Torque balance control method and system for annular knitting machine and storage equipment

A technology of balanced control and knitting machine, applied in the field of knitting machine, which can solve problems such as affecting the weaving quality of fabrics, different load torques, and stuck knitting machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

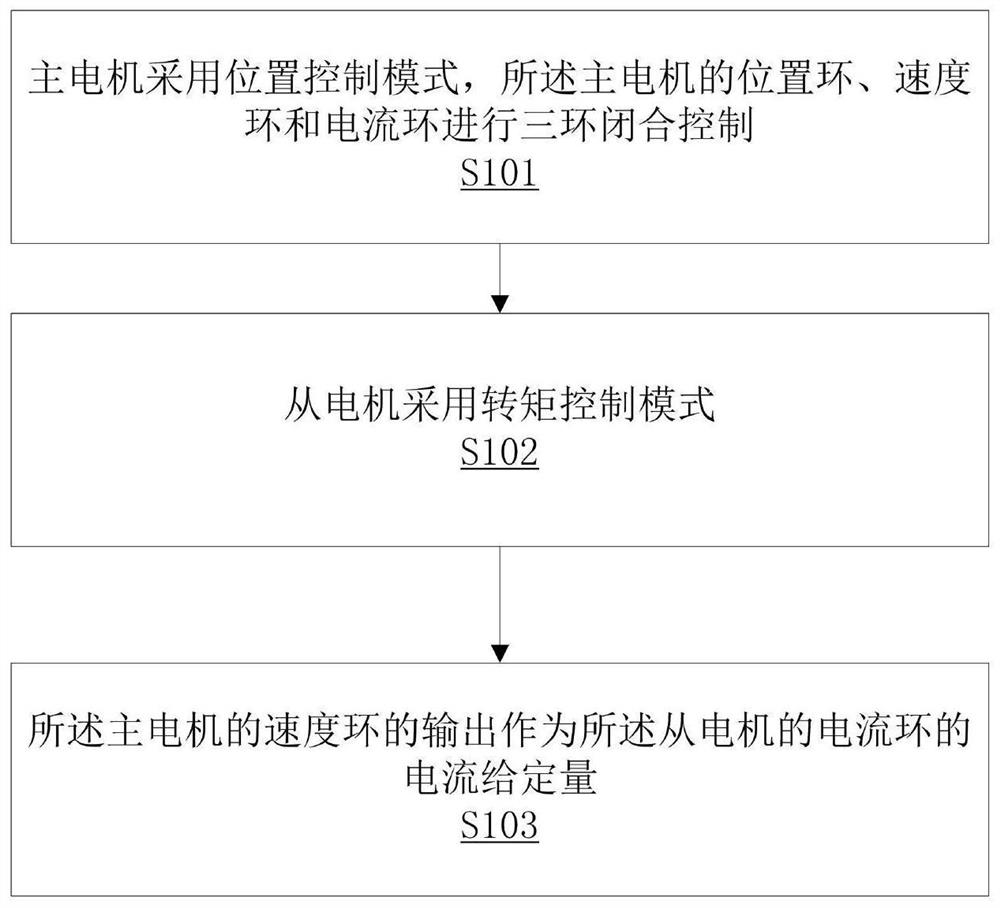

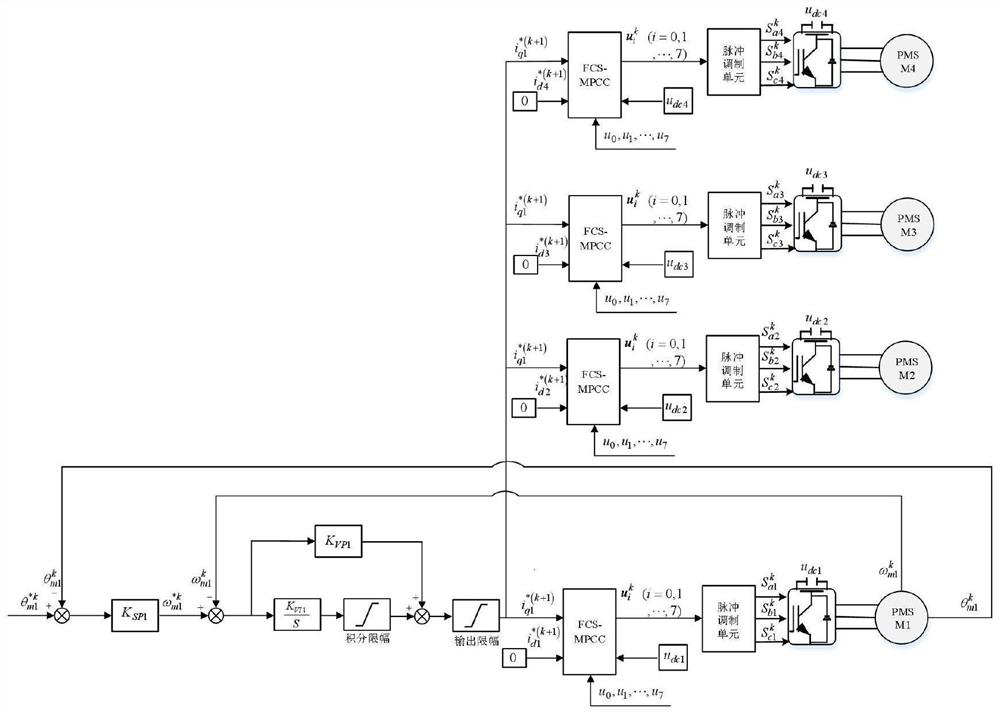

[0079] see Figure 1 to Figure 2 , in this embodiment, a torque balance control method for a circular knitting machine can be applied to a storage device, the storage device can be a circular knitting machine, and the circular knitting machine includes: a master motor and a slave motor, as follows Expand the specific description:

[0080] Step S101: The main motor adopts a position control mode, and the position loop, speed loop and current loop of the main motor are subjected to three-loop closed control.

[0081] Step S102: The slave motor adopts the torque control mode. That is, the slave motor only includes a current loop.

[0082] Step S103: The output of the speed loop of the master motor is used as the current given amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com