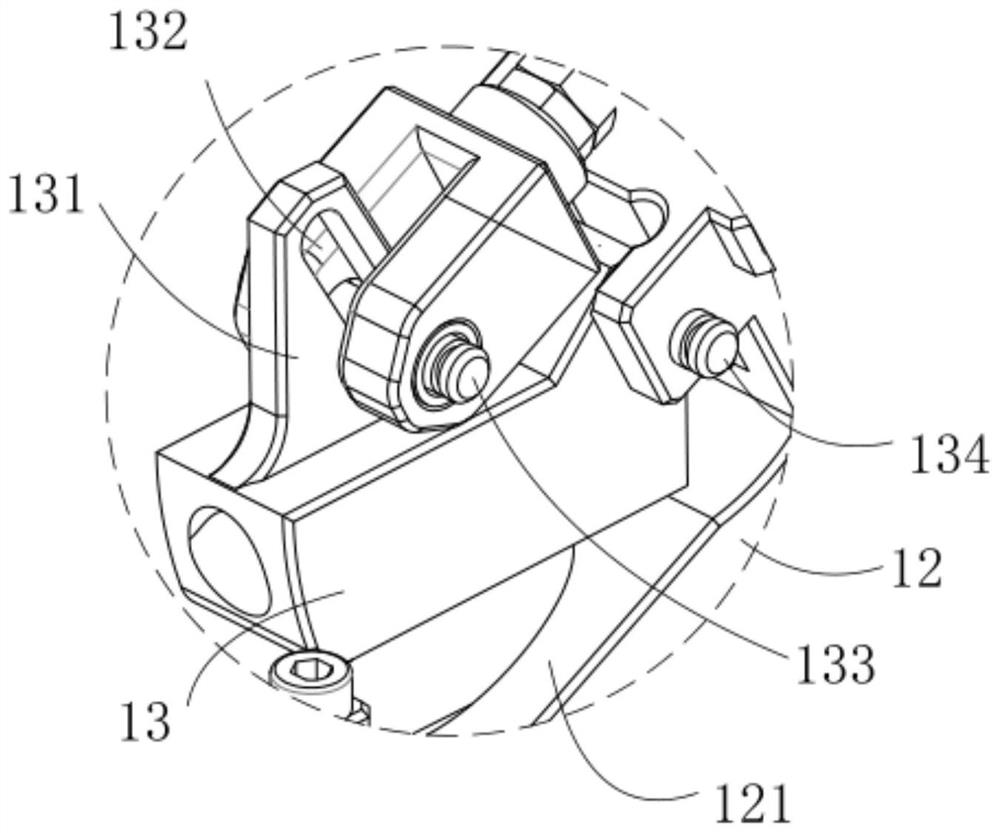

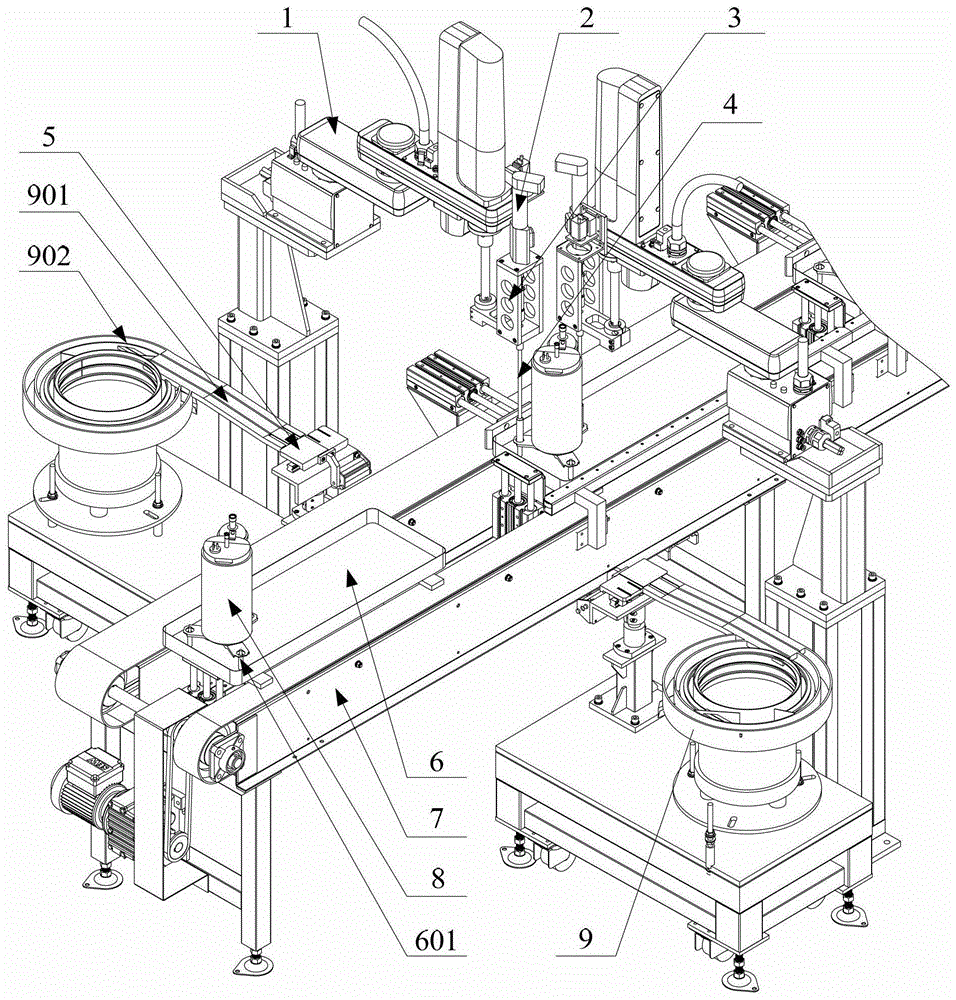

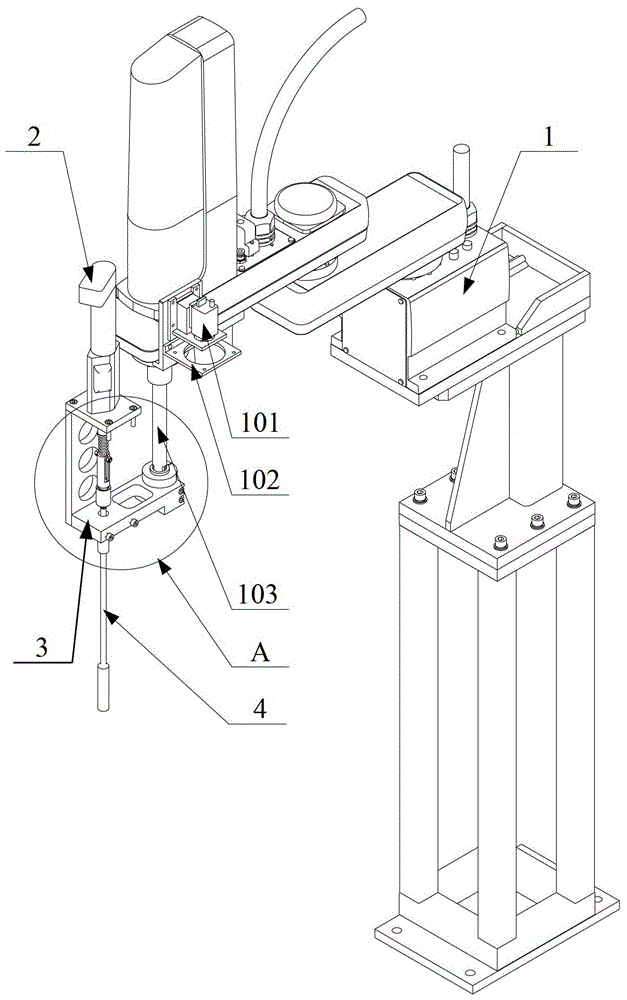

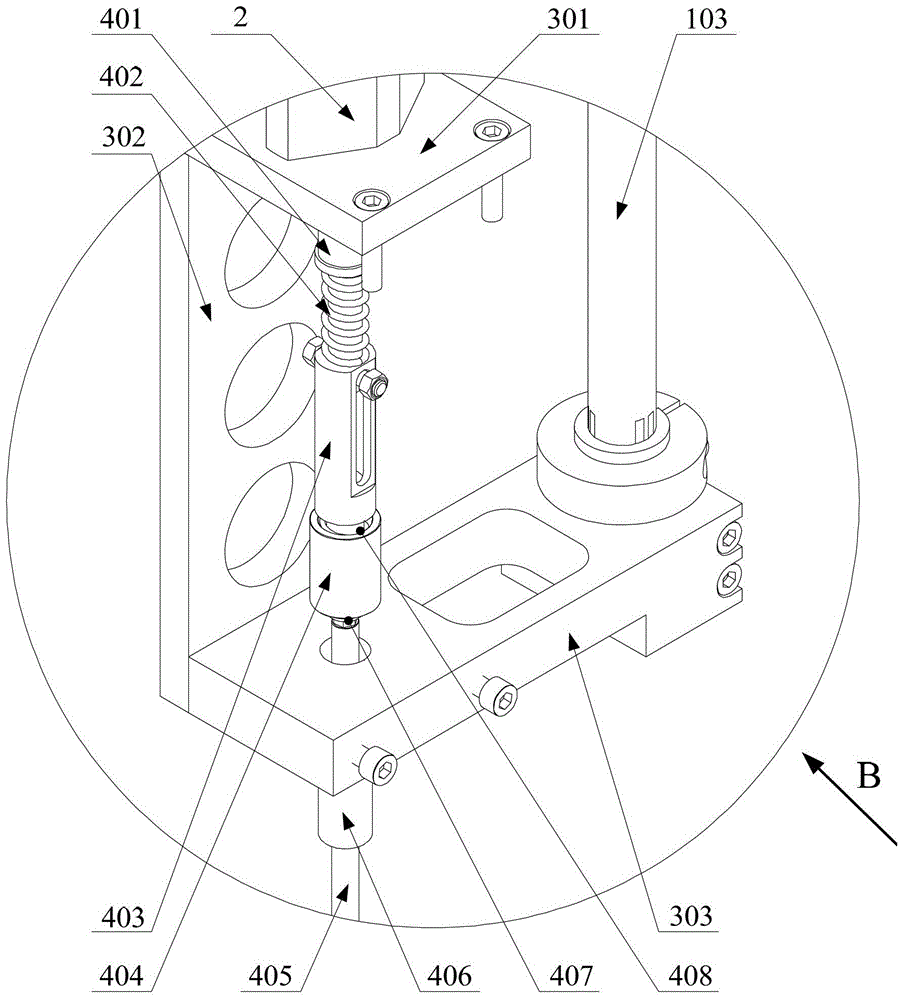

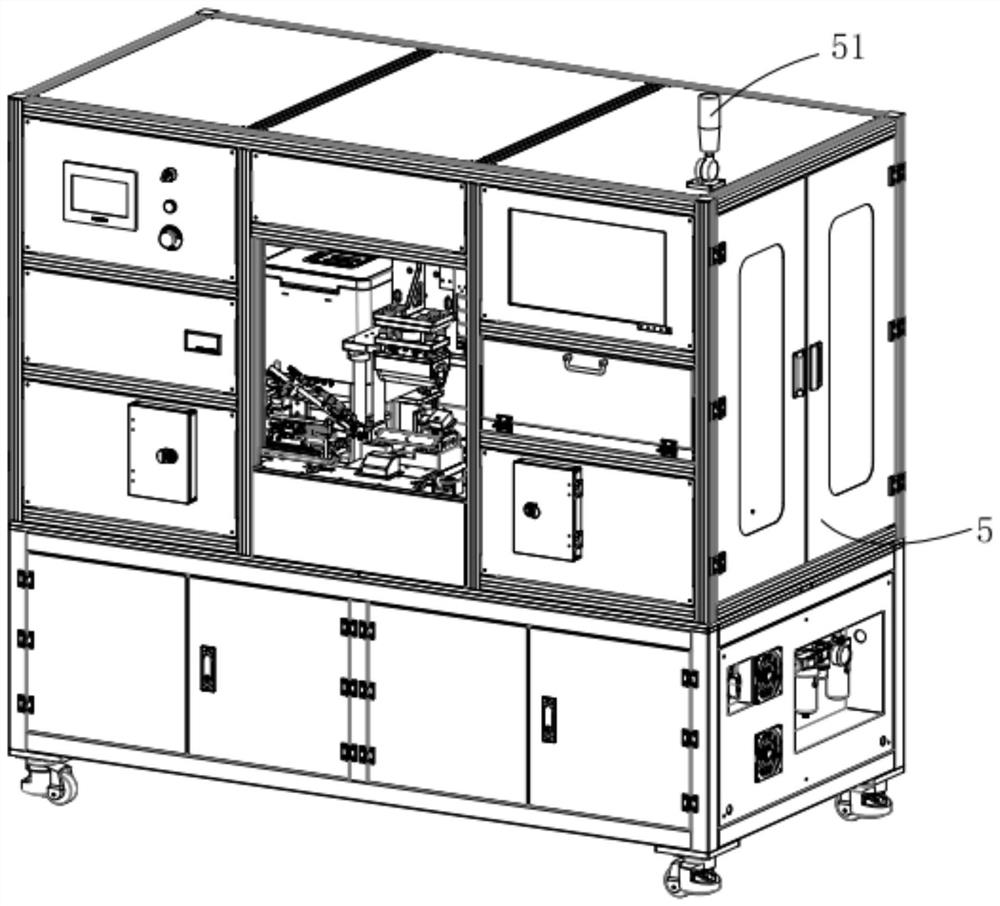

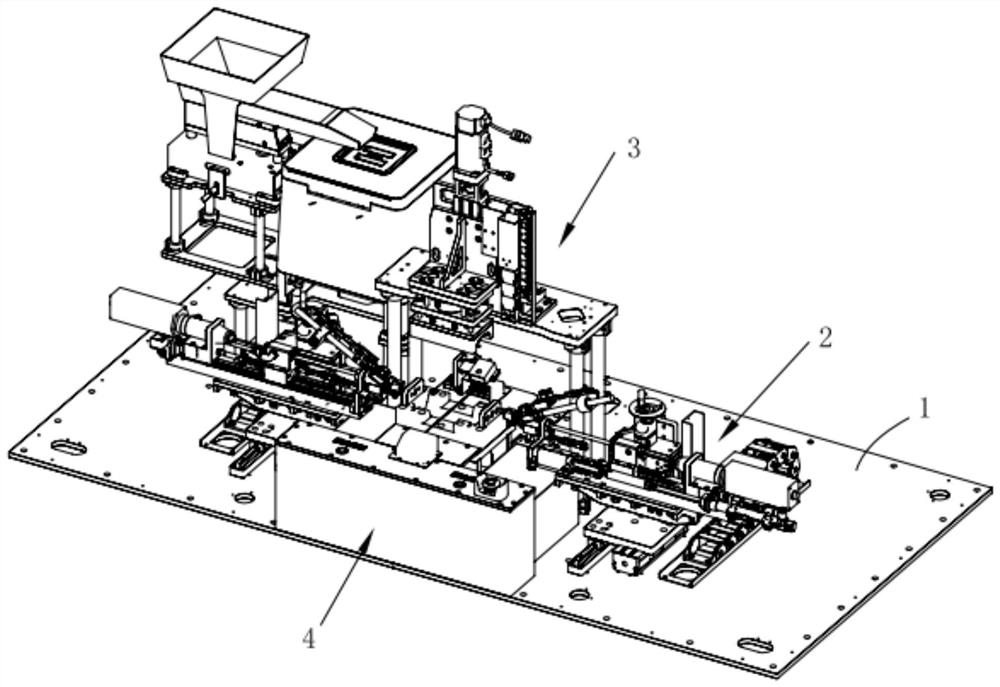

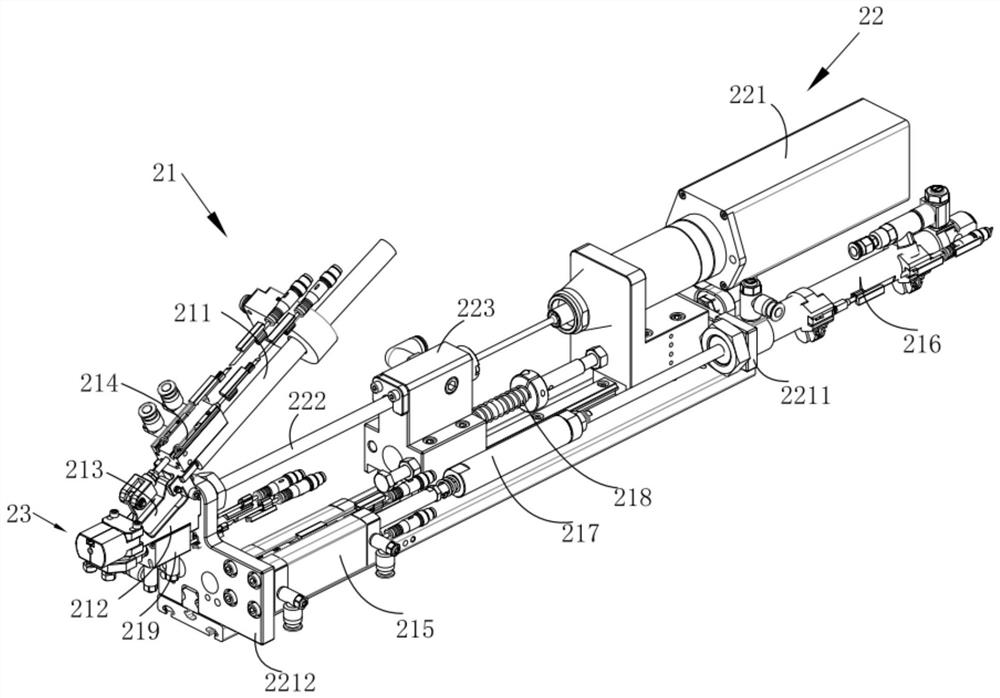

Automatic screw fastening and laser coding machine

PendingCN108188714AFully automatedConsistent torqueMetal working apparatusLaser beam welding apparatusEngineeringMachining

The invention provides an automatic screw fastening and laser coding machine. The automatic screw fastening and laser coding machine is provided with a workbench. The workbench is provided with an automatic screw fastening mechanism and an automatic laser coding mechanism. The automatic screw fastening mechanism comprises a jig conveying mechanism, a screw fastening mechanism body, an inspection mechanism and a sorting mechanism. The screw fastening mechanism body, the inspection mechanism and the sorting mechanism are arranged along the conveying path of the jig conveying mechanism in sequence. The jig conveying mechanism conveys a jig and a workpiece placed on the jig to the screw fastening mechanism for screw fastening, then conveys the jig and the workpiece placed on the jig to the inspection mechanism for workpiece inspection, and goes on to convey the jig and the workpiece placed on the jig to the sorting mechanism, so that defective products are sorted out and sent to a defective product collecting station, and qualified workpieces are sent to the laser coding mechanism for coding. The automatic laser coding mechanism is further arranged on one side of the sorting mechanism.The automatic laser coding mechanism comprises a laser coding machine and a linkage clamping mechanism. Full-automatic machining on products is realized, the production efficiency is greatly improved, and the yield of products is increased.

Owner:DONGGUAN JISHENG AUTOMATION FACILITIES TECH CO LTD

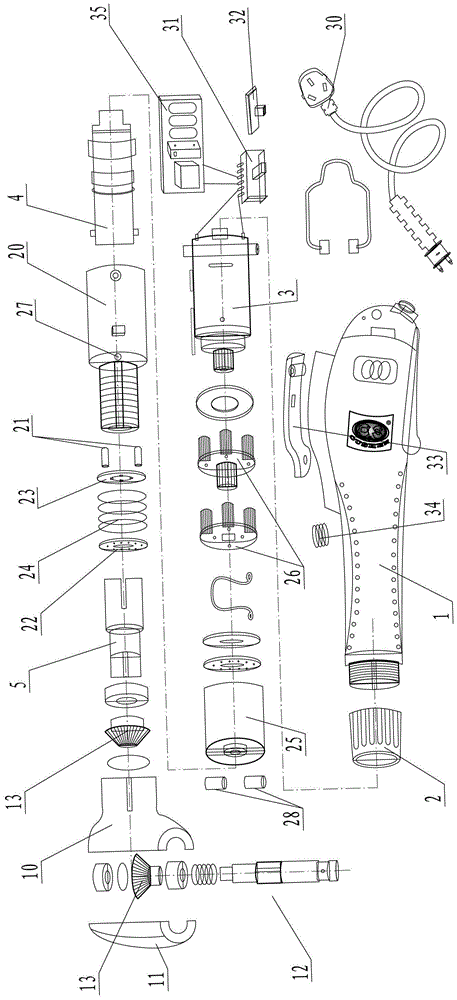

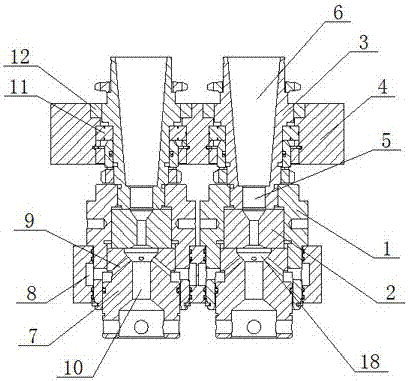

Electric screwdriver special for electric energy meter verification

PendingCN112318414AReduce labor intensitySimple structurePower driven toolsElectric machineGear wheel

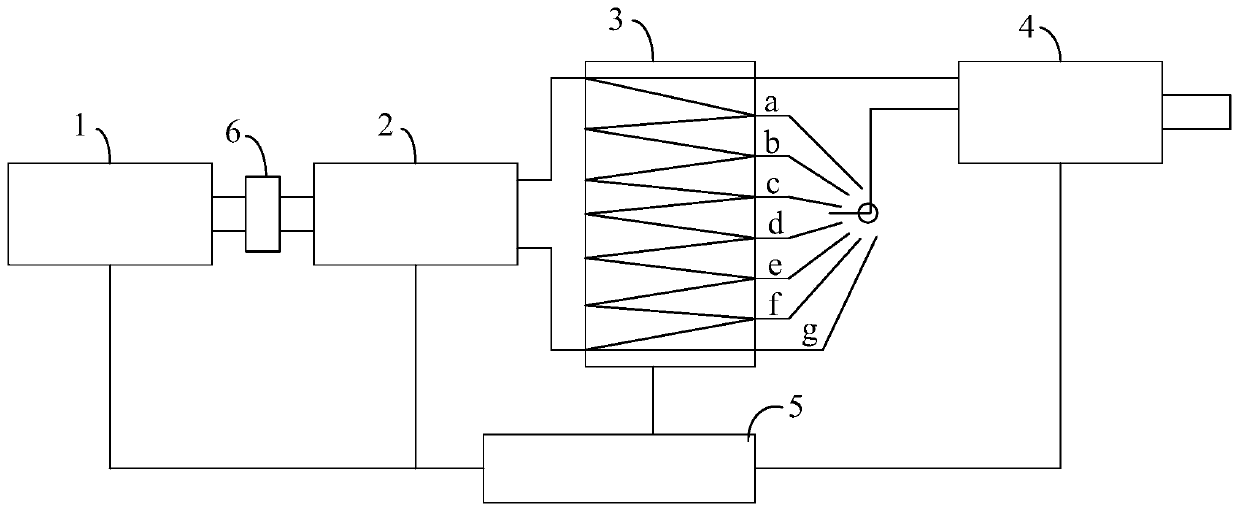

The invention provides an electric screwdriver special for electric energy meter verification, and belongs to the technical field of screwdrivers. The electric screwdriver aims to solve the problems of low efficiency of using a single-bit screwdriver and inconsistent screwing degrees of screws in the same row of an electric energy meter during meter verification. According to the technical scheme,a driving gear is arranged at one end of a motor of the electric screwdriver in a sleeving manner, first gears meshed with the driving gear are symmetrically arranged at the two sides of the drivinggear, an electric screwdriver with four screwdriver bits and an electric screwdriver with seven screwdriver bits are integrated by arranging other gears meshed with the first gears, an idling type screwdriver is arranged between the screwdriver bits and the gears, and the torque consistency of bolts in the same row is realized; and the electric screwdriver has the technical effects that the structure and the operation are simple, one row of bolts can be screwed down or dismounted at the same time, the working efficiency is improved, the torque consistency of screws in the same row can be guaranteed, and the labor intensity of workers is reduced.

Owner:LVLIANG POWER SUPPLY COMPANY STATE GRID SHANXI ELECTRIC POWER

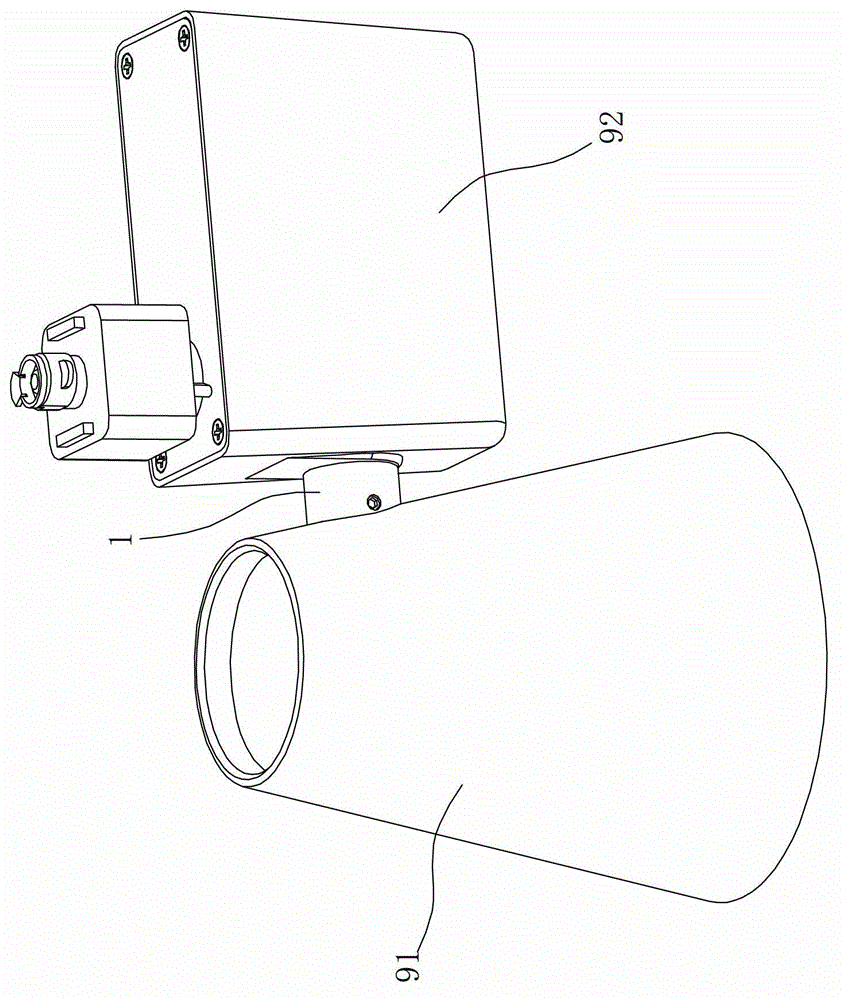

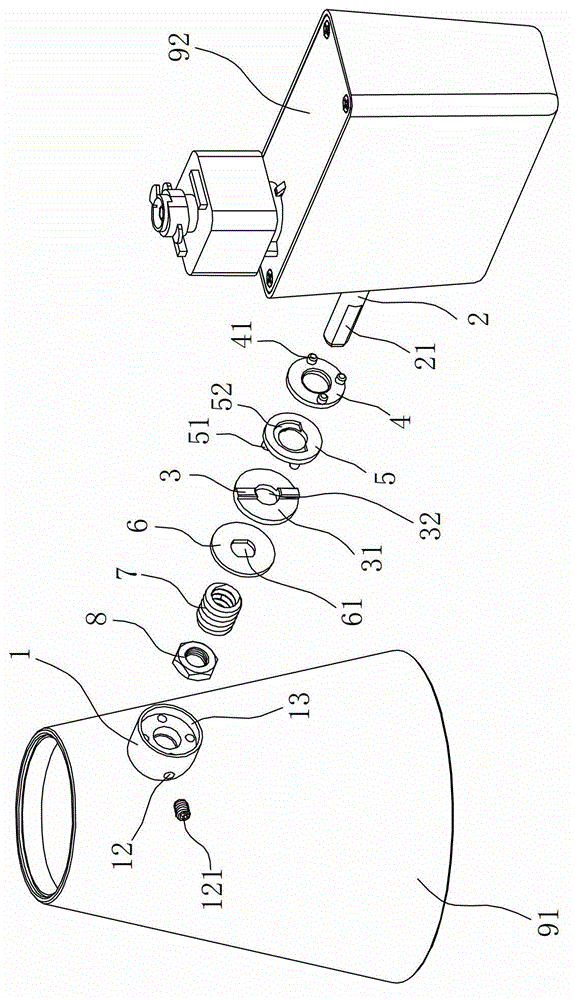

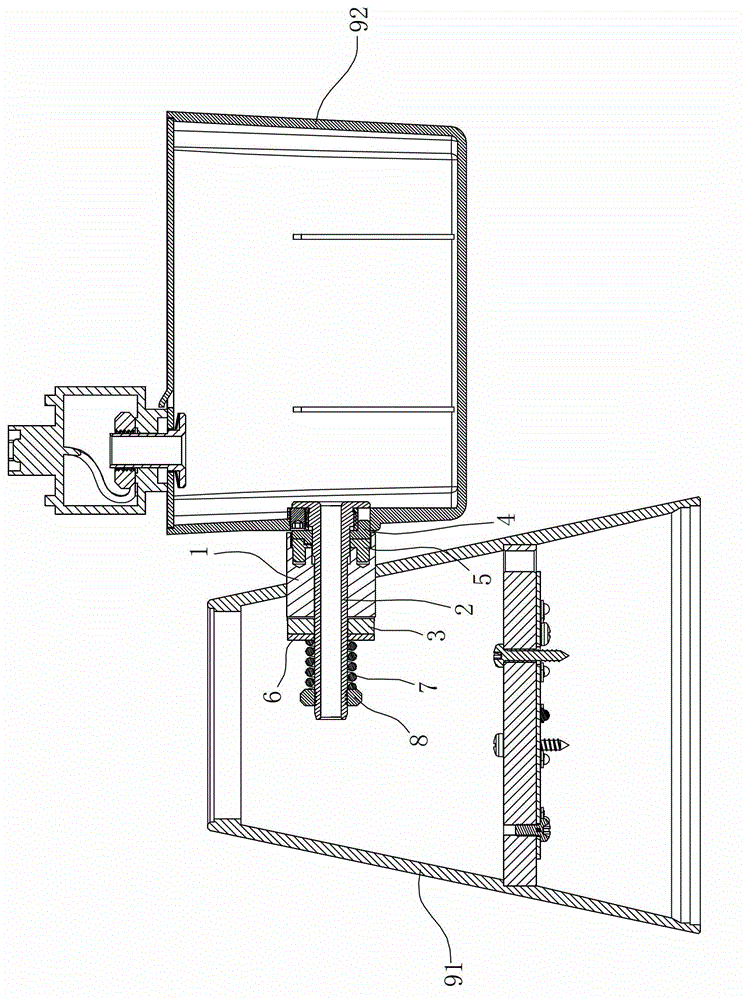

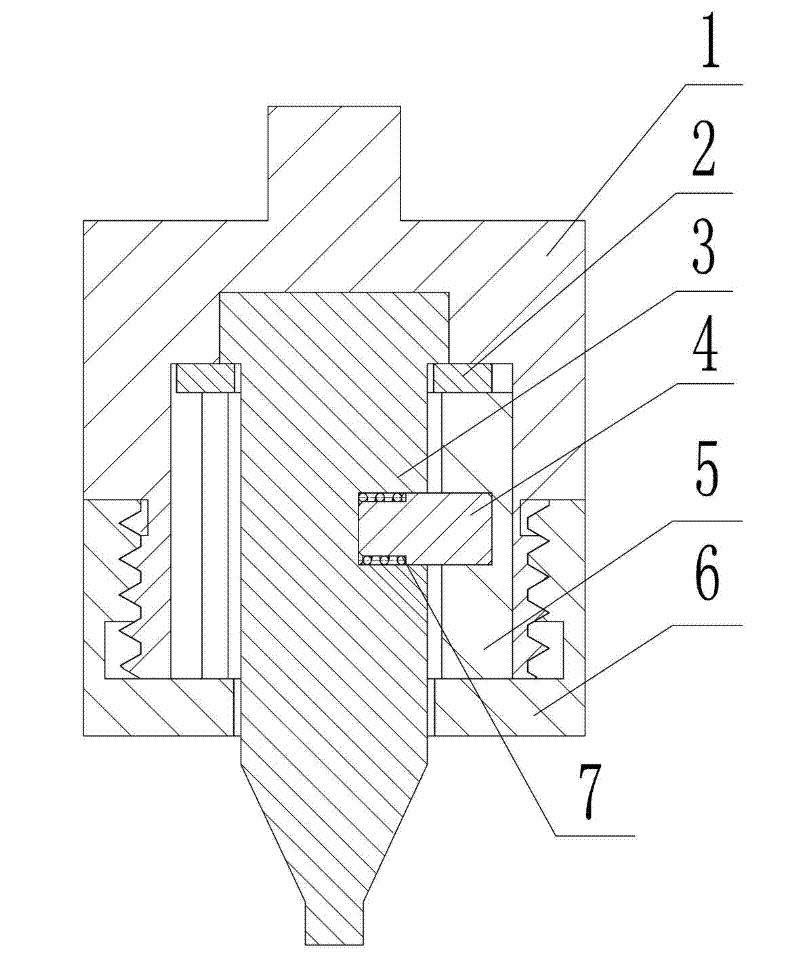

Rotating structure of lamp holder of track lamp

Owner:SELF ELECTRONICS CO LTD

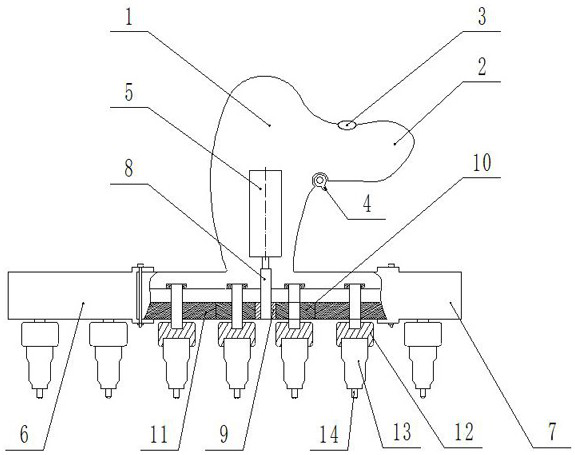

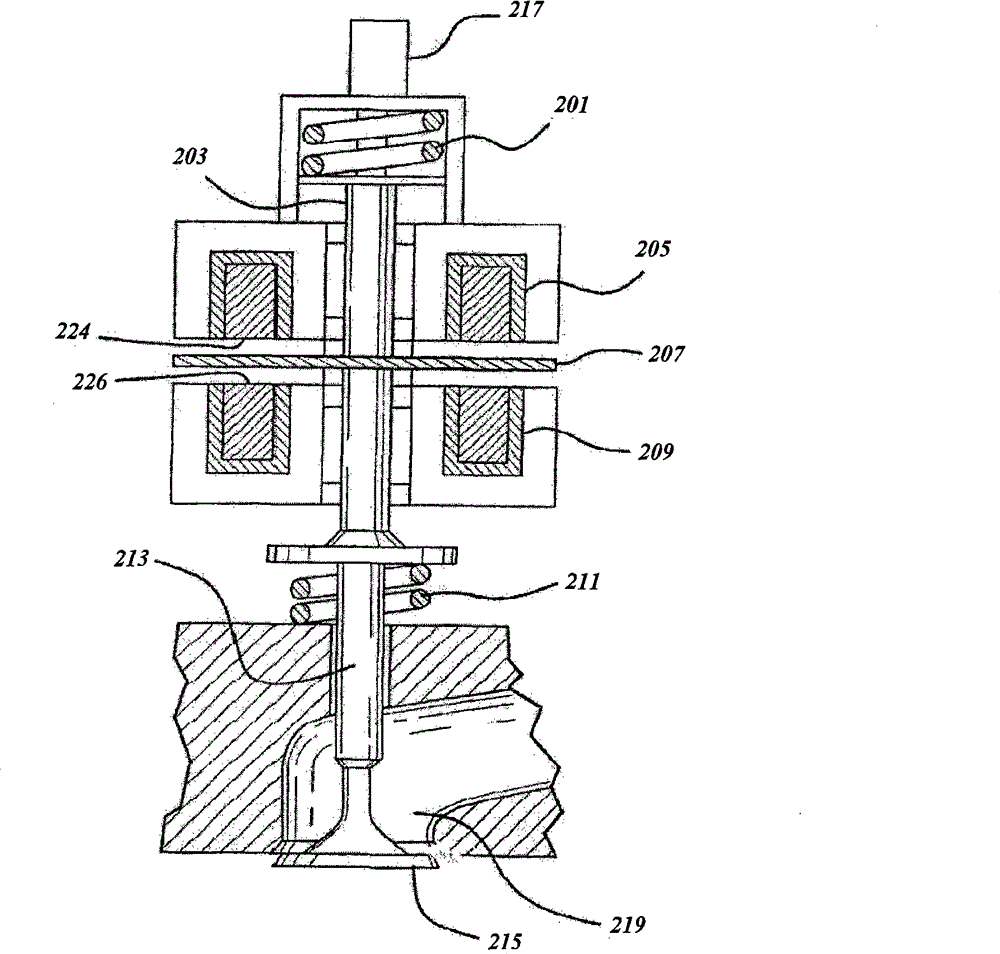

Dental implant installation tool

This invention relates to a dental implant installation tool, belonging to the field of dental implants, and is especially suitable for the place with torque requirements on tightening screw during dental surgery. The dental implant installation tool comprises an installation block, an installation cap, a connecting rod, a connecting block, a pin, a spring and a gasket, wherein the gasket is inserted into the connection rod and installed on the step surface of the connecting rod; the connecting rod, connecting block, pin, spring and gasket are separately installed in the installation block; the cylinder of the connecting rod is inserted into the cylindrical hole inside the installation block, the gasket is installed on the step surface of the inner hole of the installation block, the pretightening force of the spring clamps the pin, the pin is located against the connection block, and the outer arc surface of the connecting block and the inner arc surface of the inner hole of the installation block are closely matched together; and the connecting rod is penetrated through the via of the installation cap and is connected with the installation block through thread.

Owner:常州百康特医疗器械有限公司

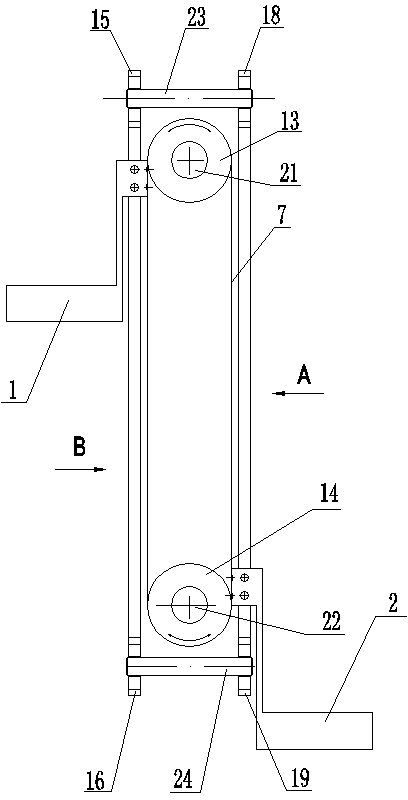

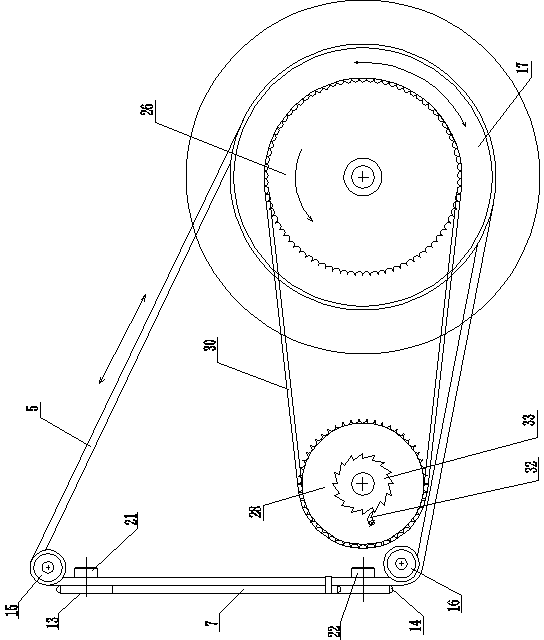

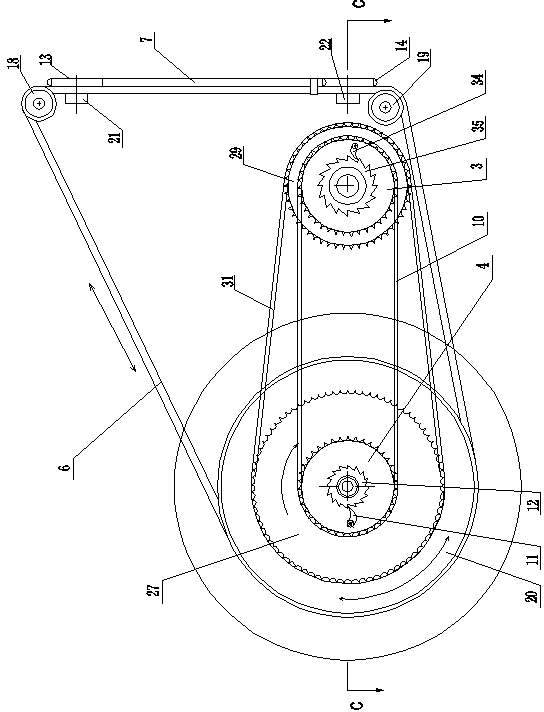

High-efficiency driving mechanism of bicycle

InactiveCN102837792AEasy to driveConsistent torqueChain/belt transmissionRider propulsionMaximum torqueEngineering

The invention discloses a high-efficiency driving mechanism of a bicycle. The high-efficiency driving mechanism comprises a left belt, a right belt and a middle belt, wherein the middle belt is connected between a middle upper reversing wheel and a middle lower reversing wheel; the left belt is connected between left upper and lower reversing wheels and a left belt pulley; the right belt is connected between right upper and lower reversing wheels and a right belt pulley; the upper end of a left pedal is simultaneously connected to the left belt and the middle belt; the upper end of a right pedal is simultaneously connected with the right belt and the middle belt; the left belt pulley and the right belt pulley are movably sleeved on a rear wheel shaft; outer side faces of the left belt pulley and the right belt pulley are provided with a left driving chain disc and a right driving chain disc respectively; a left driven chain disc and a right driven chain disc are movably sleeved on a chain wheel shaft; a front left pawl is arranged on the left driven chain disc and is matched with a front left ratchet which is fixedly sleeved on the chain wheel shaft; the right driven chain disc is provided with a front right pawl which is matched with a front right ratchet which is fixedly sleeved on the chain wheel shaft; and the front left ratchet and the front right ratchet are in bilateral symmetry. Since the left pedal and the right pedal only do rectilinear motion, pedal force can act on a part of maximum moment all the time to obtain maximum torque output.

Owner:杨渝

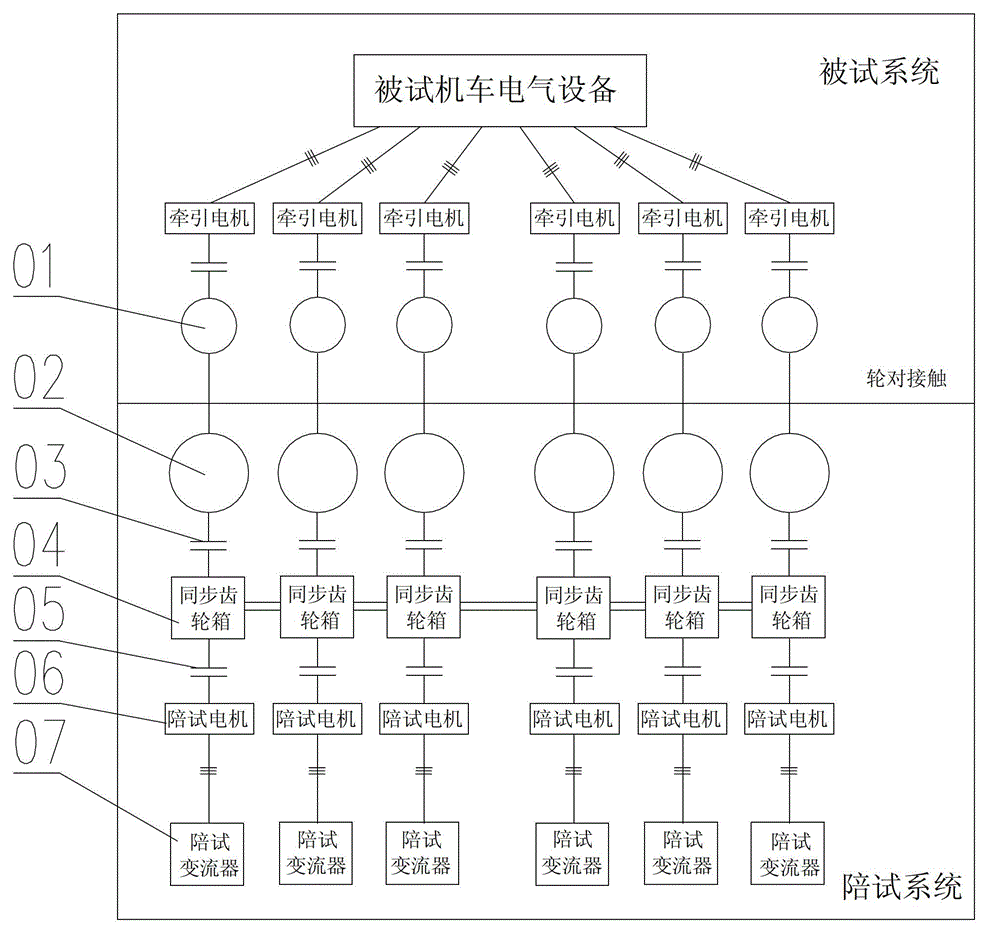

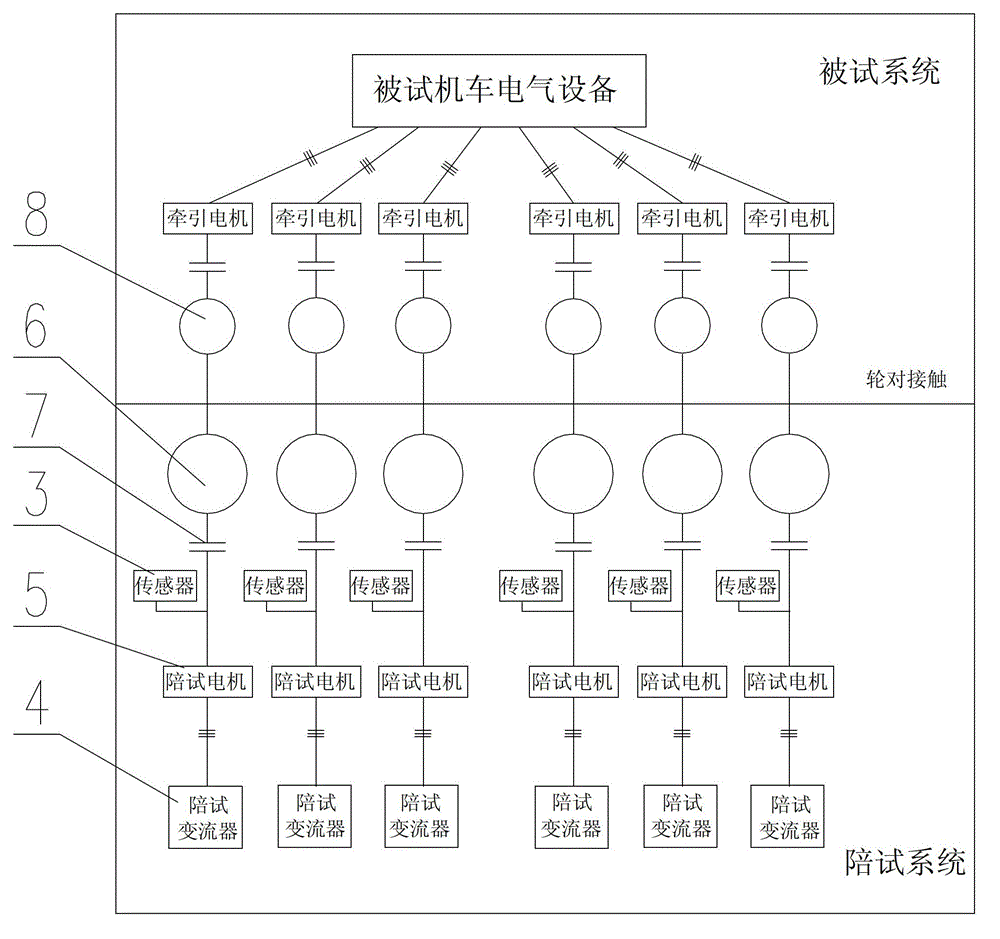

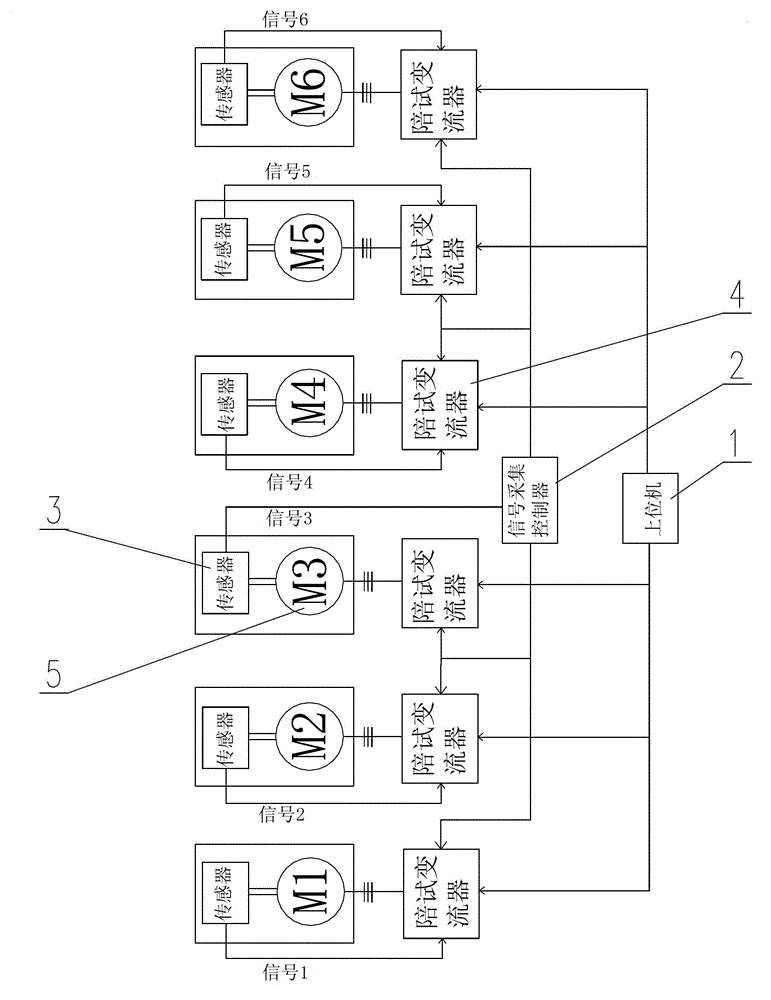

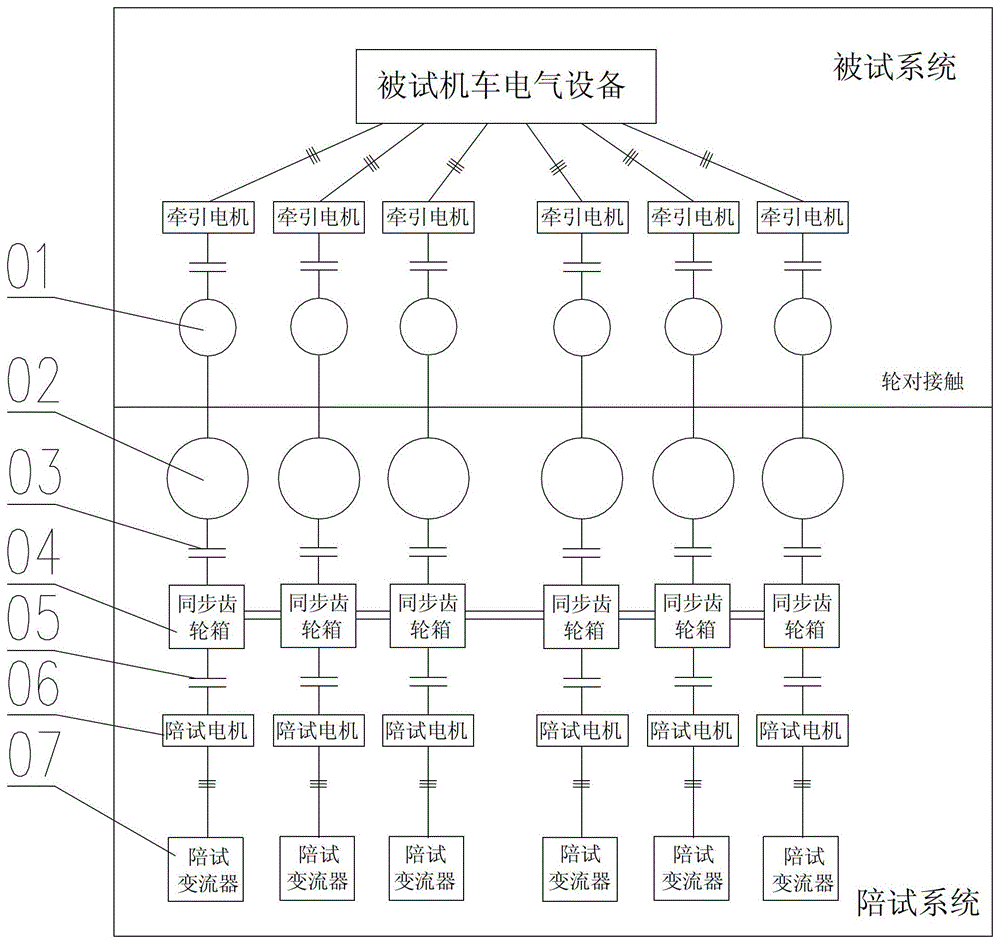

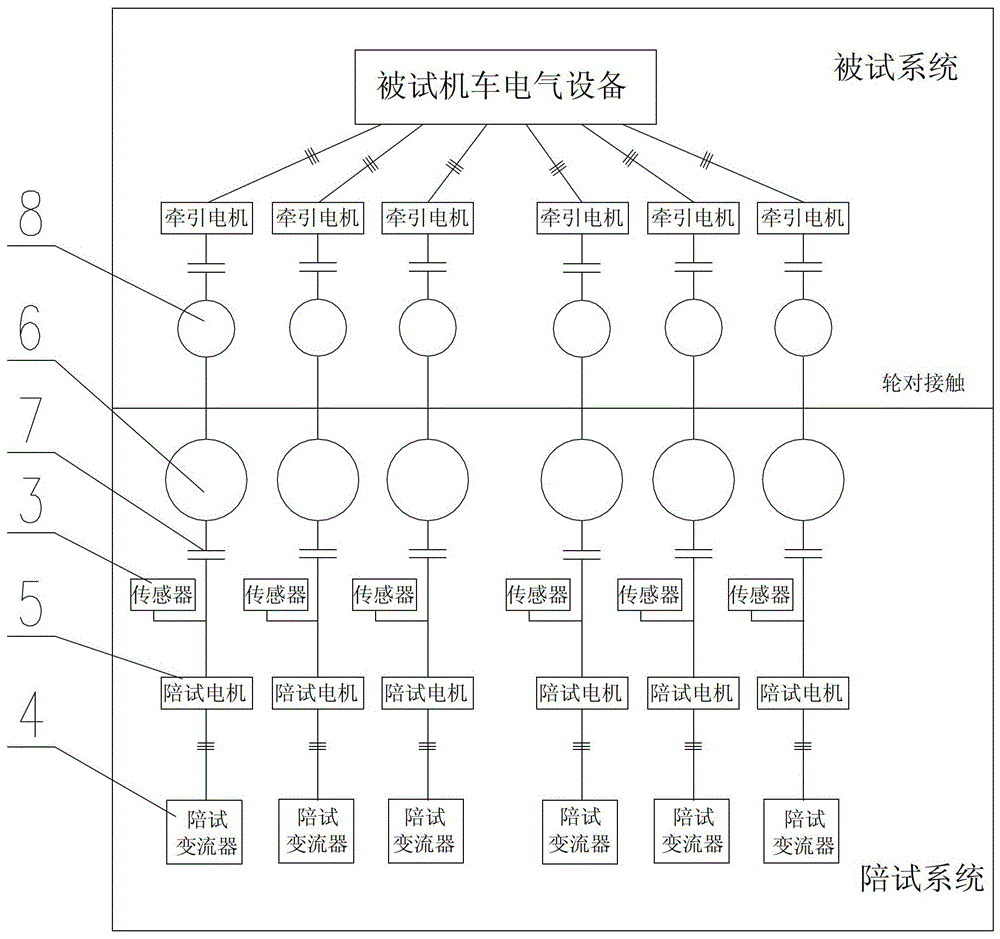

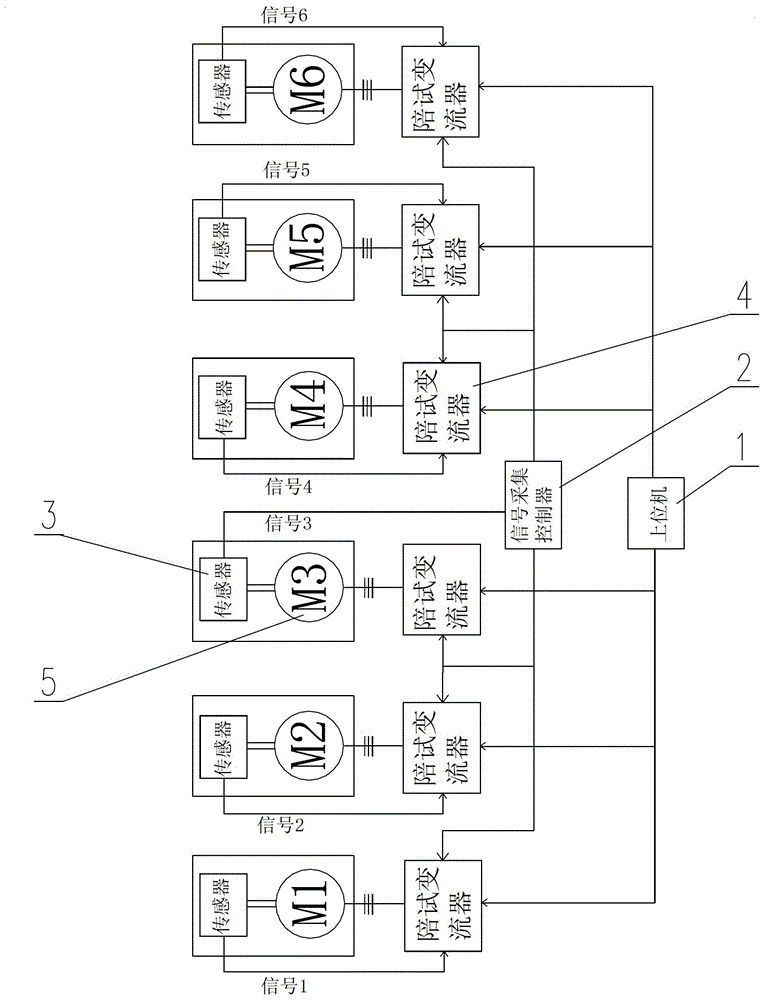

Rail wheel synchronous control device for traction power test device of rail transit vehicle

InactiveCN102945057ASame speedSame torqueRailway vehicle testingSimultaneous control of multiple variablesControl signalSynchronous control

The invention discloses a rail wheel synchronous control device for a traction power test device of a rail transit vehicle. An accompanying test motor is connected to one side of each rail wheel; a sensor is arranged between each rail wheel and an output shaft of each accompanying test motor; an accompanying test converter is connected to each accompanying test motor and is connected with a signal acquisition control unit arranged on the field; the signal acquisition control units are one or more circuit boards or circuit units arranged inside the accompanying test converters or signal acquisition controllers arranged outside the accompanying test converters; and the signal acquisition control units are used for receiving control signals from the sensors and / or other signal acquisition control units, and the control signals are integrally processed and then are outputted to the accompanying test converters. Dynamic work conditions of various motors are acquired on field in real time and are integrally processed by the signal acquisition control units for controlling various accompanying test converters, so that output rotating speeds and the torques of all motors can be enabled to be same, traction and brake work conditions of tested locomotives can be dynamically adapted and the synchronous control on the rail wheels can be realized more accurately.

Owner:北京鹏发欣光电力电子科技有限公司

Power tool torque overload clutch

InactiveCN1833826BConsistent torqueEasy to prepareMetal sawing devicesSlip couplingBall bearingEngineering

A torque overload clutch for an electrical power tool, such as a percussion hammer drill, is provided. The clutch is accommodated in a cavity in a gear cog. Spring washers are used to urge ball bearings into indentations formed in the base of the cavity. The ball bearings are accommodated in cavities formed in a drive plate which engages with the spindle drive of the power tool. The spring washers are held in position by a circlip or a threaded plate. The threaded plate arrangement provides means for compressing the spring washers with a consistent force across a manufactured batch. A method of manufacturing the clutch is also disclosed.

Owner:BLACK & DECKER INC

electric screw driver

ActiveCN103264367BAvoid the hassle of manual operationImprove ergonomicsPower driven toolsHigh-voltage direct currentEngineering

The invention discloses an electric screw driver which comprises a handle outer shell, a handle cap, a high-voltage direct-current motor, a control circuit, a deceleration torque-varying box, a main shaft, a connecting shaft and an elbow assembly. The high-voltage direct-current motor, the control circuit, the deceleration torque-varying box and the main shaft are all arranged in the handle outer shell, the main shaft penetrates through the handle cap to output twisting force of the electric screw driver, and the elbow assembly comprises an elbow base, a cover of the elbow base, an output shaft and a pair of rotary teeth, wherein one rotary tooth is arranged on the output shaft, the other rotary tooth is arranged at the front end of the connecting shaft, the output shaft and the connecting shaft are respectively fixed by bearings to arrange the rotary teeth in the elbow base, the back end of the connecting shaft is connected with the main shaft, and the connecting shaft and the main shaft share the same center shaft. The electric screw driver is strong in practicability, the twisting force can be adjusted at will, the twisting force is constant and accurate, the mains supply is directly used for working, the defect that a straight-bar type electric screw driver cannot be used in a narrow station is overcome, and the electric screw driver is suitable for assembly lines and various maintaining and installing occasions.

Owner:佛山市速可达科技有限公司

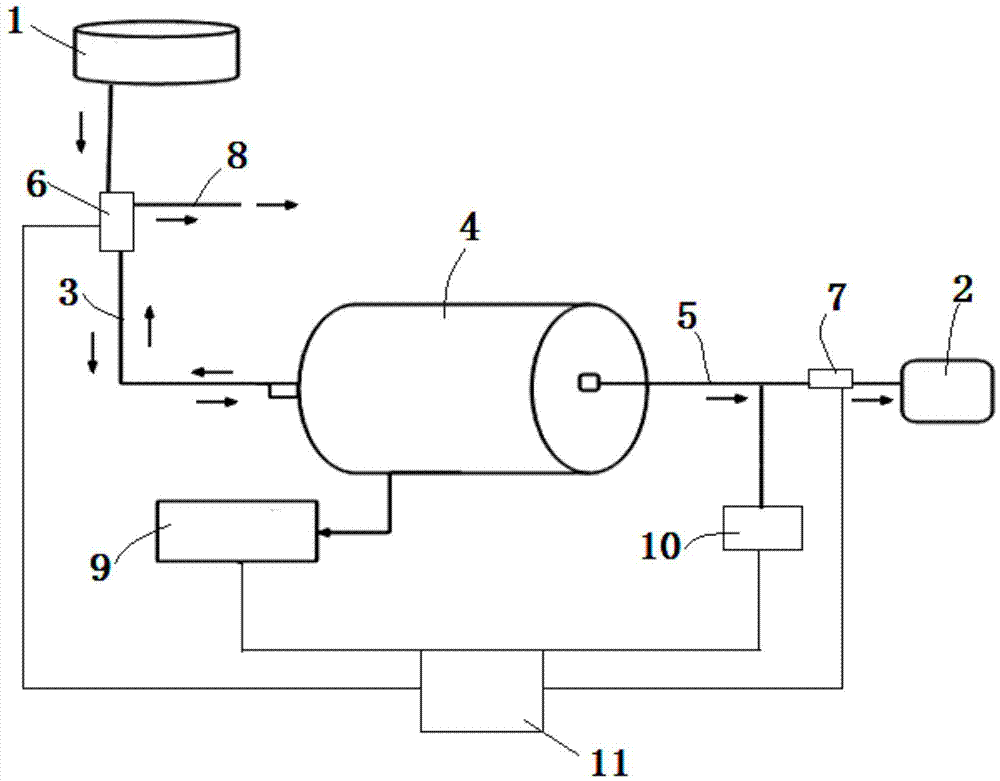

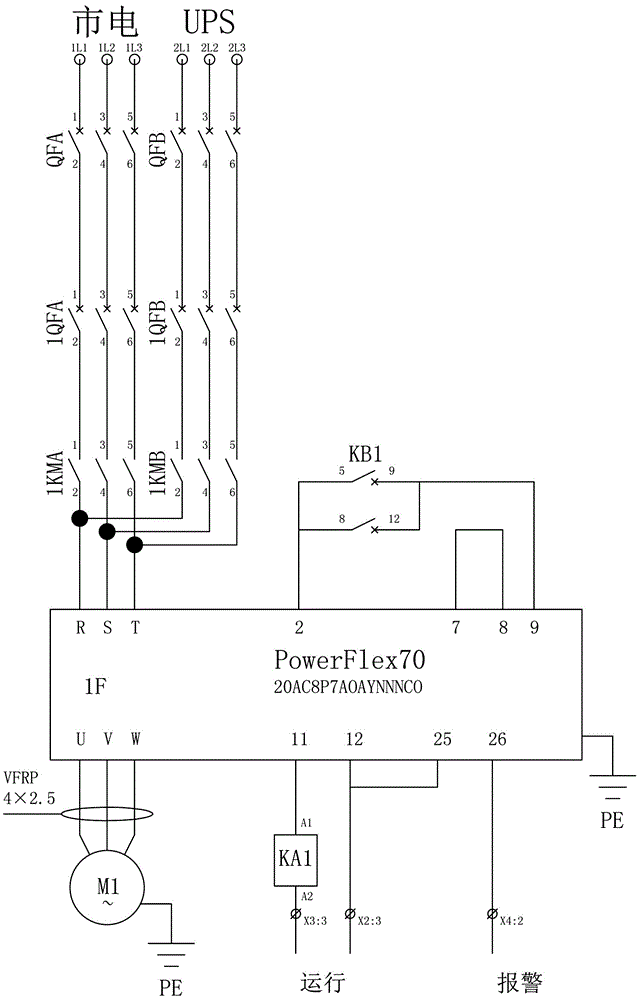

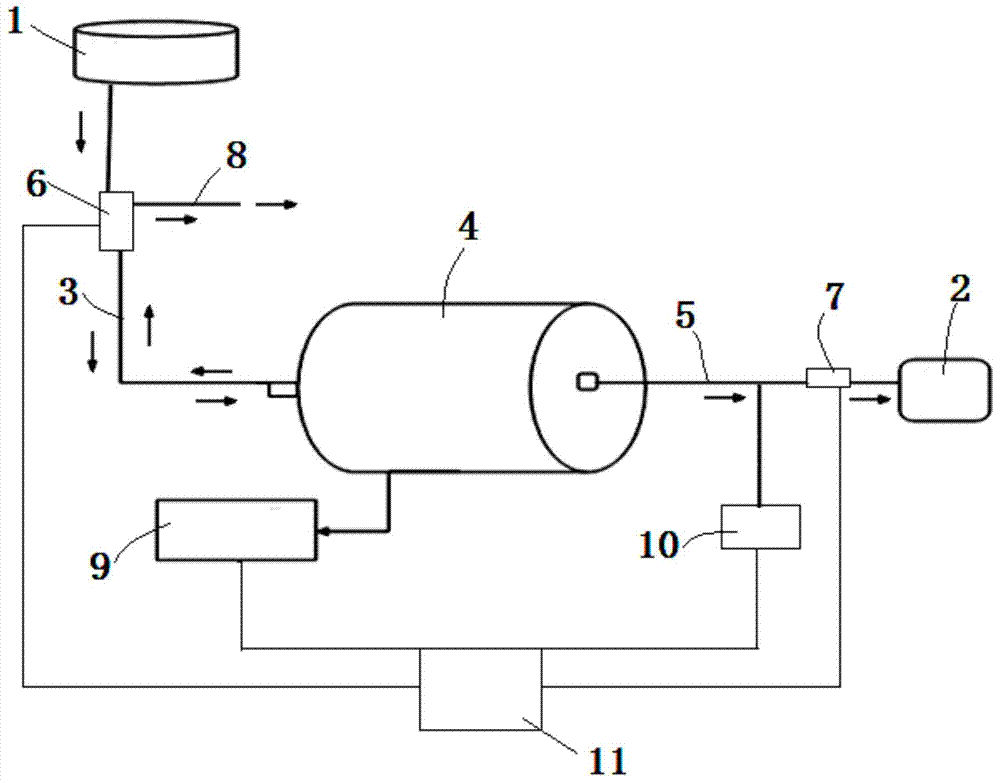

Skylight glass mounting pressure stability control system

InactiveCN104843105AGuarantee the consistency of installation qualityConsistent torqueVehiclesControl systemRivet gun

The invention discloses a skylight glass mounting pressure stability control system. The system comprises a main gas source and a wind batch or rivet gun and further comprises a gas pipe and a gas storage tank connected with the main gas source. The gas storage tank is connected with the wind batch or rivet gun through a gas inflation pipe. The gas pipe is provided with a first control valve. The first control valve is connected with a gas deflation pipe. The gas inflation pipe is provided with a second control valve. The gas storage tank is connected with a first pressure gage. The gas inflation pipe is connected with a second pressure gage. The first control valve, the second control valve, the first pressure gage and the second pressure gage are connected with a PLC through a control circuit. By means of the skylight glass mounting pressure stability control system, the input gas source of the wind batch or rivet gun is sufficient in flow and stable in pressure; meanwhile, the gas source of the wind batch or rivet gun works at the set pressure value, and it is guaranteed that the wind batch or rivet gun is the same in torque when shooting screws or rivets, so that the skylight glass screw or rivet mounting is made to meet the standard, and the consistency of the mounting quality of the skylight glass is guaranteed.

Owner:WUHU MOTIONTEC AUTOMOTIVE

Double head rotary die holder for wire drawing machine

Owner:中天智能装备有限公司

Laminated torsion spring

InactiveCN101392807AIncrease varietyIncrease flexibilityRubber-like material springsEngineeringApplication areas

The invention provides a laminated torsion spring, which is characterized by consisting of a spring body and a permanent seat, wherein the spring body is at least laminated by two elastic thin steel plates; and the permanent seat is arranged on two ends or in the middle section of the spring body. The laminated torsion spring breaks through the restriction of the traditional concept, and uses the torsion resistance of the thin steel plate to prepare the stripe torsion spring, thereby a novel type of the torsion spring is added, and the application field of the torsion spring is expanded further. Meanwhile, the torsion spring has the advantages of simple structure, convenient manufacture, wide application range, adjustable and calibrated torque force.

Owner:NANJING CHENGUANG GRP

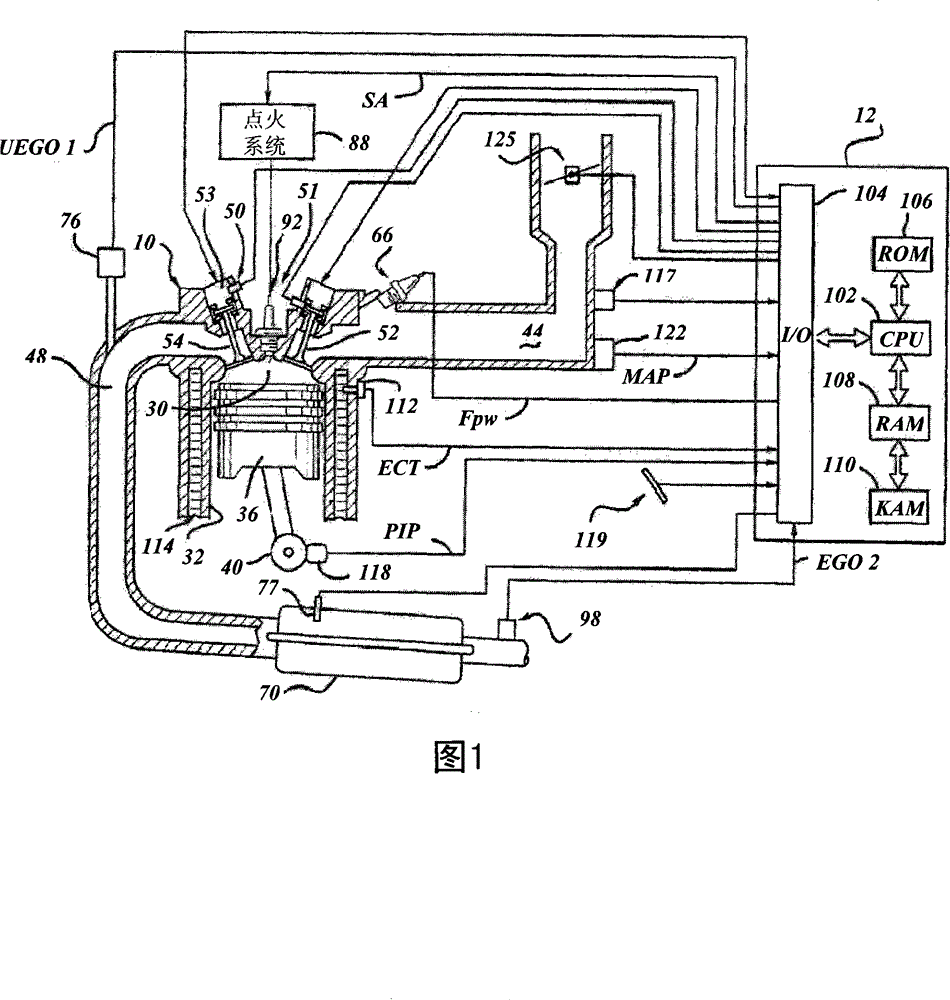

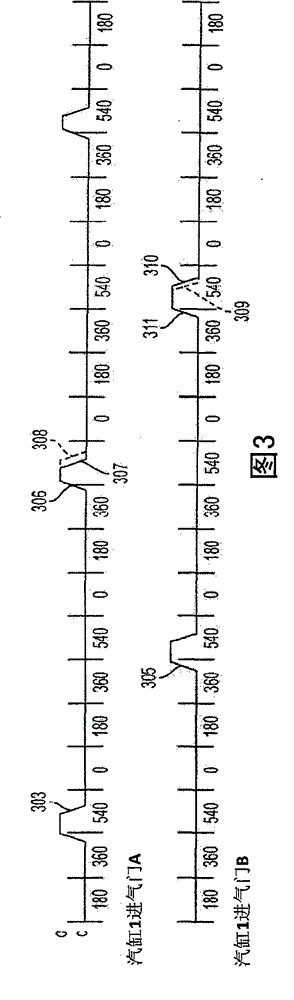

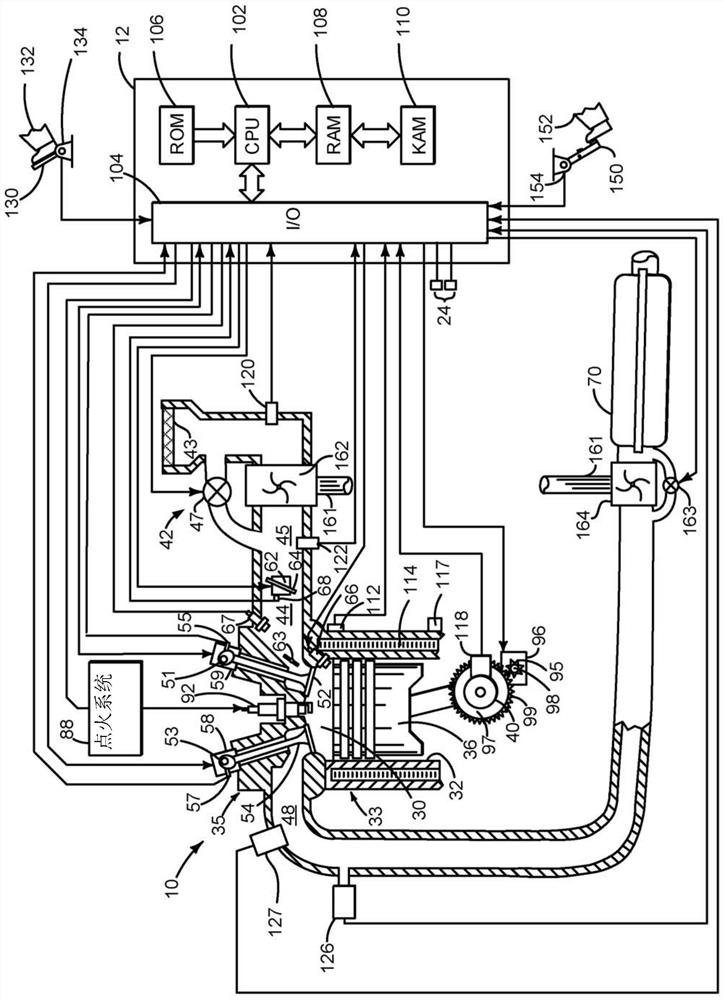

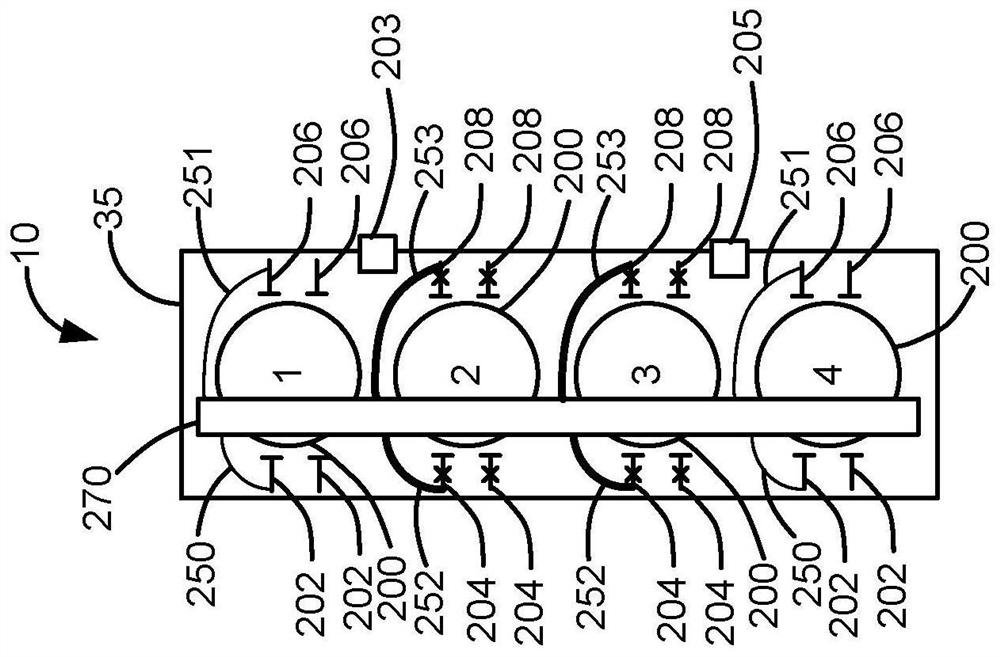

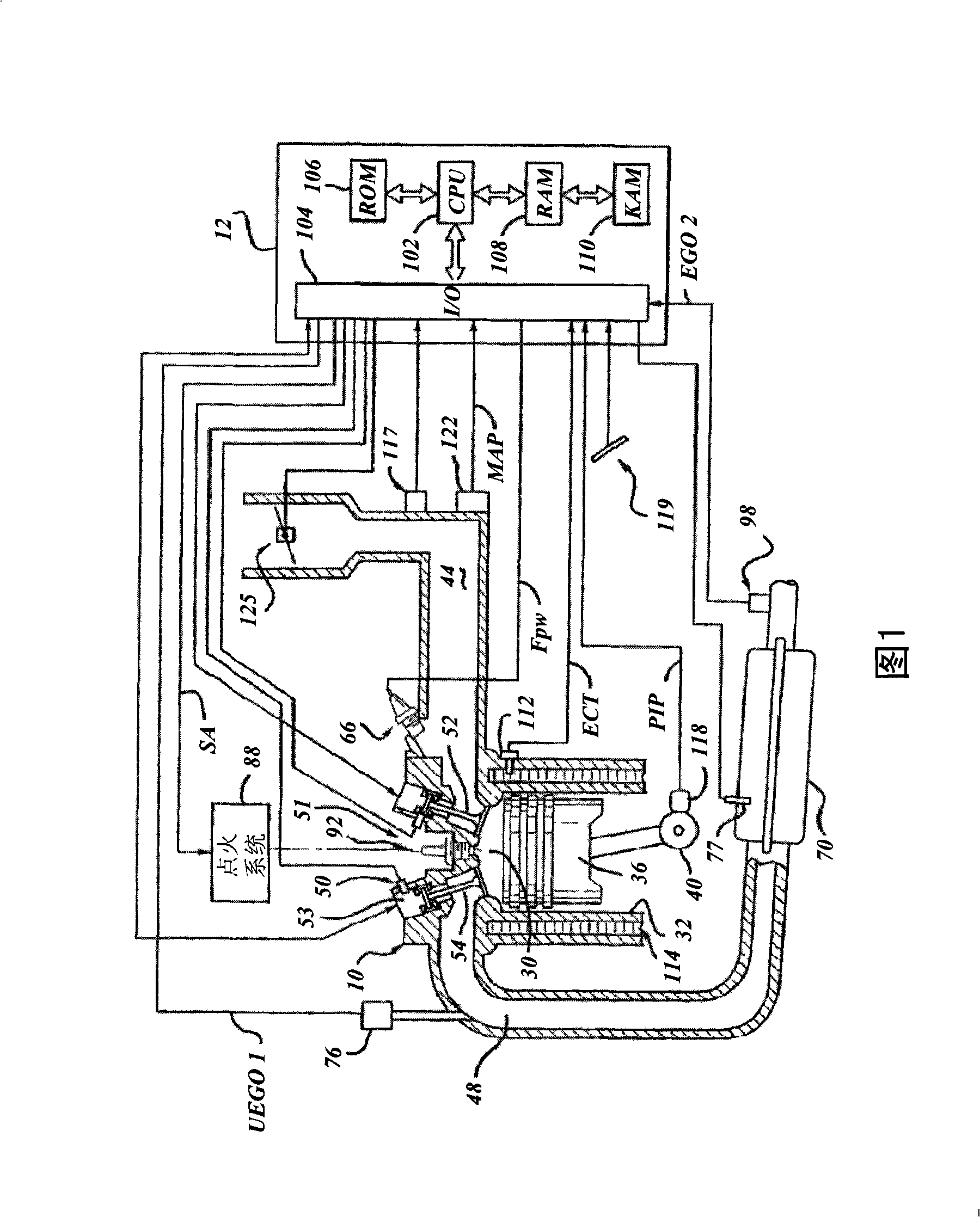

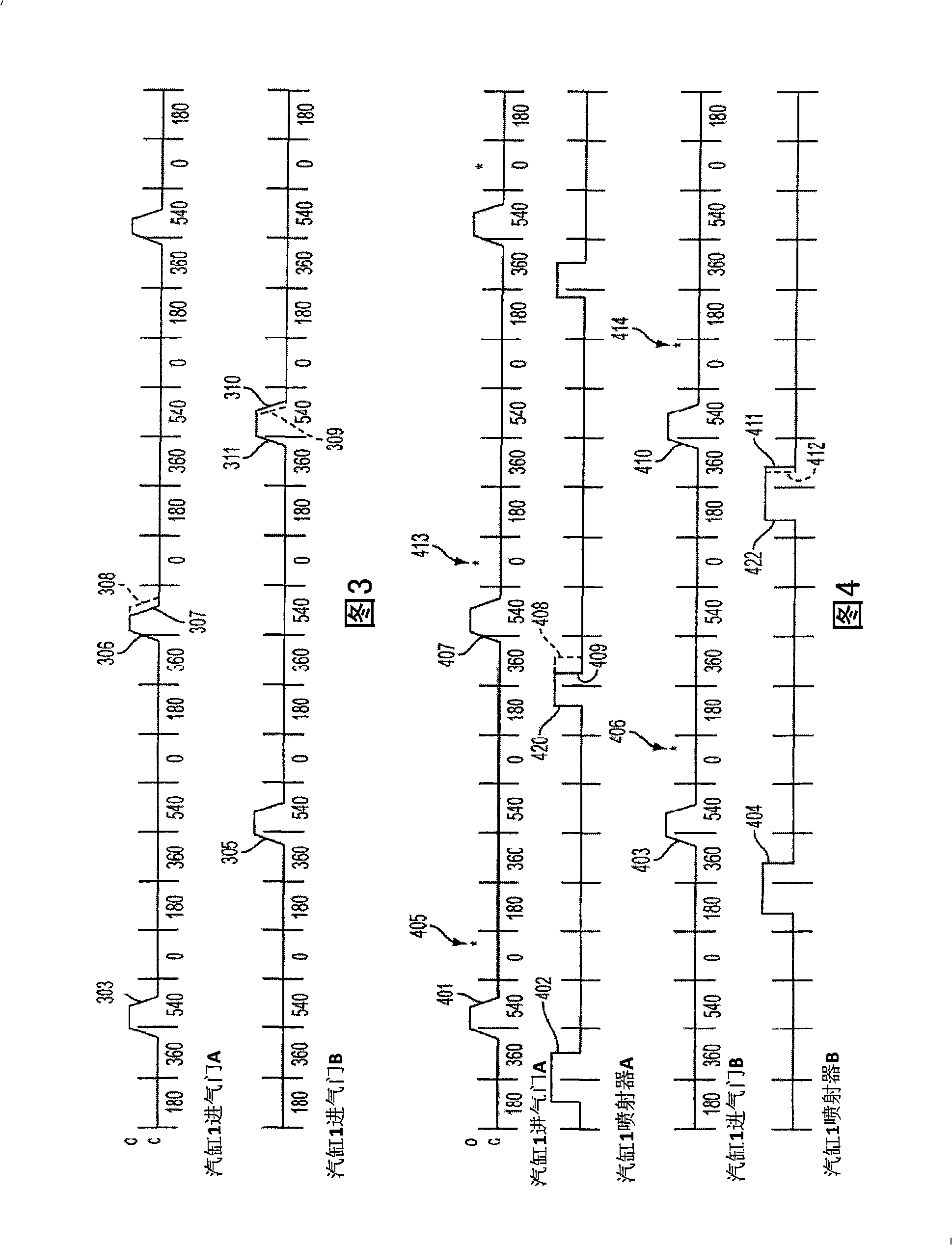

Method for controlling air-fuel ratio for an alternating valve engine

InactiveCN101408126BImproved air-fuel ratio controlConsistent torqueElectrical controlInternal combustion piston enginesInlet valveEngineering

Owner:FORD GLOBAL TECH LLC

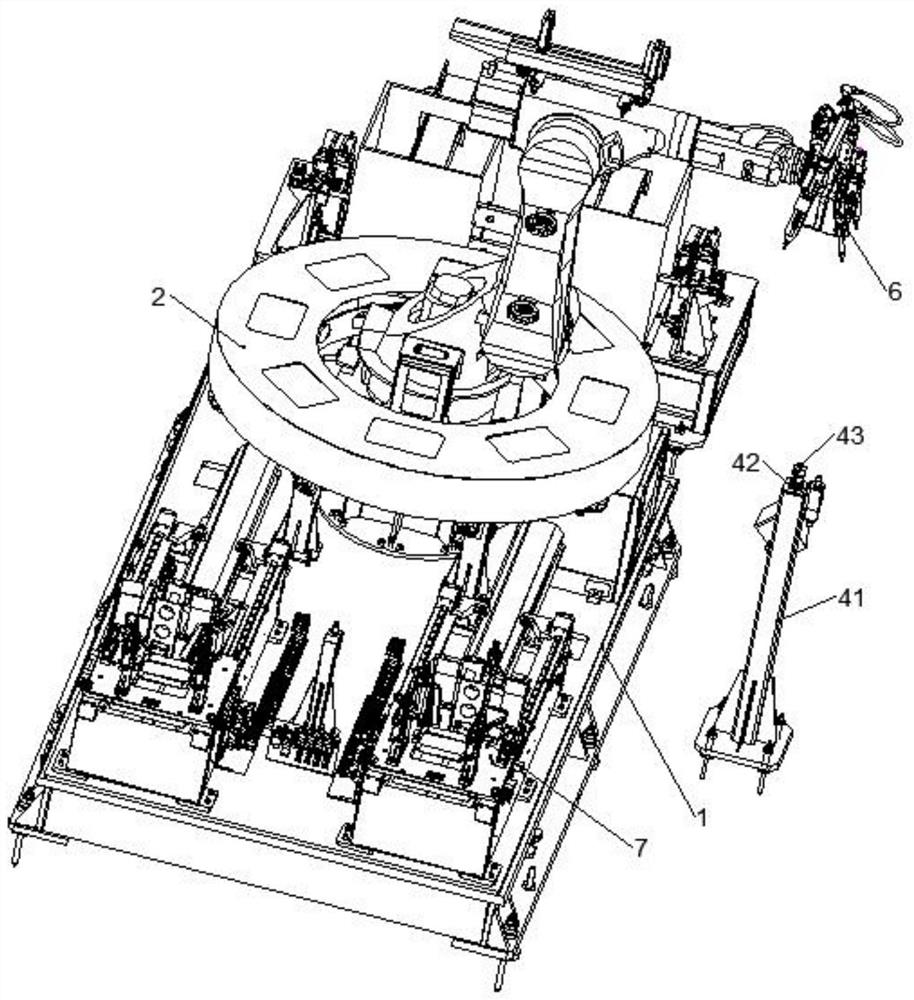

Threaded sleeve tightening equipment

PendingCN112692554AAutomate workIncrease production capacityMeasurement devicesMetal working apparatusEngineeringWorkbench

The invention discloses thread sleeve tightening equipment. The equipment comprises a workbench, a thread sleeve feeding assembly and a torque calibration assembly, the thread sleeve feeding assembly is located on the right side of the workbench, the torque calibration assembly is located on the front side of the workbench, a drag chain disc and a joint robot are arranged on the right side of the top of the workbench, a tightening assembly is installed on the joint robot, and a workpiece clamp is mounted on the top right side of the workbench. The equipment integrates the functions of thread sleeve screening, thread sleeve tightening, depth detection, tail handle punching and breaking, punching and breaking detection and torque calibration, automatic work of thread sleeve tightening can be achieved, the tightening yield and the production speed are increased, and the equipment is quite convenient to use.

Owner:BEIJING ACESTEP AUTOMATION CONTROL EQUIP CO LTD

Rail wheel synchronous control device for rail transit vehicle traction power test device

InactiveCN102945057BSame speedAvoid the defect of unequal torqueRailway vehicle testingSimultaneous control of multiple variablesSynchronous controlControl signal

Owner:北京鹏发欣光电力电子科技有限公司

Systems and methods for adjusting intake manifold pressure

ActiveCN107489548BReduce consumptionTorque controlElectrical controlInternal combustion piston enginesThermodynamicsEngineering

The present application relates to systems and methods for adjusting intake manifold pressure. Systems and methods are presented for operating an engine with deactivated and non-deactivated valves. In one example, the position of an engine intake throttle is adjusted during cylinder deactivation to control intake manifold pressure for cylinder reactivation. Throttle closing may be timed based on the actual number of cylinder induction events expected to provide a desired engine intake manifold pressure.

Owner:FORD GLOBAL TECH LLC

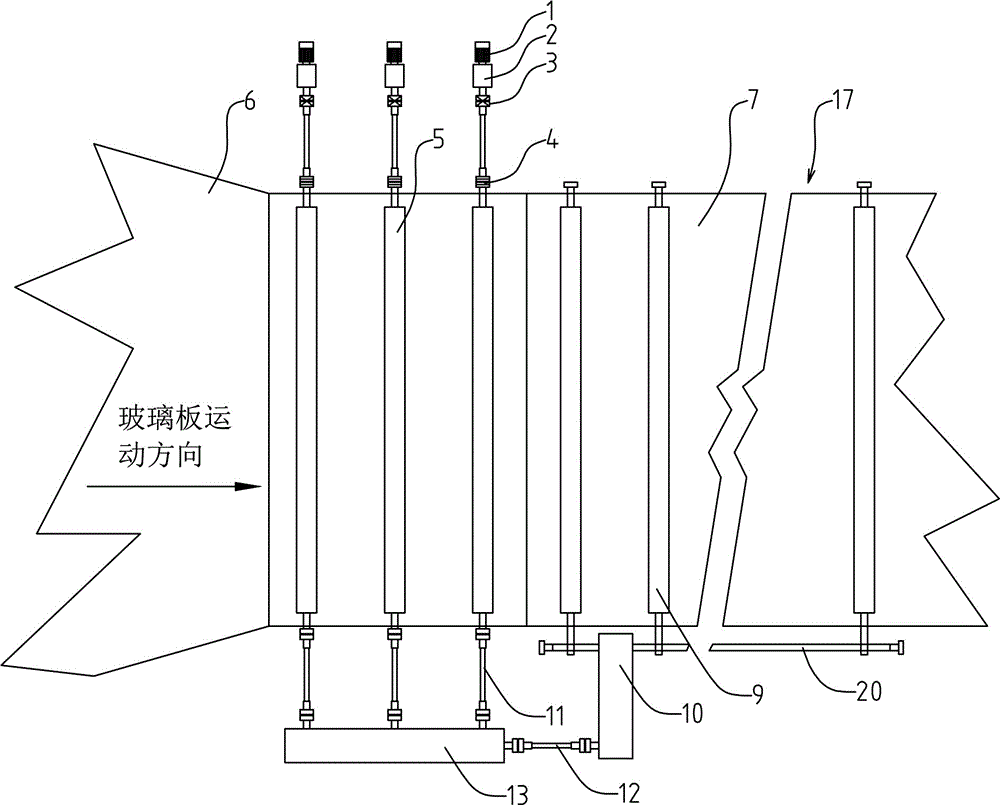

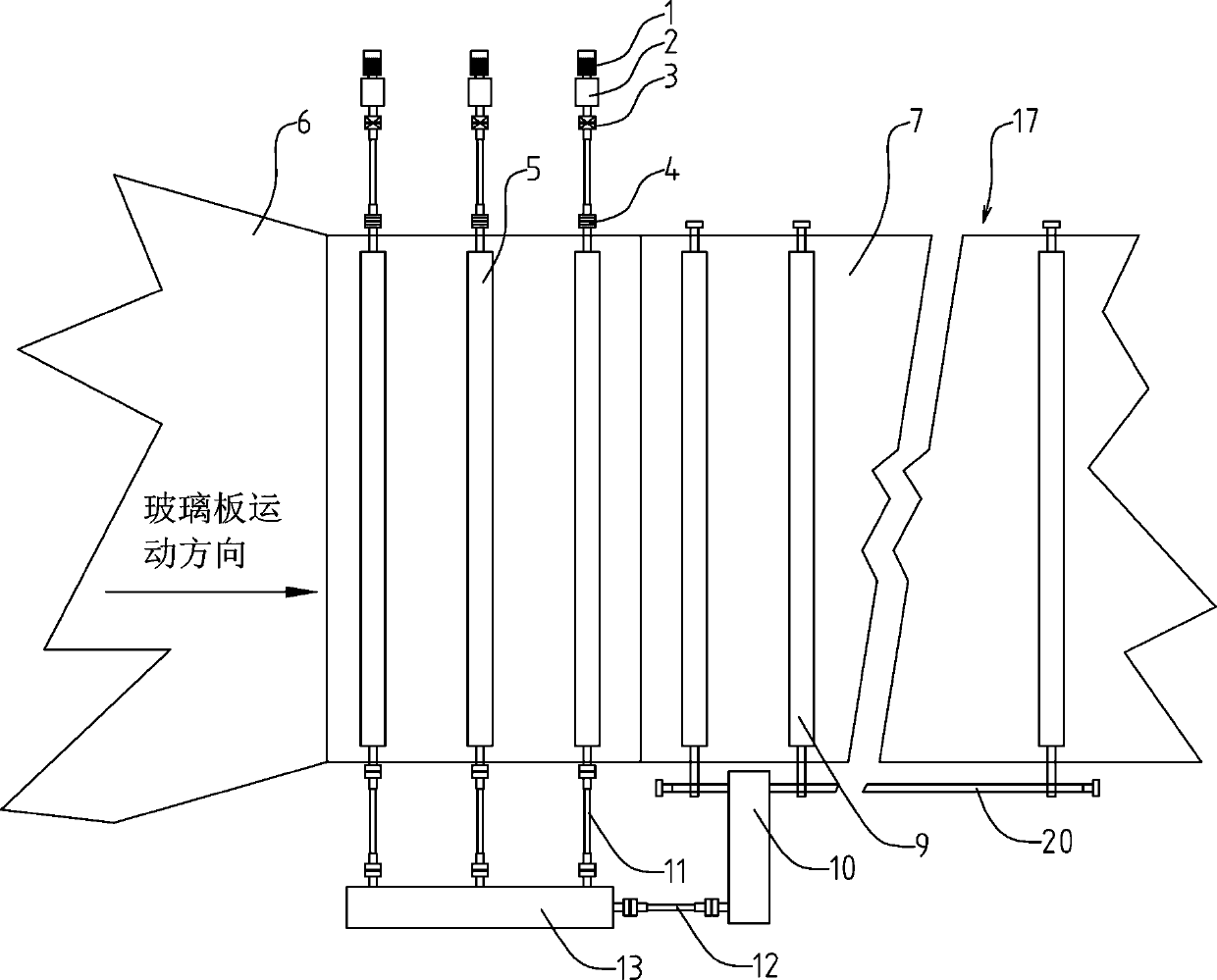

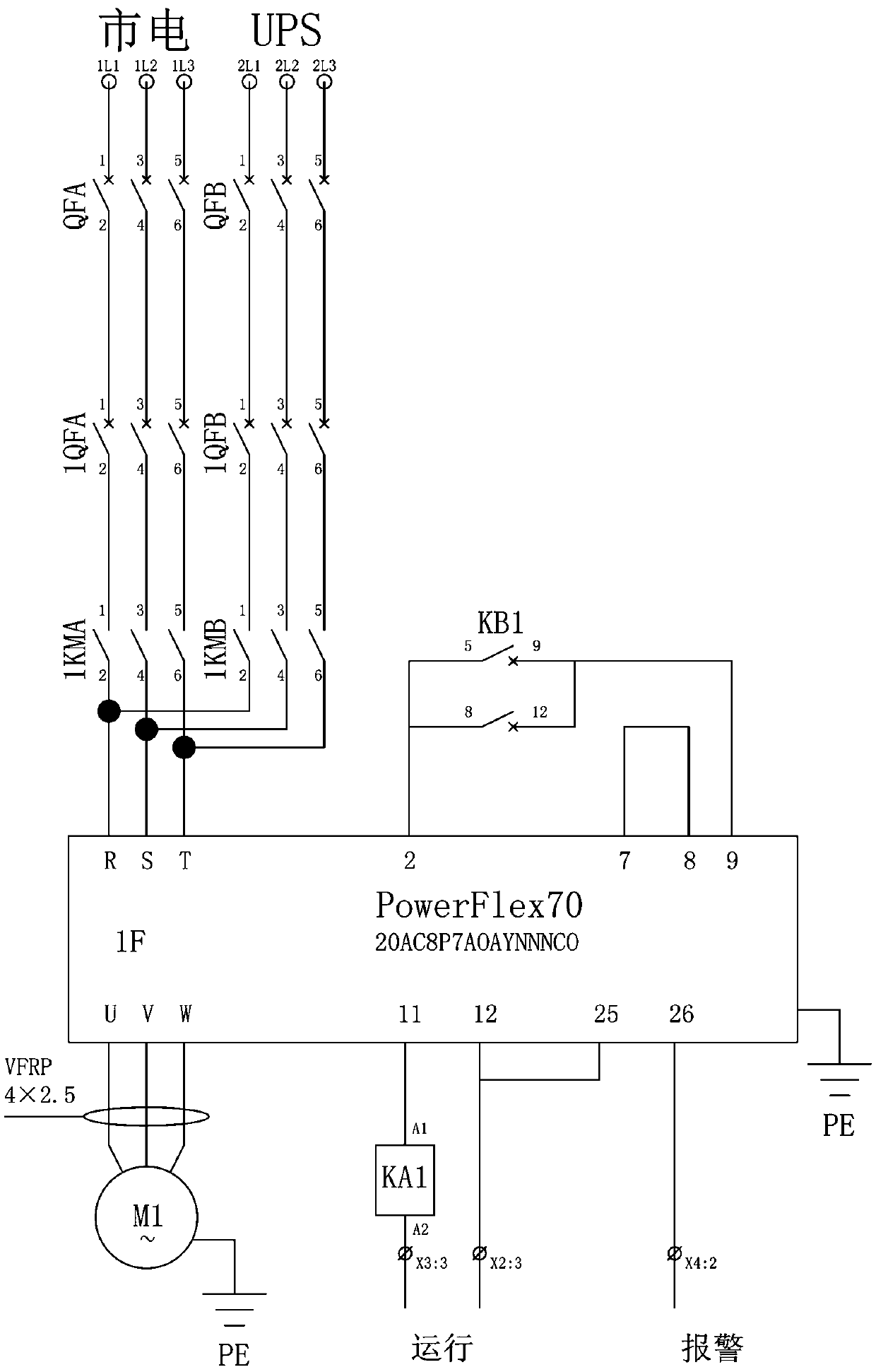

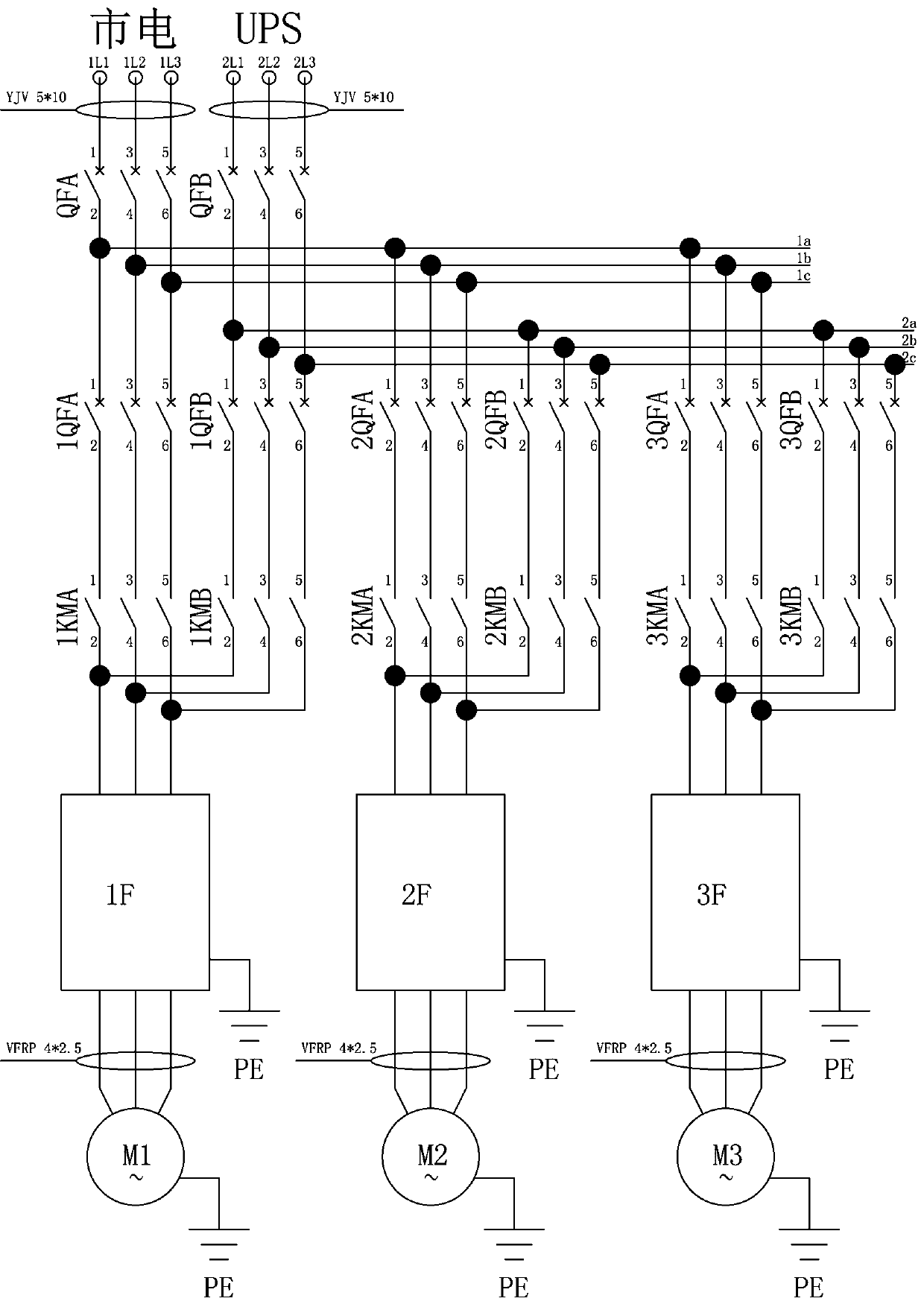

Method for improving quality of ultrathin glass lower surface

ActiveCN106707957AQuality improvementImprove appearance qualityProgramme control in sequence/logic controllersControl theoryGlass sheet

The invention provides a method for improving the quality of an ultrathin glass lower surface. The system according to the method comprises multiple transition rollers which are arranged between a tin bath and an annealing kiln. One end of each transition roller is connected with one slave transmission device. The slave transmission device drives the transition rollers to rotate. A speed sensor and a torque sensor are arranged on the slave transmission device. A PLC adjusts rotating speed of each slave transmission device according to the feedback of the torque sensor under the condition of conveying a glass plate so that the torque conveying to each transition roller is maintained to be consistent. The scheme of speed control is replaced by the scheme of torque control so that the torque of all the transition rollers is maintained to be consistent, sliding friction between the transition rollers and the glass plate lower surface can be fundamentally avoided and the problem of transmission speed fluctuation can also be overcome to some extent.

Owner:YICHANG CSG PHOTOELECTRIC GLASS

A high temperature resistant relay and its production method

ActiveCN107180730BImprove the safety of useExtended service lifeElectromagnetic relay detailsAir tightnessCopper alloy

The invention provides a high temperature-resistant relay and a production method and belongs to the circuit control equipment field. The high temperature-resistant relay includes a fixed contact lead-out end, a transition lead-out end and a ceramic cover; the fixed contact lead-out end is adopted as the static contact of the relay; the transition lead-out end is arranged between the fixed contact lead-out end and the ceramic cover; the fixed contact lead-out end is made of anti-sticking copper alloys, and therefore, the anti-sticking performance of the product can be improved, the hardness of the anti-sticking copper alloy material is almost unchanged after the anti-sticking copper alloy material is subjected to high-temperature brazing, and the consistency of the torque of the anti-sticking copper alloy material before and after the high-temperature brazing can be guaranteed; and the transition lead-out end is made of an iron-copper alloy material, and therefore, the qualified rate of the welding of the transition lead-out end and the ceramic cover can be ensured. With the high temperature-resistant relay and the production method provided by the technical schemes of the invention adopted, the sealing of ceramic brazing can be ensured, the air tightness and stability of the matching of the fixed contact lead-out end which has been subjected to the high-temperature brazing with an external connection component can be also improved, and thus, the use safety of the relay can be improved, and the service life of the relay can be prolonged.

Owner:XIAMEN HONGFA ELECTRIC POWER CONTROLS

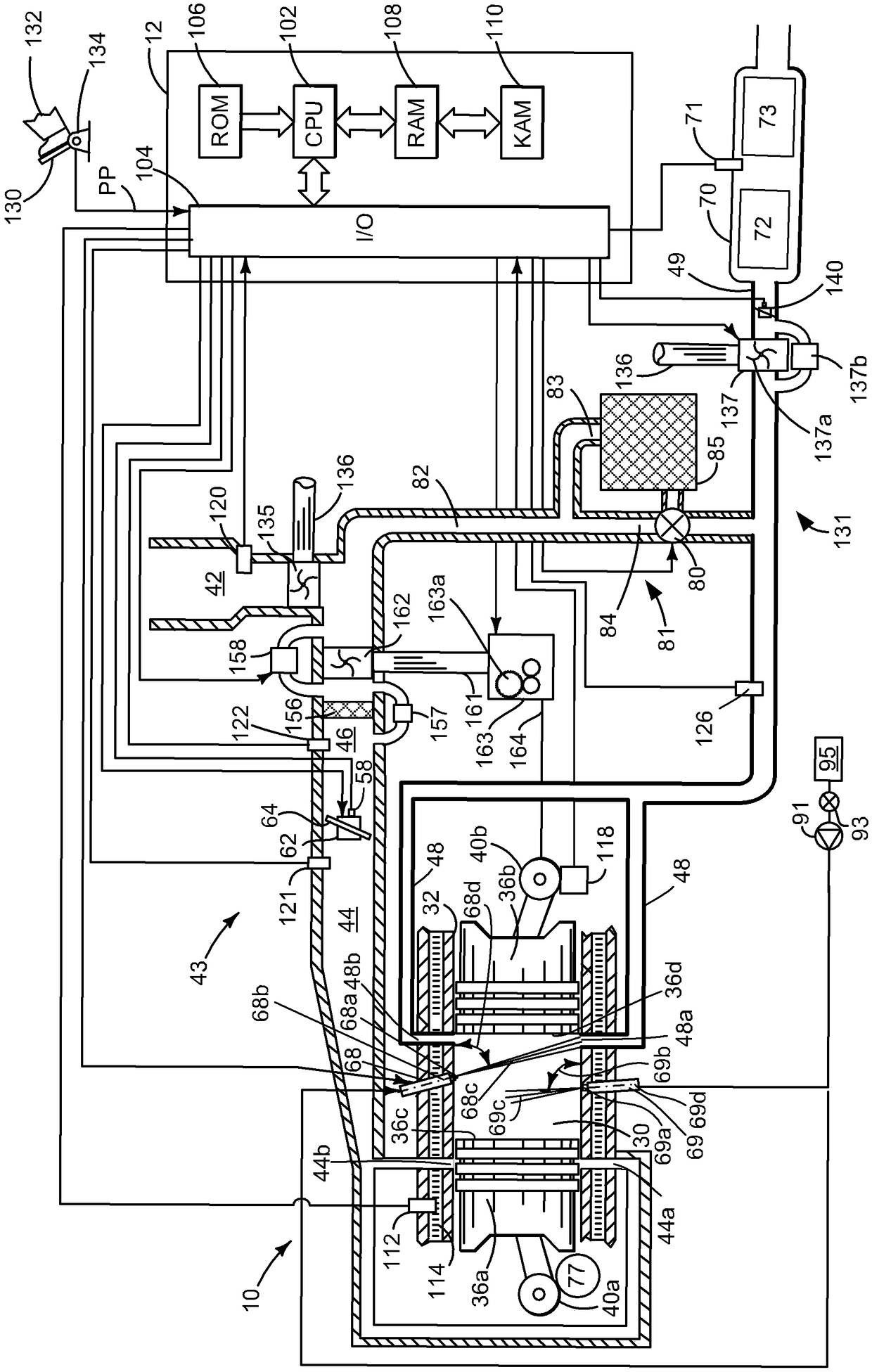

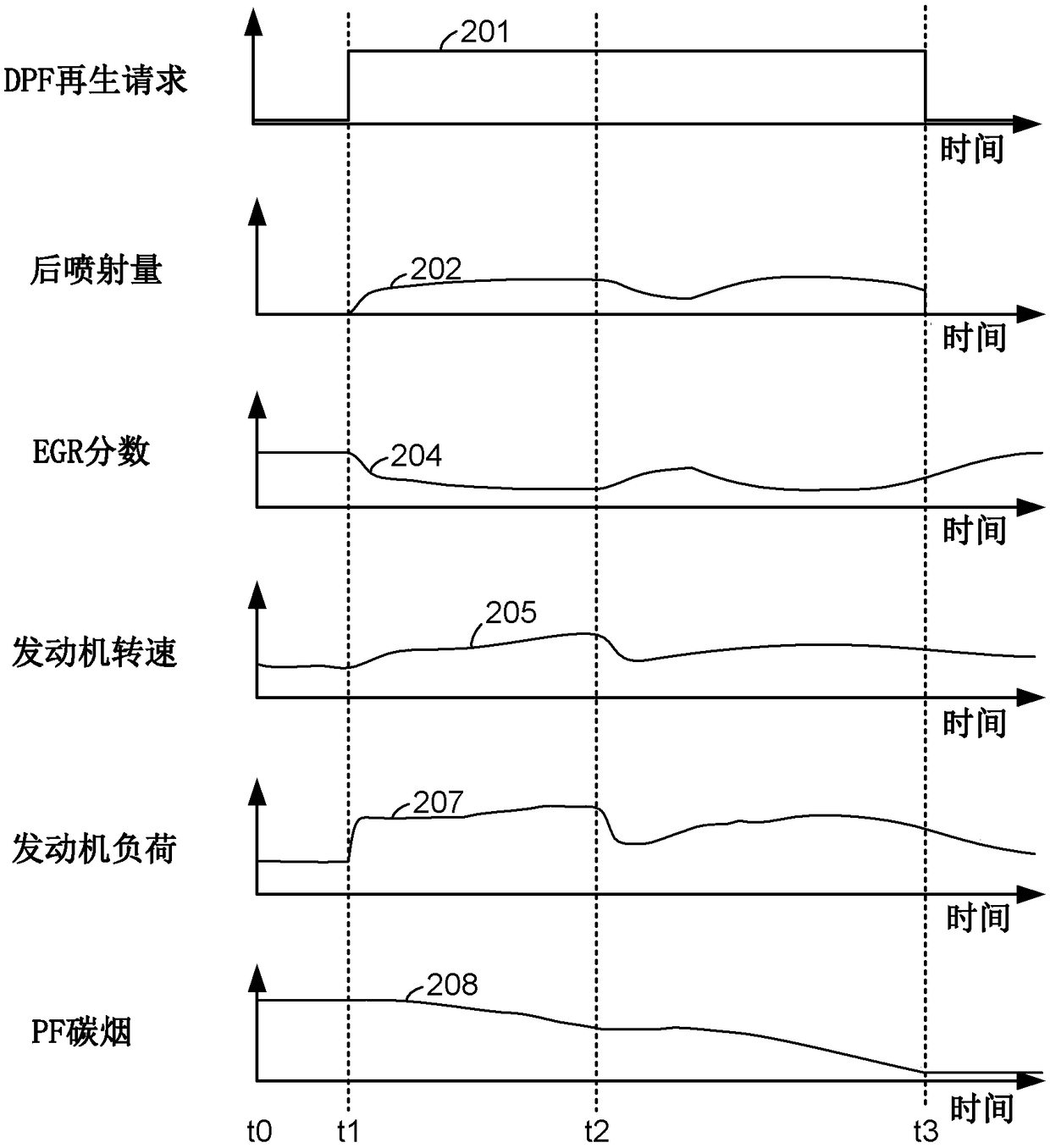

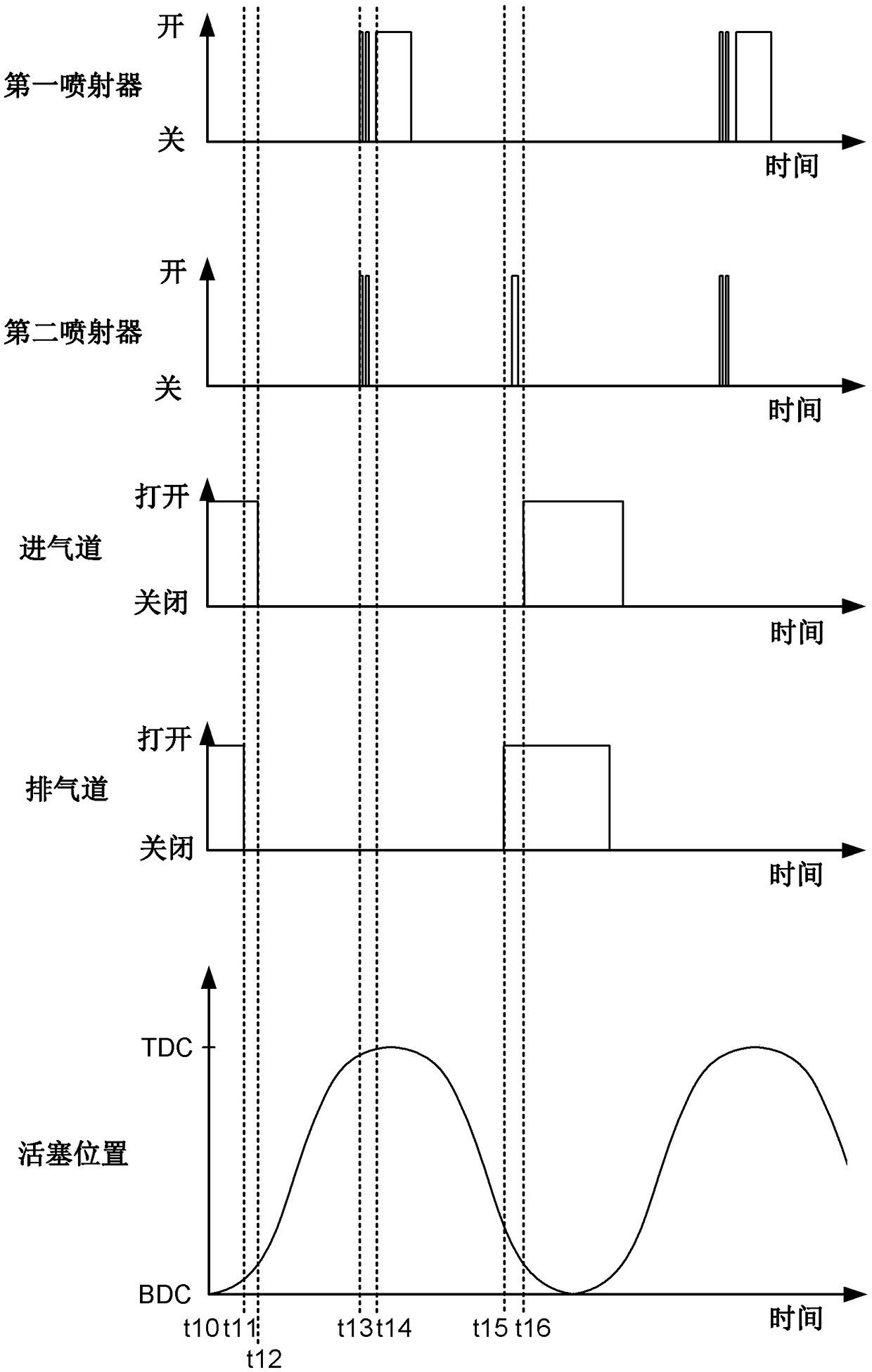

Diesel engine particulate filter regeneration system and methods

PendingCN109488474AReduces the likelihood of auto-ignitionConsistent torqueElectrical controlInternal combustion piston enginesParticulatesTwo-stroke diesel engine

The invention relates to a diesel engine particulate filter regeneration system and methods, and describes methods and systems for supplying post injection fuel to a two stroke diesel engine. In one example, post injection fuel timing is adjusted responsive to an amount of internal residual combustion products in a cylinder so that less post injected fuel may be trapped in the cylinder for a subsequent cycle of the cylinder. The start of post injection fuel timing and the amount of post injection fuel may be adjusted responsive to internal residual in the cylinder.

Owner:FORD GLOBAL TECH LLC

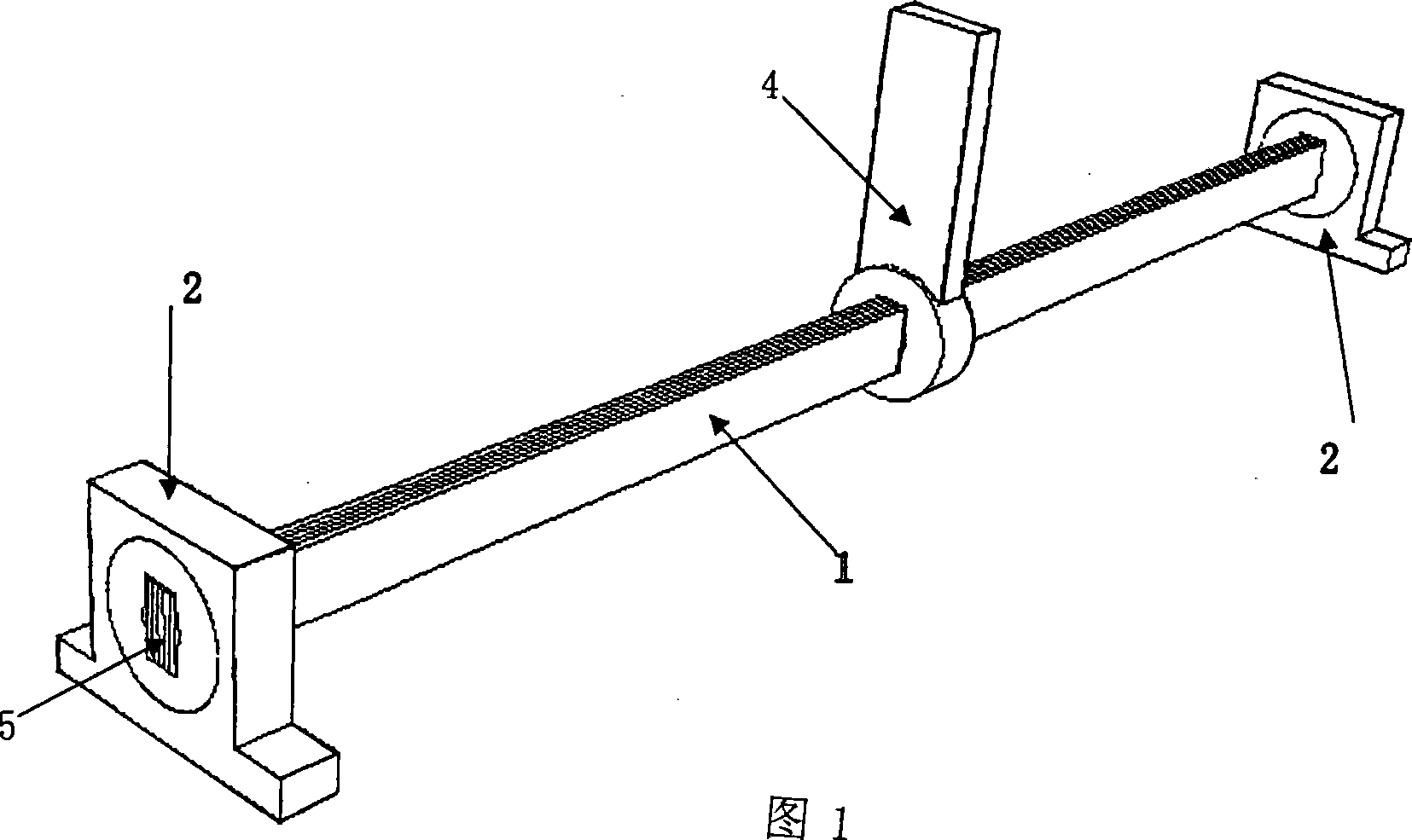

Method for checking paper-making forming fabrics

InactiveCN103193101AEasy to find quality problemsConsistent torqueWebs handlingElectric machineryIndustrial engineering

A method for checking paper-making forming fabrics includes following steps: a, placing a forming fabric to be checked on an upper fabric rolling steel pipe and feeding the forming fabric from top to bottom; b, rolling the forming fabric fed by the upper fabric rolling steel pipe by a lower fabric rolling steel pipe; and c, checking the forming fabric fed downwards along the upper fabric rolling steel pipe while using moment to control a fabric rolling motor. During checking of the forming fabric, tension of the forming fabric is reasonably controlled, so that subtle quality problems of the forming fabric can be found more easily to provide high-quality forming fabrics. In addition, tension control is realized through a moment control motor, different from a speed control motor, the moment control motor can constantly maintain uniform moment on the forming fabric and cannot pull the forming fabric, speed is low when resistance applied to the motor is large, speed is high when resistance applied to the motor is small, and the moment is fixed, so that the service life of the rolling motor is effectively guaranteed.

Owner:JIANGSU JINNI ENGINEERED FABRIC CO LTD

A method for improving the quality of the lower surface of ultra-thin glass

ActiveCN106707957BQuality improvementImprove appearance qualityProgramme control in sequence/logic controllersThin glassControl theory

The invention provides a method for improving the quality of an ultrathin glass lower surface. The system according to the method comprises multiple transition rollers which are arranged between a tin bath and an annealing kiln. One end of each transition roller is connected with one slave transmission device. The slave transmission device drives the transition rollers to rotate. A speed sensor and a torque sensor are arranged on the slave transmission device. A PLC adjusts rotating speed of each slave transmission device according to the feedback of the torque sensor under the condition of conveying a glass plate so that the torque conveying to each transition roller is maintained to be consistent. The scheme of speed control is replaced by the scheme of torque control so that the torque of all the transition rollers is maintained to be consistent, sliding friction between the transition rollers and the glass plate lower surface can be fundamentally avoided and the problem of transmission speed fluctuation can also be overcome to some extent.

Owner:YICHANG CSG PHOTOELECTRIC GLASS

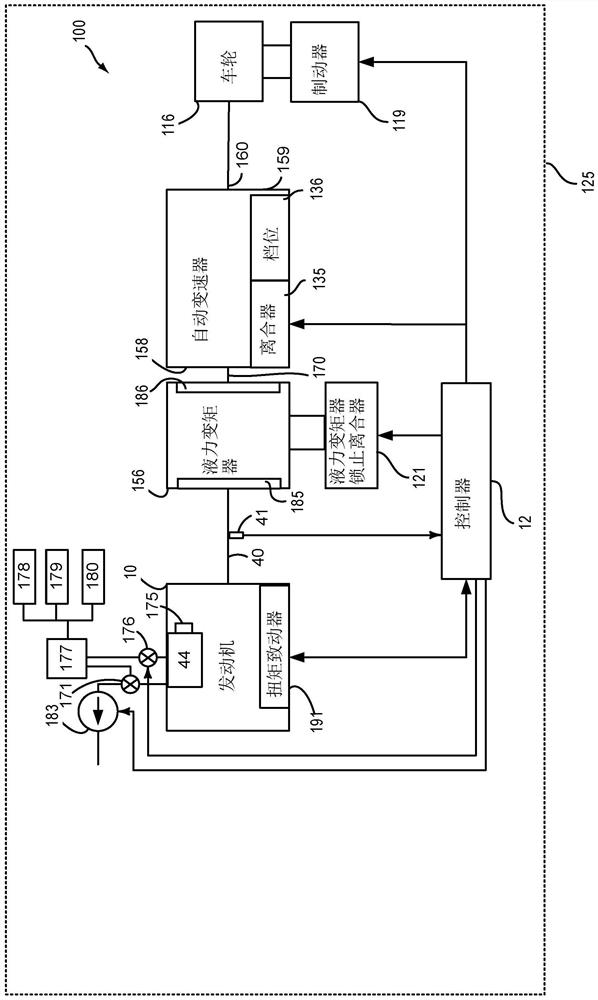

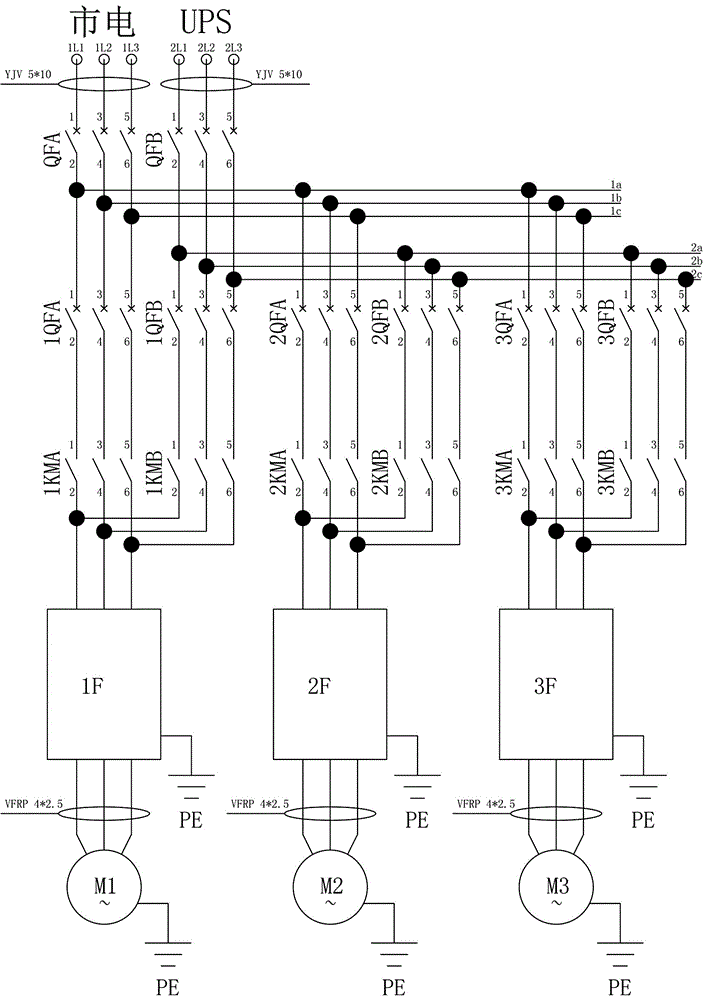

Automobile equipower electromechanical direct drive system

PendingCN110154782AConsistent powerConsistent torqueSpeed controllerElectric energy managementNew energyMechanical energy

The invention relates to the technical field of new energy automobiles, and discloses an automobile equipower electromechanical direct drive system. The automobile equipower electromechanical direct drive system comprises an engine, a power generator, an equipower adjusting circuit, an electromotor and a controller. The engine is connected with the power generator and provides mechanical energy for the power generator, the equipower adjusting circuit is connected with the power generator and the electromotor, the power generator is used for converting the mechanical energy into a circuit and outputting the circuit to the equipower adjusting circuit, the controller is connected with the engine, the power generator, the equipower adjusting circuit and the electromotor and used for monitoringoperating parameters of the engine, the power generator and the electromotor in real time, controlling the equipower adjusting circuit to adjust electric energy output by the power generator according to the operating parameters and outputting the adjusted electric energy to the electromotor, and it is guaranteed that the powers of the engine, the power generator and the electromotor are kept consistent.

Owner:张治成

Method for controlling air-fuel ratio for an alternating valve engine

InactiveCN101408126AImproved air-fuel ratio controlConsistent torqueElectrical controlInternal combustion piston enginesInlet valveControl theory

A method for controlling the air-fuel ratio of an internal combustion engine operating with alternating intake valves is presented, comprising: operating at least one cylinder of the internal combustion engine with a first inlet port and a second inlet port; operating the first inlet port and the second inlet port in the during an alternating cylinder cycle; and adjusting the timing of the first inlet port or the second inlet port in response to the air intake of the cylinder sucked into the cylinder, wherein the air intake of the cylinder is sucked during the cylinder cycle of the cylinder, and the cylinder circulation generates before the adjusted timing is used for the cylinder. According to the method, the air-fuel ratio of the internal combustion engine is adjusted through changing valve timing or fuel timing during the cylinder cycle. The inventive method reduces discharge of the engine.

Owner:FORD GLOBAL TECH LLC

Skylight glass mounting pressure stability control method

InactiveCN104847743AGuarantee the consistency of installation qualityConsistent torqueFluid-pressure actuator testingServomotor componentsRivet gunEngineering

The invention discloses a skylight glass mounting pressure stability control method. The method includes the specific control steps that 1, the pressure of a gas storage tank connected with a main gas source is controlled at the set value to achieve the purpose that the input gas source of a wind batch or a rivet gun for mounting skylight glass is stable in pressure; 2, when the pressure of an air inflation pipe of the wind batch or the rivet gun connected with the gas storage tank is controlled to be the set value, the wind batch or the rivet gun starts to work, the output driving torque of the wind batch or the rivet gun is made to be the same when assembled, and the mounting quality of the skylight glass is made to be consistent. According to the skylight glass mounting pressure stability control method, the input gas source of the wind batch or the rivet gun is sufficient in flow and stable in pressure; meanwhile, the gas source of the wind batch or the rivet gun works at the set pressure value, and it is guaranteed that the wind batch or the rivet gun is the same in torque when shooting screws or rivets, so that the skylight glass screw or rivet mounting is made to meet the standards, and the consistency of the mounting quality of the skylight glass is guaranteed.

Owner:WUHU MOTIONTEC AUTOMOTIVE

Full-automatic screw locking machine

The invention relates to the field of automatic machinery, in particular to a full-automatic screw locking machine. The full-automatic screw locking machine comprises a screw conveying device and a screw screwing device. The screw conveying device comprises a first conveying channel and a second conveying channel, screws in the first conveying channel can be conveyed into the second conveying channel, the screw screwing device comprises an electric screwdriver and a moving rod connected to the output end of the electric screwdriver, and the screws in the second conveying channel can be arranged at the end portion of the moving rod; and the electric screwdriver can drive the moving rod to move and rotate, so that the screws rotate along with the moving rod and are locked to parts. According to the full-automatic screw locking machine, manpower is saved, the working efficiency of screw locking is improved, the torsion of each screw can be kept consistent, then it is guaranteed that the screws are evenly stressed in the locking process, the phenomena of thread loosening and inclined screwing are avoided, and therefore the service life of the parts is prolonged.

Owner:昆山威典电子有限公司

Locking device for threaded fasteners

ActiveCN104227390BReplace manual operationReduce manual labor intensityMetal working apparatusEngineeringThreaded fastener

Owner:GREE ELECTRIC APPLIANCES INC

Dental implant installation tool

This invention relates to a dental implant installation tool, belonging to the field of dental implants, and is especially suitable for the place with torque requirements on tightening screw during dental surgery. The dental implant installation tool comprises an installation block, an installation cap, a connecting rod, a connecting block, a pin, a spring and a gasket, wherein the gasket is inserted into the connection rod and installed on the step surface of the connecting rod; the connecting rod, connecting block, pin, spring and gasket are separately installed in the installation block; the cylinder of the connecting rod is inserted into the cylindrical hole inside the installation block, the gasket is installed on the step surface of the inner hole of the installation block, the pretightening force of the spring clamps the pin, the pin is located against the connection block, and the outer arc surface of the connecting block and the inner arc surface of the inner hole of the installation block are closely matched together; and the connecting rod is penetrated through the via of the installation cap and is connected with the installation block through thread.

Owner:常州百康特医疗器械有限公司

Screw locking machine

PendingCN113414579AImprove stabilityHigh precisionWork holdersMetal working apparatusPhysicsEngineering

The invention relates to the field of automatic machinery, in particular to a screw locking machine. The screw locking machine mainly comprises a frame body, a carrier module, a press-fit stripping mechanism module and a screw driving module. The carrier module is arranged on the frame body, and the carrier module is used for placing parts; the press-fit stripping mechanism module is movably arranged on the frame body and used for being matched with the carrier module to fix the parts and stripping the parts subjected to screw locking; the press-fit stripping mechanism module is located over the carrier module; and the screw driving module is arranged on the frame body, and the screw driving module can rotate a screw and lock the screw to the part. According to the screw locking machine, manpower is saved, the working efficiency of screw locking is improved, the torsion of each screw can be kept consistent, then it is guaranteed that the screws are evenly stressed in the locking process, the phenomena of screw loosening and inclined screwing are avoided, and therefore the service life of parts is prolonged.

Owner:昆山威典电子有限公司

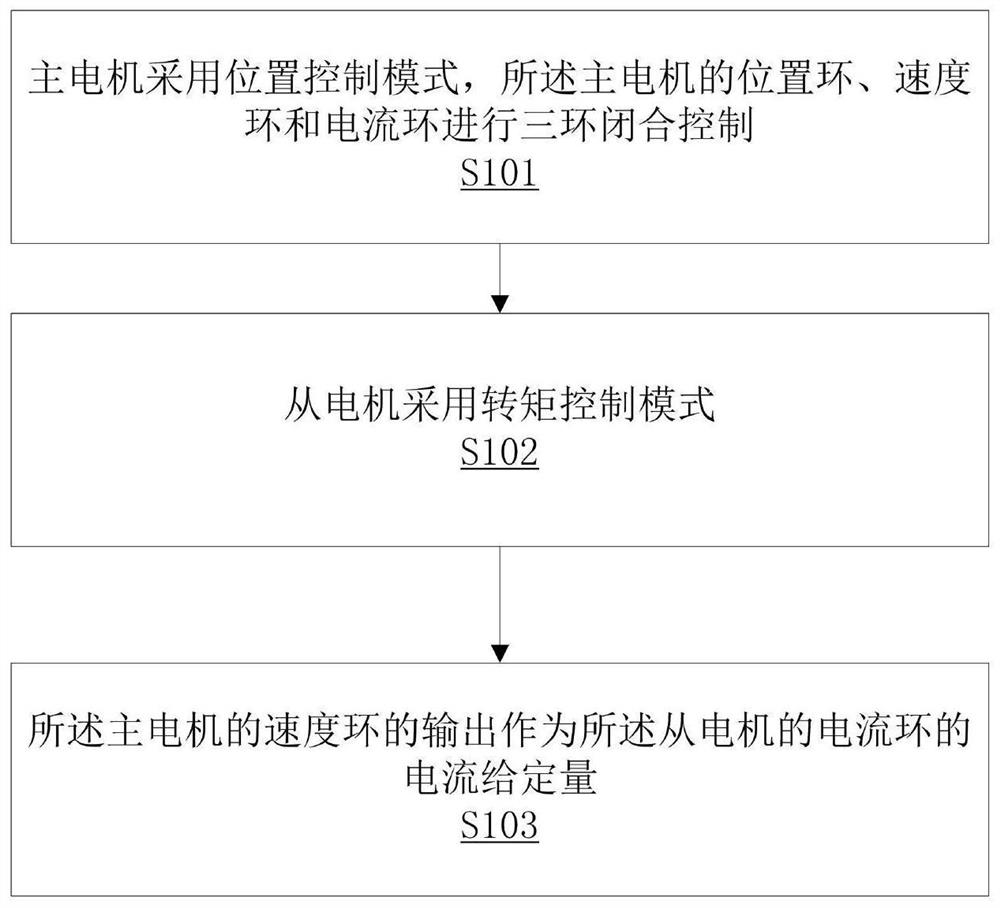

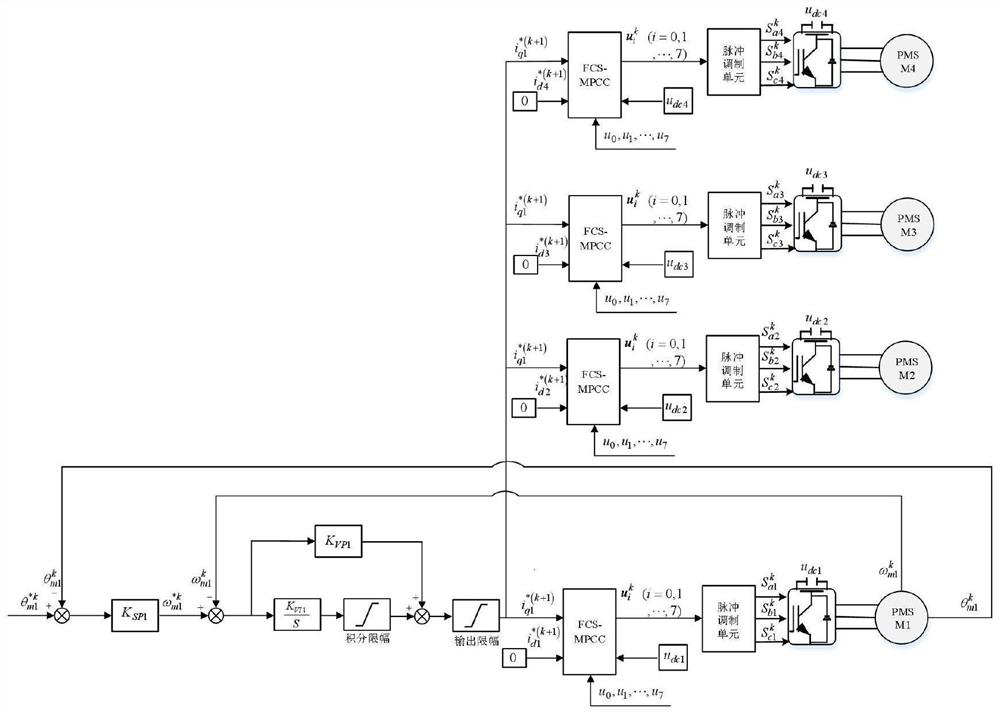

Torque balance control method and system for annular knitting machine and storage equipment

PendingCN113992067ANo stuck phenomenonTorque balance controlAC motor controlElectric motor controlElectric machineryControl engineering

The invention relates to the technical field of knitting machines, in particular to a torque balance control method and system for an annular knitting machine and storage equipment. The torque balance control method for the annular knitting machine comprises the following steps: a main motor adopts a position control mode, and a position ring, a speed ring and a current ring of the main motor are subjected to three-ring closed control; a slave motor adopts a torque control mode; and the output of the speed loop of the main motor is used as the current given quantity of the current loop of the slave motor. By means of the method, torque balance control and rotation speed synchronization of the motors can be achieved, stable operation of the knitting machine is guaranteed, and fabric quality and production efficiency are improved.

Owner:江苏高倍智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com